12 V DC

0,09 - 0,18 l/h

900 - 1800 W

456x343x208mm

8 m

100 cm2

2 m

4300

~ 12 kg

en

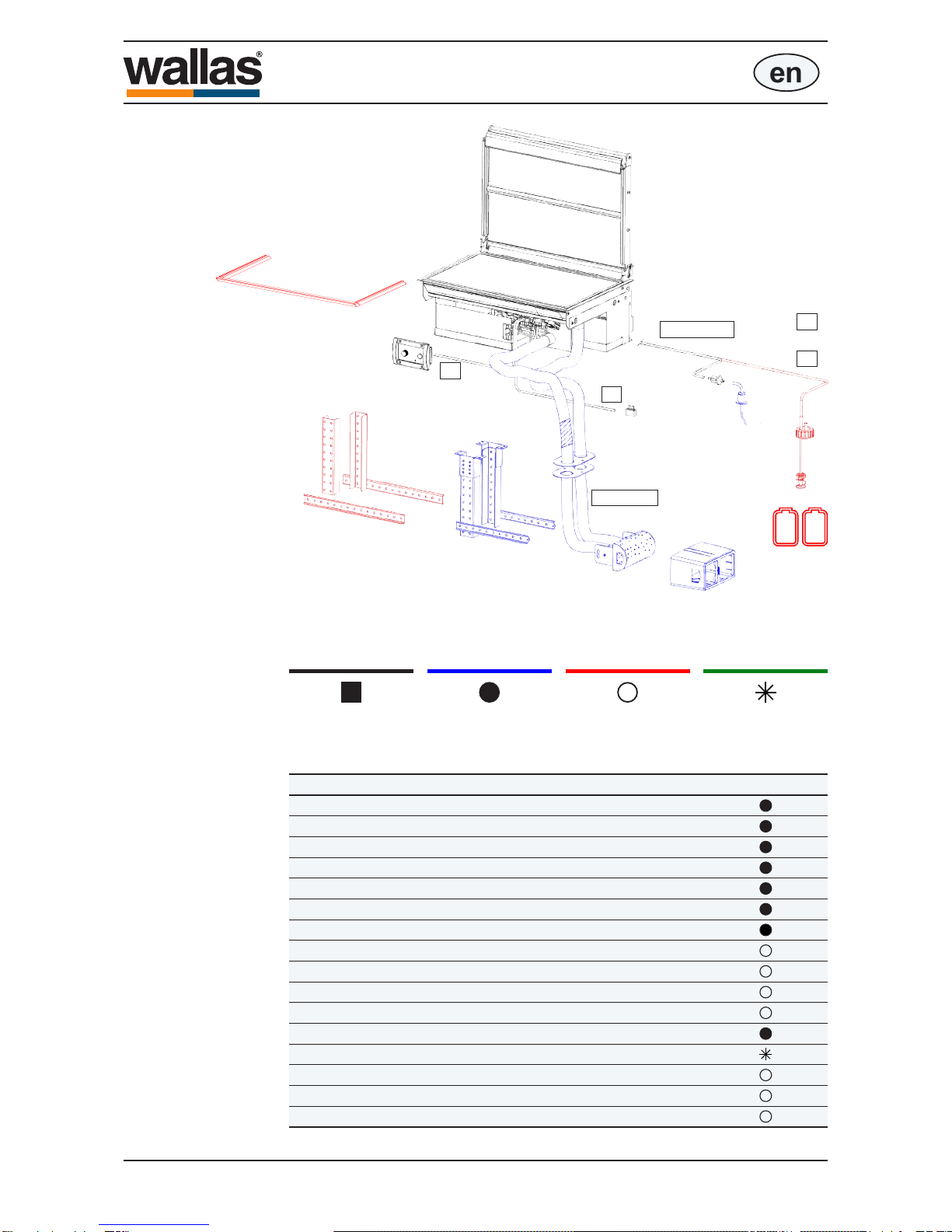

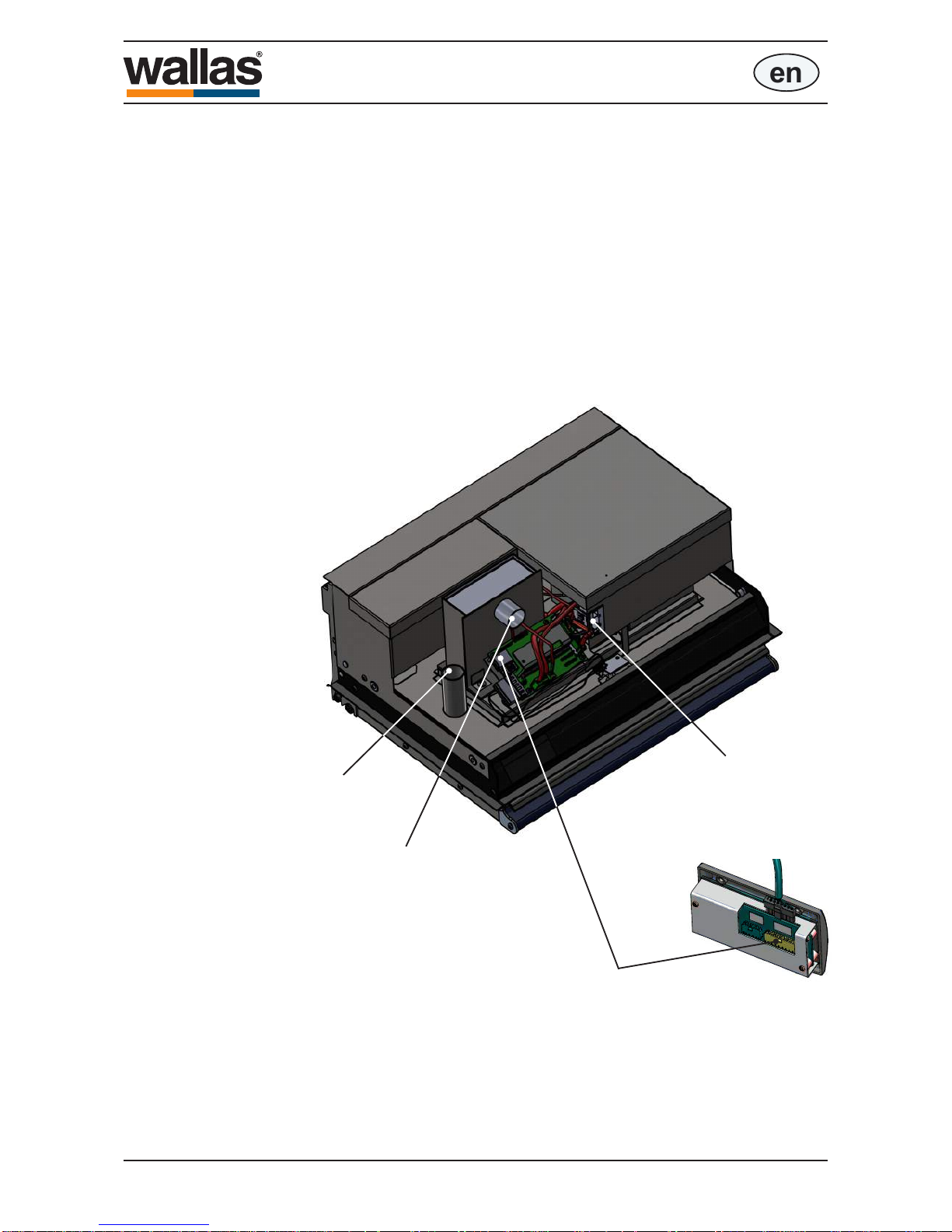

Technical information

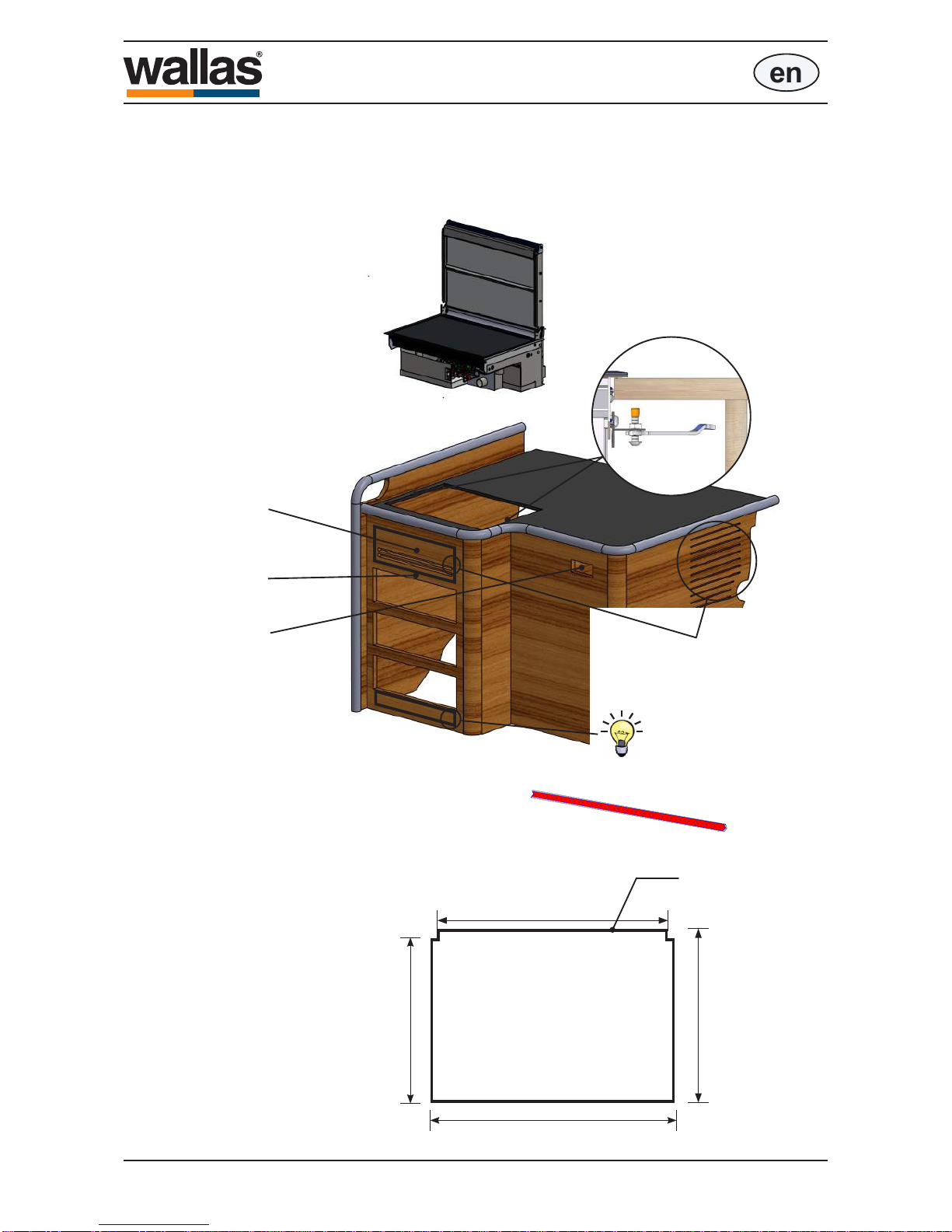

Stove operation

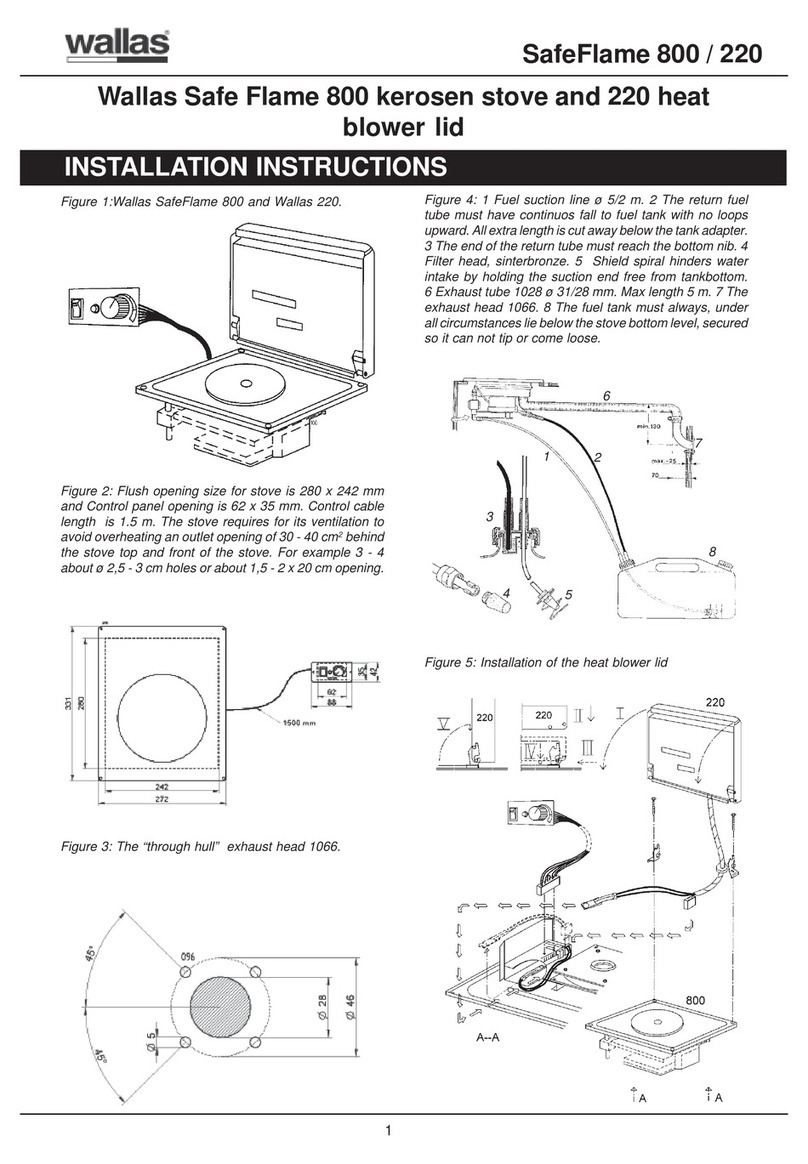

The XC Duoisasafedieselstovewithnoopename.Thestoveisequippedwith

a single burner which burns either diesel oil or light furnace oil (diesel heating oil).

The stove takes the air needed for the burning process from outside of the vehicle

