VOH Wheeltest III User manual

Wheeltest III

User’s manual

Translated from french

Mecatronic solution

EN_Wheeltest3_guid

e.doc

Created 17.03.2011

Page 2

U ser’s manual F.M

G:\Documents VOH\Modes d'emploi VOH\WHEELTEST VOH\Wheeltest_3\EN\EN_Wheeltest3_guide.doc

1General information .......................................................................................................................................3

.1 Warranty....................................................................................................................................................3

.2 Safety information .....................................................................................................................................3

.3 Transportation...........................................................................................................................................3

.4 Storage......................................................................................................................................................3

2Parts of the machine......................................................................................................................................4

3Use...................................................................................................................................................................4

.1 Start-up......................................................................................................................................................4

.2 Use............................................................................................................................................................5

.2.1 Placing the specific jaws on the base................................................................................................. 5

.2.2 Adjustments ........................................................................................................................................ 6

4Resolution of common problems.................................................................................................................7

5Exclusion of responsibility/warranty............................................................................................................7

6Maintenance and care....................................................................................................................................7

7Technical data.................................................................................................................................................7

8Representation/distribution ..........................................................................................................................7

Mecatronic solution

EN_Wheeltest3_guid

e.doc

Created 17.03.2011

Page 3

U ser’s manual F.M

G:\Documents VOH\Modes d'emploi VOH\WHEELTEST VOH\Wheeltest_3\EN\EN_Wheeltest3_guide.doc

1 General information

1.1 Warranty

Warranty is as stated in the General terms and conditions of sale, except for the length of the warranty, which is

set at 24 months.

1.2 Safety information

Warning

Do not use the Wheeltest III if it is damaged. Before using the Wheeltest III, inspect its casing and its

electrical connections.

The Wheeltest III must be used on the way specified by the manufacturer

The Wheeltest 2 must only be used by people who have been trained to do so.

Beware!!!

Please read the information included in this manual before using this apparatus. Incorrect use may

damage the system or cause errors.

Before connecting the machine for the first time, verify that the supply voltage of the power grid

corresponds to that required by the machine.

In case of prolonged non-use, disconnect the electrical supply cable.

Do not dismantle the machine. Only the manufacturer is entitled to replace or repair a faulty component.

Use this machine at a temperature between 10°C and 40°C (140 °F)

1.3 Transportation

This machine is not intended to be frequently transported. If it is nevertheless necessary to transport it, ensure

that no shocks are caused that might deteriorate the mechanism of the device. Also, in case of transport over a

long distance, it is preferable to use anti-shock packaging

1.4 Storage

The Wheeltest III must be stored in a dry and dust-free place. The storage temperature must be between 10°C

and 40°C. It is advisable to wrap up the machine to protect it from dust and humidity.

Mecatronic solution

EN_Wheeltest3_guid

e.doc

Created 17.03.2011

Page 4

U ser’s manual F.M

G:\Documents VOH\Modes d'emploi VOH\WHEELTEST VOH\Wheeltest_3\EN\EN_Wheeltest3_guide.doc

