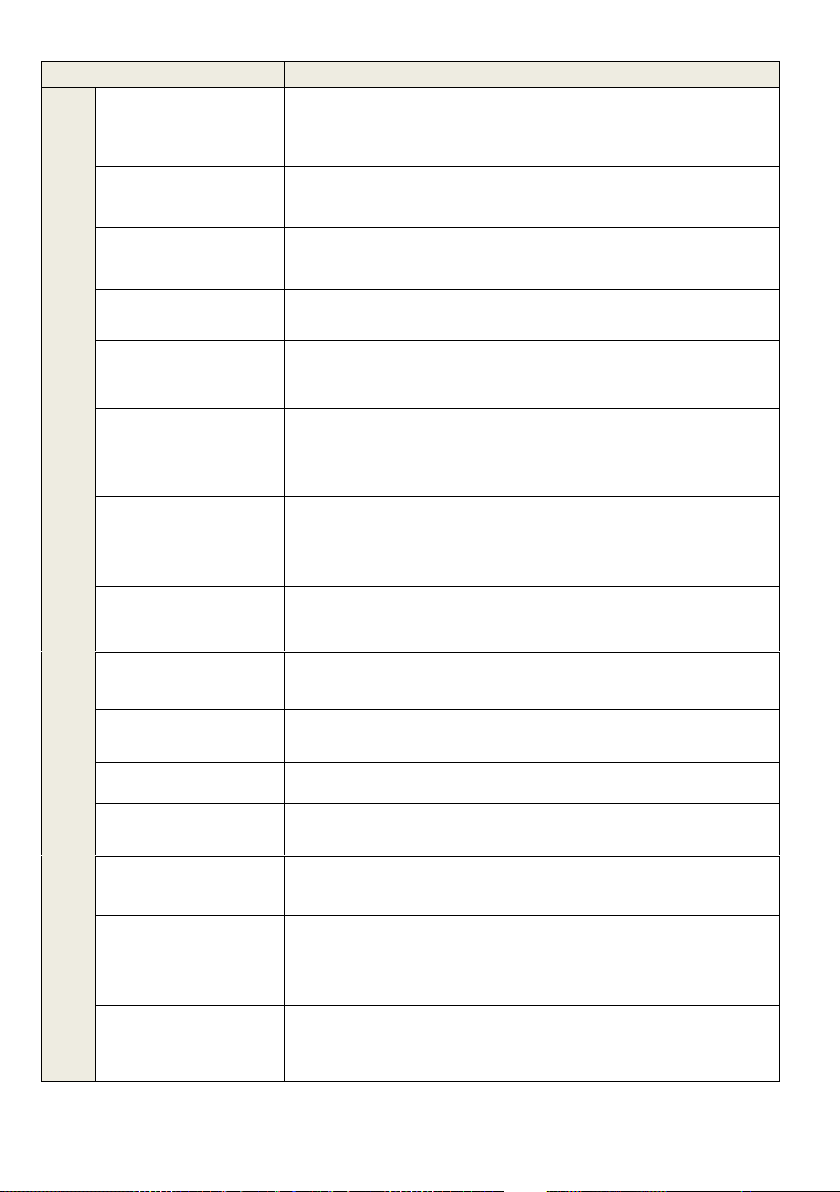

Group P4: V/F control parameters ..................................................................................... 60

Group P5: Input terminals X ............................................................................................... 62

Group P6: Output terminals ............................................................................................... 67

Group P7: Control panel and display .................................................................................. 69

Group P8: Auxiliary functions ............................................................................................. 72

Group P9: Faults and protection ........................................................................................ 75

Group PA: PID process control functions ........................................................................... 81

Group PB: Variable frequency, fixed length and count ...................................................... 84

Group PC: Multiple functions and simple PLC function ..................................................... 85

Group PD: Communication parameters ............................................................................. 89

Group PF: Reserved for service purposes .......................................................................... 89

Group PP: Restoring the factory setting and blocking the change of parameters ………..…90

Group C0: Torque control and parameter limitation ......................................................... 90

Group C5: Control optimization parameters ...................................................................... 91

Group C6: FI curve setting (FI is FIV or FIC) ....................................................................... 91

Group C9: Special function PID ........................................................................................... 92

Group CC: Correction of FI/FO values ................................................................................ 93

Group D0: Monitoring parameters...................................................................................... 94

Example No. 1 Parameterizations of inverse control 10 V to 0 V ................................ 96

Example No. 2 Parameterization of braking resistance ............................................... 96

Example No. 3 Parameterizations for the control of the el. motor of the crane ….. ……….. 97

Example No. 4 Application PID ........................................................................................... 98

Example No. 5 High-speed spindle operation parameters ................................................. 98

Chapter 5: Detailed description of parameters .................................................. 99

Group P0: Basic parameters .............................................................................................. 99

Group P1: Start / Stop control ..................................................................................... 110

Group P2: Motor parameters ........................................................................................ 116

Group P3: Vector control parameters .......................................................................... 118

Group P4: V/F control parameters ................................................................................. 121

Group P5: Input terminals ............................................................................................... 127