~ 3 ~

6. Start-Up

Before starting the pump, make sure

the following:

6.1 For three phase motors, verify if

the rotating direction is correct. It

should be clockwise viewing from

the motor fan cover end.

6.2 All piping joints are completely

tight. Leakage in piping may cause

the pump hydraulic loss.

6.3 The pump is filled with liquid.

6.4 The suction filter is not blocked by

any foreign objects.

7. Operation and Maintenance

It is dangerous to operate

the pump against a closed

discharge outlet because it

will cause extre-mely high

liquid flow temperature and

damage the pump in 20

minutes.

7.1 Lubrication

The pumped liquid lubricates the

mechanical seal and shaft

sleeves.

7.2 Suction Filter

Always keep suction filter clean

and make sure it is not blocked by

impurities.

7.3 Periodic Checks

To ensure regular operation,

please follow the below-checking

points:

7.3.1. Check the amount of liquid

and operating pressure.

7.3.2. Check there are no leaks on

piping joints.

7.3.3. Check the tripping of the

motor starter.

7.3.4. Check that all controls are

functioning normally.

TPU Instruction Manual

Before installing your new

system, please study all

instructions carefully, as the

warranty does not cover

failures caused by incorrect

installation and operation.

1. Application

1.1 The TPU Series is single-stage

centrifugal pump designed for

farm or fishery use.

1.2The pump can not be used to trans-

fer explosive liquids, such as gaso-

line, diesel oil or similar liquids. It

is suitable to carry liquids such as

water, coolant, low viscosity or

other non-corrosive liquids.

2. Product Code Designation

The pump is named by motor’s output

power. There are numbers in name-

plate.

3. Operating Limits

1. Ambient Temperature: Max. +40℃

2. Liquid Temperature range: +4℃~

+40℃

3. Enclosure Class: IP54

4. Operating pressure: Max. 3kg/cm²

5. Inlet Pressure: 0 kg/cm²

6. Kinematical Viscosity: 1 cst

(mm²/s)

7. Max. Suction depth: 6m

8.Stop and Restarts:

5.4 For your safety, please make sure

that the wiring is correctly ground-

ed.

5.5 To avoid the possibility of dry

running, we strongly recommend

installing dry running protection.

5.6 The pumps must be supplied

through a Residual Current Device

(RCD) with a rated residual operat-

ing current not exceeding 30 mA.

5.7 If the supply cord is damaged, it

must be replaced by the manufac-

turer, authorized service agent, or

qualified persons in order to avoid

causing a hazard.

5.8 This pump appliance is not intend-

ed for use by persons (including

children) with reduced physical,

sensory or mental capabilities or

lack of experience and knowledge

unless they have been given super-

vision or instruction concerning

use of the pump appliance by a

person responsible for their

safety.

