5. Electrical Connection

5.1 The electrical connection

should be carried out in

accordance with local

regulations. Never make

any connections unless the

electricity supply has been

switched off.

5.2. The electrical hazard warn-

ing mark is placed outside

the connection box. Be

careful.

5.3. Electrical data (voltage and frequency)

are shown on the pump nameplate.

Verify if these data match your electric-

ity supply. A circuit breaker should be

installed and the grounding be proper-

ly connected for your safety.

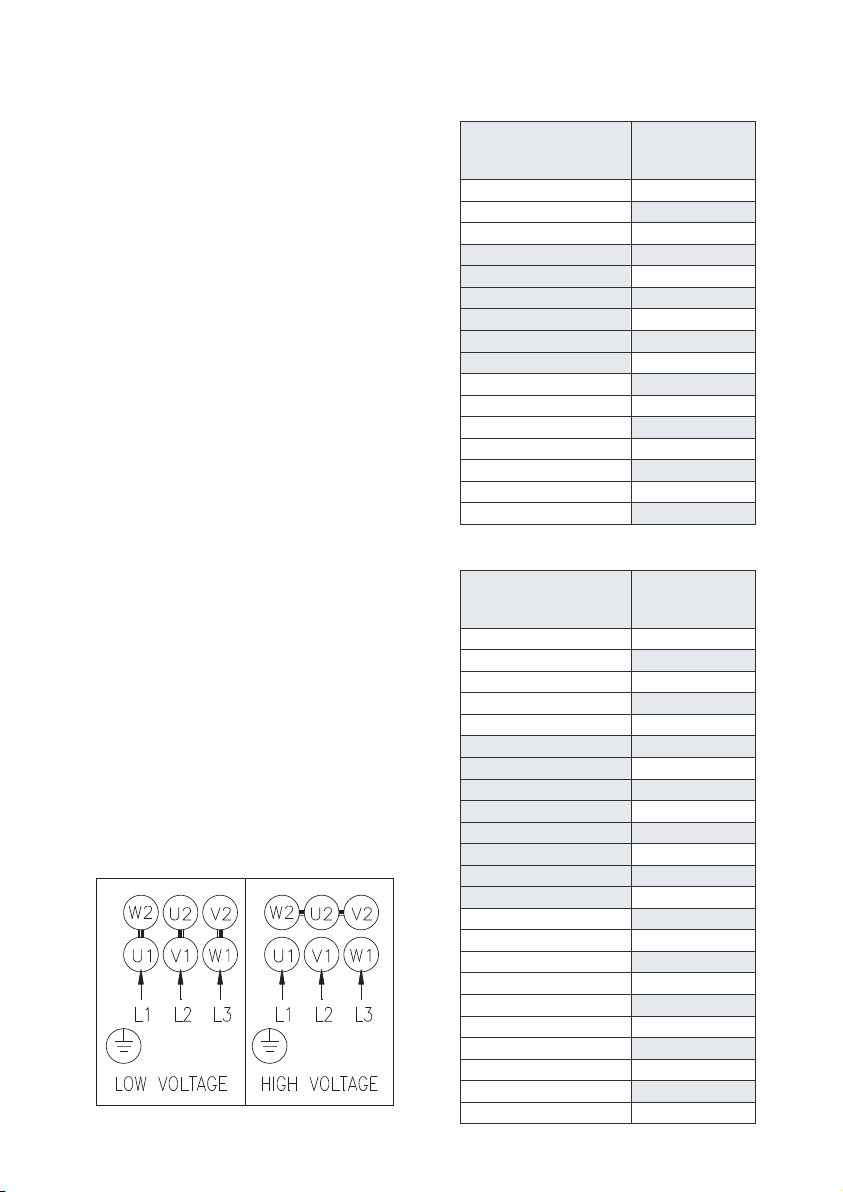

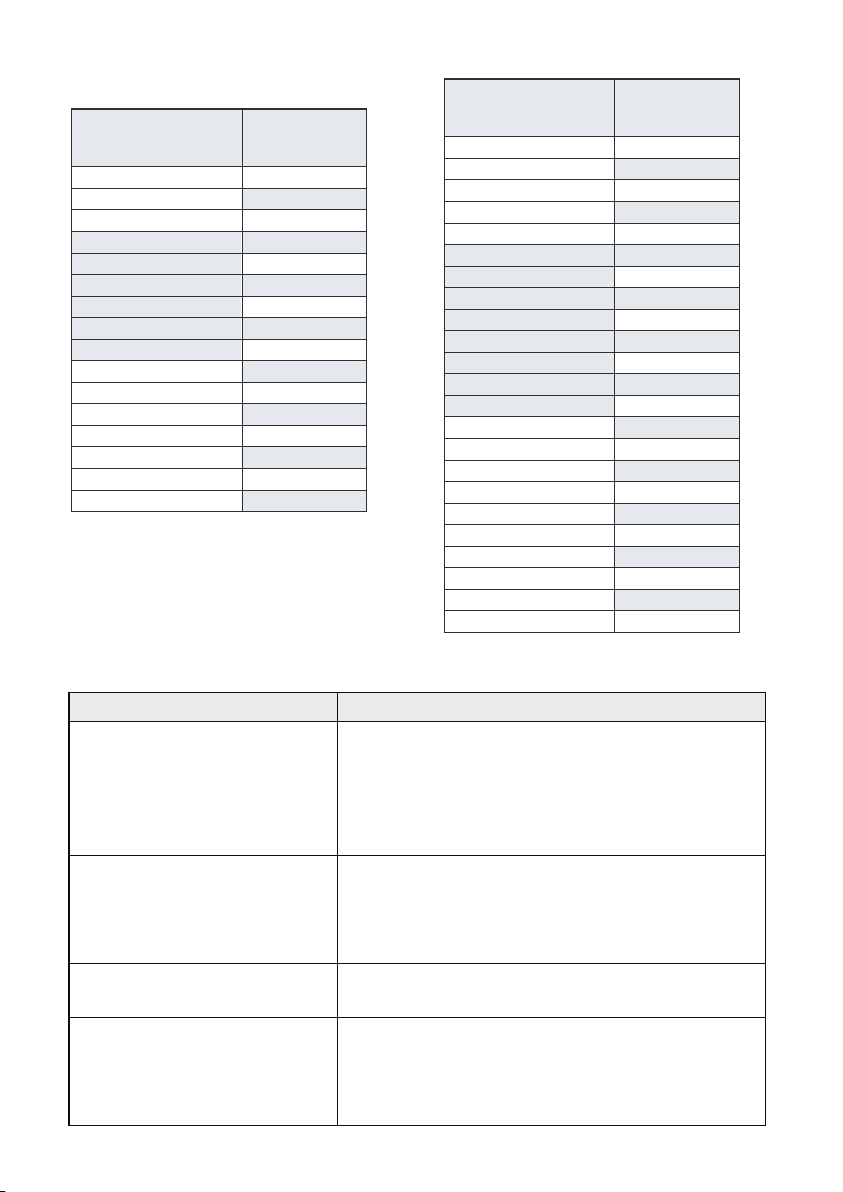

5.4. Make electrical connection in accor-

dance with connecting diagram

located inside the connection box. The

motor current must be within the rated

amps range indicated on nameplate.

Three phase motor requires a magnet-

ic starter for safety.

5.5. For three phase motors, please check

the correct direction of rotation of the

pump on the motor fan cover. When

seen from motor fan cover end, the

pump should rotate clockwise. You

can reverse the direction of rotation by

interchanging any two of the incoming

supply wires.

6. Start-up

Before starting the pump, make sure the

following:

6.1. For three phase motors, verify if the

rotating direction is correct. It should

be clockwise viewing from the motor

fan cover end.

