9EN |INSTRUCTION MANUAL |VWR

Disassembly Options/Cleaning

WARNING Do not use force in assembly or disassembly.

Disassembly should only be undertaken after the unit has been cleaned using the recommended cleaning

procedure. Wear protective clothing and goggles during disassembly.

1. Move the cursor (6) down the scale and undo the dispense sleeve cap (1) by turning anti-clockwise

andlifting.

2. The piston holder (2) is now exposed and the piston (4) is ready for removal. Remove the piston

assemblycarefully.

3. Clean the piston’s surface with a suitable cleaning solution. Do not use hard tools to scrape off residue

of reagent from the piston as this will damage the surface and will not seal with the glass barrel when

reassembled.

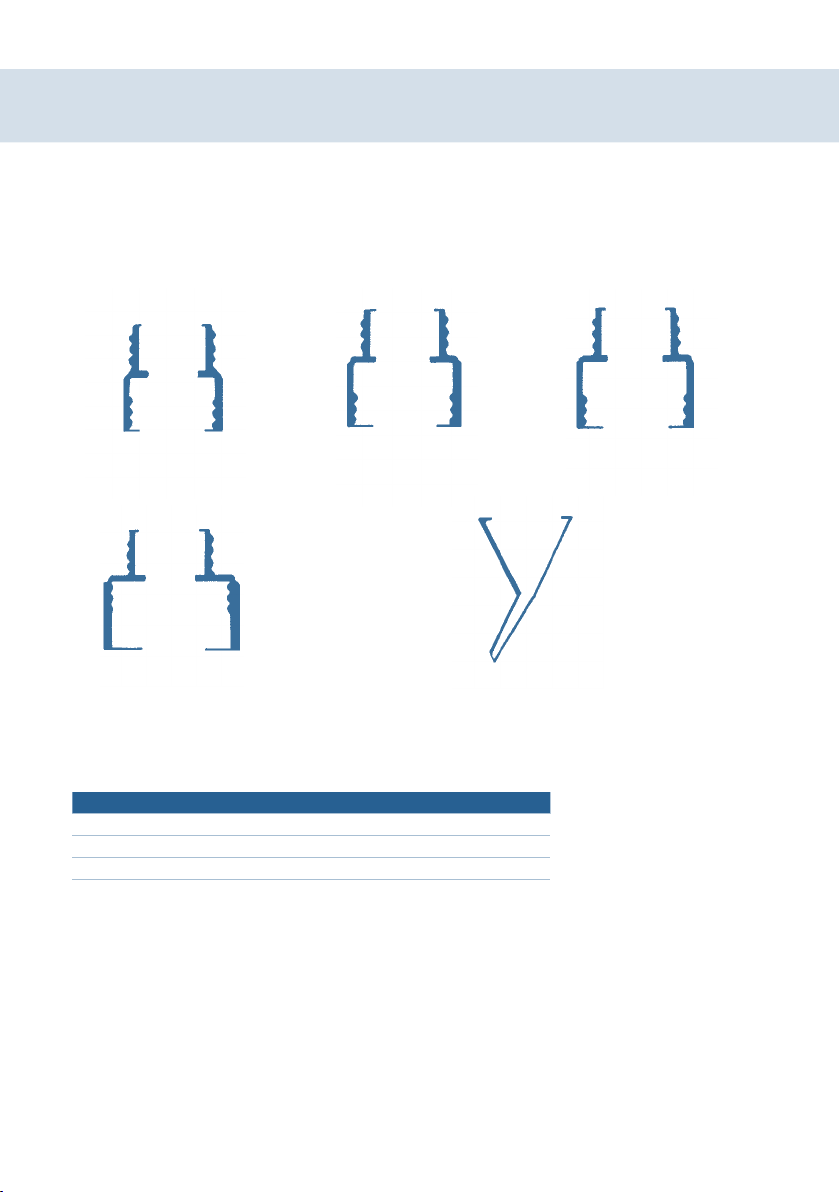

4. If it is necessary to clean or replace the graduated outer dispense sleeve (5) of your Zippette Classic, this

is carried out with the help of the supplied assembly tool (17).

a. Loosen the polypropylene threaded ring (9) on the base by approximately one turn.

b. Using the assembly tool (17), undo the top stop ring (3) by turning clockwise and lifting it out. You

can now lift off the dispense sleeve (5).

c. To remove the polypropylene protection sleeve (11) and borosilicate glass barrel (10), fully undo the

threaded ring (9), remove the polypropylene protection sleeve (11) and gently lift out the glass barrel

(10) for replacement or cleaning.

Note: Bevelled inside edge of barrel must be at the top end when tted.

d. Removal of FEP dispense tube (14); Firstly turn the anti-drip tap to the closed position.

Then remove dispense tube protection cover (15) in an upward direction allowing dispense tube (14)

to be pulled out of anti-drip shut-off valve assembly in direction indicated on pages 12 and 13.

e. Reassemble in reverse, make sure the front end of the dispense tube is clipped into the dispense tube

protection cover (15) from the underside.

f. Reassemble the remaining components following the above points in reverse order, making sure that

the FEP ‘O’ ring (12) is well located into its platform recess. Take special care not to damage the piston

when inserting it into the glass barrel.

g. Before tightening the threaded ring (9) fully onto the threaded platform base (13), rotate the

polypropylene protection sleeve (11) so that the tooth on its base locates properly into the notch on

the threaded ring (9).

h. After reassembling the instrument, prime with distilled water to ensure that assembly has been

correctly followed and the piston is working smoothly. Check that no leaks occur.