C

o

n

t

e

n

t

s

W

a

l

d

o

r

f

Ga

s

Gr

i

dd

l

e

Toa

s

ter

GT

8600G

I

ntrodu

ct

i

on

................................................................................................

2

Spec

i

f

i

cat

i

on

s

..............................................................................................

3

M

o

d

e

l Nu

m

b

ers

C

o

vere

d in

t

hi

s

S

p

e

ci

f

ic

a

t

i

o

n

G

e

n

er

al

Op

t

i

o

nal Acc

essor

i

es

Ga

s

S

uppl

y

R

e

qui

reme

n

ts

Ga

s

C

o

nn

e

c

t

i

o

n

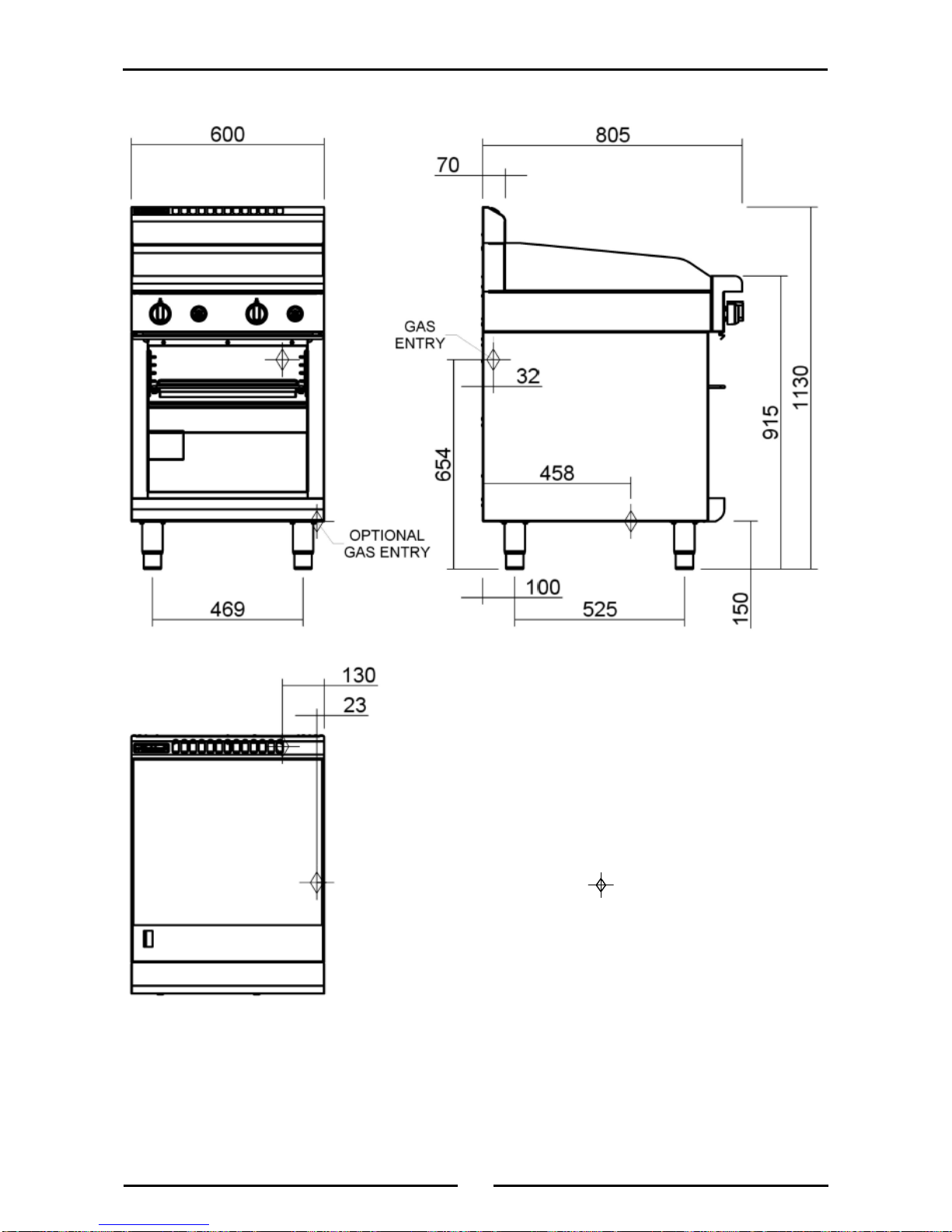

D

i

men

si

on

s

..................................................................................................

5

W

e

igh

t

(N

ett

)

In

s

ta

ll

at

i

on

..................................................................................................

6

I

n

st

alla

t

i

o

n R

e

qui

reme

n

ts

U

npac

k

ing

L

o

ca

t

i

o

n

Cl

e

a

r

anc

es

A

ssem

bl

y

F

i

tt

ing R

e

a

r

R

o

ll

ers

Ga

s

C

o

nn

e

c

t

i

o

n

C

omm

i

ss

i

o

ning

Operat

i

on

...................................................................................................

10

Op

er

a

t

i

o

n Guid

e

D

es

c

r

ip

t

i

o

n

of

C

o

n

tro

l

s

Ligh

t

ing

P

il

ot

Bu

r

n

ers

Us

ing G

r

iddl

e

Us

ing

To

a

ster

C

l

ean

i

ng and

Ma

i

ntenance

........................................................................

12

G

e

n

er

al

A

fter

Each

Use

Dail

y

Cl

e

aning

W

eek

l

y

Cl

e

aning

Per

i

o

dic Main

te

nanc

e

Fau

l

t F

i

nd

i

ng

..............................................................................................

15

Ga

s

Con

v

er

si

on and Spec

i

f

i

cat

i

on

s

...........................................................

16

C

o

n

vers

i

o

n

Pro

c

e

du

re

Ga

s

S

p

e

ci

f

ica

t

i

o

n

s

Rep

l

acement

Part

s

L

is

t

.............................................................................

20