Industrial Shields Raspberry PLC Series Instruction manual

RASPBERRY PLC FAMILY

RASPBERRY PLC FAMILY

Rev. 8: 29-04-2021

3

Preface

This User Guide is been implemented by Boot & Work, S.L. working

under the name Industrial Shields.

Purpose of the manual

The information contained in this manual can be used as a reference to operate and

get a better understanding of the technical data of the signal modules, power supply

modules and interface modules.

Intended Audience

This User Guide is intended for the following audience:

•Persons in charge of introducing automation devices.

•Persons who design automation systems.

•Persons who install or connect automation devices.

•Persons who manage working automation installation.

Warnings:

•Unused pins should not be connected. Ignoring the directive may damage the

controller.

•Before using this product, it is the responsibility of the user to read the product’s User

Guide and all accompanying documentation.

•Industrial Shields PLCs must be powered between 12Vdc and 24Vdc. If a higher voltage

is supplied to the equipment can suffer irreversible damage.

•Maintenance must be performed by qualified personnel familiarized with the

construction, operation, and hazards involved with the control.

•Maintenance should be performed with the control out of operation and disconnected

from all sources of power.

•The Industrial Shields Family PLCs are Open Type Controllers. It is required that you

install the Raspberry PLC in a housing, cabinet, or electric control room. Entry to the

housing, cabinet, or electric control room should be limited to authorized personnel.

•Inside the housting, cabinet or electric control room, the Industrial Shields PLC must be

at a minimum distance from the rest of the components of a minimum of 25 cm, it can

be severely damaged.

•Failure to follow these installation requirements could result in severe personal injury

and/or property damage. Always follow these requirements when installing Raspberry

family PLCs.

Rev. 8: 29-04-2021

4

•In case of installation or maintenance of the PLC please follow the instructions marked

in the Installation and Maintenance section on the User Guide.

•Do not disconnect equipment when a flammable or combustible atmosphere is

present.

•Disconnection of equipment when a flammable or combustible atmosphere is present

may cause a fire or explosion which could result in death, serious injury and/or

property damage.

•Inside the encapsulated, there are supercapacitors if 25F which can be dangerous. Be

careful with them.

Rev. 8: 29-04-2021

5

Table of Contents

General Description RASPBERRY PLC FAMILY Product....................................................... 8

Reference Table................................................................................................................ 8

Zones Table....................................................................................................................... 9

Measures Table ................................................................................................................ 9

Zone - Nomenclature...................................................................................................... 10

Zone Distribution............................................................................................................ 10

Zone Features................................................................................................................. 11

Mechanical dimension ................................................................................................... 12

General Features............................................................................................................ 13

Technical Specifications: ........................................................................................................ 14

General Specifications:................................................................................................... 14

Performance Specification: ............................................................................................ 15

Symbology ...................................................................................................................... 15

Precautions ............................................................................................................................ 16

Raspberry Board............................................................................................................. 16

Intended Audience......................................................................................................... 16

General Precautions....................................................................................................... 16

How to connect PLC to power supply.................................................................................... 17

How to access to the Raspberry PLC...................................................................................... 18

Raspberry PLC access ..................................................................................................... 18

5.1.1 Linux..................................................................................................................... 18

5.1.2 Windows .............................................................................................................. 20

How to change the IP............................................................................................................. 22

Linux ............................................................................................................................... 22

Windows......................................................................................................................... 22

How to transfer files from the PC to the Raspberry PLC........................................................ 24

Windows......................................................................................................................... 24

Linux ............................................................................................................................... 25

Raspberry PLC Family Pinout ................................................................................................. 26

I/Os Table ....................................................................................................................... 26

Rev. 8: 29-04-2021

6

0 Zone connection (Communications) ........................................................................... 27

Analog/Digital Zone connection (I/Os)........................................................................... 29

Relay Zone connection (I/Os) ......................................................................................... 30

Interrupt equivalence table............................................................................................ 31

Switch Configuration.............................................................................................................. 31

Analog / Digital Zone...................................................................................................... 31

Relay Zone ...................................................................................................................... 31

I/O RASPBERRY PLC 3.3V pins ................................................................................................ 32

Serial –RX/TX ................................................................................................................. 32

SPI0 –MISO/MOSI/SCK .................................................................................................. 33

GPIO25............................................................................................................................ 33

Equivalence Table .................................................................................................................. 34

Pin-Out............................................................................................................................ 34

11.1.1 Analog/Digital Devices Analog I/Os ..................................................................... 34

11.1.2 Digital I/Os............................................................................................................ 35

11.1.3 Relay Devices Analog I/Os.................................................................................... 35

11.1.4 Digital I/Os............................................................................................................ 36

11.1.5 Relay..................................................................................................................... 36

Internal I2C and SPI Connections........................................................................................... 37

Input & Output control .......................................................................................................... 37

Scripts Location .............................................................................................................. 37

13.1.1 Analog/Digital Shield............................................................................................ 37

13.1.2 Relay Shield.......................................................................................................... 37

13.1.3 Generic Shield ...................................................................................................... 37

Set Value......................................................................................................................... 38

Get Value........................................................................................................................ 40

Fan Functions ................................................................................................................. 41

13.4.1 Start Fan............................................................................................................... 41

13.4.2 Stop Fan ............................................................................................................... 41

A & B Zone Features: Communications & RTC & uSD............................................................ 42

RS-485............................................................................................................................. 42

I2C................................................................................................................................... 42

SPI................................................................................................................................... 43

TTL .................................................................................................................................. 43

Rev. 8: 29-04-2021

7

Ethernet.......................................................................................................................... 43

Wi-Fi ............................................................................................................................... 44

BLE .................................................................................................................................. 44

RTC.................................................................................................................................. 46

uSD ................................................................................................................................. 46

Additional family features...................................................................................................... 48

GPRS Family.................................................................................................................... 48

Revision Table ........................................................................................................................ 50

