CENTERPOINTE BUTCHER BLOCK COUNTERTOPS

Additional considerations should be made when

installing a CenterPointe butcher block countertop

around appliances and countertops with stove

cutouts. Where appliances have heat acting on the

countertop, such as dishwasher, under counter oven,

or warming drawer, attach self-adhering aluminum

flashing to the underside of the butcher block. This

will assist in keeping heat and steam away from the

block and cut down heat transference. The fitting

of cooktops must not restrict the countertop from

expanding and contracting. Ensure that there is at

least 1/4” clearance all around the cooktop. To avoid

splintering when cutting into the butcher block, it

is recommended that masking tape be applied over

the area that will be cut.

NOTE: Reapply finish to any areas that have been

cut during installation.

3

KITCHEN APPLIANCE PLACEMENT

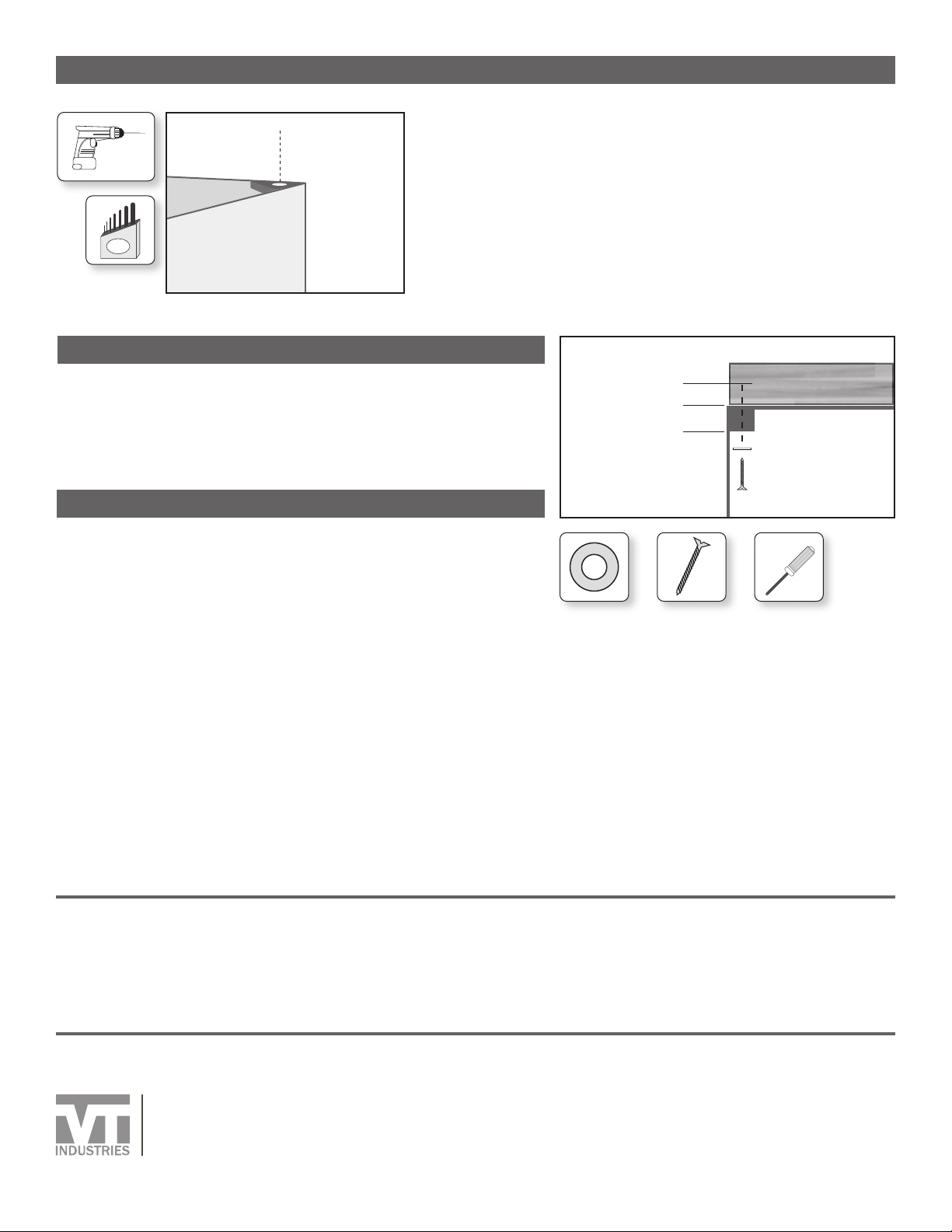

STEP 4 - CUT

To begin cutting using the circular saw, adjust the blade

so that it extends 1/4” below the bottom of the butcher

block countertop. A blade that hangs too low beyond

the thickness of the wood may pull at the wood bers,

causing tears and splintering. Make the necessary cuts

into the butcher block along the pencil line. Move the

circular saw at a slow and even pace to ensure the blade

does not tear the wood.

