WAGO-SPEEDWAY 767 Table of Contents 3

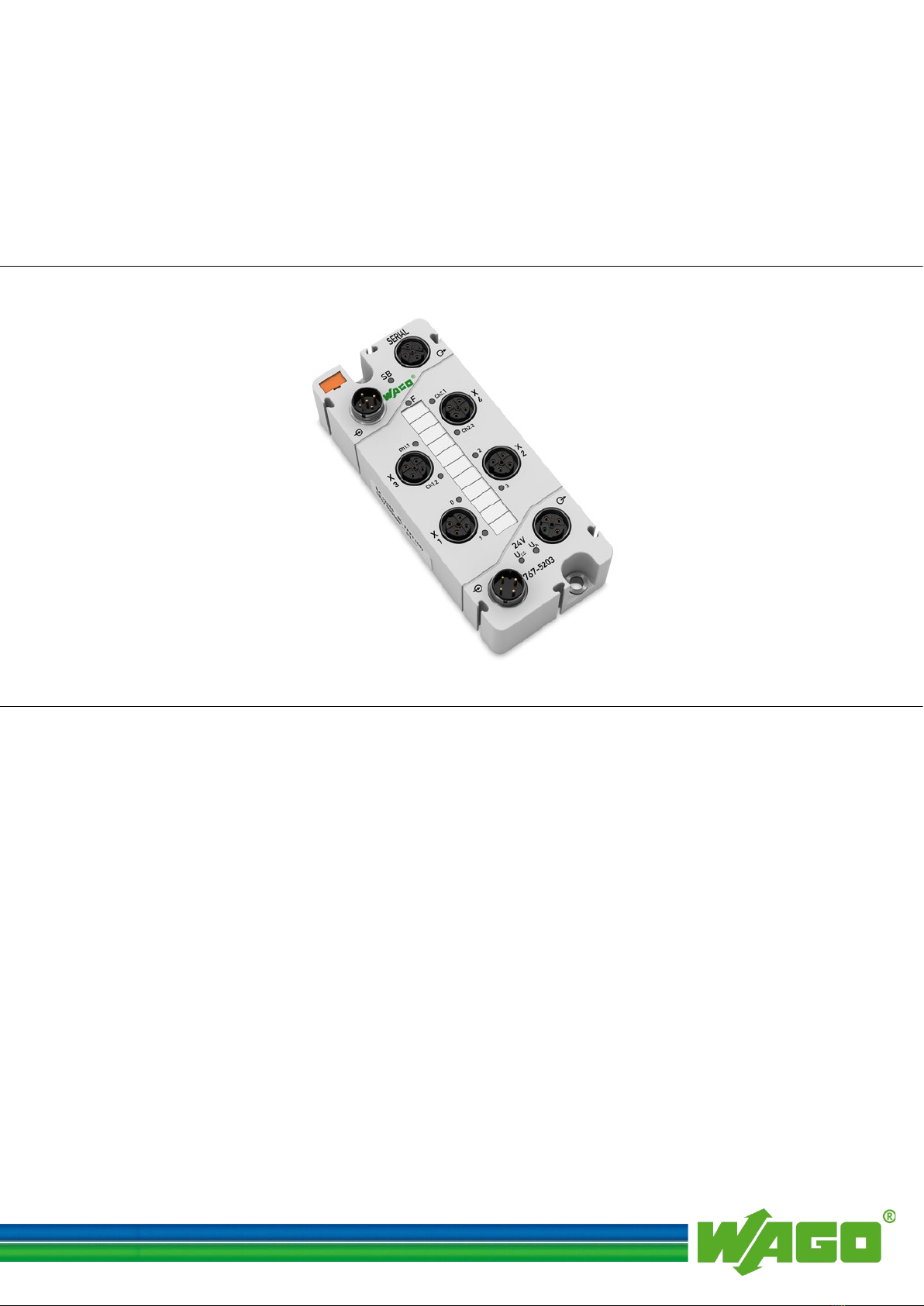

767-5203 Serial Interface (RS-232, RS-422/-485)

Manual

Version 1.1.0

Pos: 5 /D o ku ment ati on allg e mei n /Ver zei c hni ss e/I nh alt s verz ei ch nis - Ü b er schr if t oG und Ver zei ch nis @ 3\mod_1219151230875_21.docx@21063 @ @ 1

Table of Contents

1Notes about this Documentation................................................................. 6

