Table of contents

3

Table of contents

Foreword....................................................................1

Identification numbers ............................................................ 2

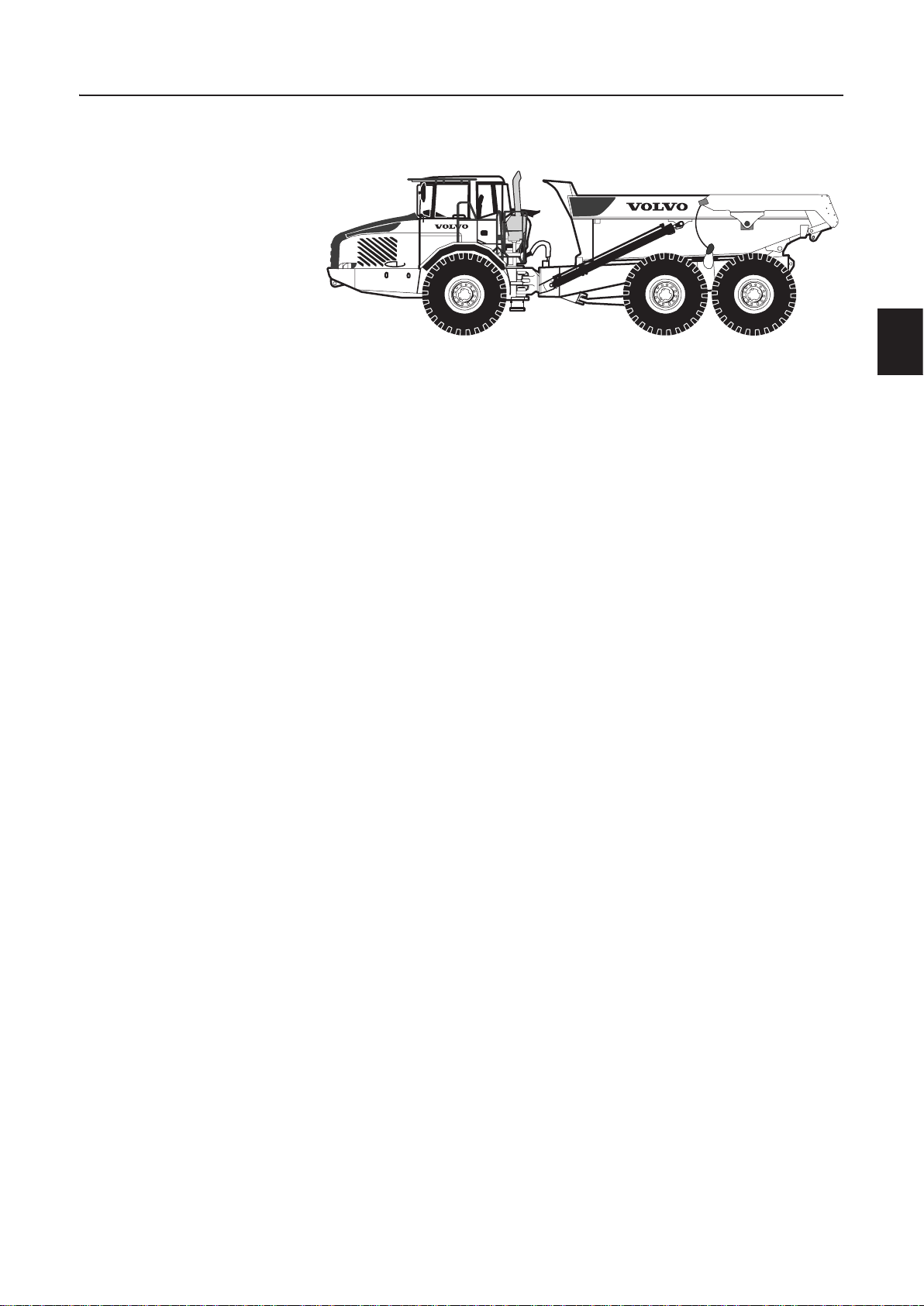

Presentation ..............................................................5

CE marking, EMC directive .................................................... 9

Communication equipment, installation................................ 10

Plates and decals ................................................................. 11

The USA Federal Clean Air Act............................................ 14

Instrument panels ...................................................17

Left instrument panel ............................................................ 18

Centre instrument panel ....................................................... 20

Right instrument panel.......................................................... 24

Display unit........................................................................... 28

Other controls .........................................................43

Controls ................................................................................ 43

Operator comfort .................................................................. 50

Ventilation system ................................................................ 52

Operating instructions ...........................................55

Safety rules when operating ................................................. 57

Measures before operating................................................... 61

Starting engine ..................................................................... 62

Gear shifting ......................................................................... 63

Operating with differential locks............................................ 65

Steering ................................................................................ 67

Braking ................................................................................. 68

Stopping machine................................................................. 69

Parking ................................................................................. 70

What to do if the machine gets stuck ................................... 71

Recovering/towing ................................................................ 72

Tipping.................................................................................. 75

Dump body, emergency lowering ......................................... 76

Full Suspension, emergency lowering.................................. 77

Transporting the machine..................................................... 78

Operating techniques .............................................81

Whole body vibrations .......................................................... 82

Transport operation .............................................................. 84

Operating on inclines............................................................ 85

Off-road operation ................................................................ 86

Loading................................................................................. 87

Transporting with load .......................................................... 87

Dumping load ....................................................................... 88

Safety when servicing ............................................89

Service position .................................................................... 89

Before service, read ............................................................. 90

Preparations before service.................................................. 92

Fire protection....................................................................... 95

Handling hazardous substances .......................................... 97