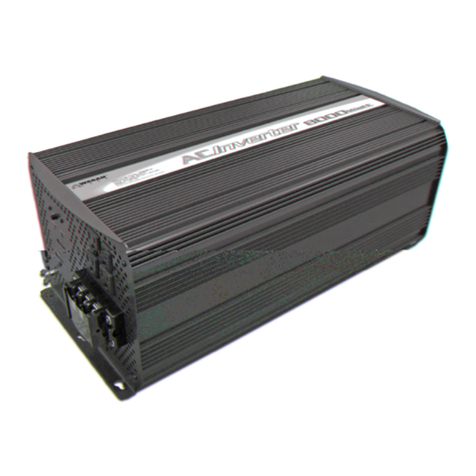

ProLine™ 5000W Power Inverter by Wagan Tech®

www.wagan.com

7

©2012 Wagan Corporation. All Rights Reserved.

Wagan Tech and wagan.com are trademarks used by Wagan Corporation.

User’s Manual—Read before using this equipment

8

PLANNING THE INVERTER SYSTEM

Any large wattage inverter system requires planning before installation. There are

several steps to the planning process so the user must determine the following:

• Maximum inverter wattage required.

• Operating time (run time) needed between battery recharges.

• Battery bank capacity in amp-hours.

• Charger requirement to charge batteries within a practical time.

• Distance between battery bank and inverter.

DETERMINING MAXIMUM APPLIANCE WATTAGE

Maximum AC appliance wattage is the first factor in planning battery and charging

systems.

SOME BACKGROUND:

Large microwave oven specifications list cooking power (watts) and appliance

power. Appliance power is the AC load the inverter has to supply.

Most other electrical tools, appliances and audio/video equipment have labels that

list the unit’s power requirements in watts. If the tool or device is rated in amps,

multiply the amps by 115 (115V AC) to determine the watts. For example, a power

tool rated at 4 amps will draw 460 watts. Determine the wattage of each appliance

you need to simultaneously operate. Add all of the appliance wattages to obtain

an estimated “total watts” number. Remember to consider the startup surge that

motorized appliances will cause. Do not exceed the surge rating of this inverter

(10,000 watts) this can cause immediate overload shut down.

At 5000 watts continuous output this inverter requires a DC power supply (battery

bank) that can continuously supply 500 amps at 12V DC for the duration of the run

time.

CONFIGURING THE BATTERY BANK

A battery bank is an interconnection of batteries; in this case, to provide 12 volts.

To determine the minimum battery ampere-hour rating that you will need to operate

appliances from the inverter and any DC appliances powered by the battery bank,

follow these steps:

1. List the maximum continuous wattage that an inverter has to supply.

2. Estimate the number of hours each appliance will be in use between battery

recharges. This will vary. For example, a typical home-use coffee maker

draws 500 watts during its brew time of 5 minutes, but maintaining pot

temperature only requires 100 watts. Typically, a microwave oven only

operates for a few minutes. Refrigerators and air conditioners cycle on

and off. Some longer operating time appliances are lamps, televisions,

computers and sound systems.

3. Determine the total watt-hours of energy needed by multiplying average

power consumption in watts by hours of run time. For example: 1500 watts

for 10 hours = 15,000 watt hours.

4. To get an estimate of the maximum current (in amps) that a battery bank

must be capable of delivering to the inverter, divide the AC load watts by

ten. For example, a 1500 watt AC load will need 150 amps at 12 volts DC.

This relationship holds for 12V DC inverters with 90% efficiency.

Using the 1500 watts (or 150 amps) for 10 hours example, 150 amps are needed

for 10 hours. This provides us with the basic amp-hours (AH) of battery life that is

required. Ten hours at 150 amps equals 1500 Amp-hours (AH). This answer is just

a starting point because there are additional factors that determine actual run time.

These include:

• Cable gauge and length (cable losses)

• Charge level of the batteries (between use, chargers have to be able to fully

charge the batteries)

• Temperature of the batteries (colder batteries provide fewer amps)

• Age and condition of the batteries (older batteries lose AH capacity)

• Use of DC appliances

• Compliance with turning off unnecessary AC and DC loads.

DERATING THE BATTERY BANK

Most lead-acid batteries have a rating expressed in amp-hours (AH). The most

common rating of AH is “at the 20 hour rate”.

NOTE: Despite several internet explanations, there is no relationship between cold

cranking amps (CCA) and ampere-hours (AH).

For example; if a 20 AH battery is discharged at a 1 amp rate, is will take 20 hours

to discharge that battery. The terms “charged” and “discharged” relate to actual

battery voltage. This means that the output voltage of a nominal 12 volt battery

starts at 13.2 volts (fully charged) then drops to 10.6 volts (discharged). If the load

on the battery causes the battery to discharge faster than the 20 hour rate, the

capacity (AH) of the battery is measurably reduced (derated). Derating is a major

run time factor. The following curve can help to determine what the battery bank

can deliver under load. The results are used to estimate how much additional battery

capacity is needed to achieve the desired run time.

The left vertical numbers of the curve represents percentage of the battery capacity

at the 20 hour rate. In this example, the user needs a one hour run time. If the

example battery is 220 AH (20 hour rate), and the load is 220 amps that is 100%

(horizontal number) of the AH (20 hour rate), starting at the 100% horizontal point

and looking up to the curve the results are that only 56% of the battery capacity is

available. This means that a higher battery capacity is required to get the desired

run time: one hour. The curve also shows that a load of 200% of the 20 hour rate