1.1 Validity of these Operating Instructions ................................................... 6

1.2 Copyright................................................................................................... 6

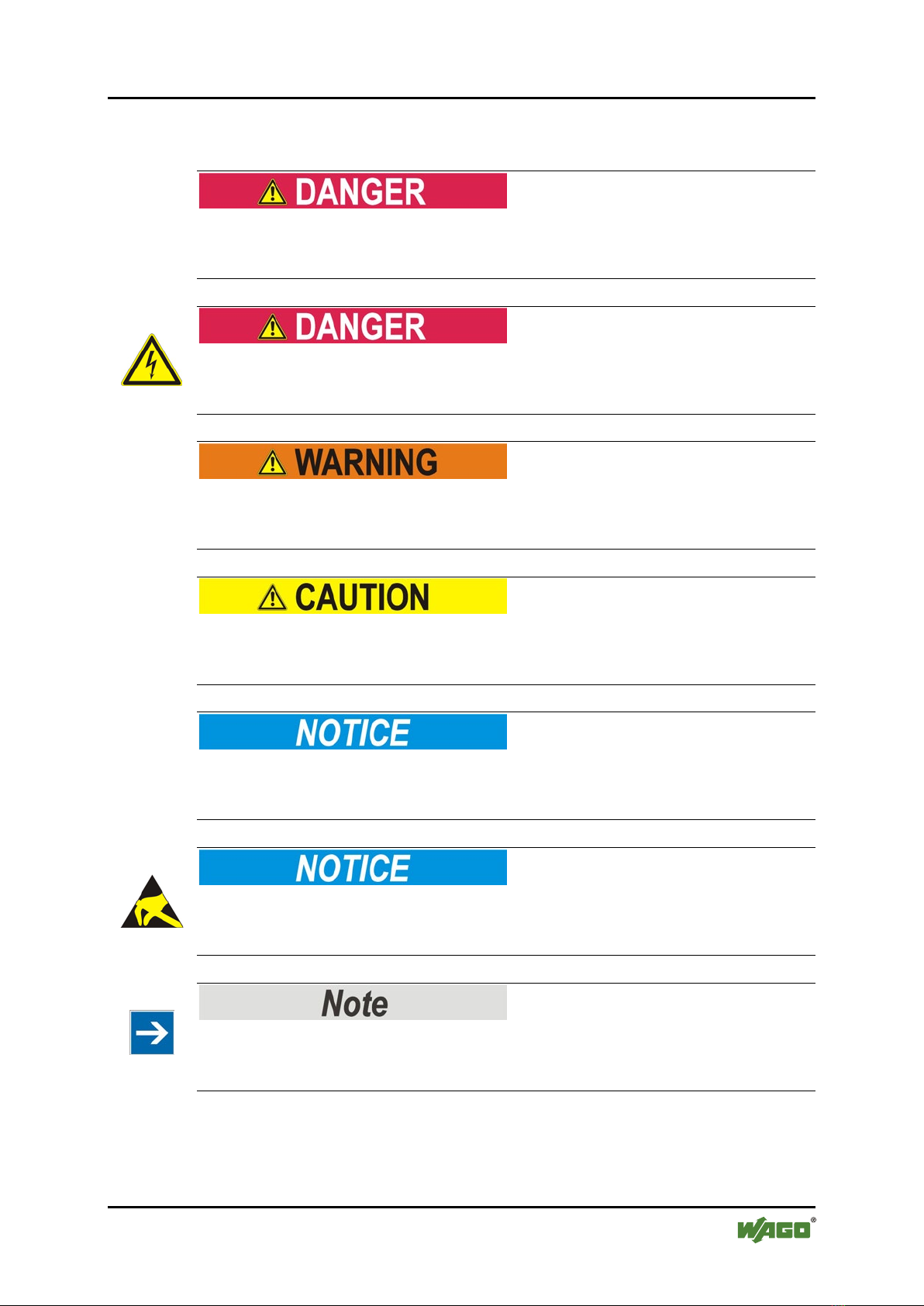

1.3 Symbols..................................................................................................... 7

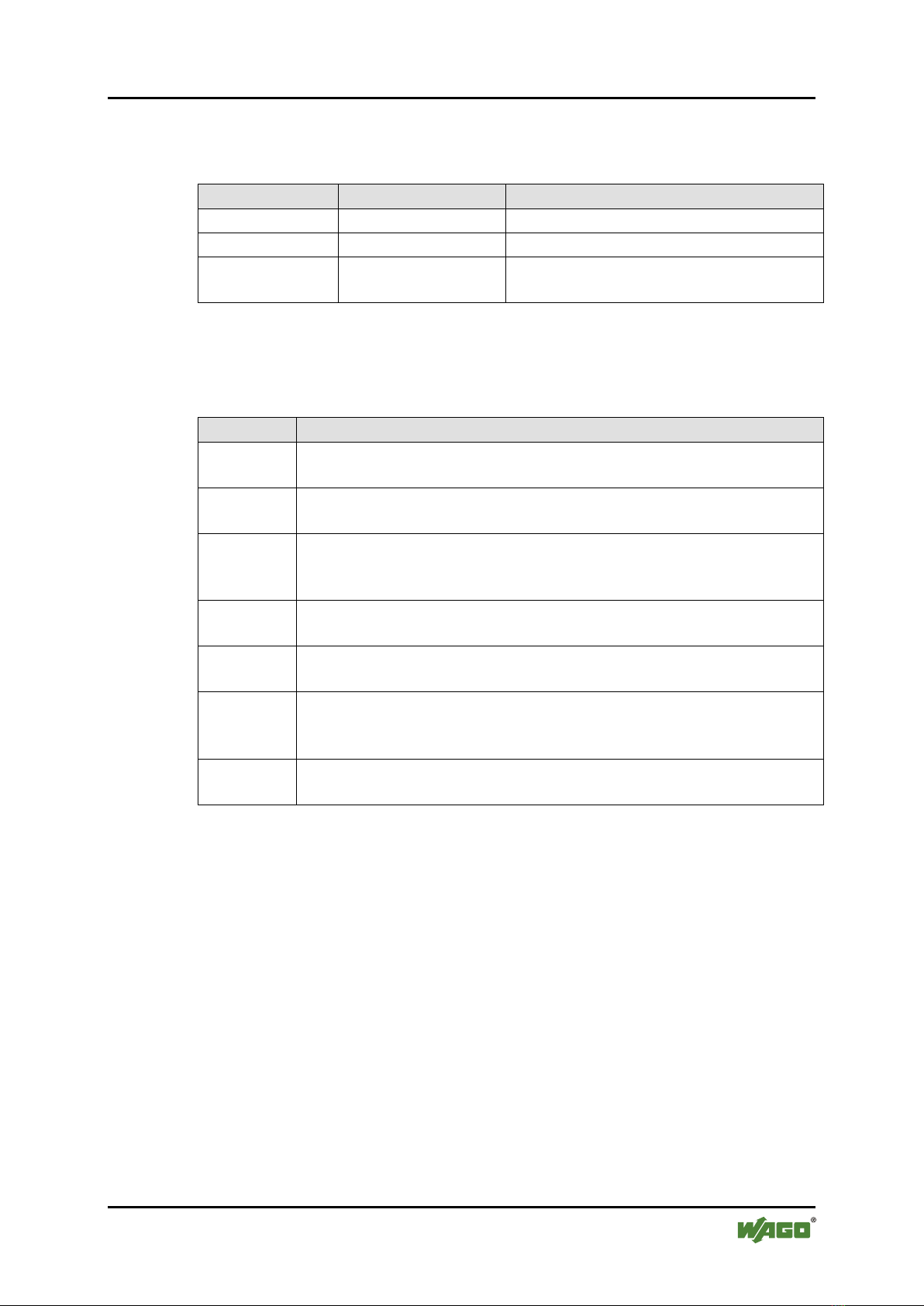

1.4 Number Notation....................................................................................... 9

1.5 Font Conventions ...................................................................................... 9

2Important Notes ......................................................................................... 10

2.1 Legal Bases ............................................................................................. 10

2.1.1 Subject to Changes ............................................................................. 10

2.1.2 Personnel Qualification ...................................................................... 10

2.1.3 Intended Use....................................................................................... 11

2.1.4 Technical Condition of Specified Devices ......................................... 11

2.2 Safety Advice (Precautions).................................................................... 12

2.3 Safety Equipment .................................................................................... 13

2.4 Notes on Operation ................................................................................. 14

3Device Description ..................................................................................... 15

3.1 Connectors............................................................................................... 17

3.2 Marking Possibilities and Fastening ....................................................... 18

3.3 Display Elements .................................................................................... 19

3.4 Labeling................................................................................................... 20

3.5 Schematic Diagram ................................................................................. 22

3.6 Dimensions.............................................................................................. 23

