WABCO SYSTEM SAVER HP MM1736 User manual

SYSTEM SAVER HP

AIR DRYER

MAINTENANCE MANUAL

MM1736

Table of Contents

3

Table of Contents

EN

Table of Contents

1 General Information ......................................................................................................................................... 4

2 Safety Information............................................................................................................................................ 6

3 Introduction ...................................................................................................................................................... 7

3.1 Overview .........................................................................7

3.2 AirDryerIdentication ...............................................................7

3.3 HowtheAirDryerWorks .............................................................7

3.3.1 Air Dryer Cycle .......................................................................................................................... 8

3.3.2 System Saver HP Air Dryer System .......................................................................................... 9

3.4 AirDryerComponents ..............................................................10

3.4.1 DryerIdenticationTag ........................................................................................................... 11

3.4.2 DescriptionofComponents..................................................................................................... 11

4 Component Removal and Installation.......................................................................................................... 14

4.1 ComponentReplacement ...........................................................14

4.1.1 Requirements.......................................................................................................................... 14

4.2 ComponentRemovalandInstallationProcedures ........................................16

4.2.1 DesiccantCartridge................................................................................................................. 16

4.2.2 Outlet Check Valve Assembly ................................................................................................. 18

4.2.3 Heater Assembly ..................................................................................................................... 19

4.2.4 TurboCut-OValveAssembly ................................................................................................ 20

4.2.5 Governor ................................................................................................................................. 20

4.2.6 PurgeValveAssembly ............................................................................................................ 21

4.2.7 Air Dryer Assembly.................................................................................................................. 21

5 Troubleshooting and Testing ........................................................................................................................ 23

5.1 Maintenance .....................................................................23

5.1.1 MaintenanceTips .................................................................................................................... 24

5.2 Troubleshooting ...................................................................24

5.2.1 Tests........................................................................................................................................ 27

5.2.2 Air Pressure Checks................................................................................................................ 28

6 Glossary.......................................................................................................................................................... 30

7 Application Information................................................................................................................................. 31

7.1 Recommendations.................................................................31

7.1.1 OperatingEnvironment ........................................................................................................... 31

7.1.2 DischargeLine ........................................................................................................................ 31

7.2 SystemSaverInstallationCriteria .....................................................32

Edition 2

10.2019

MM1736 1 (en)

This publication is not subject to any update service. Information contained in this

publication was in effect at the time the publication was approved for printing and is

subject to change without notice or liability. WABCO reserves the right to revise the

information presented or to discontinue the production of parts described at any time.

4

General Information General Information

EN 1 General Information

Symbols used in this document

DANGER

Descriptionofanimmediatesituationwhichwillresultinirreversibleinjuryordeathifthewarningis

ignored.

WARNING

Descriptionofapossiblesituationwhichmayresultinirreversibleinjuryordeathifthewarningis

ignored.

CAUTION

Descriptionofapossiblesituationwhichmayresultinirreversibleinjuryifthewarningisignored.

NOTICE

Descriptionofapossiblesituationwhichmayresultinmaterialdamageifthewarningisignored.

i

i

Importantinformation,notesand/ortips

www www

@

@ @@

Referencetoinformationontheinternet

1. Actionstep

- Actionstep

ÖConsequenceofanaction

List

• List

Note on the use of a tool/WABCO tool

How to Obtain Additional Maintenance, Service and Product Information

Ifyouhaveanyquestionsaboutthematerialcoveredinthispublication,orformoreinformationabout

theWABCOproductline,pleasecontactWABCOCustomerCareCenterat855-228-3203,byemailat

[email protected],orvisitourwebsite:www.wabco-na.com.

5

General Information

EN

WABCO Academy

www www

@

@ @@

https://www.wabco-academy.com/home/

WABCO online product catalog

www www

@

@ @@

http://inform.wabco-auto.com/

Your direct contact to WABCO

WABCO North America

WABCO USA LLC

1220 Pacic Drive

Auburn Hills, MI 48326

Customer Care Center: (855) 228-3203

www.wabco-na.com

6

Safety Information Introduction

EN 2 Safety Information

Provisions for a safe work environment

Onlytrainedandqualiedautotechniciansandautomechanicsmaycarryoutworkonthevehicle.

Readthispublicationcarefully.

Followallwarnings,noticesandinstructionstoavoidpersonalinjuryandpropertydamage.

Alwaysabidebythevehiclemanufacturer'sspecicationsandinstructions.

Observeallaccidentregulationsoftherespectivecompanyaswellasregionalandnational

regulations.

Theworkplaceshouldbedry,sucientlylitandventilated.