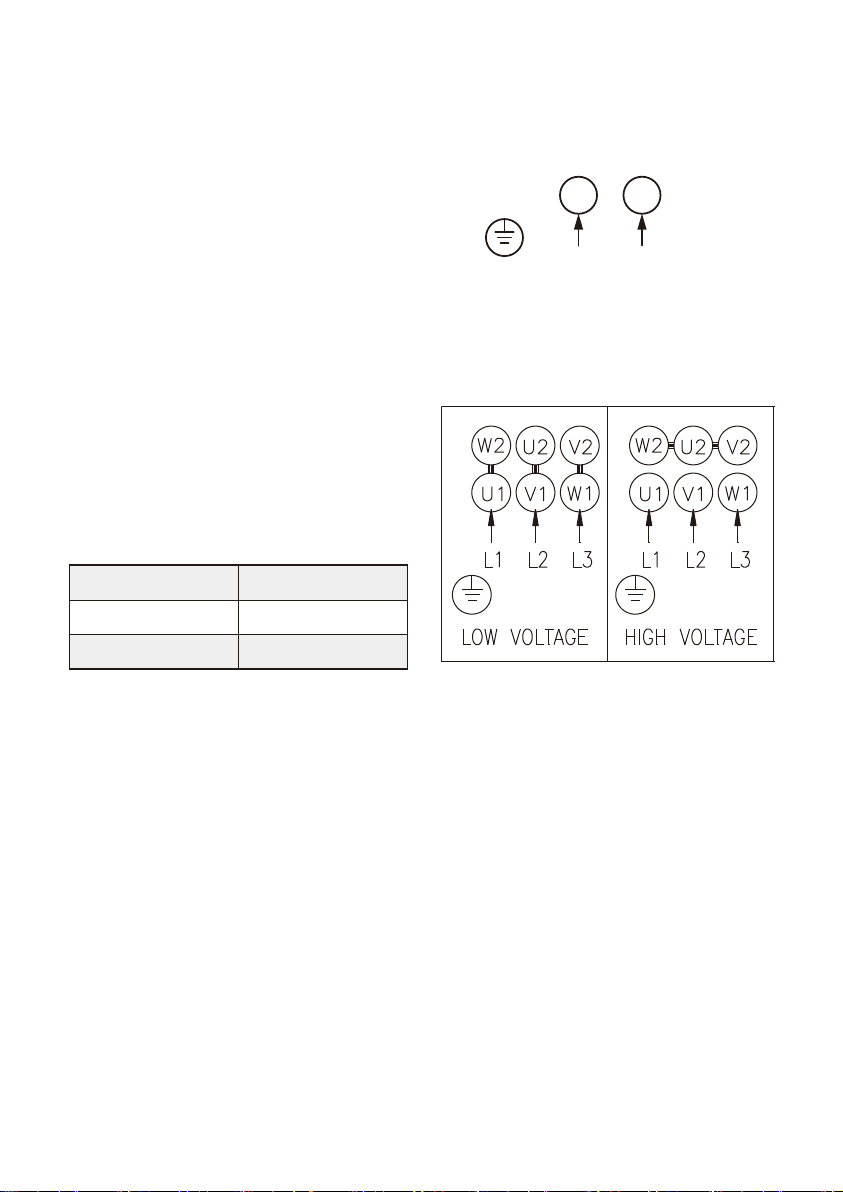

5.9 Make electrical connection in

accordance with connecting

diagram located inside the

connection box. The motor current

must be within the rated amps

range indicated on nameplate.

Three phase motor requires a

magnetic starter for safety.

5.10 For three phase motors, please

check the correct direction of

rotation of the pump on the motor

fan cover. When seen from motor

fan cover end, the pump should

rotate clockwise.You can reverse

the direction of rotation by inter-

changing any two of the incoming

supply wires.

4. Installation

The pump has hot surface

on the motor. It must be

installed so that persons

cannot accidentally come

into contact the hot surface.

4.1 We recommend outlet and inlet

should stay the same size as the

original. If you marrow the pipe

size, it will affect the performance

of the pump.

4.2 For convenient replace or mainte-

nance, the outlet side must be

installation valve and union, and

the inlet side should install union

too.

4.3 Please shorten the pipe as possi-

ble as well, so that reduce leakage.

4.4 Please install filter at inlet, if there

is easily inhale Impurities.

4.5 Install the pump in a well-ventilat-

ed and well-drained place.

5. Electrical Connection

5.1 The electrical connection

should be carried out in

accordance with local

regulations. Never make

any connections unless

the electricity supply has

been switched off.

5.2 The electrical hazard

warning mark is placed

outside the connection

box. Be careful.

5.3 The electrical connection should

be carried out in accordance with

local regulations. The operating

voltage and frequency are marked

on the nameplate. Please make

sure that these data match your

job requirement.

The above drawing shows the noise

level while the pump operated with a

closed outlet.

The tolerance of noise level is ±3dB(A).

9. Wiring Diagram

Three Phase

Single Phase

200-240V

U1 V1

Motor dB(A)

TPU1100

TPU1500

75

78

7.4 When pump is not in use for a

period, it should be drained. For

start up after long time inactivity

please check if the impeller and

mechanical seal are free. If they

are locked up by sand, rust or

something else please clean them

up.

7.5 DO NOT use the pump should not

be used to transfer toxic or

contaminated liquids. Please

carefully follow all instructions in

the manual as Walrus may refuse

to accept the contaminated pump

for servicing.

7.6 If the power supply cord is dam-

aged, it must be replaced by an

authorized engineer or assembly

available from the manufacturer or

service agent.

8. Noise Level