Rev. 8: 29-04-2021

8

General Description RASPBERRY PLC FAMILY Product

Reference Table

Rev. 8: 29-04-2021

9

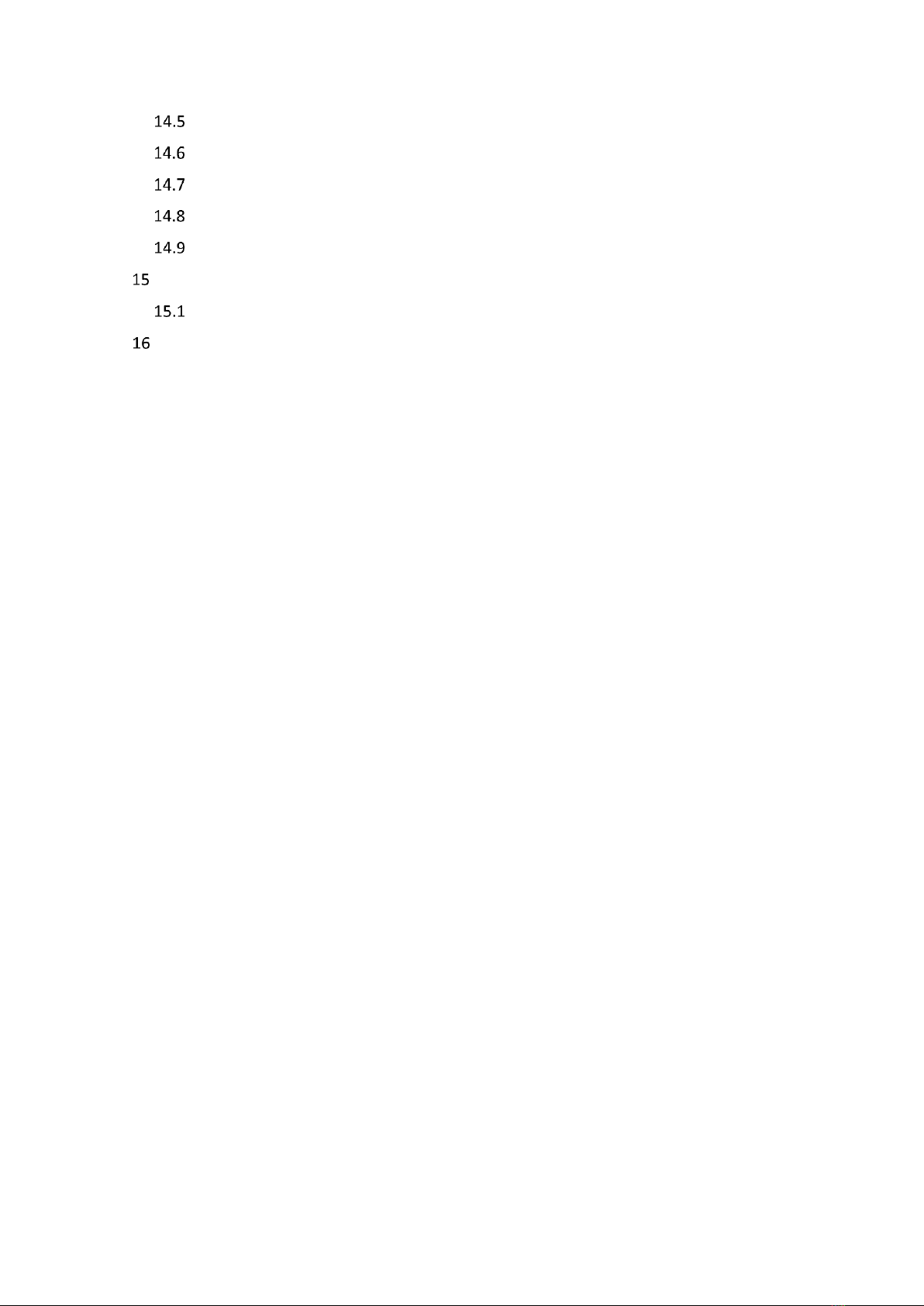

Zones Table

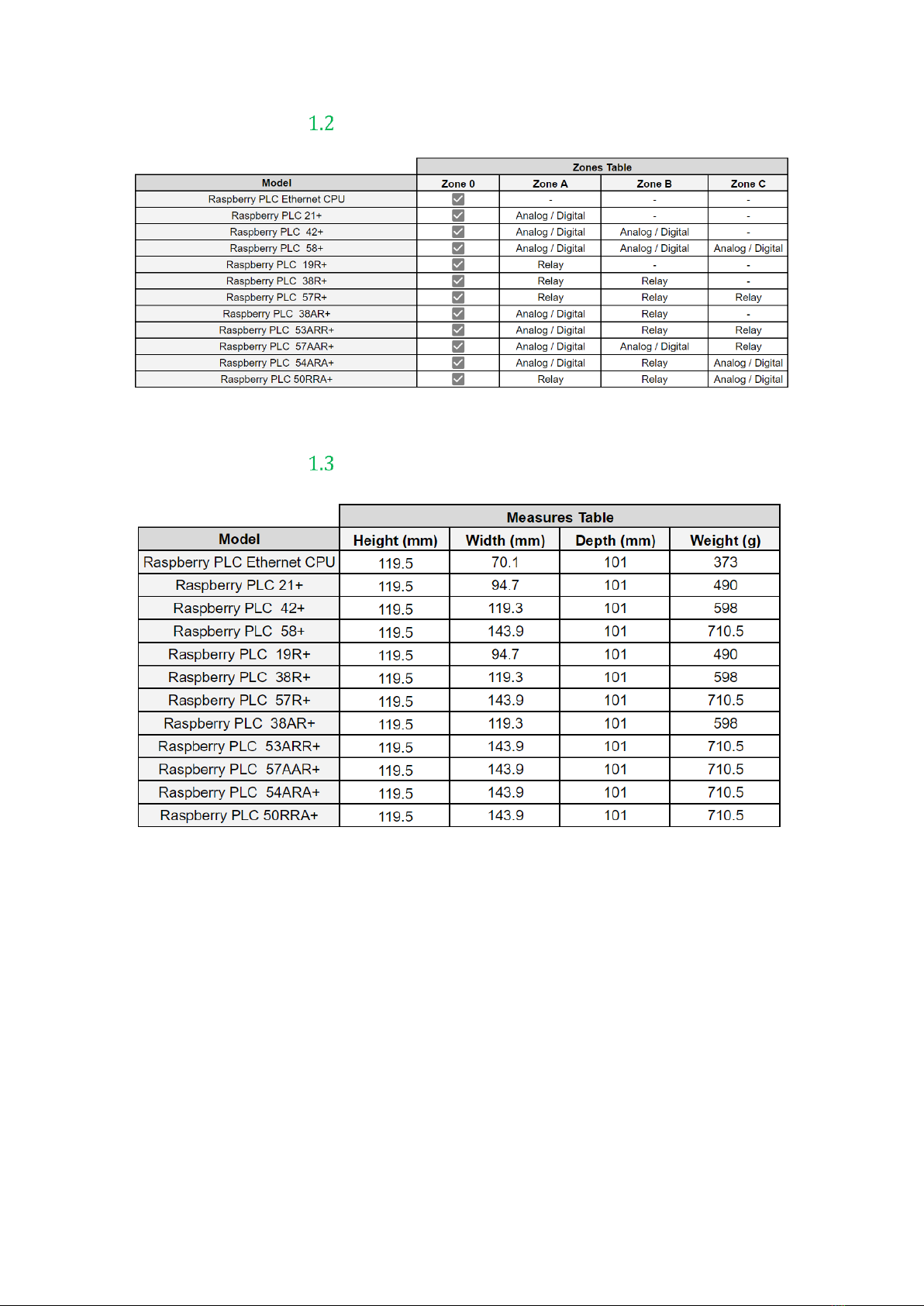

Measures Table