6.2. All piping joints are completely tight.

Leakage in piping may cause the

pump hydraulic loss.

6.3. The pump is filled with liquid.

6.4. The suction filter is not blocked by any

foreign objects.

7. Operation and Maintenance

It is dangerous to operate the

pump against a closed

discharge outlet because it will

cause extremely high liquid flow

temperature and damage the

pump in a few minutes.

7.1. Lubrication

The mechanical seal and shaft

sleeves are lubricated by the pumped

liquid.

~ 3 ~

4. Installation

The pump has hot surface on

the motor. It must be installed so

that persons cannot accidental-

ly come into contact the hot

surface.

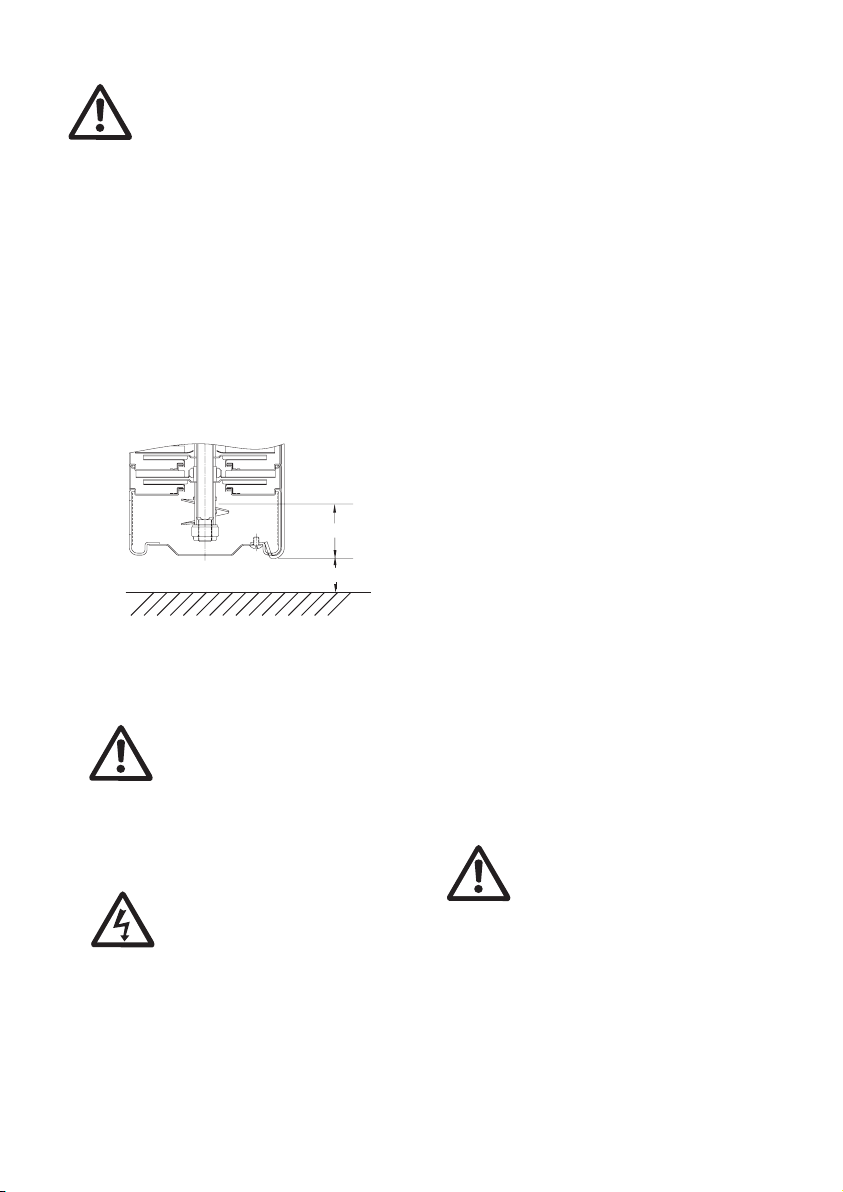

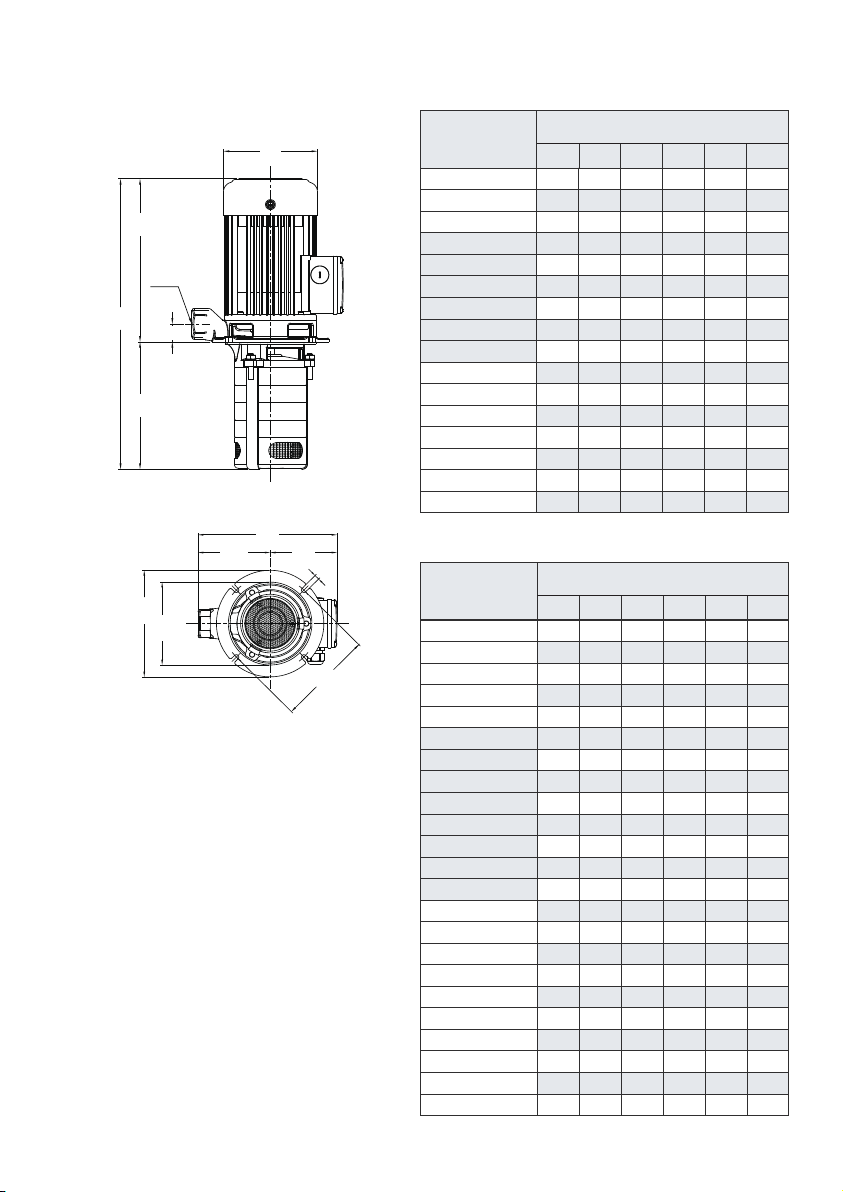

4.1. Submerged Depth

To avoid dry running and damage the

pump during operation, the minimum

pump submerged depth is 40mm (15

/

8

”) as shown in Fig 1. In addition, the

bottom of the pump suction inlet must

be at least 25 mm (1”) above the

bottom of the tank.

Fig.1

Min. 40 mm

25 mm