3R110 Plus User Manual

szruitech.com

Contents

1. Product overview......................................................................................................................................... 1

1.1 Characteristic......................................................................................................................................... 1

2. Application environment and installation..................................................................................................1

2.1 Environmental requirement..................................................................................................................1

2.2 Driver installation dimensions..............................................................................................................2

3. Driver port and connection......................................................................................................................... 2

3.1 Power supply and motor port function description........................................................................... 2

3.2 Control signal connection.....................................................................................................................3

3.2.1 PUL, DIR port(IN1,IN2)...............................................................................................................3

3.2.2 ENA(IN3)port............................................................................................................................. 4

3.2.3 ALM(OUT1)port ........................................................................................................................4

3.3 USB port .................................................................................................................................................4

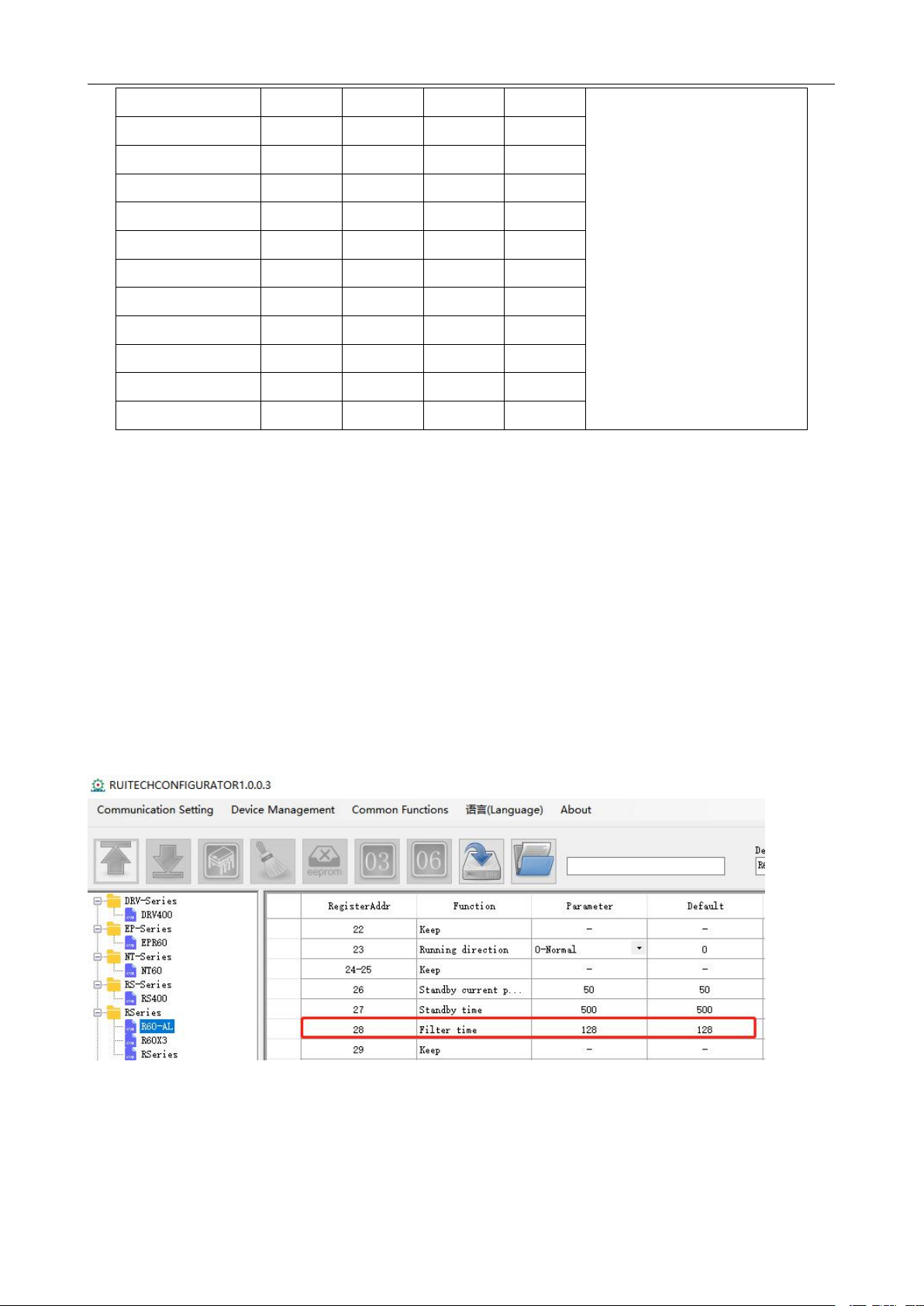

4. The setting of DIP switches and operating parameters.........................................................................5