Rev. 8: 29-04-2021

10

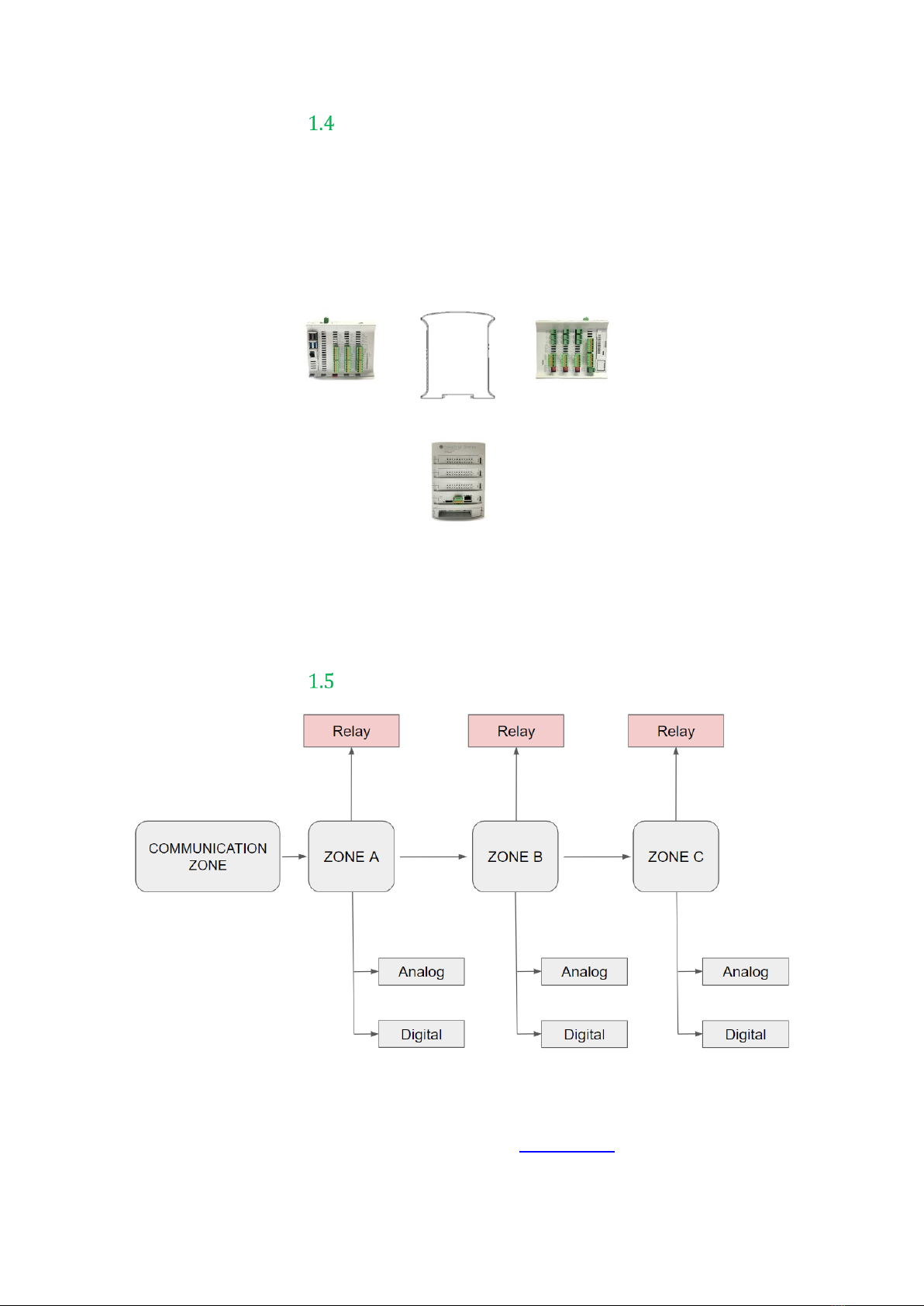

Zone - Nomenclature

The nomenclature shown in this point will be used in the whole User Guide, so it is

important to understand this nomenclature.

