CONTENTS

4

TC6XX-TM6XX Series

Contents

A. General ........................................................................................................................................................................... 5

A.1 Introduction .................................................................................................................................................................. 5

A.2 Definition of the range .................................................................................................................................................. 5

A.3 Parts ............................................................................................................................................................................. 5

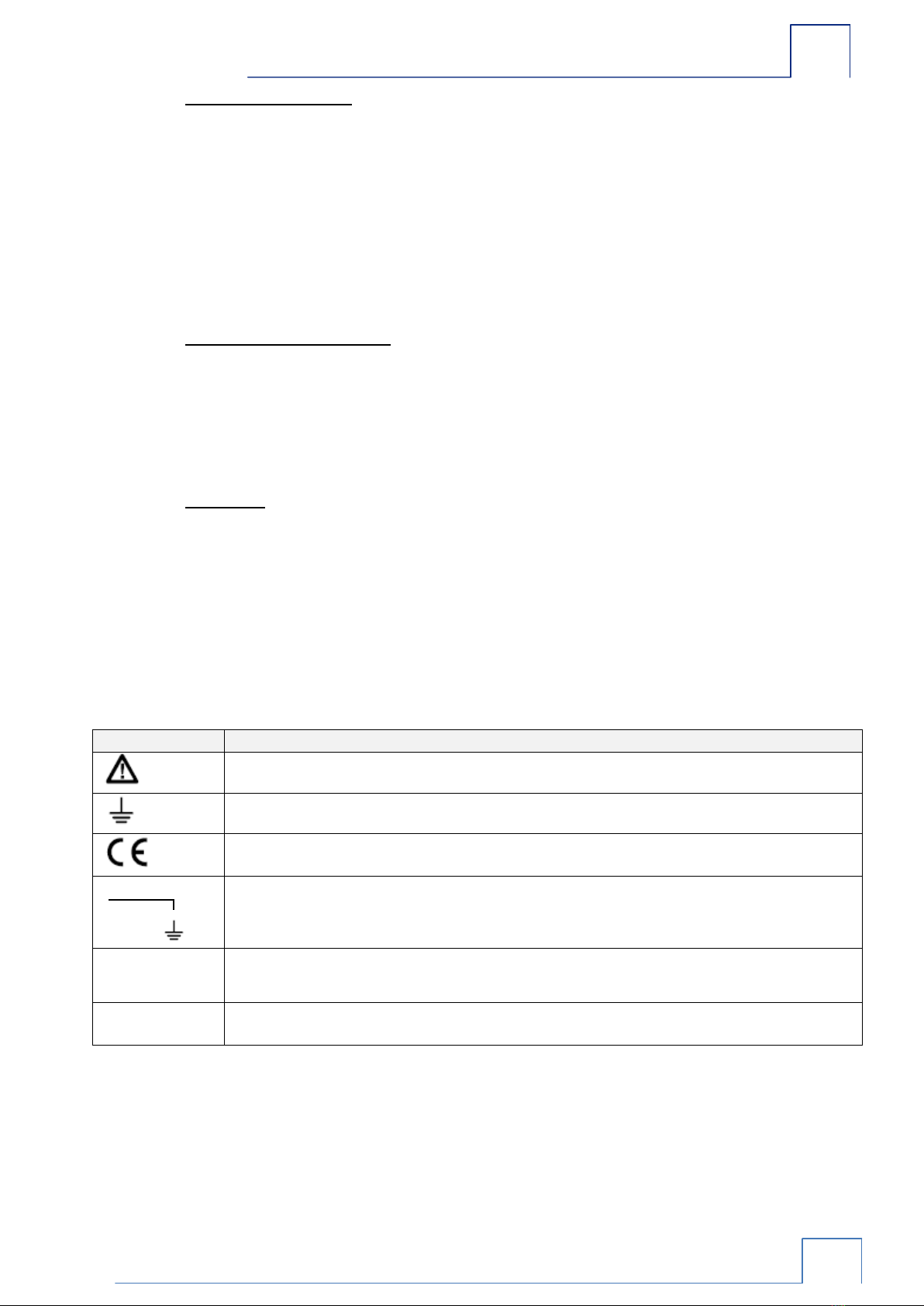

A.4 Directives CE ...............................................................................................................................................................6