Usepersonalprotectiveequipmentifrequired(safetyshoes,protectivegoggles,respiratory

protectionandearprotectors).

ReadandobserveallDanger,WarningandCautionhazardalertmessagesinthispublication.They

provideinformationthatcanhelppreventseriouspersonalinjury,damagetocomponents,orboth.

WARNING

Topreventseriouseyeinjury,alwayswearsafeeyeprotectionwhenyouperformvehicle

maintenanceorservice.

WARNING

Parkthevehicleonalevelsurface.Blockthewheelstopreventthevehiclefrommoving.Supportthe

vehiclewithsafetystands.Donotworkunderavehiclesupportedonlybyjacks.Jackscansliporfall

over.Seriouspersonalinjuryanddamagetocomponentscanresult.

WARNING

Removeallairpressurefromtheairsystembeforeyoudisconnectanycomponent,includingthe

desiccantcartridge.Pressurizedaircancauseseriouspersonalinjury.

7

Introduction

EN

3 Introduction

3.1 Overview

MaintenanceManualMM1736containstroubleshootingstepsandserviceinformationfortheWABCO

SystemSaverHPsinglecartridgeairdryers.

IfyouhaveaWABCOSystemSaver(1200or1800)singlecartridgeairdryer,useMM34,WABCO

SystemSaverSeries(1200and1800)SingleCartridgeAirDryers.IfyouhaveaWABCOSystemSaver

Twinairdryer,useMM35,WABCOSystemSaverTwinAirDryer.Todownloadthesepublications,goto

wabco-na.com.

3.2 Air Dryer Identication

TheSystemSaverHPairdryerhasthegovernorintegratedintothebodyoftheairdryerandalsohasan

integratedpurgetank.Figure1.

Fig.1

4013285a

PURGE

TANK

GOVERNOR

3.3 How the Air Dryer Works

Duringsystempressurebuild-up,compressedairpassesintotheairdryerwheretheltersystemremoves

contaminantsandpassestheairintothedryingstage.

Moisture-ladenairpassesthroughthedesiccantbedintheairdryercartridgeandmoistureisretainedby

thedesiccant.Moisturethatcondensesoutalsocollectsinthebaseofthedryer.Whenthecompressor

unloads,thewaterisexpelledanddriedairowsbackthroughthedryer,dryingthedesiccantforthenext

cycle.

8

Introduction Introduction

EN 3.3.1 Air Dryer Cycle

AsinglecartridgeairdryercycleisillustratedinTableA.

Table A: Air Dryer Cycle

Cycle Stage Air Flow

Thegovernorturnsthecompressorloading

onwhensupplytankpressuredropsbelow

cut-inpressure,between105-115psi

(724-792kPa)dependingonthegovernor

settings.

4013565c

CONTROL

“WET” AIR

“DRY” AIR

COMPRESSOR

INTAKE LINE

Compressedairpassesintotheairdryerat

theinletport:

Moisture-ladenairandcontaminants

enterthedesiccant.

Moistureisretainedbydesiccant;

moisturealsocollectsinthebaseofthe

dryer.

Contaminantsareremovedasair

passesthroughthedesiccantbed.

4013286a

INLET

PORT 1

CARTRIDGE

OUTLET

PORT 2.1/2.2

Thegovernorunloadsthecompressor

whenthesystemreachescut-outlevel132

psi(910kPa)+/-3psi,dependingonthe

governorsettings.

4013566c

CONTROL

“WET” AIR

“DRY” AIR

COMPRESSOR

INTAKE LINE

9

Introduction

EN

Cycle Stage Air Flow

Whenthecompressorunloads,thepurge

valveopens.OntheSystemSaverHP:

Dryairowsfromtheintegratedpurge

tankbackthroughtheairdryer.Aircan

befeltandheardowingfromthepurge

valveforanextendedperiodoftime.

Drysystemairowsbackthroughthe

airdryertoregeneratedesiccant.