The nomenclature to differentiate the zones is based on Alphanumeric values, being 0

the internal communication shield and A, B or C the I/Os or Relay shield.

●The inputs in the zone A/B/C are named IX.X, being X any number suitable in

the Shield. Outputs are named as QX.X.

Zone Distribution

This is the possible zones scheme, whether the zone is Analog/Digital or Relay

depends on your device, you can consult it on the Zones Table. The distribution of the

different features that provide the Raspberry PLC Family are described below.

0 ZONE

A ZONE

B ZONE

C ZONE

C ZONE

B ZONE

A ZONE

0 ZONE

C ZONE

B ZONE

A ZONE

0 ZONE

Rev. 8: 29-04-2021

11

Zone Features

Shield

Zone Characteristics

Communication Shield

(2x) Ethernet

(4x) USB

(1x) I2C

(1x) TTL

(2x) HALF Duplex RS-485

(1x) SPI external Port

(1x) RTC

(1x) Bluetooth

(1x) Wi-Fi

(1x) μSD Socket

(1X) CAN

(x1) μHDMI

Analog Shield

13 Inputs:

8 Outputs:

13 Digital inputs, 6 of which can work as Analog Input

8 Digital Outputs, 3 of which can work as Analog Output

Relay Shield

6 Inputs:

11 Outputs:

6 Digital Inputs, 4 of which can work as Analog Input

8 Relay Outputs

3 Digital Outputs, 3 of which can work as Analog Output

Rev. 8: 29-04-2021

13

General Features

CONNECTABLE PLC RASPBERRY 24 VCC

MODEL TYPE

Controller General Specifications

Information

Input Voltage

12 to 24 Vdc

Fuse Protection (2.5 A) Polarity

protection

I max.

1.5 A

Size

Consult the Measure Table section

Clock Speed

1.5 GHz

Flash Memory

-

SRAM

2 - 4 - 8 GB

Communications

I2C –Ethernet (x2) –USB (x4) –(x2) RS485 –SPI –WiFi –

Bluetooth - Serial TTL –CAN - μSD - RTC

MAX485 –W5500

Digital GPIO25

(3.3 V)

3.3 V

An/Dig Input 10bit

(0-10Vcc)

0 to 10Vac

Rated Voltage: 10Vac

5 to 24Vdc

I min: 2 to 12 mA

Galvanic Isolation

Rated Voltage: 24 Vdc

Digital Isolated Input (24Vcc)

5 to 24Vdc

I min: 2 to 12 mA

Galvanic Isolation

Rated Voltage: 24 Vdc

* Interrupt isolated Input HS

(24Vcc)

5 to 24Vdc

I min: 2 to 12 mA

Galvanic Isolation

Rated Voltage: 24Vdc

Analog Output 8 bits

(0 - 10 Vcc)

0 to 10 Vdc

I max: 20 mA

Separated PCB Ground

Digital Isolated Output

(24 Vcc)

5 to 24 Vdc

I max: 70 mA

Galvanic Isolation

Diode Protected for Relay

I max 24 Vdc: 410 mA

Relay Output

(220 Vac)

24 VDC / 220 VAC

I max: 5 A

Galvanic Isolation

Diode Protected for Relay

Rev. 8: 29-04-2021

14

PWM Isolated Output 8 bits

(24 Vcc)

5 to 24 Vdc

I max: 70 mA

Galvanic Isolation

Diode Protected for Relay

Expandability

I2C: 127 elements –Serial Port RS485

* By using this type of signal can no longer use Digital signal (24Vdc)

Technical Specifications:

General Specifications:

Item

RASPBERRY PLC

Power supply

voltage

DC power supply

12 to 24Vdc

Operating

voltage range

DC power supply

11.4 to 25.4Vdc

Power

consumption

DC power supply

30 W max.

External

power supply

Power supply

voltage

24 Vdc

Power supply

output capacity

700 Ma

Insulation resistance

20MΩ min.at 500Vdc between the AC terminals and the protective earth terminal.

Dielectric strength

2.300 VAC at 50/60 Hz for one minute with a leakage current of 10mA max. Between all the

external AC terminals and the protective ground terminal.

Shock resistance

80m/s2in the X, Y and Z direction 2 times each.

Ambient temperature (operating)

0º to 50ºC with Raspberry OS Lite / 0º to 40º with Raspberry OS Desktop

Ambient humidity (operating)

10% to 90% (no condensation)

Ambient environment (operating)

With no corrosive gas

Ambient temperature (storage)

-20º to 60ºC

Power supply holding time

2ms min.

Weight

Consult the Measure Table section

Rev. 8: 29-04-2021

15

Performance Specification:

Raspberry Board

Raspberry Pi 4

I/O control method

Combination of the cyclic scan and immediate refresh processing methods.

Programming language

Linux applications : Python, C++, etc.

Program capacity (SRAM)

2 –4 - 8 GB

EEPROM

4 MB/512 KB

Clock Speed

1.5 GHz

CPU

Broadcom BCM2711, Quad core Cortex-A72 (ARM v8) 64-bit SoC @ 1.5GHz

Symbology

Table that includes all the symbology that is used in the serigraph of the RASPBERRY PLC

FAMILY:

Symbol

Standard No. /

Standard Title

Standard

Reference No. /

Symbol Title

Symbol Meaning

IEC 60417 /

Graphical symbols

for use on

equipment

5031 / Direct

Current

Indicates that the equipment is

suitable for direct current only;

to identify relevant terminals

IEC 60417 /

Graphical symbols

for use on

equipment

5032 / Alternating

Current

Indicates that the equipment is

suitable for alternating current

only; to identify relevant

terminals

IEC 60417 /

Graphical symbols

for use on

equipment

5130 / Pulse

General

To identify the control by

which a pulse is started.

