Page 2of 13

TABLE OF CONTENTS

1. Introduction ............................................................................................................................................ 3

2. Manufacturer .......................................................................................................................................... 3

3. General information................................................................................................................................ 3

4. Warnings ................................................................................................................................................. 5

5. Technical data ......................................................................................................................................... 6

5.1. Product performance .............................................................................................................................. 6

5.2. Brake lining wear..................................................................................................................................... 6

5.3. Special note............................................................................................................................................. 6

6. Transport and storage............................................................................................................................. 7

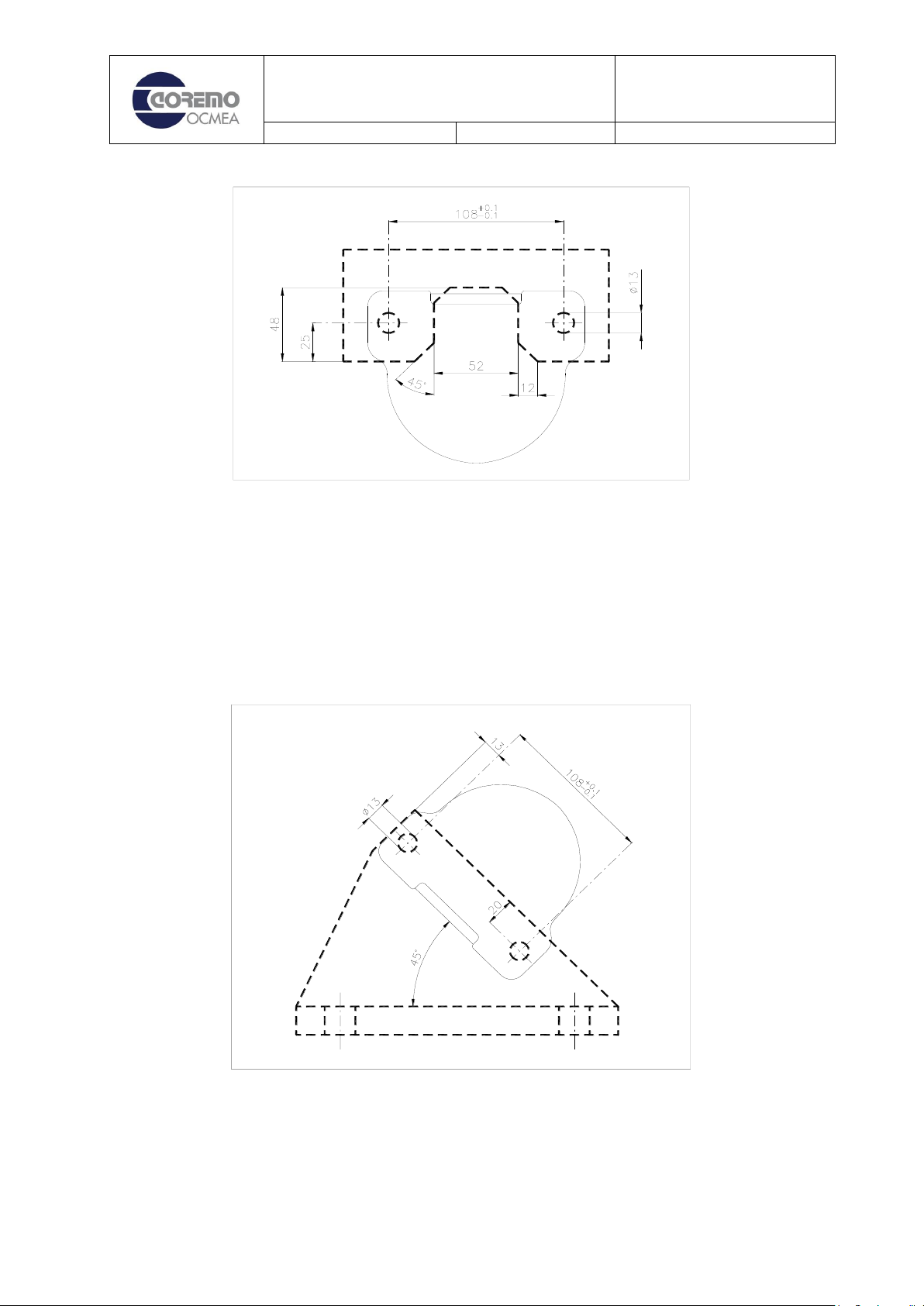

7. Installation............................................................................................................................................... 7

8. Operation .............................................................................................................................................. 10

8.1. Power supply of the safety component ................................................................................................ 10

8.2. Improper use......................................................................................................................................... 10

9. Maintenance and cleaning.................................................................................................................... 11

9.1. Changing the linings pads...................................................................................................................... 11

9.2. Cleaning the friction surfaces................................................................................................................ 11

9.3. Changing the sealing rings..................................................................................................................... 12

9.4. Periodic maintenance............................................................................................................................ 12

10. Spare parts list....................................................................................................................................... 13