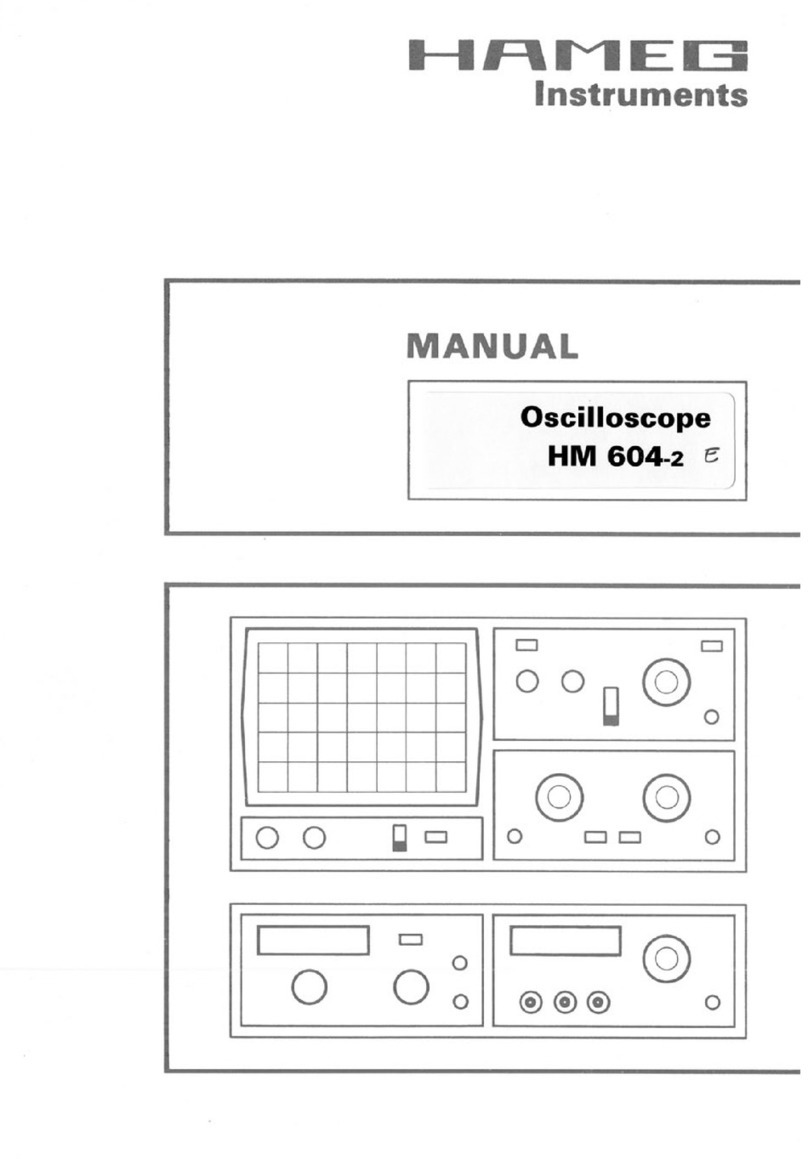

2 Parts of the machine

A watch wheel is placed on the specific jaws that are positioned on the base by two pins. There is a set of jaws

for each part reference. Rotation is guaranteed by a belt that drives the wheel. The Wheeltest III comprises a

series of control knobs for the motor. The position of the motor may be adjusted by means of 2 buffers (axial

position and as to height).