withacombustionairbloweranddischargestheresultantexhaustoutsideofthe

vehicle.

The fuel pump in the stove dispenses fuel, and the electronics control the combus-

tionairandtheamountoffuelautomaticallytokeeptheameoftheburnerclean.

Whenthestoveisrstswitchedon,theglowplugintheburnerignitesthefuelthat

has been pumped into the burner. The glow time begins and ends automatically.

TheheatsensorinthestovedetectstheheatoftheameandlightstheredLED

lighttosignalthattheamehasbeenignited.

The heat which is released as the fuel burns is transferred into the ceramic stove

top. The left side of the stove top is hotter, as the burner is located under it. The

power of the stove can be adjusted steplessly. The control adjusts both sides of the

stove simultaneously.

When the stove is switched off, a cool down cycle begins. The cooling function ven-

tilatestheburneranddischargestheexhaustgasesgeneratedduringcooldown

outside the vehicle.

Thestovelendsitselfextremelywelltocookingandheatingallkindsoffoods.

It has been manufactured entirely from stainless and aluminium materials.

Function as a heater

By lowering the blower lid to the horizontal position, the stove works as a cabin

heater.

Adjustment of heat control works either manually or with the help of control panel

built-in thermostat.

Fuel Diesel oil, light furnace oil (diesel heating oil)

0,55...0.85 A (when ignited ca. 5-10 min. 8 - 10 A)

Operating voltage

Consumption

Heating power

Power consumption

Measurements

Weight

Max.permissiblelengthoftheuegas

pipe

Max. permissible length of the fuel hose

Minimum size of the replacement air

opening

Suitableuegaslead-throughs

Technical information

D80121B

- 43 -