IEC 60417 /

Graphical symbols

for use on

equipment

5017 / Earth,

Ground

To identify an earth (ground)

terminal in cases where

neither the symbol 5018 nor

5019 is explicitly required.

IEC 60417 /

Graphical symbols

for use on

equipment

5115 / Signal lamp

To identify the switch by

means of which the signal

lamp(s) is (are) switched on or

off.

Medical Devices

Directive

93/42/EEC

CE Marking

CE marking indicates that a

product complies with

applicable European Union

regulations

Rev. 8: 29-04-2021

16

ISO 7000/

Graphical symbols

for use on

equipment

0434B /

Warning symbol

Indicates a potentially

hazardous situation which, if

not avoided, could result in

death or serious injury

ISO 7000/

Graphical symbols

for use on

equipment

5036 / Dangerous

Voltage

To indicate hazards arising

from dangerous voltages

Precautions

Read this manual before attempting to use the RASPBERRY PLC FAMILY and follow its

descriptions for reference during operation.

Raspberry Board

The RASPBERRY PLC FAMILY includes a Raspberry Pi 4 Board as controller.

Intended Audience

This manual is intended for technicians, which must have knowledge on electrical systems.

General Precautions

The user must operate Raspberry PLC according to the performance specifications described in

this manual.

Before using the RASPBERRY PLC FAMILY under different conditions from what has been

specified in this manual or integrating into nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety

equipment and other systems, machines, and equipment that may have a serious influence on

lives and property if used improperly, consult your INDUSTRIAL SHIELDS representative. Ensure

that the rating and performance characteristics of the Raspberry PLC are sufficient for the

systems, machines, and equipment, and be sure to provide the systems, machines, and

equipment double safety mechanisms. This manual provides information for programming and

operating the Raspberry PLC.

Rev. 8: 29-04-2021

17

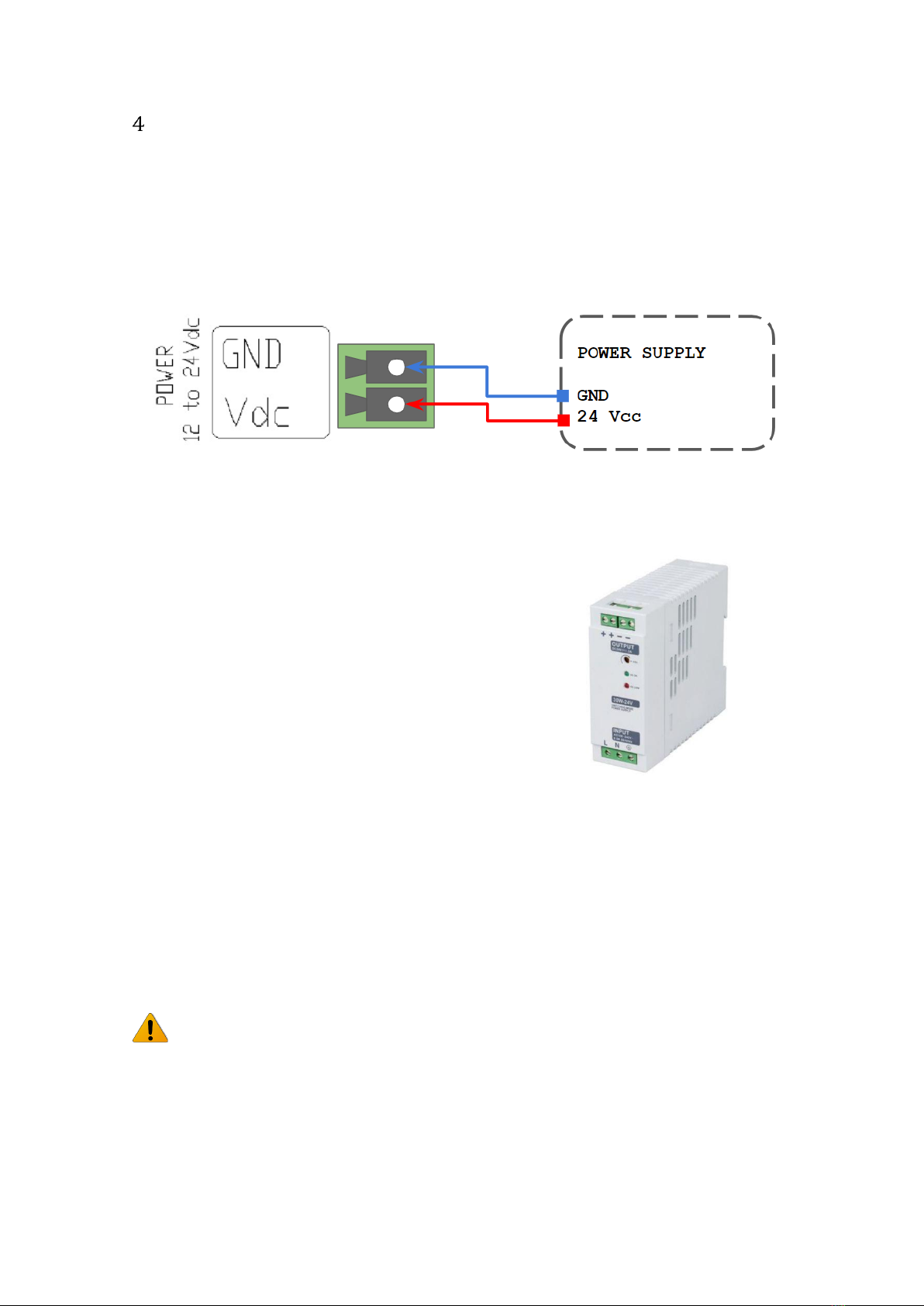

How to connect PLC to power supply

-Raspberry PI Family PLCs are 12-24Vdc supplied. IMPORTANT: The polarity IS NOT

REVERSAL!