A.4.1 Conformity with standards .....................................................................................................................................6

A.4.2 Environmental conditions .......................................................................................................................................6

A.4.3 Worn devices .........................................................................................................................................................6

A.4.4 Instructions ............................................................................................................................................................6

A.4.5 Making measurements ..........................................................................................................................................7

A.4.6 Unusual faults and stresses ...................................................................................................................................7

A.4.7 Definitions ............................................................................................................................................................ ..7

A.5 Maintenance ................................................................................................................................................................8

B. Using the instrument .......................................................................................................................................................9

B.1 Power-up ......................................................................................................................................................................9

B.1.1 Battery replacement ...............................................................................................................................................9

B.1.2 Back-up battery (date and time).............................................................................................................................9

B.1.3 The keyboard .........................................................................................................................................................9

B.1.4 The measuring and simulation terminals for each device ....................................................................................10

B.1.5 The USB connector .............................................................................................................................................12

B.1.6 The screen ...........................................................................................................................................................12

B.1.7 Operating modes .................................................................................................................................................13

C. Programming MODE .....................................................................................................................................................15

C.1 Voltage / resistance or temperature measurement ....................................................................................................15

C.2 Voltage / resistance or temperature simulation ..........................................................................................................17

D. Related Functions .........................................................................................................................................................20

D.1 Scaling .......................................................................................................................................................................20

D.2 Differential measurements .........................................................................................................................................21

D.3 Calibrated sensors .....................................................................................................................................................22

D.4 Configuration of default value points ..........................................................................................................................24

D.5 Storage of acquisitions in progress ............................................................................................................................25

D.5.1 Synthesizer configuration ....................................................................................................................................29

D.5.2 Configuration of the ramp generation ..................................................................................................................30

E. Parameter settings ........................................................................................................................................................33

E.1 Contrast adjustment ...................................................................................................................................................33

E.2 Date and time setting .................................................................................................................................................33

E.3 “Preferences” setting ..................................................................................................................................................33

E.3.1 Filtering setting ....................................................................................................................................................33

E.3.2 Display resolution setting .....................................................................................................................................34

E.3.3 Lighting duration setting .......................................................................................................................................34

E.3.4 “Key beeping” setting ...........................................................................................................................................34

E.3.5 Language setting .................................................................................................................................................34

E.3.6 Temperature unit setting ......................................................................................................................................34

E.4 “Maintenance” menu ..................................................................................................................................................35

E.4.1 Adjustment from the Maintenance menu .............................................................................................................35

E.5 “About the instrument” menu ......................................................................................................................................38

F. Software Update ...........................................................................................................................................................39

G. Technical specifications ................................................................................................................................................40

G.1 Thermocouple measurement function ........................................................................................................................40

G.1.1 Constant voltage (TC621,TM602 and TM630).....................................................................................................40

G.1.2 Temperature by thermocouples (TC621,TM602 et TM630). ...............................................................................40

G.2 Thermocouple emission function (TC621) .................................................................................................................42

G.2.1 Constant voltage ..................................................................................................................................................42

G.2.2 Temperature by thermocouple ............................................................................................................................42

G.3 Resistive sensor measurement function ....................................................................................................................44

G.3.1 Resistance (TC622, TM612 and TM630) .............................................................................................................44

G.3.2 Temperature by resistive sensors (TC622, TM612 and TM630)..........................................................................44

G.4 Resistive sensor simulation function (TC622) ............................................................................................................45

G.4.1 Resistance ...........................................................................................................................................................45

G.4.2 Temperature by resistive sensors ........................................................................................................................45