3.7 Technical Data ........................................................................................ 24

3.7.1 Device Data ........................................................................................ 24

3.7.2 Supply................................................................................................. 24

3.7.3 Communication .................................................................................. 24

3.7.4 Serial Interfaces .................................................................................. 25

3.7.5 Digital Inputs ...................................................................................... 25

3.7.6 Input Characteristic ............................................................................ 25

3.7.7 Digital Outputs ................................................................................... 26

3.7.8 Information for Actuator Selection .................................................... 26

3.7.9 Effect of Operating States .................................................................. 27

3.7.10 Configurable Functions of the Serial Interfaces ................................. 27

3.7.11 Configurable Functions of the Digital Inputs/Outputs ....................... 27

3.7.12 Diagnostics ......................................................................................... 27

3.7.13 Process Image..................................................................................... 28

3.7.14 Indicators ............................................................................................ 28

3.7.15 Isolation .............................................................................................. 28

3.8 Approvals ................................................................................................ 29

3.9 Standards and Guidelines ........................................................................ 30

4Mounting..................................................................................................... 31

4.1 Information on Mounting........................................................................ 31

4.2 Tools and Accessories Required for Mounting....................................... 33

4.3 Direct Mounting on Your System ........................................................... 34

4.4 Mounting on a Carrier Rail (only with WAGO Accessories)................. 35