Table of Contents

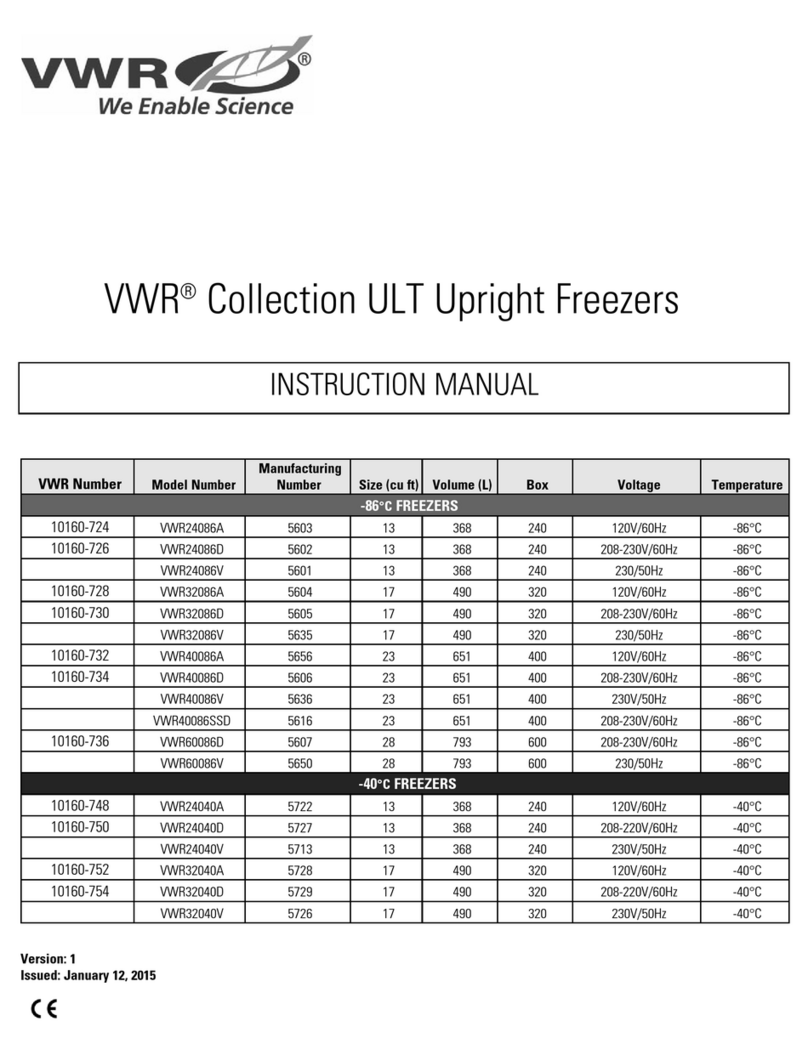

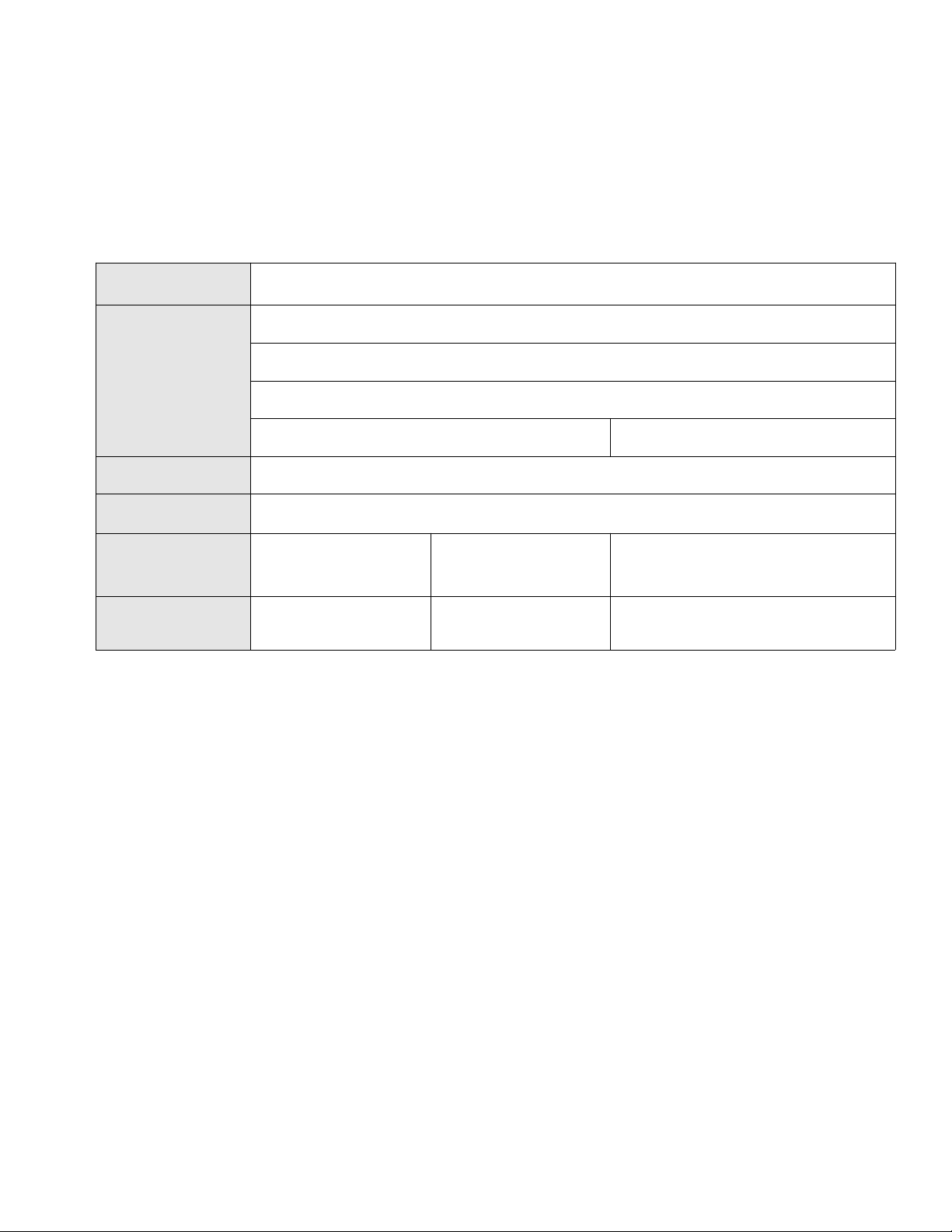

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

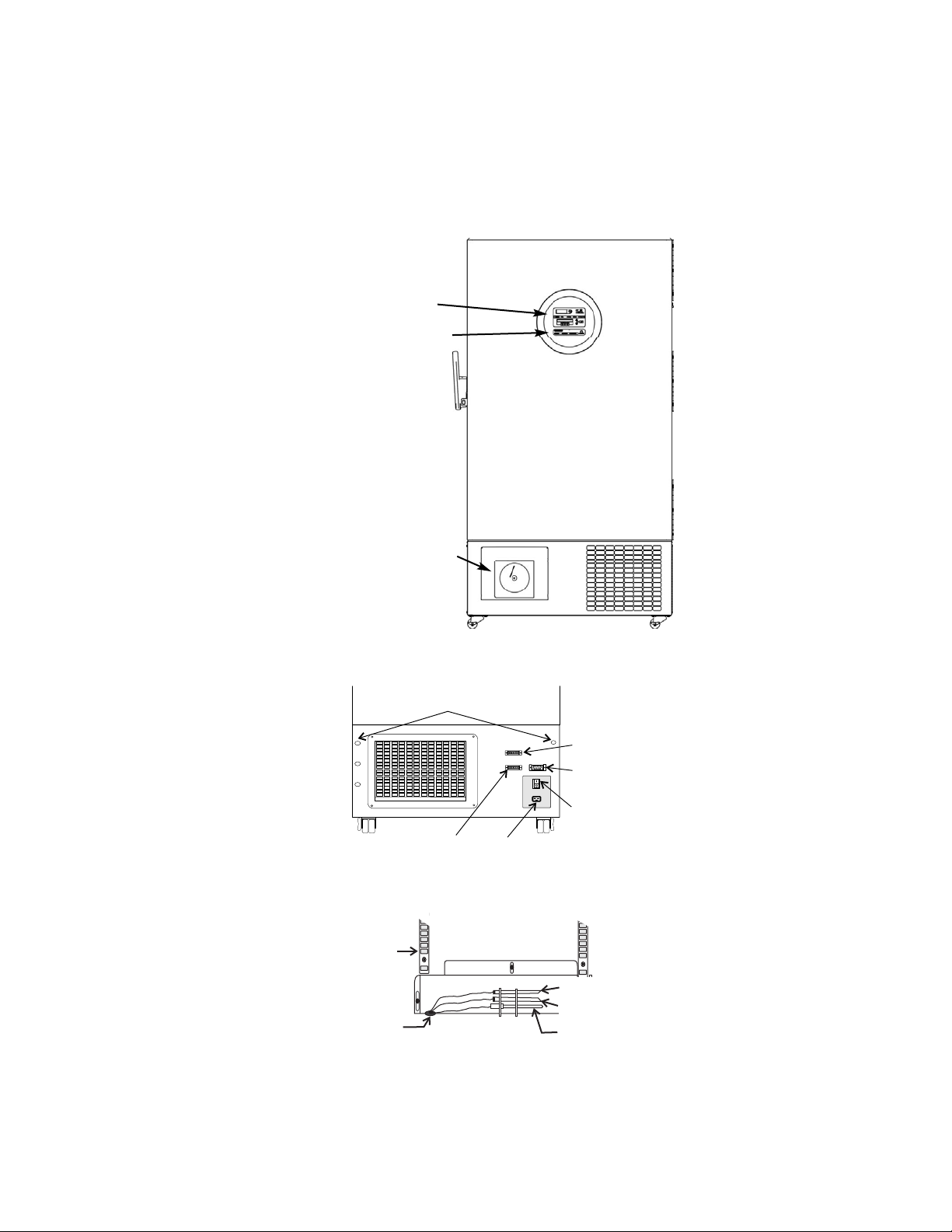

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Control Panel Keys, Displays & Indicators . . . . . . . . . . . . . . . . . . . .2-3

Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Install the Freezer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Choose the Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Install the Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

RS-232 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Install the Wall Bumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Remote Alarm Contacts and Analog Output . . . . . . . . . . . . . . . . .2-7

Attach the Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Connect Unit to Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Freezer Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Set the Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Set the High Temperature Alarm . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Set the Low Temperature Alarm . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Access Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Calibrate the Control Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Calibrate the Optional Sample Probe . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Temperature Stabilization Periods . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

High Alarm Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Low Alarm Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

System Battery Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

BUS Battery Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Display Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Clear High Stage Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Set Access Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

RS485 Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Back-Up System Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Cold Excursion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Warm Excursion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Reset Excursion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Section 1

Section 2

Section 4

Section 3

Upright Freezer vVWR International