2

CONTENTS

Page

1 - GENERAL INFORMATION ……………………………………………………………………………………... 4

Application field ……………………………………………………………………………………………………………………………. 4

Copyrights …………………………………………………………………………………………………………………………………… 4

Protection of environment. Priority tasks of our company ………………………………………………………………… 4

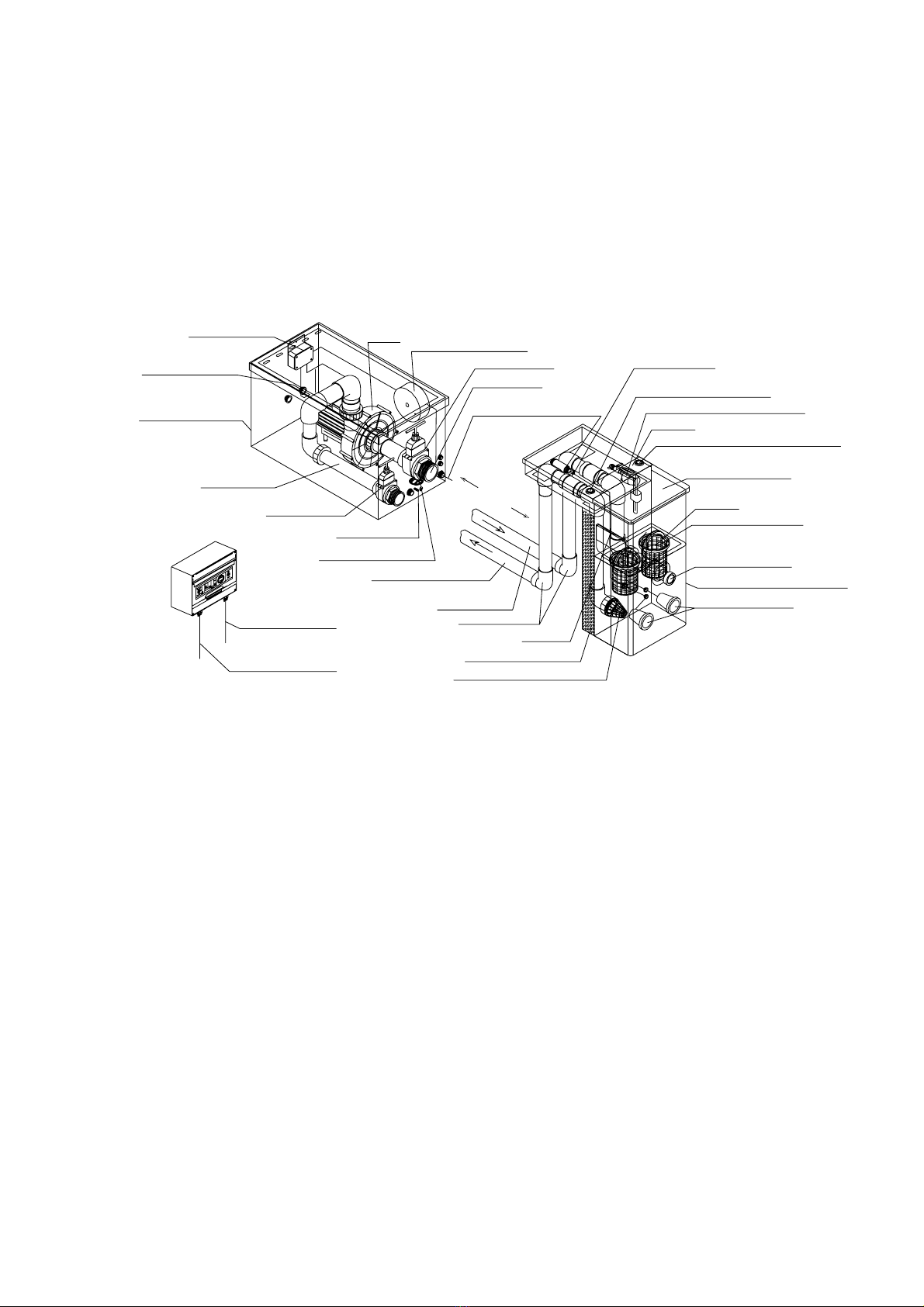

2 - DESCRIPTION OF EQUIPMENT. STANDARD VERSIONS AND THEIR COMPONENT PARTS ….. 5-8

2.1. Principal scheme of universal blocks VUВ……………………………………………………….. 5

2.1/a Block VUВ15 …………………………….…………………………………………………………………………….……….. 6

