5

General information

1 General information

Purpose of the document

This publication describes the installation of the tire pressure monitoring system

OptiTireTM.

Copyright and trademark notice

The content, particularly technical information, descriptions and gures,

correspond to the state current at the time of printing and are subject to change

without notice.

This document, including all its parts, in particular texts and gures, are

protected by copyright. Use outside the statutory or contractual limits require

authorisation by the copyright owner. All rights reserved.

Any brand names, even if not indicated as such, are subject to the rules of the

trademark and labelling rights.

Technical documents

– Open the WABCO INFORM online product catalogue:

http://inform.wabco-auto.com

– Search for documents by entering the document number.

The WABCO online product catalogue INFORM provides you with convenient

access to the complete technical documentation.

All documents are available in PDF format. Please contact your WABCO

partner for printed versions.

Please note that the publications are not always available in all language

versions.

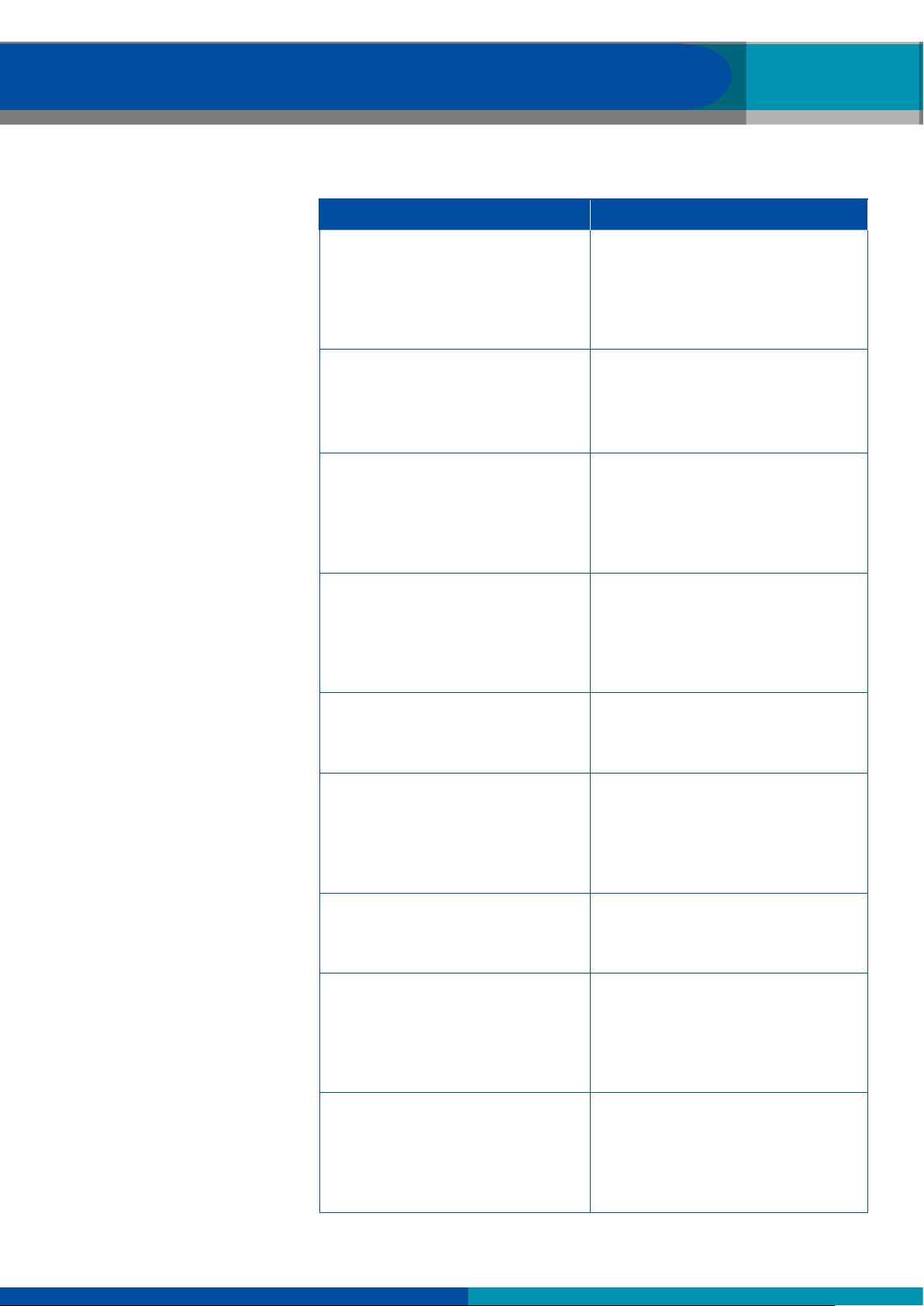

Document Title Document Number

OptiTireTM – Installation Manual 815 XX0 230 3

OptiTireTM – System Description 815 XX0 229 3

Diagnosis – Product Overview 815 XX0 037 3

SmartBoard – User Manual 815 XX0 138 3

TEBS E System Description 815 XX0 093 3

TEBS C/D System Description 815 XX0 020 3

*Language code XX: 01 = English, 02 = German, 03 = French, 04 = Spanish, 05 = Italian,

06 = Dutch, 07 = Swedish, 08 = Russian, 09 = Polish, 10 = Croatian, 11 = Romanian,

12 = Hungarian, 13 = Portuguese (Portugal), 14 = Turkish, 15 = Czech, 16 = Chinese,

17 = Korean, 18 = Japanese, 19 = Hebrew, 20 = Greek, 21 = Arabic, 24 = Danish, 25 = Lithuanian,

26 = Norwegian, 27 = Slovenian, 28 = Finnish, 29 = Estonian, 30 = Latvian, 31 = Bulgarian,

32 = Slovakian, 34 = Portuguese (Brazil), 35 = Macedonian, 36 = Albanian, 97 = German/English

98 = = multilingual, 99 = non-verbal