EN

VTS reserves the right to implement changes without prior notice

2

Table of contents

Table of contents ................................................................................................................................................................................................... 2

SAFETY INSTRUCTIONS AND ALARMS! .................................................................................................................................................................... 3

Technical data ........................................................................................................................................................................................................ 4

Control gear construction ................................................................................................................................................................................. 4

Main internal elements:..................................................................................................................................................................................... 4

Operation parameters ....................................................................................................................................................................................... 4

Short-circuit and overload protection................................................................................................................................................................. 5

Relay pump ....................................................................................................................................................................................................... 5

Control circuit.................................................................................................................................................................................................... 5

Table I/O (for ver. to 1.0.004)............................................................................................................................................................................. 5

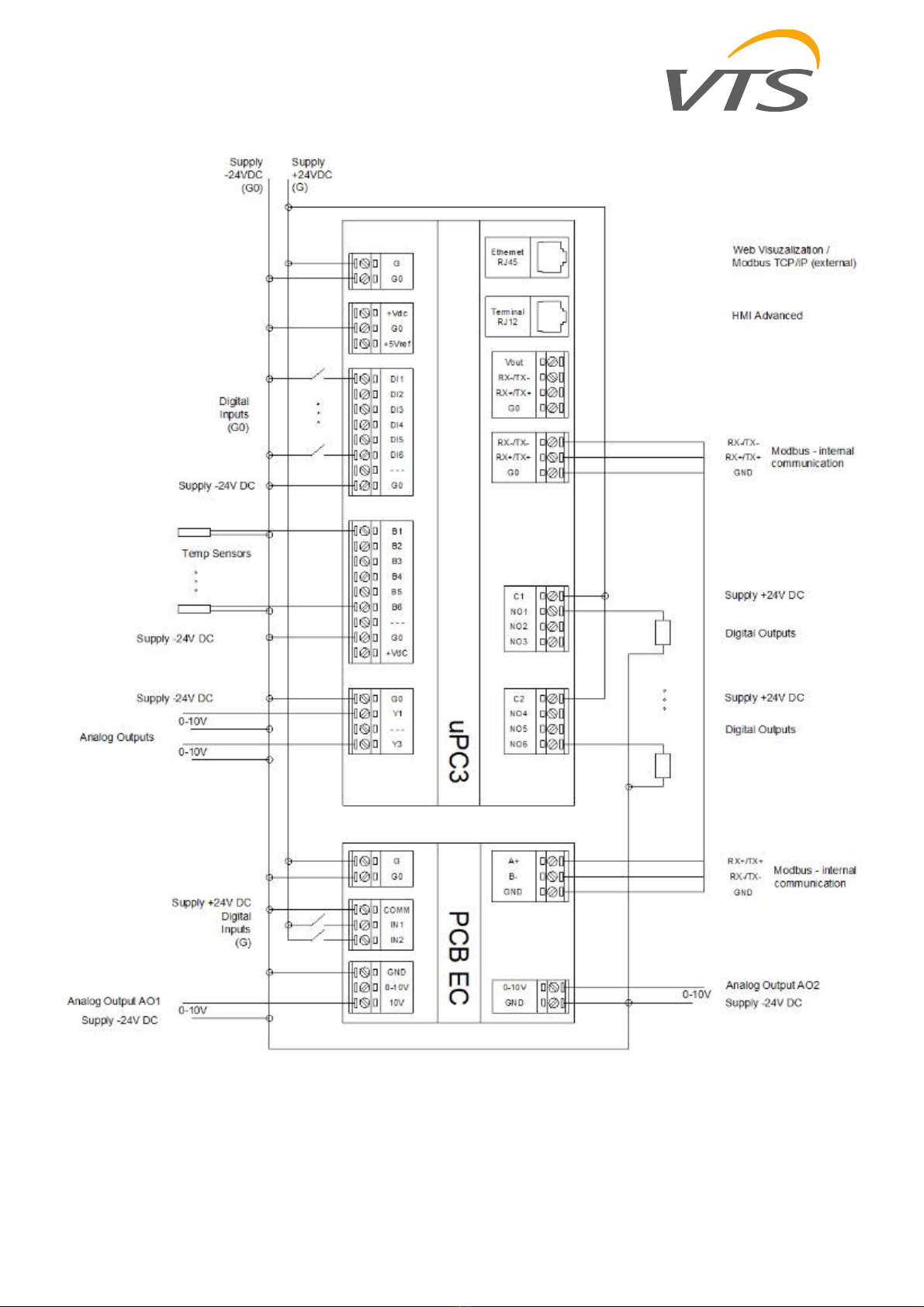

Connection controller diagram........................................................................................................................................................................... 7

Dimensions and weight...................................................................................................................................................................................... 8

Cabling .............................................................................................................................................................................................................. 9

