4

1.4. Limitations

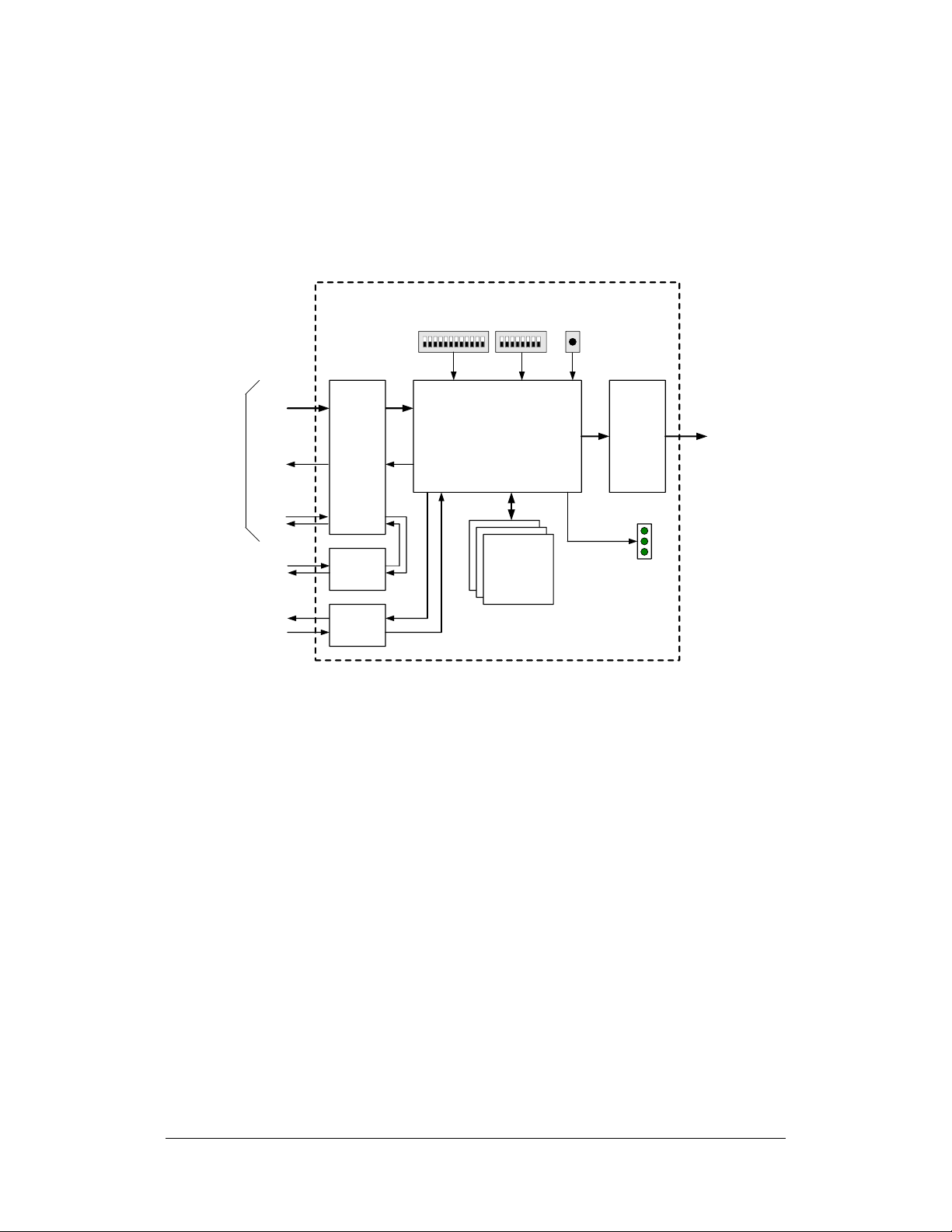

The CLT-371A is a “standard product” converter from Camera Link to HD-SDI and

works with most base-configuration cameras. However, Camera Link cameras vary

widely. Thefollowing is alist of requirements and limitations when using the CLT-371A:

Minimum Image Size:

The camera image must be at least 128 pixels per line, and 4 lines per frame (128x4).

Dual-Tap Limitation:

The CLT-371A only supports dual-tap images with “interleaved” format. This is the most

common dual-tap format inwhich two adjacent pixels from the same video line are

transmitted at a time. No other dual tap formats are supported.

