4

2.2SHIPMENTANDTRANSIT

Thefreezerhasbeenassembled,operatedandinspected

at the factory. Upon arrival at the final destination, the

completefreezermustbecheckedforanydamagewhich

mayhaveoccurredduringtransit.

With the method of packaging used, the freezer should

arriveinexcellentcondition.THECARRIERISRESPON-

SIBLEFORALLDAMAGEINTRANSIT,WHETHERVIS-

IBLEORCONCEALED.Donotpaythefreightbilluntilthe

freezerhasbeencheckedfordamage.Havethecarriernote

anyvisibledamageonthefreightbill.Ifconcealeddamage

and/orshortageisfoundlater,advisethecarrierwithin10

days and request inspection. The customer must place

claim for damages and/or shortages in shipment with the

carrier.Stoelting,Inc.cannotmakeanyclaimsagainstthe

carrier.

2.3FREEZERINSTALLATION

Installationofthefreezerinvolvesmovingthefreezerclose

to its permanent location, removing all crating, setting in

place,assembling parts, and cleaning.

A. Uncratethefreezer.

B. Accuratelevelingisnecessaryforcorrectdrainage

of freezer barrel and to insure correct overrun.

Placea bubble levelon topof the freezerat each

cornertocheckforlevelcondition.Ifadjustmentis

necessary,levelthefreezerbyturningthebottom

part of each leg in or out. Then separate freezer

basegasketandinstallwithseamtothebackand

angle to the top.

C. If the freezer is equipped with an air cooled

condenser,correctventilationisrequired.Theright

side of the freezer is the air intake and left side

discharge.Bothsidesmusthave3"clearancethe

toprequires 10"ofclearance.

CAUTION

Failuretoprovideadequate ventilation willvoidwar-

ranty.

D. Place the OFF-ON switch in the OFF position.

E. Connect the power cord to the proper power

supply.Theplugisdesignedfor208or230volt/20

ampduty.Checkthenameplateonyourfreezerfor

proper supply. The unit must be connected to a

properlygroundedreceptacle.Theelectricalcord

furnishedaspartofthefreezerhasathreeprong

grounding type plug (Fig. 2-3). The use of an

extensioncordisnotrecommended,ifnecessary

useonewithasize12gaugeorheavierwithground

wire.Donotuseanadaptertogetaroundgrounding

requirement.

WARNING

Do not alter or deform electrical plug in any way.

Altering the plug to fit into an outlet of different con-

figuration may cause fire, risk of electrical shock,

productdamageand will voidwarranty.

F. Install the drip tray, drain tray, hopper cover and

othermiscellaneouspartsonthefreezer.

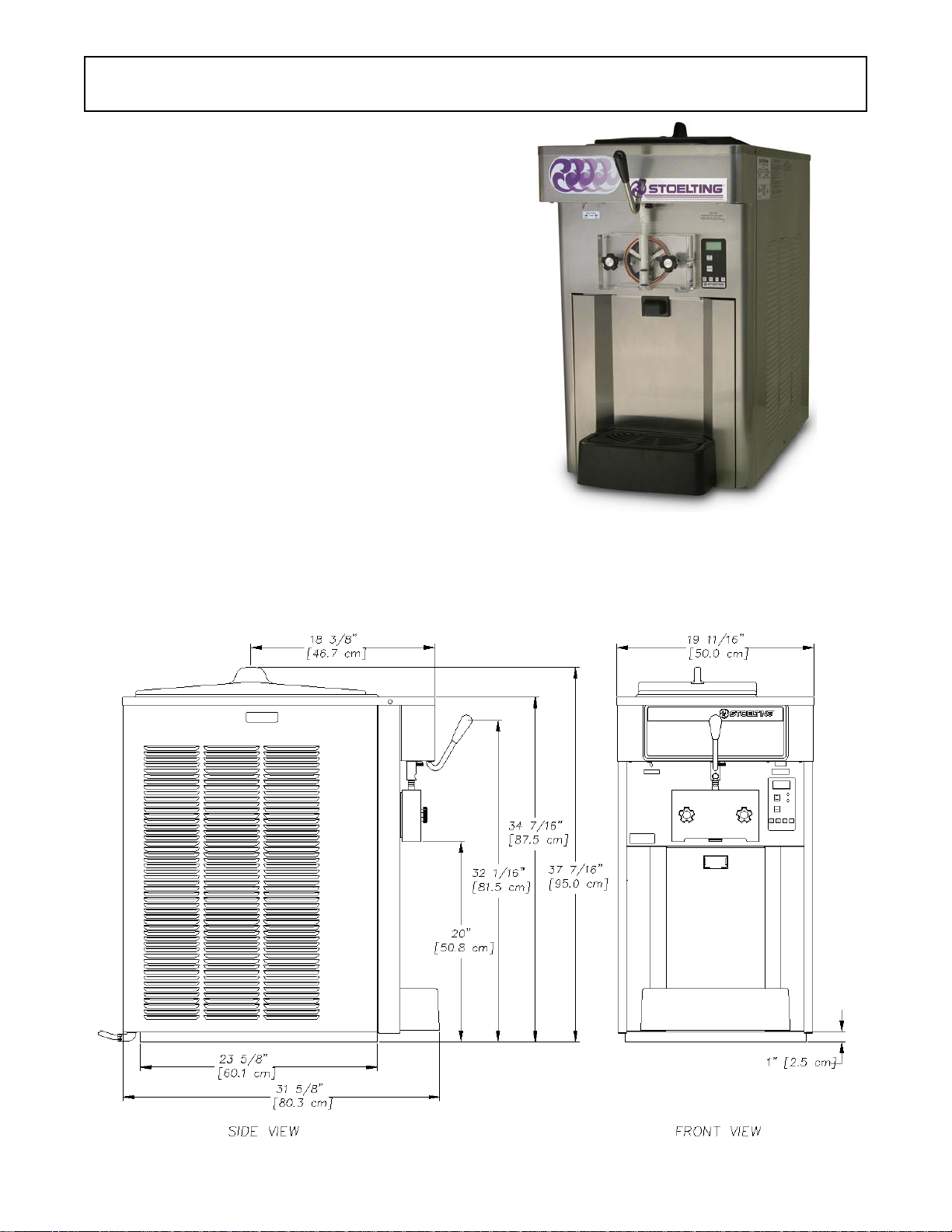

Figure 2-2 Space and Ventilation Requirements

115V

20Amp

Figure 2-3 Electrical Plug

208/230V

20Amp