2.1/b Block VUВ25 …………………………….…………………………………………………………………………….……….. 6

2.1/c Block VUВ20/50 …………………………….…………………………………………………………………………….….. 6

2.1/d Block VUВ15 + heat exchanger ………....…………………………………………………………………………..… 7

2.1/e Block VUВ25 + heat exchanger ………....…………………………………………………………………………..… 7

2.1/f Block VUВ20/50 + heat exchanger ………....………………………………………………………………………… 7

2.1/g Block VUB15 + electric heater ….....……………..……………………………………………………………………. 8

2.1/h Block VUB25 + electric heater ….....……………..……………………………………………………………………. 8

2.1/i Block VUB25 + electric heater ….....……………..…………………………………………………………………….. 8

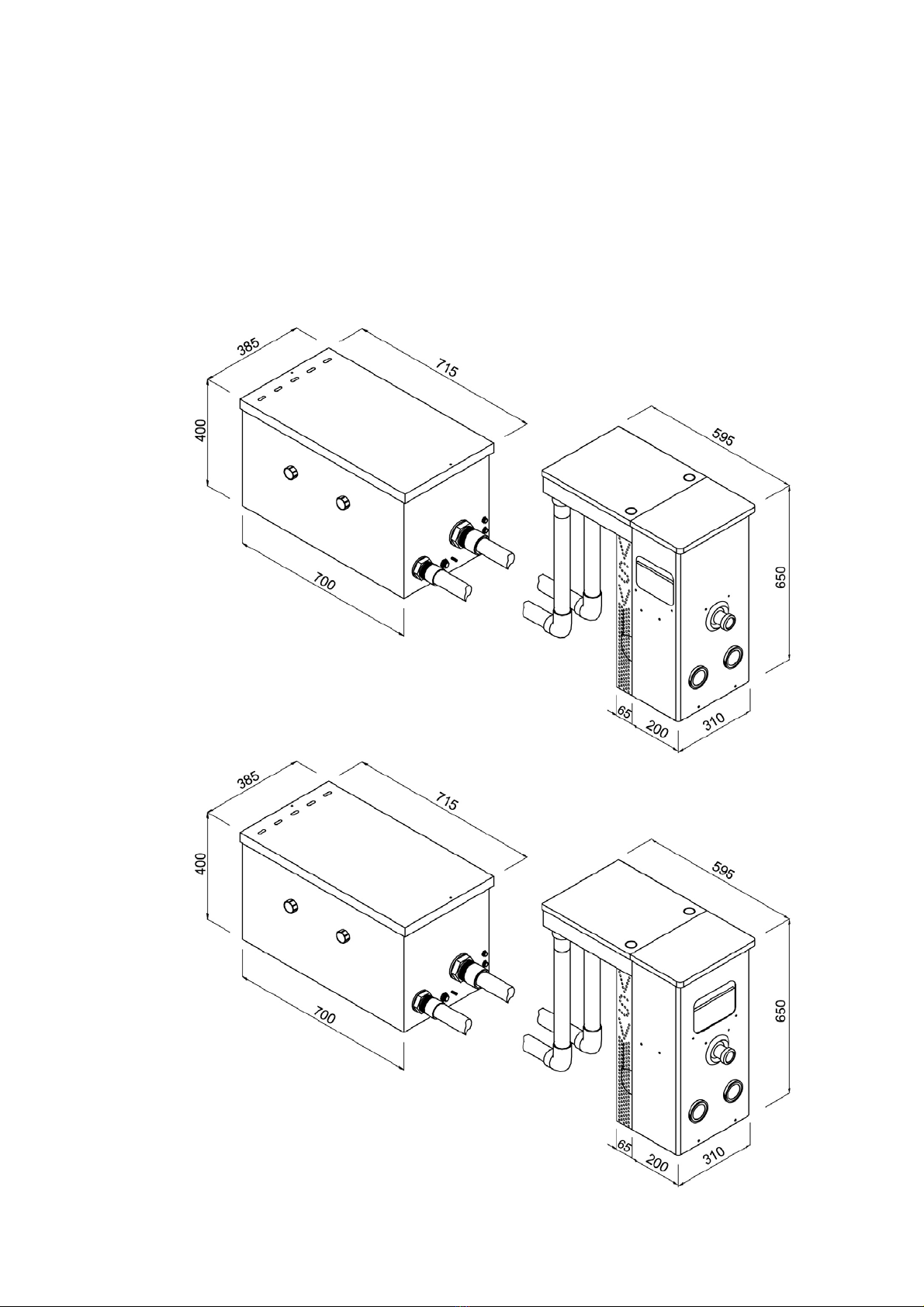

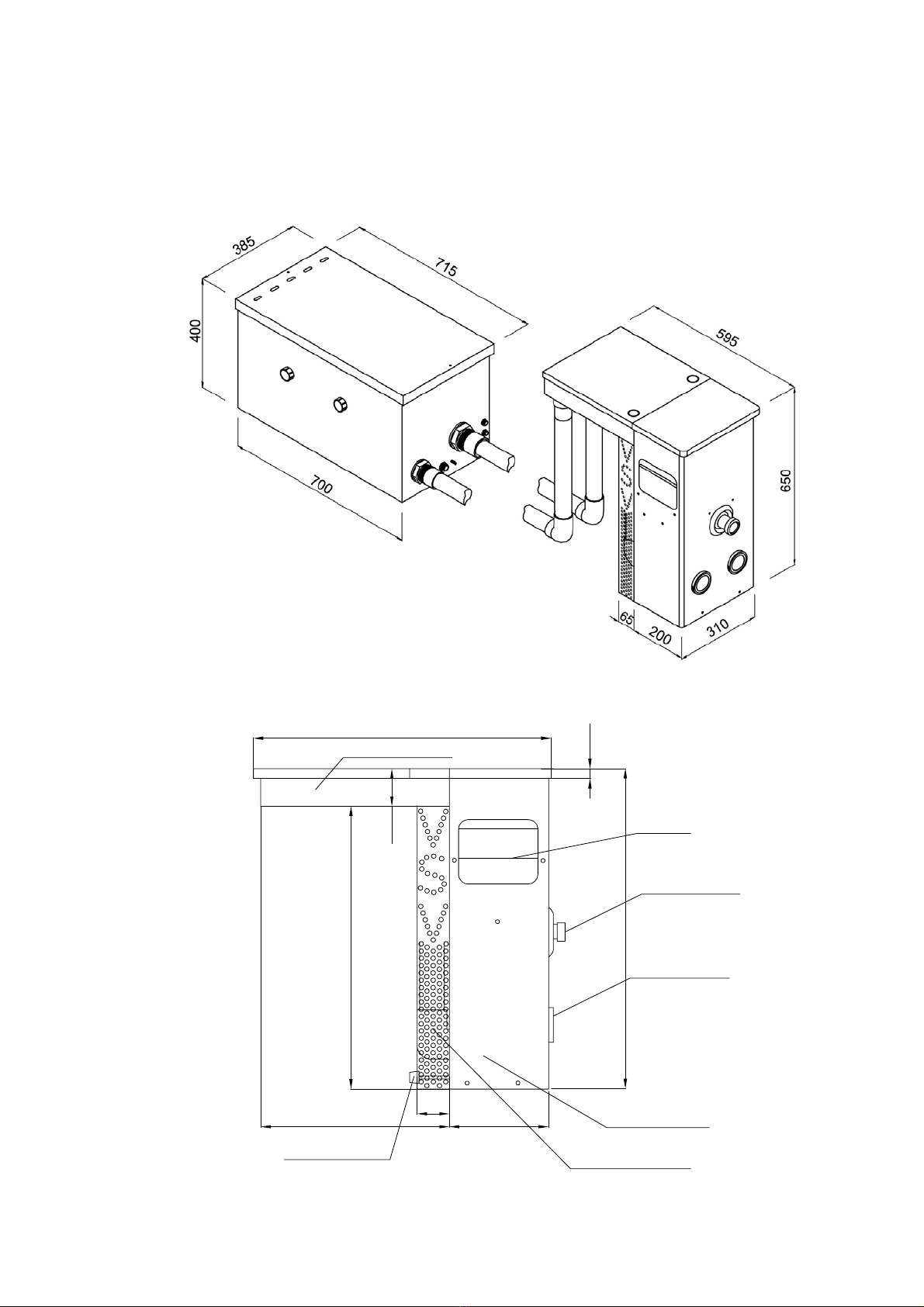

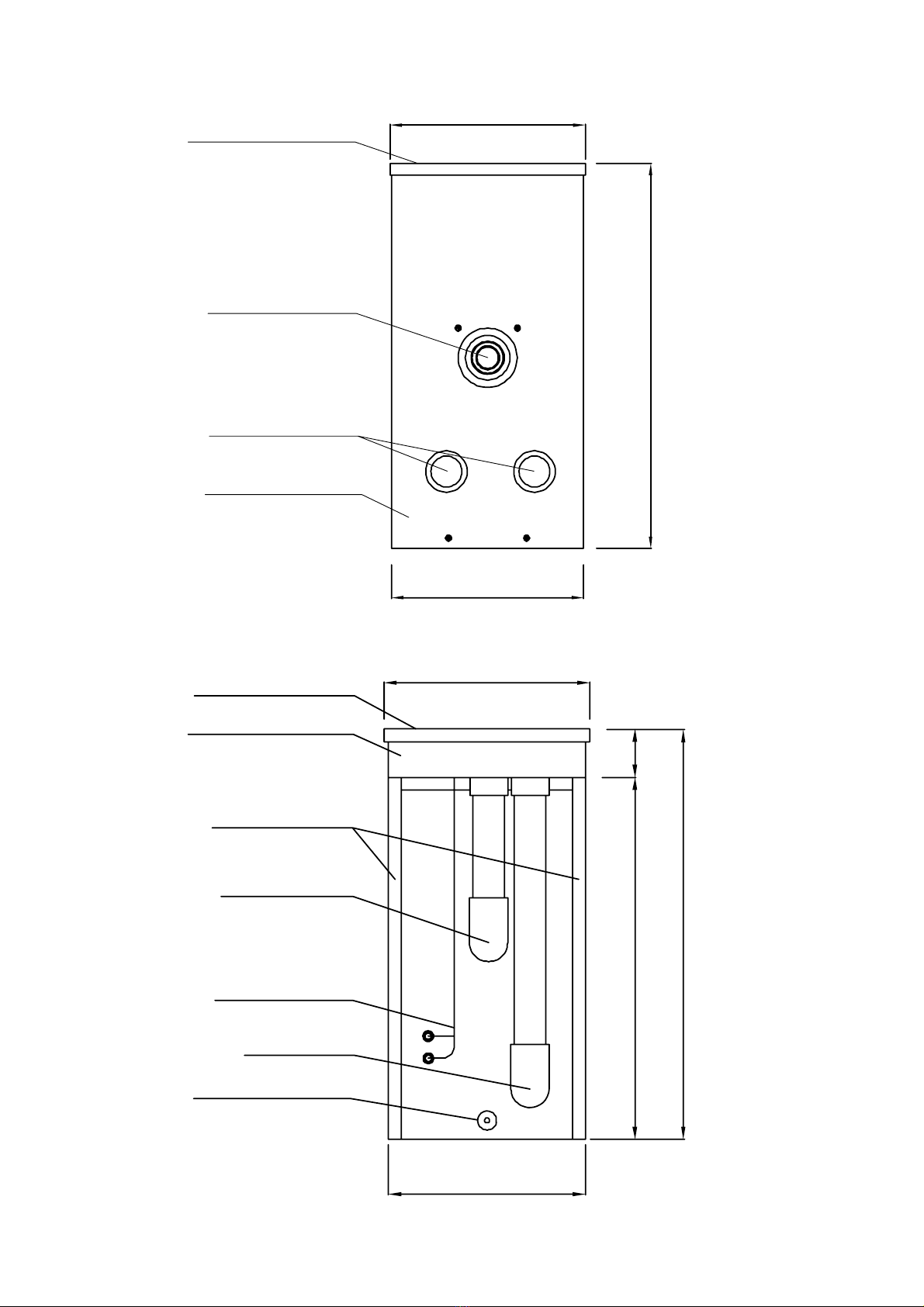

3 - TOTAL VIEW AND DIMENSIONS OF EQUIPMENT ..…………………………………………………… 9-10

3.1 Total view and dimensions of universal blocks …………………......................................... 9

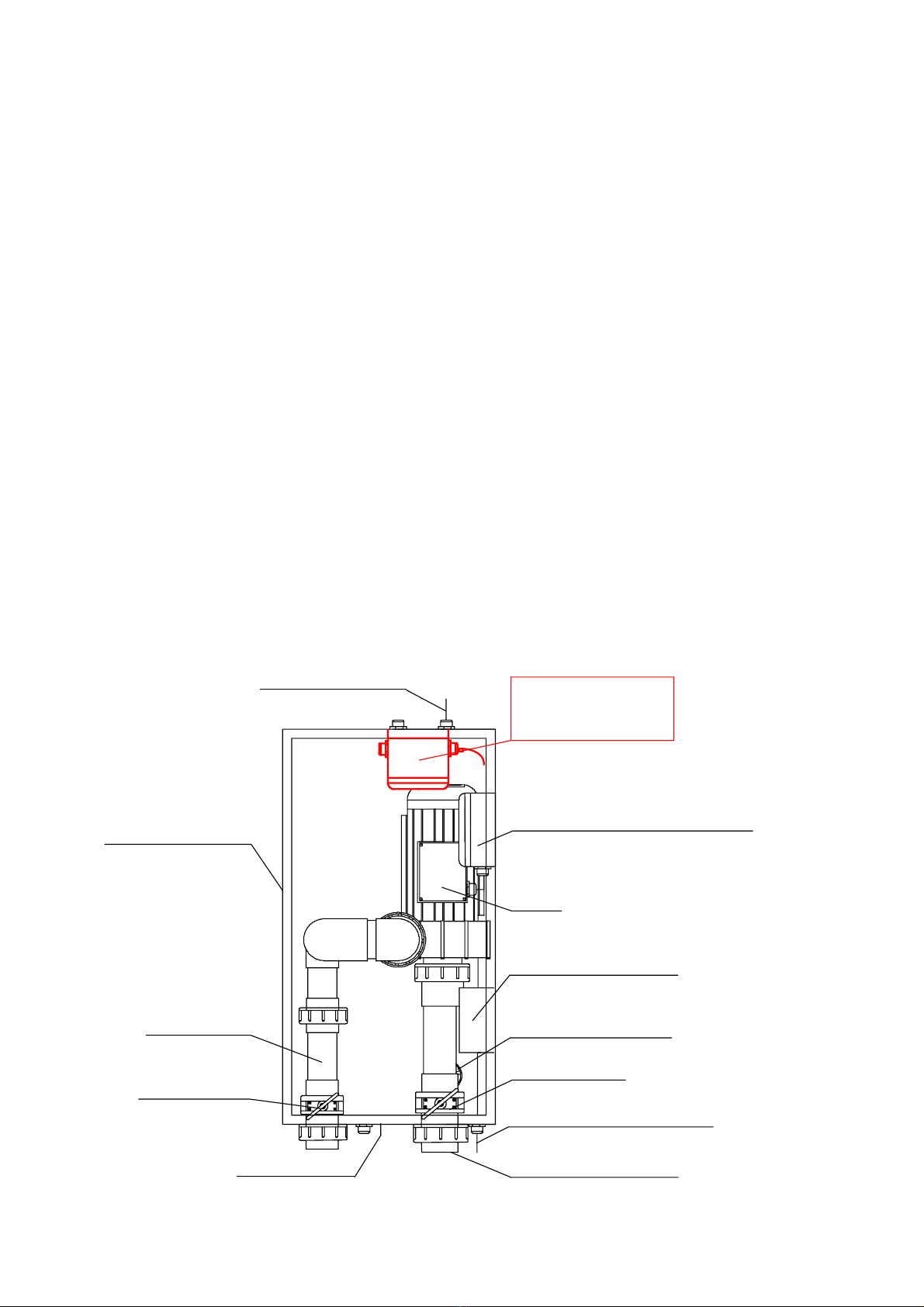

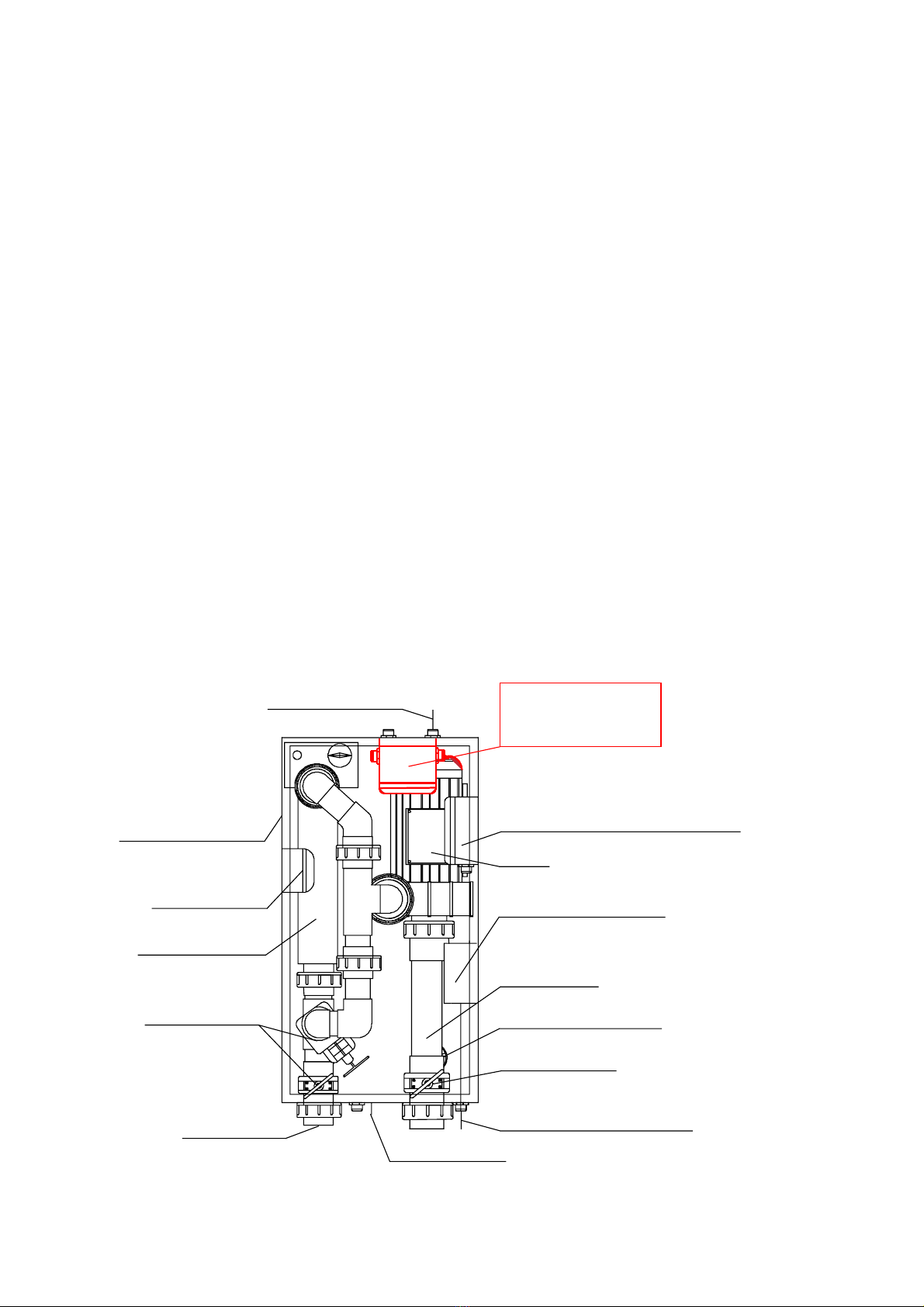

4 - INSTALLATION OF EQUIPMENT …………………………………………………………………………… 11-12

4.1. Installation of universal blocks ………………………………….…………………………………. 11

4.2. Installation of technical compartment of universal blocks ………………………………….. 12