-Make sure that the live and GND connector of the power supply match the PLC.

-Make sure that the power supply mains output is not higher than 24Vdc.

-Suggested power suppliers

The standard, Part 1 of IEC 61010, sets the general safety requirements for the following types

of electrical devices and their accessories, regardless of where use of the device is intended.

The equipment must be powered from an external power source in accordance with IEC

61010-1, whose output is MBTS and is limited in power according to section 9.4 of IEC 61010-

1.

Warning:

Once the equipment is installed inside an electrical cabinet, the MTBS cables of the equipment

must be separated from the dangerous voltage cables.

Compact DIN rail power supply. Assembled on 35mm

DIN Rail:

- 24Vdc

- 10A

- 240W

Industrial Shields power supplies provide parallel

operation, overvoltage protection, and overcurrent

protection. There is a LED inductor for power status,

the power supply is certified according to UL.

Rev. 8: 29-04-2021

18

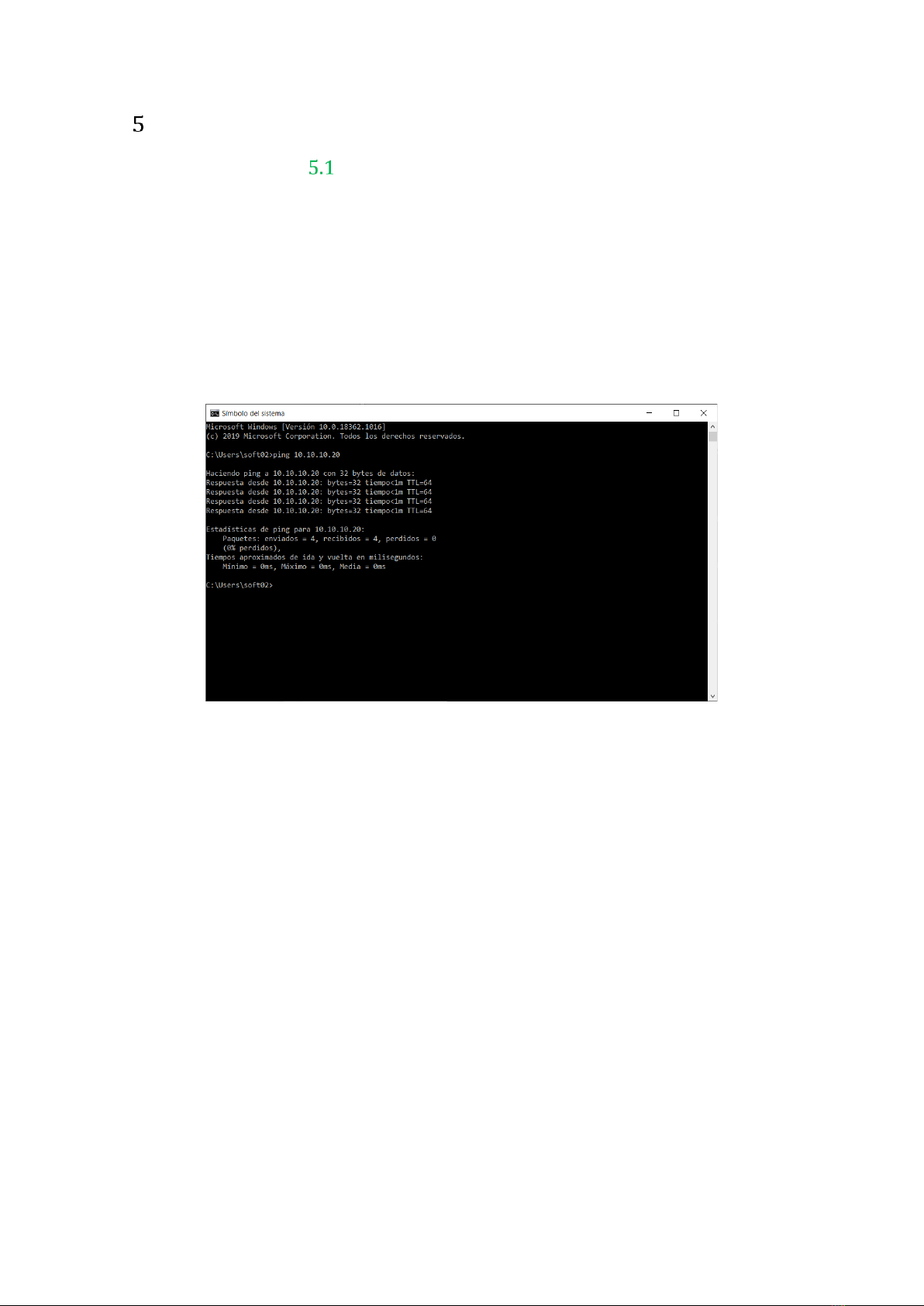

How to access to the Raspberry PLC

Raspberry PLC access

To facilitate the connection to the Raspberry PLC, our company has set a default IP for it. For

the first time of use, an Ethernet connection between the Raspberry PLC and a PC will be

necessary. The Raspberry is given with the local IP address 10.10.10.20/24*, the default user is

pi and the password is raspberry. For connecting to it, you must change your local address for

being in the same local network as the Raspberry. After the first connection you can add users

or change each user’s password anytime. In order to know if the Raspberry is connected and

the Ethernet connection is going on, a ping command can be run on the terminal (for windows

users enter cnm in the windows searching tab to open it):

*Note: To use this local IP address you must connect the Ethernet cable to the Ethernet port

located in the right side of the PLC. Do not use the upper side Ethernet port for this purpose.

