MI.33.J2.02 - VLT®is a registered Danfoss trademark

VLT®AutomationDrive FC 300

Safe PLC Interface Option MCB 108

The MCB 108 option module is a galvanically isolated via an internal DC/DC converter and it can be fitted into option

slot B.

What is the MCB108 Option:

It is designed to be built in between the Safe dual pole(plus/minus) on the Safe PLC and the Safe Stop input

on FC302. The Safe PLC interface allows the safe output on the Safe PLC, to maintain the test pulses on the

plus and minus output without impacting the sensor signal to safe stop T37.

Can be used in combination with safety devices to satisfy the requirement of IEC61800-5-2 SIL 2,

ISO13849-1 PL d, and Category 3 (EN954-1) for Safe Torque Off (STO)

Electrical Data:

Input voltage (DC)..................................................................................................... .................................. 18 to 28 V DC

Typical current input (DC)..................................................................................................... ....................... 60 mAmp

Max. current input (DC)...................................................................................................... ......................... 110 mAmp DC

Max. current inrush (DC)........................................................................ ................................................... 500 mAmp DC

Output voltage (DC) ............................................................................................................................ 20 V DC@Vin = 24 V

Turn on delay ....................................................................................................................................... 1 mSec

Turn off delay ....................................................................................................................................... 3 mSec

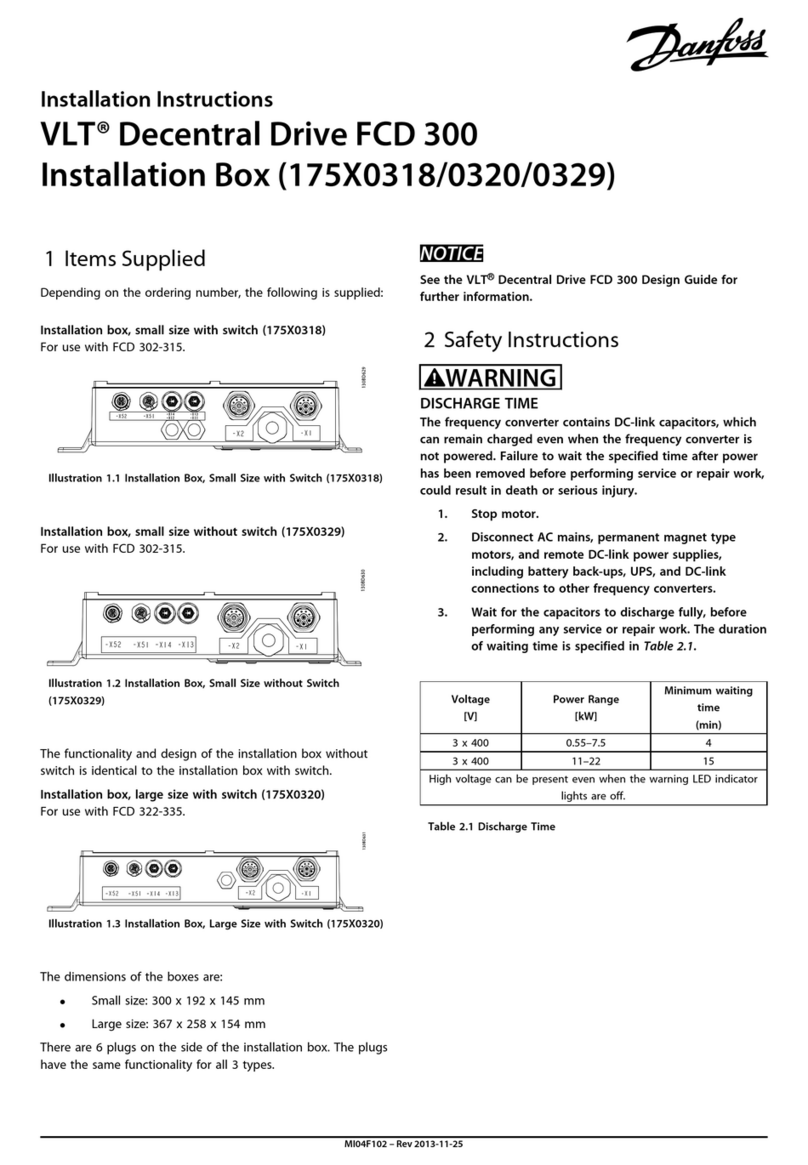

How to mount the MCB 108 option:

1

Following precautions have to be observed:Following precautions have to be observed:

Following precautions have to be observed:Following precautions have to be observed:

Following precautions have to be observed:

- The FC 302 with MCB 108 (including the connections

between X31/9 and Terminal 37) must be placed inside

an IP54 enclosure.

- Safe Stop activation (i.e. removal of 24 V DC voltage

supply to terminal 37 by removing voltage to dual pole

input of MCB 108) does not provide electrical safety.

- The safety device connected to the dual pole input op

MCB 108 must itself fulfill the requirements of EN 954-1

Cat. 3 ISO13849-1 P Ld for interrupting the voltage/

current to MCB 108. This is also valid for the connections

between MCB 108 and the safety device. You must read

and follow the instructions for the safety device in order

to connect it properly to MCB 108.

- The power to the frequency converter must be

disconnected.

- Remove the LCP, the terminal cover and the cradle from

the FC 300.

- Fit the MCB 108 option in slot B.

- Connect the control cables and relief the cables by the

enclosed cable strips.

- Various systems must not be mixed.

- Fit the extended cradle and terminal cover.

- Replace the LCP.

- Connect the input to the Safety PLC’s Output.

- Remove the connection betweeen terminal 13 and 37 of

the FC 302.

Option Slot B

Safe PLC Interface

Cradle

Terminal Cover