5 - GENERAL SAFETY RULES ……………………………………………………………………………………………………….. 13

Electrical safety…………………………….…………………………………………………………………………………………… 13

Differential switch ………………………………………………………..…………………………………………………………… 13

6 - EQUIPMENT MOUNTING ……………………………………………………………………………………. 14

6.1. Universal blocks mounting …………………………………………………………………………… 14

Automatic water topping-up ……………………………….…………………………………………………………………….. 14

Connection of universal block’s filtration compartment with technical compartment ………………………… 14

a) connection with pump ………………………………………………………………………………..…………………………. 14

b) connection with counter-swimming pneumatic button ………….………………………………………………….. 14

c) laying of spotlight electric cable ……………………………………..………………………………………………………. 14

d) connection with spotlight pneumatic button ……………………………………………………………………………. 14

e) connection of technical compartment with drainage …………………………………………………………………. 14

7 – ELECTRICAL CONNECTIONS ……………………………………………………………………….............. 15-20

Electrical control panel …………………..…………………………………………………………………………………………. 15

Electrical control panel connection scheme ………………………………………………..……………………………….. 16

Multiconductor connection boxes of universal blocks ……………………………………………………………………. 17-18

Heat exchanger electrical connection scheme in the universal blocks ……………….………………………..…. 18

Heat exchanger hydraulic connection scheme in the universal blocks ……………….………………………..…. 19

Electric heater connection scheme in the universal blocks ………………………………………..…………………… 20

8 – GROUND CONNECTION MOUNTING ……………………………………………………………………….. 21

9 – PUTTING INTO OPERATION ………………………………………………………………………………….. 22

9.1. Universal block’s start-up and operation ………………….……………………………………... 22

Initial start-up …………………………..……………………………………………………………………………………………… 22

Timer setting in the electrical control panel …………………………………………………………………………………. 22

Counter-swimming function ……………………………………………..……………………………………………………….. 22

10 – FILTRATION MEMBRANE AND ITS INSTALLATION .………………………………………………….. 23-24

Filtration membrane cleaning and replacement ……………………………………………………………………………. 23

Vacuum-cleaner connection and operation ………………………………………………………………………………….. 24

Big filtration membrane …………………………………………………………………………………………………………….. 24

11 – REPLACEMENT OF SPOTLIGHT BULB …………………………………………………………………….. 25

12 – EQUIPMENT WINTERIZING …………………………………..…………………………………………..... 25