4013569a

PURGE PORT

3.2

CARTRIDGE

PURGE

TANK

3.3.2 System Saver HP Air Dryer System

Fig.2

4013288a

COMPRESSOR

DISCHARGE

LINE

COMPRESSOR

CONTROL

(PURGE)

PORT

DRYER

INLET PORT

COMPRESSOR

INTAKE LINE

SUPPLY

TANK

SYSTEM

RESERVOIRS

ONE-WAY

CHECK

VALV E

SYSTEM SAVER

IP AIR DRYER

UNLOADER

LINE

SUPPLY

LINE

PURGE VALV E

(EXHAUST)

ONE-WAY

CHECK

VALV E

10

Introduction Introduction

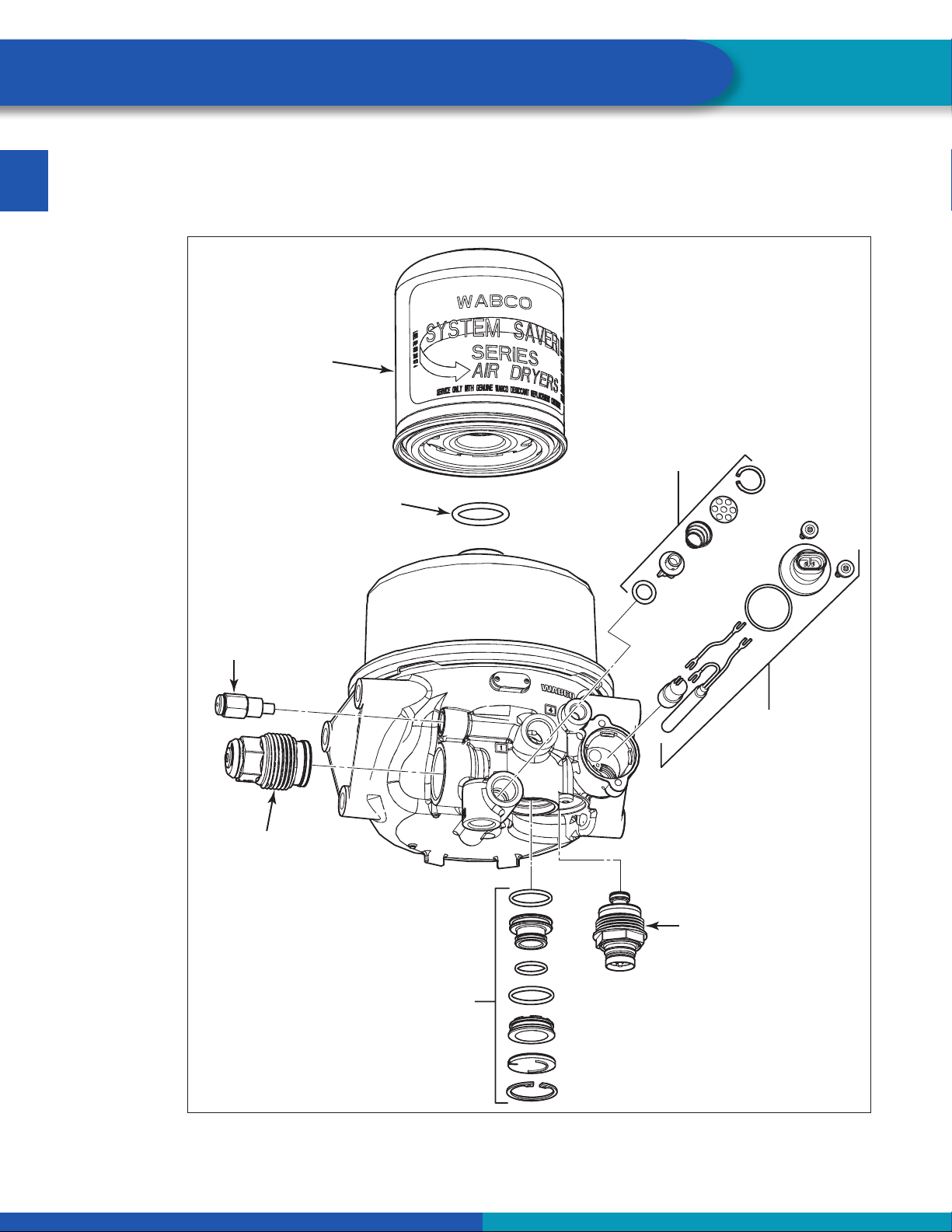

EN 3.4 Air Dryer Components

WABCOSystemSaverHPsinglecartridgeairdryerscontainreplaceablecomponentpartsshownin

Figure3.RefertoSection4forinstructionsforremovalofoldpartsandinstallationofnewparts.

Fig.3

4013289a

GOVERNOR

PORT 3.3

PRESSURE

RELIEF VALV E

PORT 3.1

DESICCANT

OR COALESCING

CARTRIDGE

O-RING

HEATER

ASSEMBLY

PORT 6

PURGE VALV E

ASSEMBLY

PORT 3.2

TURBO CUT-OFF

VALVE ASSEMBLY

PORT 3.4

OUTLET

CHECK VALV E

ASSEMBLY

PORT 2.1

Table of contents