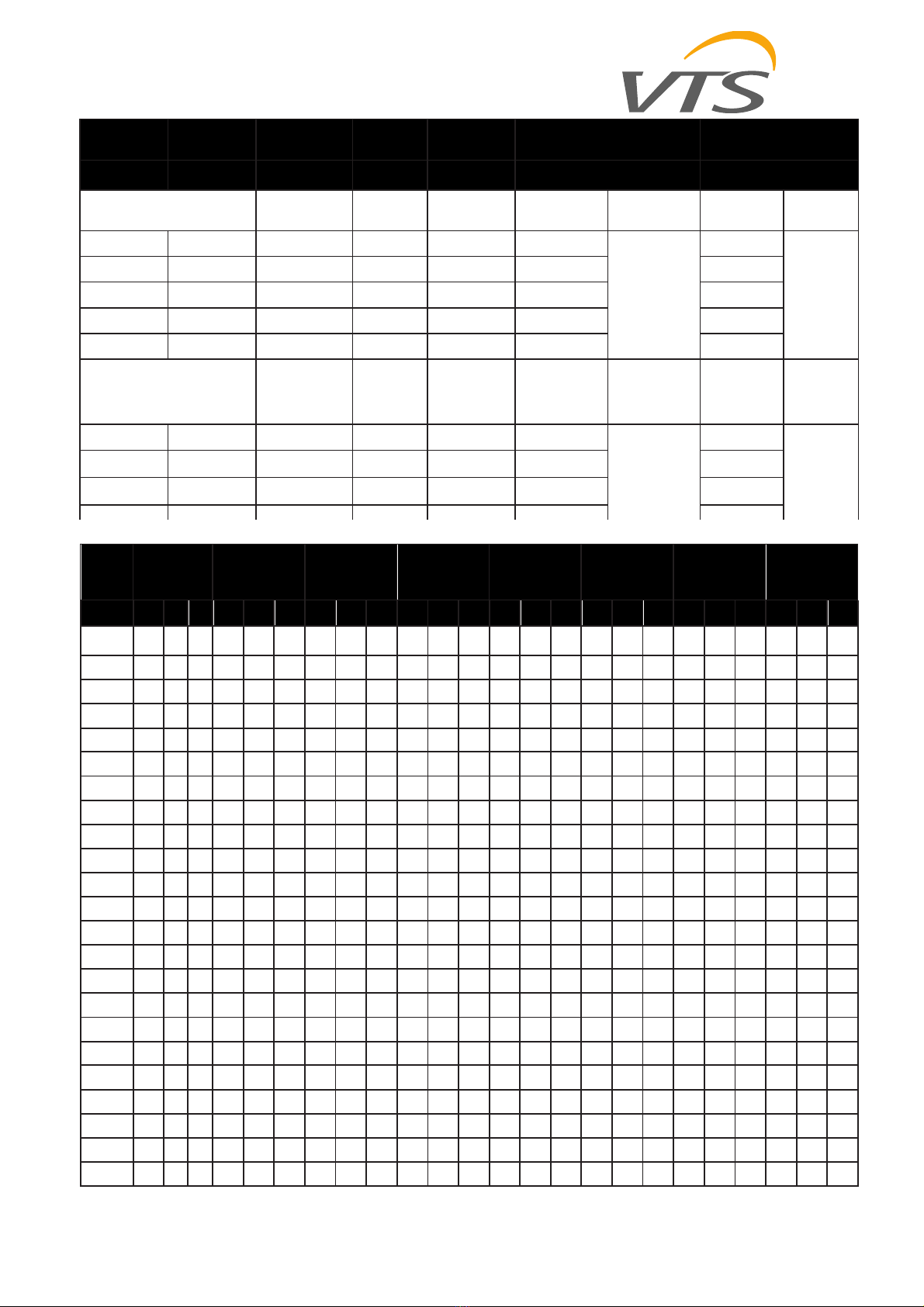

Table A ....................................................................................................................................................................................................... 10

Table B ....................................................................................................................................................................................................... 10

Table B ....................................................................................................................................................................................................... 11

Table B ....................................................................................................................................................................................................... 12

Table C ....................................................................................................................................................................................................... 13

Appendix 1 Circuit diagram of “CBX uPC3 3x400V 2x1VFD <2,2kW” control gear ............................................................................................... 14

Appendix 2 Circuit diagram of “CBX uPC3 3x400V 2x1VFD <11kW” control gear ................................................................................................ 16

Appendix 3 Circuit diagram of “CBX uPC3 3x400V 2x2VFD <11kW” control gear ................................................................................................ 18

Appendix 4 Circuit diagram of “CBX uPC3 3x400V 2x3VFD <11kW” control gear ................................................................................................ 20

Appendix 5 Circuit diagram of “CBX uPC3 3x400V 2x4VFD <11kW, 2x5VFD <7,5kW” control gear ...................................................................... 22

Appendix 6 Circuit diagram of “CBX uPC3 3x400V 1x1VFD <11kW” control gear ................................................................................................ 24

Appendix 7 Circuit diagram of control circuit .................................................................................................................................................... 25