WWW.VORONDESIGN.COM

HARDWARE - REFERENCES

6

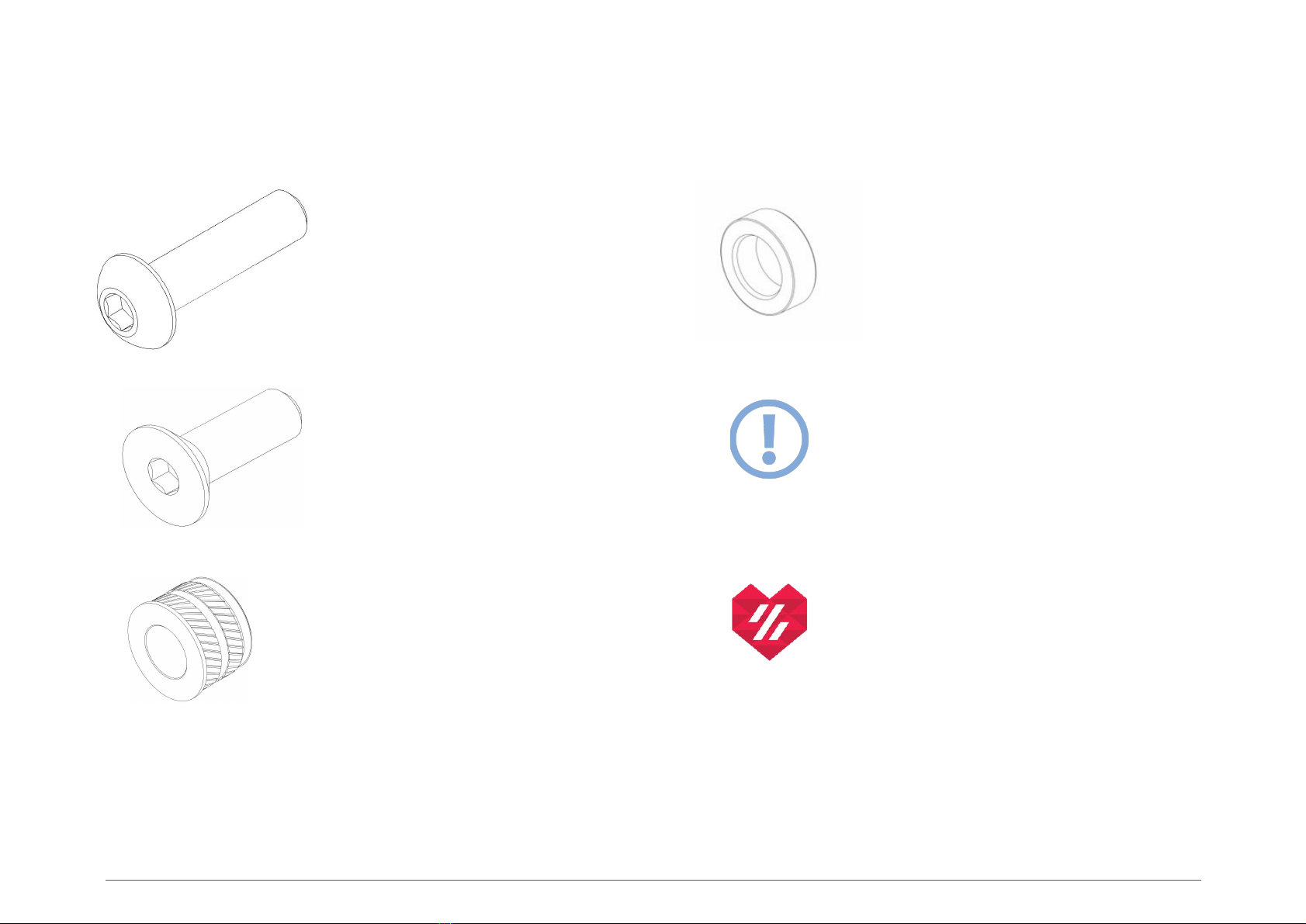

BUTTON HEAD CAP SCREW (BHCS)

Metric fastener with a domed shaped

head and hex drive. Most commonly

found in locations where M3 fasteners

are used.

ISO 7380-1

MR85 BEARING

A small ball bearing. 5x8x2.5mm

in size.

FLAT HEAD CAP SCREW (FHCS)

Metric fastener with a cone shaped head

and a flat top.

ISO 10642

ATTENTION BUBBLE

This logo denotes steps that are

common areas that mistakes can

occur.

HEAT SET INSERT

Heat the inserts with a soldering iron so

that they melt the plastic when installed.

As the plastic cools, it solidifies around

the knurls and ridges on the insert for

excellent resistance to both torque and

pull-out.

VORON HEART

Look for Voron heart next to

the part. It indicates that this is a

part that is usually printed in the

accent color.

6