Content

30 GENERAL

300 Comprehensive info, electrical system

Electrical system, work instructions ............................................................ 5

Electrical system, description ..................................................................... 8

Electronic control system, description ...................................................... 10

Communication with data buses ............................................................... 12

Software, description ................................................................................ 13

Instrument control unit I-ECU, description ................................................ 14

Vehicle control unit V-ECU, description .................................................... 15

Vehicle control unit V2-ECU, description .................................................. 16

Engine control unit E-ECU, description .................................................... 16

Climate control unit ECC, description ....................................................... 17

31 BATTERY

310 General, common info about 311 - 313

Battery, description ................................................................................... 18

Battery, charging ....................................................................................... 19

Batteries, replacing ................................................................................... 20

System voltage ......................................................................................... 22

Key feed .................................................................................................... 22

32 ALTERNATOR; CHARGE REGULATOR

320 General, common info about 321 - 322

Alternator 80 A, description ...................................................................... 23

33 STARTING SYSTEM

331 Starter motor inclusive solenoid

Booting sequence ..................................................................................... 24

35 LIGHTING

350 General, common info about 351 - 356

Lighting, description .................................................................................. 25

36 OTHER ELECTRICAL EQUIPMENT

360 General, common info about 361 - 367

Reduced computer communication .......................................................... 28

Interruption in computer communication ................................................... 29

Limp Home ............................................................................................... 29

Intermittent wiper and washer ................................................................... 30

Theft protection ......................................................................................... 32

38 INSTRUMENT; SENSOR; WARNING AND INFORMATION

SYSTEM

380 General, common info about 383 - 387

Instruments ............................................................................................... 33

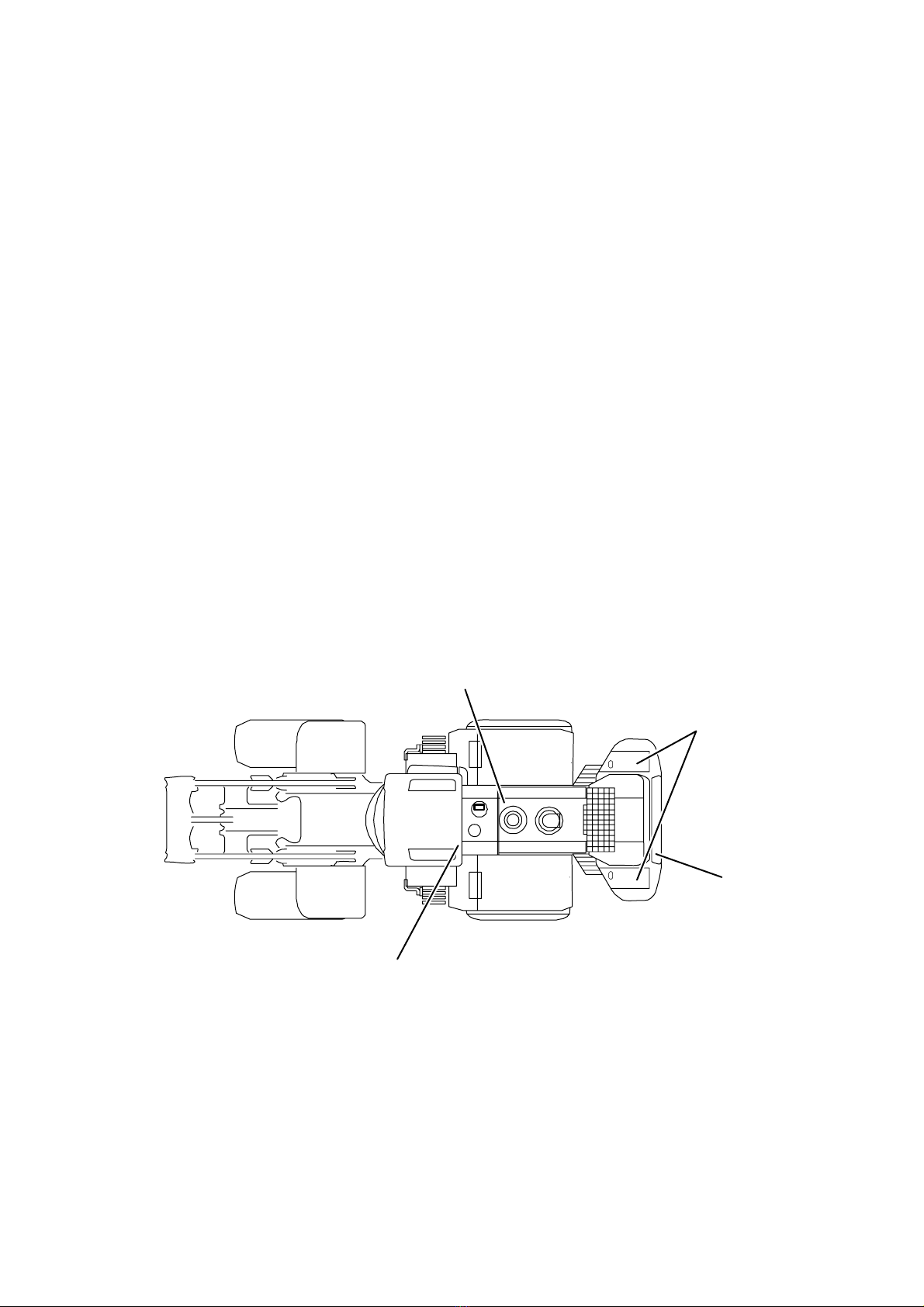

Instrument panels, position .................................................................... 33

Middle instrument panel with warning lights ............................................. 34

386 Sender, monitoring system

Washer fluid level ..................................................................................... 35

Fuel consumption ..................................................................................... 36

Travelling speed ....................................................................................... 37

Machine hours .......................................................................................... 37

387 Warning/information unit, display unit

Information display, general ...................................................................... 38

Information display, start lockout .............................................................. 41

Information display, operating display ...................................................... 42

Information display, engine ....................................................................... 43

Information display, transmission ............................................................. 45

3