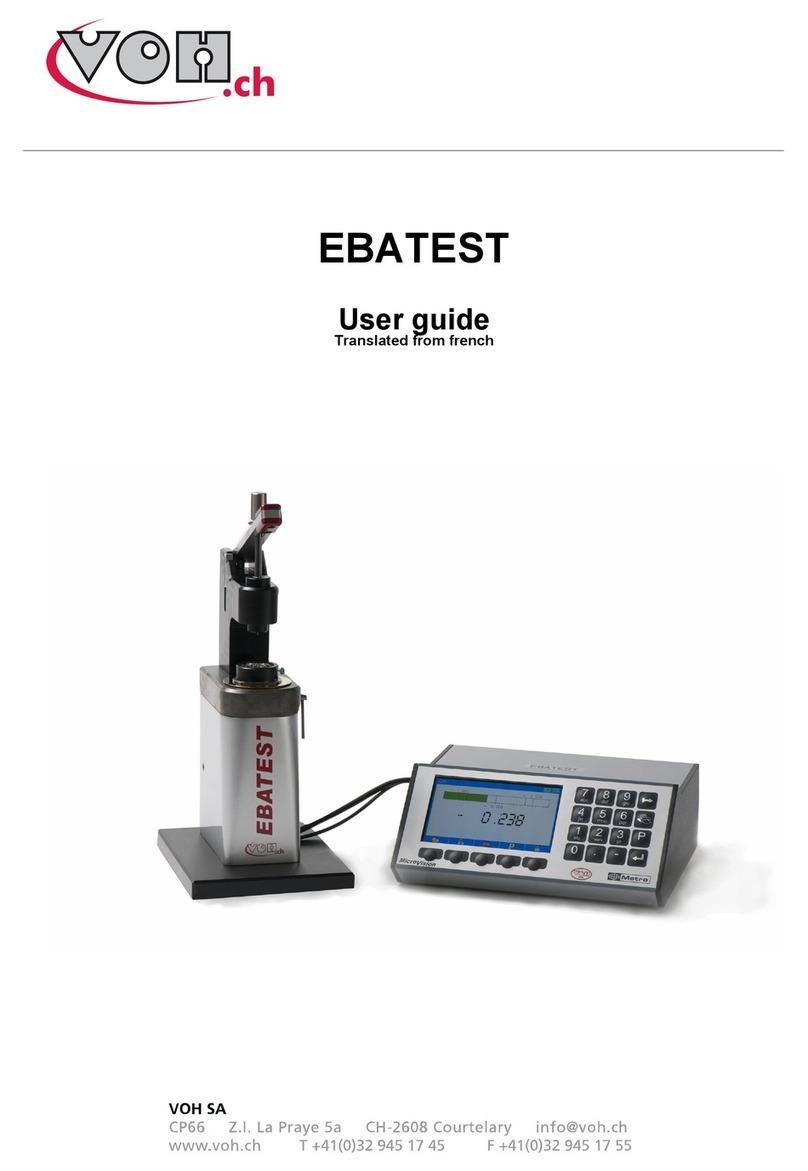

Figure 1: General view of the Wheeltest III

3 Use

3.1 Start-up

The machine is started by the slide switch next to the power connection. When it is turned on, the motor will not

turn, but the last parameters used (speed and direction of rotation) will be restored.

Control panel

Motor

5V connection + switch

Belt

Interchangeable sets

of jaws

Motor holding

element

Motor raising lever

Adjustable buffer

Mecatronic solution

EN_Wheeltest3_guid

e.doc

Created 17.03.2011

Page 5

U ser’s manual F.M

G:\Documents VOH\Modes d'emploi VOH\WHEELTEST VOH\Wheeltest_3\EN\EN_Wheeltest3_guide.doc

3.2 Use

3.2.1Placing the specific jaws on the base

The specific jaws are interchangeable and are positioned on the base by 2 pins.

The adjustment of the specific jaws is carried out by VOH Ltd.

Figure 2: Wheeltest III with a set of specific jaws

Figure 3: Positioning pins

Figure 4: Placing the set of specific jaws

Figure 5: System ready to function

Mecatronic solution

EN_Wheeltest3_guid

e.doc

Created 17.03.2011

Page 6

U ser’s manual F.M

G:\Documents VOH\Modes d'emploi VOH\WHEELTEST VOH\Wheeltest_3\EN\EN_Wheeltest3_guide.doc

3.2.2 Adjustments

To adjust the axial position of the motor (figure 6), the knurled knob screw must be used.

Height adjustment of the motor belt is made by the positioning screw (figure 7).

Knurled knob screw

Figure 6: Adjustment of the axial position of the

motor

Adjustable buffer positioning screw

Figure 7: Adjustment of buffer height

Then adjust rotation speed of the wheel and drive direction

Figure 8: control panel

Change of

direction

Speed

adjustment

Turn on/off

Mecatronic solution

EN_Wheeltest3_guid

e.doc

Created 17.03.2011

Page 7

U ser’s manual F.M

G:\Documents VOH\Modes d'emploi VOH\WHEELTEST VOH\Wheeltest_3\EN\EN_Wheeltest3_guide.doc

4 Resolution of common problems

Type of error

Cause

Resolution

No LED turns on when

powered up

Speed was set at minimum during last

use

Connections are faulty

Increase speed to confirm that the

Wheeltest III is being supplied with power

Check connections.

The wheel is not driven The belt is not resting against the wheel Reposition, or replace the belt

Adjust the position of the adjustable buffer

5 Exclusion of responsibility/warranty

Damages caused by use, transportation or storage that do not comply with those described in this manual are

not taken care of by the manufacturer. Modifications to the machine and opening the casing are forbidden and

entail an exclusion of responsibility. The right to a warranty expires when these are demonstrated or if the faults

noted cannot be original. Consumables (belts) are not subject to warranty.

6 Maintenance and care

No special care is necessary for the Wheeltest III except classic cleaning with a dry cloth. The belt is a

consumable to be replaced when the user deems necessary.

7 Technical data

Parameter

Value

Supply voltage

5V DC

Power

850 mW

Dimensions

Depth : 90 mm

Width : 110 mm

Height : 65 mm

8 Representation/distribution

Table of contents

Other VOH Test Equipment manuals

Popular Test Equipment manuals by other brands

pico Technology

pico Technology PicoScope 5000 Series user guide

Shimpo

Shimpo DT-311J instruction manual

MKS

MKS Ophir FluxGage FGC100 user manual

Kurth

Kurth KE301 manual

Berkeley Varitronics Systems

Berkeley Varitronics Systems Gazelle user manual

Akron Brass

Akron Brass 9015 Instruction manual and parts list