Note: If burn marks appear while cutting, sand the

surface lightly with 120 grit sandpaper and re-apply

nish.

EXAMPLE:

1-1/2”+1/4”= 1-3/4” BLADE DEPTH

SAW

COUNTERTOP 1-1/2”

BLADE 1/4” BELOW

COUNTERTOP

SELF-ADHERING ALUMINUM FLASHING

UNDER-MOUNT APPLIANCE

Underside Front View

WALL

APPLIANCE

Overhead View

1/4” 1/4”

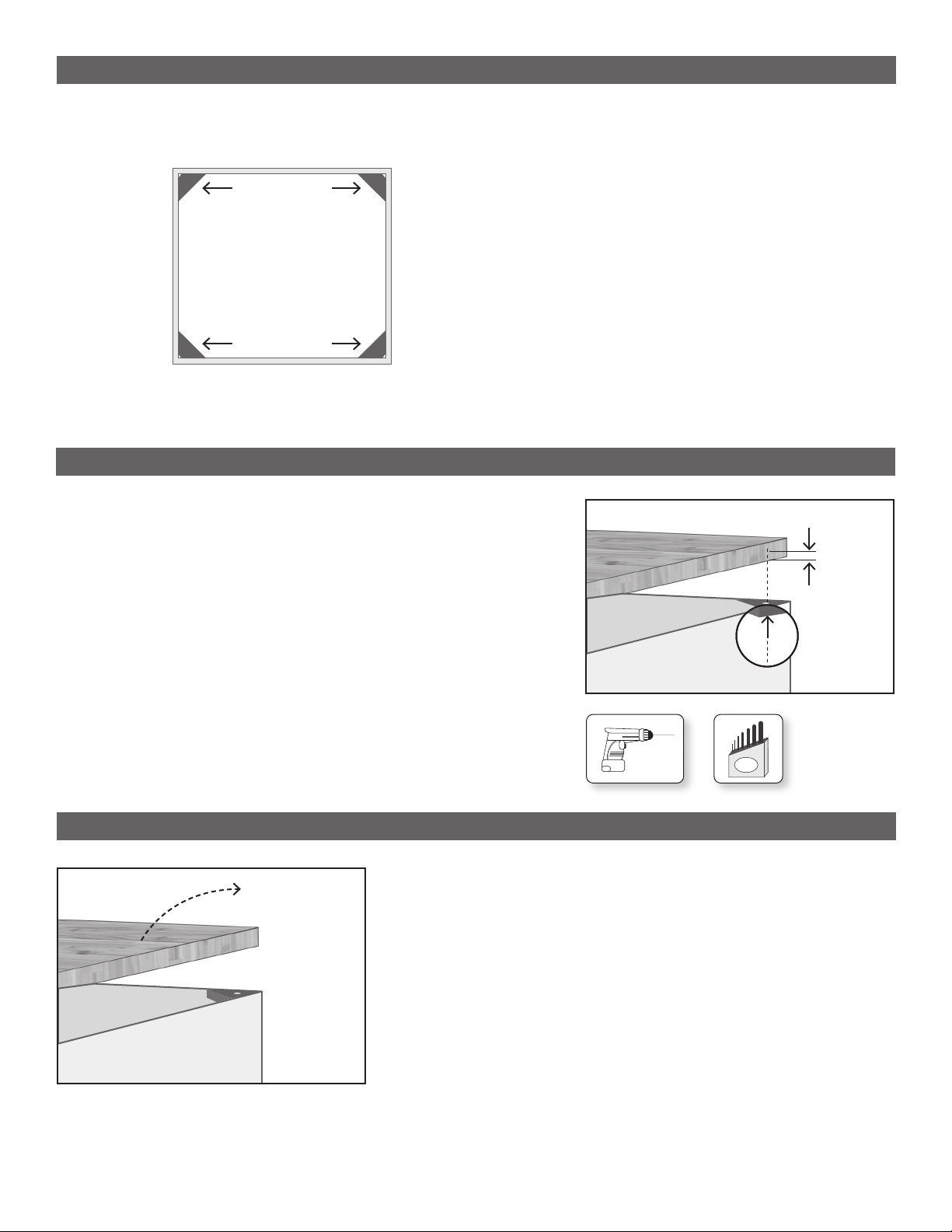

STEP 3 - TAPE & MARK CUT LINE

Carefully measure the width of the run of cabinets to be covered

with butcher block, including any desired overhang, if applicable.

After determining the necessary cuts to be made, draw the cut line

boldly with a pencil, using a carpenter’s square to draw a straight

line. Place a layer of masking tape over the pencil line. Press the

masking tape rmly.

Overhead View