TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

SECTION1 INTRODUCTION .............................................................................................................. 1

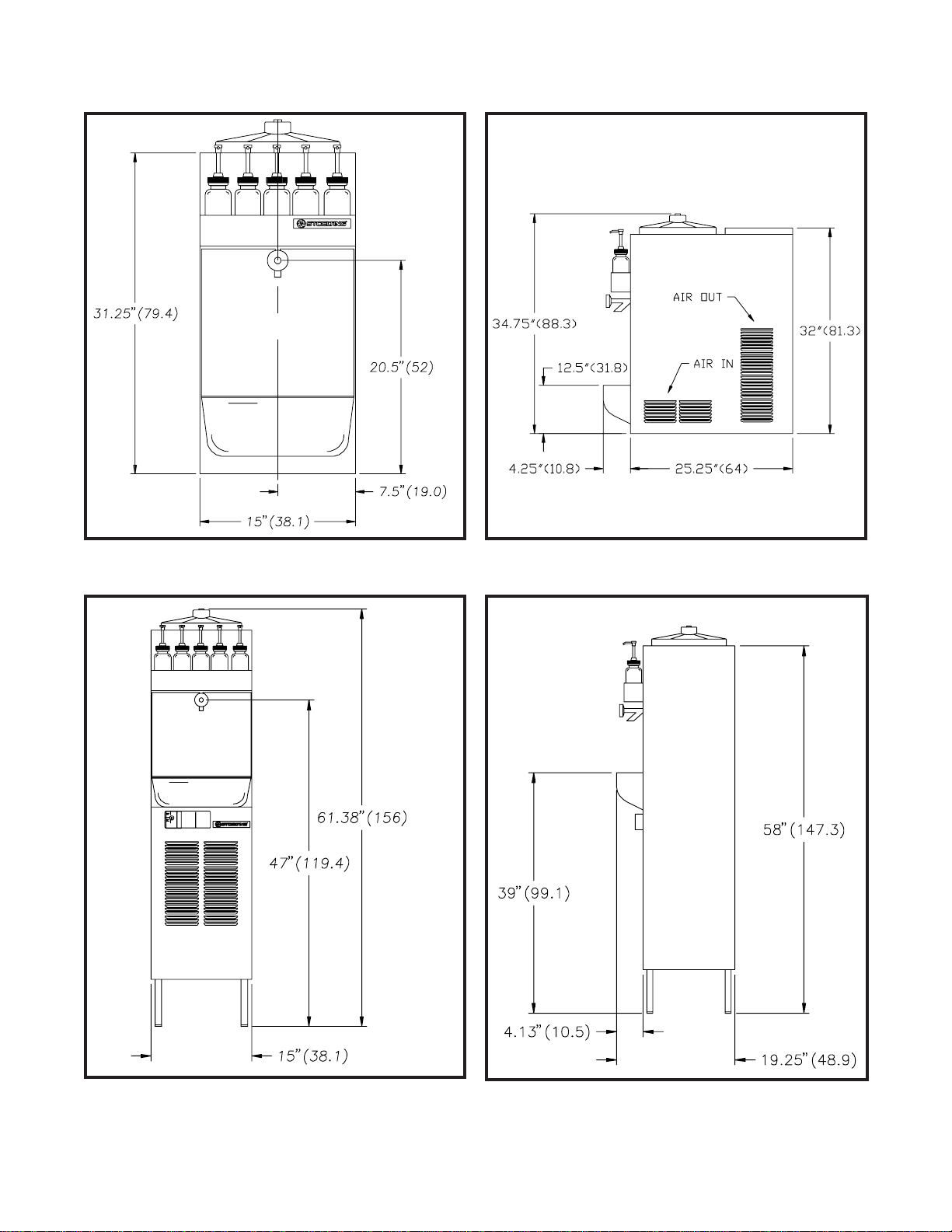

1.1 Descriptions .................................................................................................................... 1

1.2 Specifications.................................................................................................................. 1

SECTION2 INSTALLATIONINSTRUCTIONS...................................................................................... 3

2.1 SafetyPrecautions .......................................................................................................... 3

2.2 ShipmentandTransit ...................................................................................................... 3

2.3 FreezerInstallation .......................................................................................................... 3

2.4 AdjustingCupDispensers ............................................................................................... 7

SECTION3 INITIALSET-UPANDOPERATION ................................................................................. 9

3.1 Operator'sSafetyPrecautions ......................................................................................... 9

3.2 OperatingControlsandIndicators.................................................................................... 9

3.3 DrainingtheFreezerForDisassemblingandCleaning ..................................................... 10

3.4 DisassemblyandCleaningofFreezerParts .................................................................... 10

3.5 SanitizingTheFreezersandFreezerParts...................................................................... 15

3.6 AssemblyofFreezer ....................................................................................................... 15

3.7 MixInformation ................................................................................................................ 17

3.8 FreezeDownandOperation ............................................................................................ 17

3.9 DispensingProduct ......................................................................................................... 17

3.10 RoutineCleaning ............................................................................................................. 17

3.11 PreventativeMaintenance ................................................................................................ 17

3.12 ExtendedStorage............................................................................................................ 18

SECTION4 DECALSANDTAGS....................................................................................................... 21

4.1 HowtoOrderDecalsandTags ........................................................................................ 21

SECTION5 REFRIGERATIONCOMPONENTSANDADJUSTMENTS ............................................... 23

5.1 RefrigerationSystem ....................................................................................................... 23

5.2 Compressor..................................................................................................................... 23

5.3 Condenser....................................................................................................................... 23

SECTION6 ELECTRICALSYSTEMOPERATIONANDADJUSTMENTS ........................................... 27

6.1 24HourTimer.................................................................................................................. 27

6.2 ElectronicTorqueControl ................................................................................................ 27

SECTION7 MAJORCOMPONENTREMOVALANDINSTALLATION................................................. 29

7.1 Introduction ..................................................................................................................... 29

7.2 CondenserFanRemoval.................................................................................................. 29

7.3 DriveMotorRemoval ........................................................................................................................... 29

7.4 CompressorRemoval ...................................................................................................... 29

7.5 CompressorInstallation ................................................................................................... 30

7.6 DriveMotorInstallation .................................................................................................... 31

7.7 CondenserFanInstallation .............................................................................................. 31

SECTION8 TROUBLESHOOTING ..................................................................................................... 33

8.1 CompressorRunCapacitorOpen,ShortedorBlown........................................................ 34

8.2 CompressorRelayDefectiveorBurnedOut ..................................................................... 34

8.3 CompressorStarts andRuns, But Short CyclesOn OverloadProtector .......................... 34

8.4 CompressorRunsContinuously ...................................................................................... 34

8.5 Unit Noisy ....................................................................................................................... 34

8.6 Compressor Will Not Start............................................................................................... 34

8.7 CompressorWill Not Start - Hums But Trips On Overload Protector ................................ 35

8.8 Compressor Starts, But Does Not Switch Off of Start Winding ........................................ 35