4.1 The setting of current............................................................................................................................ 5

4.2 Standby current......................................................................................................................................5

4.3 The setting of pulse per revolution......................................................................................................5

4.4 Pulse command filtering....................................................................................................................... 6

4.5 The setting of pulse mode....................................................................................................................7

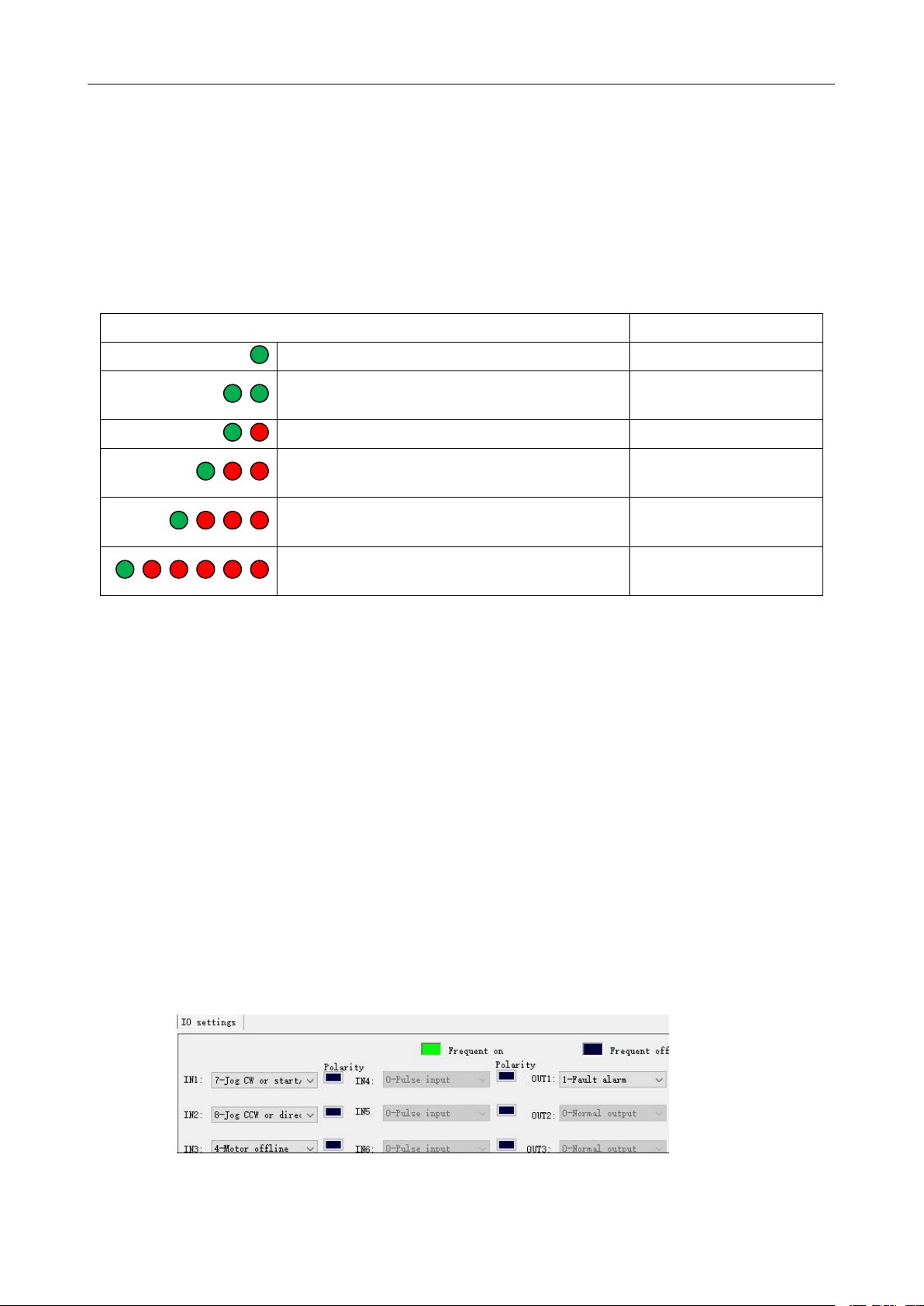

5. Driver working status LED indication........................................................................................................7

6. Phase loss alarm......................................................................................................................................... 7

7. Internal motion control function................................................................................................................. 7

7.1 Communication control mode..............................................................................................................8

7.1.1 Point control mode......................................................................................................................... 8

7.1.2 Jog control mode............................................................................................................................9

7.2 IO Control: Start and Stop + Direction............................................................................................. 10

7.3 IO Control: Forward + Reverse......................................................................................................... 11

8. Common faults and troubleshooting.......................................................................................................12

9. Guarantee clause...................................................................................................................................... 12