Small Image Limitation:

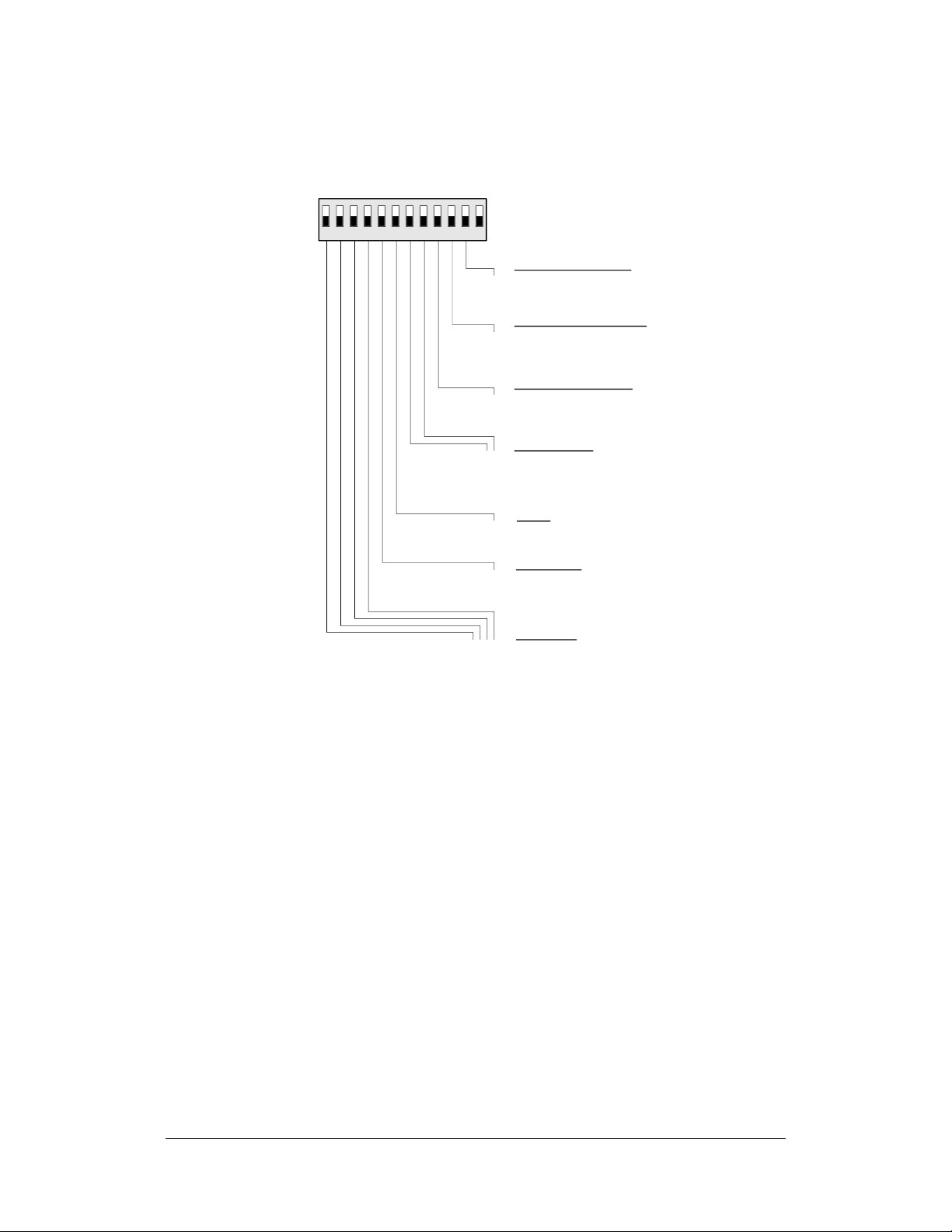

Images smaller than the selected HD-SDI image size (1920x1080 or 1280x720) will be

cropped to multiples of 128 pixels per line. Therefore when camera “X” dimension is >=

128 pixels but less than the HD-SDI (1920 or 1280), the camera image will becropped on

the right side as necessary to reduce image “X” size to

128/256/384/512/640/768/896/1024/1152… pixels. Similarly, images smaller than the

selected HD-SDI image size will be cropped to multiples of 4 lines per frame. Therefore

when camera image “Y” dimension is >= 4 pixels but less than HD-SDI (1080 or 720), the

camera image will be cropped at the bottom as necessary to reduce image “Y” size to

4/8/12… pixels.

Large Image Limitation:

Camera images larger than 16K in the “X” dimension and/or 16K in the “Y” dimension

are not supported.

Minimum Frame Rate Requirement:

Cameras with continuous frame rates less than 2 Hz are not supported.

Active Video Requirement:

The CLT-371A measures camera video (i.e. x/y dimensions) upon connection in order to

determine processing requirements. A camera should be active (i.e. outputting video

frames) when connected to the CLT-371A. Once measured and the front panel “CAM”

light is green, camera frames may be suspended for purposes such as external triggering.

The CLT-371A must be power cycled or the reset input asserted when camera settings

affecting output image size are changed while the camera is already active.

No Zoom:

The CLT-371A does not perform zoom in or zoom out. Images larger/smaller than

1920x1080 or 1280x720 are handled using crop and center only.