The steps to follow for both Linux and Windows are explained below:

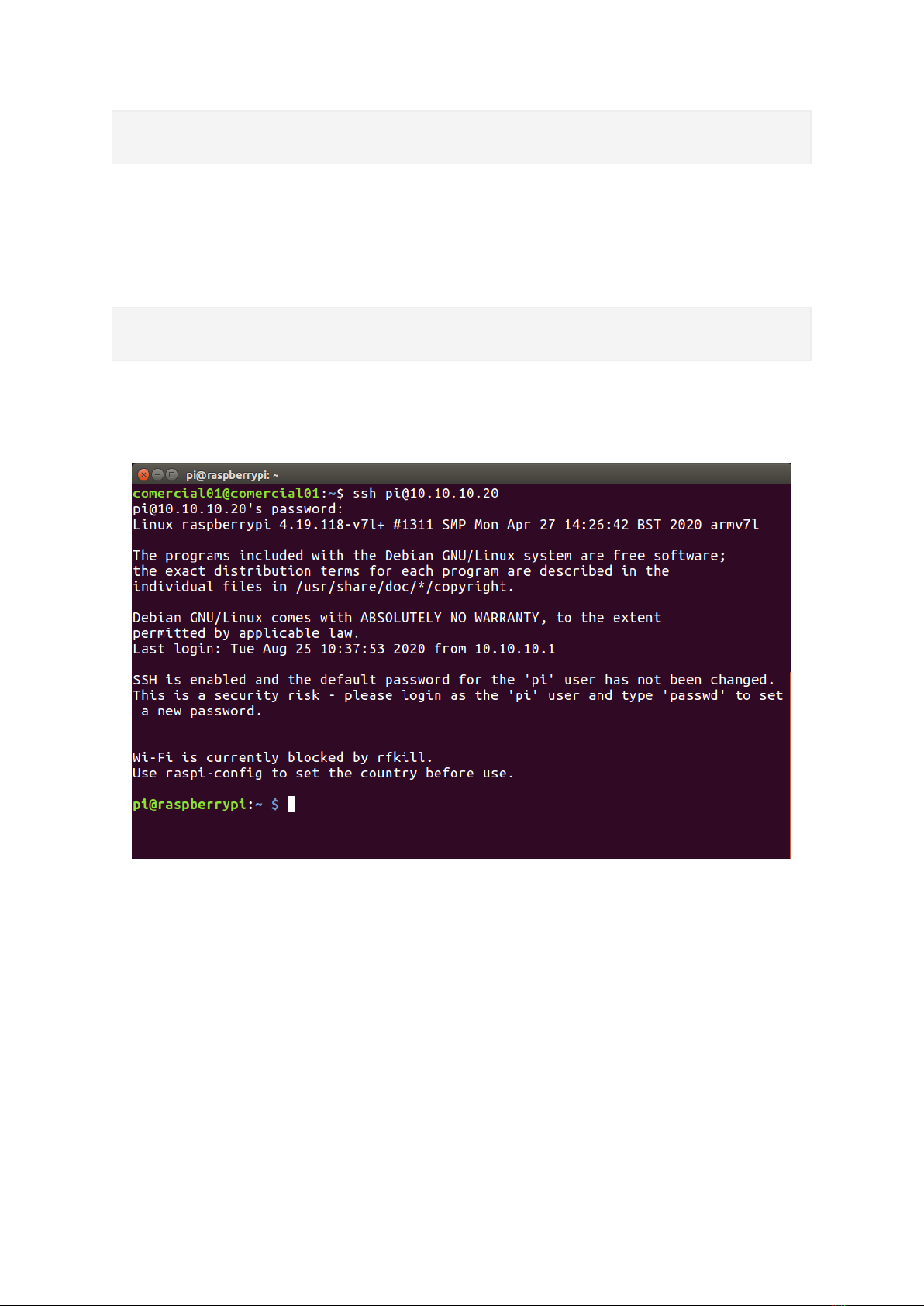

5.1.1 Linux

In order to access the Raspberry PLC, Linux users have to enter by SSH protocol, which should

have been installed before by the user. As has been said, the Raspberry is given with a local IP

address by default for making an easier path for the customer. So, first of all we have to check

if our local Ethernet Network is set with the same local IP address as our raspberrian device. In

case that you do not know how to set it, check the section 6 of the guide. As have been

mentioned before, you can use the ping command with the address 10.10.10.20 as option:

Rev. 8: 29-04-2021

19

$ping 10.10.10.20

If the ping works successfully means that our connection is ready. If not, you can check section

6 again or read our blog about changing the local IP.

For accessing to the Raspberry PLC we will run the command ssh shown below:

$ssh [email protected]

The connection will start, but first the password provided before will be required. If the

username and password are correct, you can start the SSH session.

When an SSH connection is made for the first time, the server delivers the server's public key

to the SSH client. The system will alert you to this and offer you the option of accepting the key

or rejecting it. You have to accept the key, as it will be stored in the register and will be used to

contrast it with the one sent by the server on each connection. If for some reason the key

changes, a new notice is generated in which the authenticity of the received key will be raised,

since someone could be posing as the server to which we want to connect.

Once connected, will be a full access to the Raspberry PLC and the user will be able to control

it and set the functions needed. Also new users or the password could be changed as the

device IP. The commands for going through the Raspberry are the same as the Linux terminal.

The most useful are the following:

•cd: to navigate through the Linux files and directories.

•ls: is used to view the contents of a directory.

