I-2 BA E16 en* 1.0 * E16_10_3IVZ.fm

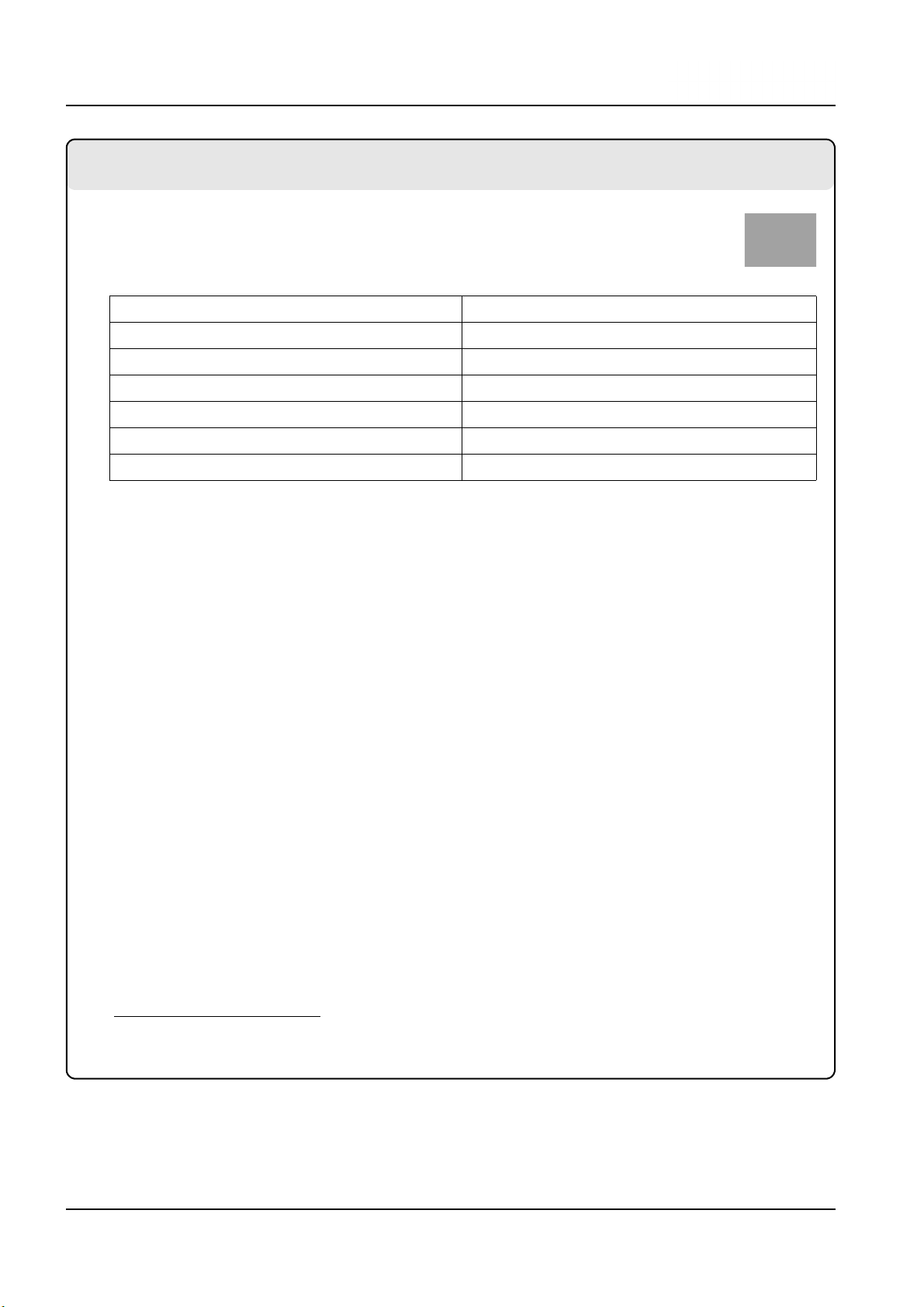

Table of contents

7 Maintenance

7.1 Information on maintenance ................................................................................................................. 7-1

7.2 Maintenance overview .......................................................................................................................... 7-2

7.3 Consumables...................................................................................................................................... 7-17

7.4 Maintenance accesses ....................................................................................................................... 7-20

7.5 Cleaning and maintenance ................................................................................................................. 7-23

7.6 Lubrication work.................................................................................................................................. 7-27

7.7 Fuel system ........................................................................................................................................ 7-27

7.8 Engine lubrication system................................................................................................................... 7-33

7.9 Cooling system ................................................................................................................................... 7-36

7.10 Air filter................................................................................................................................................ 7-39

7.11 V-belt .................................................................................................................................................. 7-40

7.12 Hydraulic system ................................................................................................................................ 7-40

7.13 Electrical system................................................................................................................................. 7-45

7.14 Heating, ventilation and air conditioning system................................................................................. 7-46

7.15 Washer system ................................................................................................................................... 7-46

7.16 Travel drive ......................................................................................................................................... 7-46

7.17 Braking system ................................................................................................................................... 7-46

7.18 Tracks ................................................................................................................................................. 7-47

7.19 Maintenance of attachments............................................................................................................... 7-50

7.20 Maintenance of options....................................................................................................................... 7-50

7.21 Exhaust gas treatment........................................................................................................................ 7-50

7.22 Machine preservation ......................................................................................................................... 7-50

8Malfunctions

8.1 Diesel engine ........................................................................................................................................ 8-1

8.2 Malfunctions (display element/multi-functional display)........................................................................ 8-2

9 Technical data

9.1 Models and trade names ...................................................................................................................... 9-1

9.2 Engine................................................................................................................................................... 9-1

9.3 Traveling drive ...................................................................................................................................... 9-2

9.4 Brake .................................................................................................................................................... 9-2

9.5 Tracks ................................................................................................................................................... 9-2

9.6 Steering system .................................................................................................................................... 9-2

9.7 Operating hydraulics............................................................................................................................. 9-2

9.8 Electrical system................................................................................................................................... 9-3

9.9 Tightening torques ................................................................................................................................ 9-8

9.10 Coolant ................................................................................................................................................. 9-9

9.11 Noise emissions.................................................................................................................................... 9-9

9.12 Vibrations............................................................................................................................................ 9-10

9.13 Weights............................................................................................................................................... 9-14

9.14 Lift capacity/load ................................................................................................................................. 9-19

9.15 Dimensions ......................................................................................................................................... 9-40

Index