This manual suits for next models

12

Table of contents

Popular Industrial Equipment manuals by other brands

Schaeffler

Schaeffler FAG PULLER-2ARM user manual

Linear Technology

Linear Technology LTC6416 Demo Manual

Aerovent

Aerovent IM-502 Installation, operation & maintenance manual

Endress+Hauser

Endress+Hauser Cleanfit COA451 operating instructions

Vestil

Vestil SPB-P-72 instruction manual

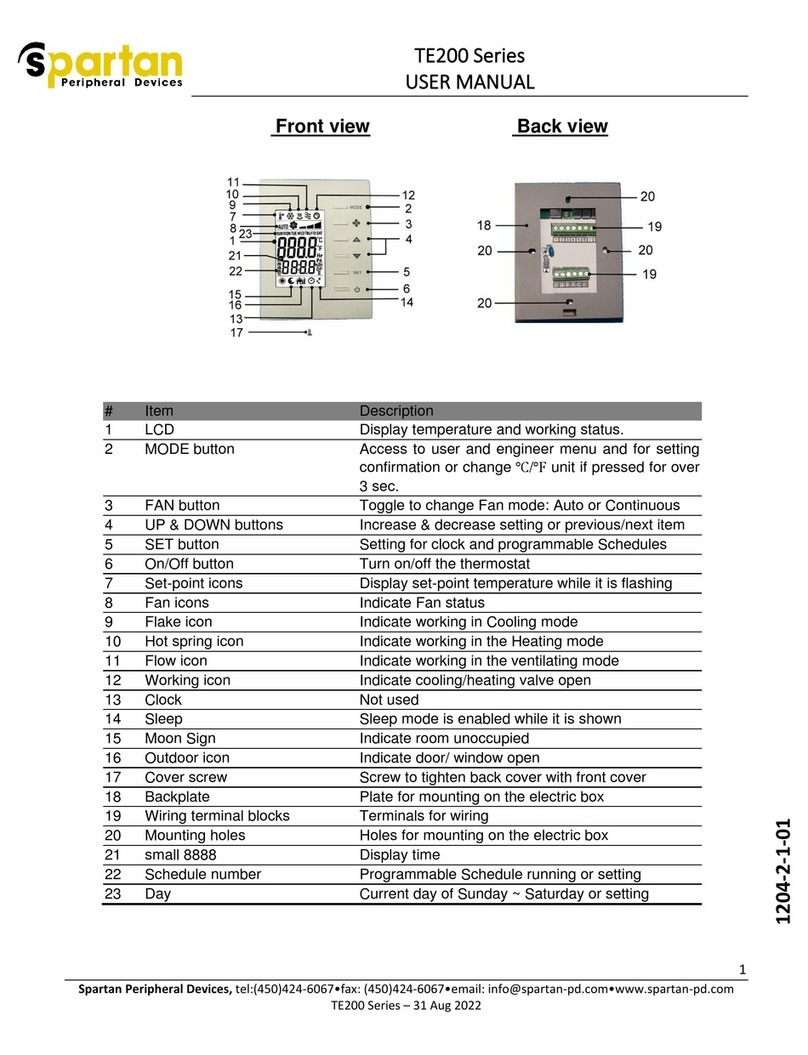

Spartan

Spartan TE200 Series user manual

goodnature

goodnature AA-375R owner's manual

Watkiss

Watkiss Vario operating manual

Delachaux

Delachaux Conductix-Wampfler 040804 Series Operating instruction

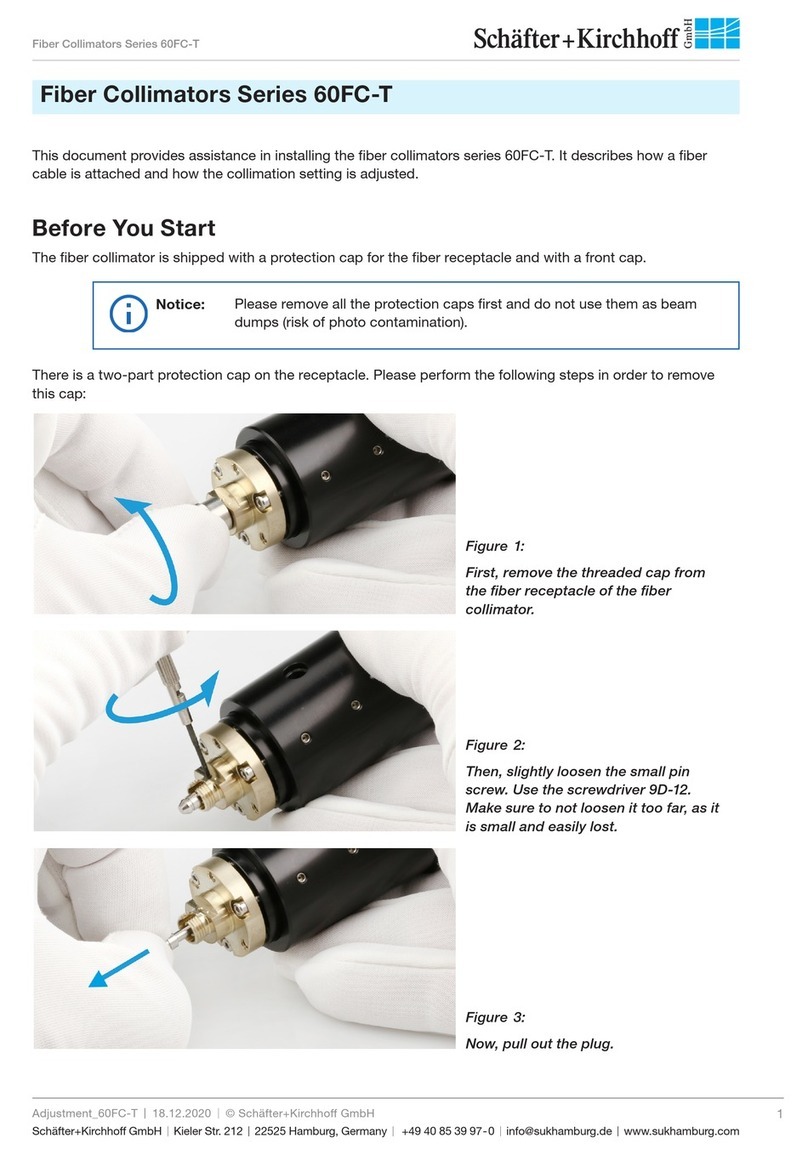

Schäfter+Kirchhoff

Schäfter+Kirchhoff 60FC-T Series quick start guide

BROSA

BROSA 0206 operating manual

Magnetek

Magnetek Electrobar 8-Bar instruction manual