L2

Input power Grounding

L1

L2

Input power Grounding

L3

L1

Single-phase power supply

3-phase power supply (check if rotation is correct)

Fig. 1

VII. Starting

1. Before starting, the pump must be primed.

Please follow the procedure as shown in

Fig 3.

a. Remove the filling plug

b. Fill water in chamber

Water

c. Replace the filling plug

Fig. 2

2. Installation where the pump inlet is below

the water supply, remove the priming plug

and allow the water to flow into the priming

chamber until all air is expelled.

3. The priming procedure should be repeated

until all air is expelled and the pump delivers

a full stream of water without air bubbles.

4. The pump must always be checked for

prime if not used for a prolonged period. It is

imperative to fill the pump with liquid before

operation as dry running causes irreparable

damage to the mechanical seal.

5. When 3-phase motor is supplied, please

ensure if the rotation is correct. You can

switch any of the 2 wires to get your desired

rotation.

VIII. Precautions

1. The pump should be shut down and the

trouble corrected if the pump is running at

speed and found to have any of the following

problems:

- No liquid discharged - Not enough liquid

discharged

- Excessive vibration - Motor runs hot

2. Do not allow the pump to continually start

and stop (cycling) as this will reduce the

motor life.

~ 3 ~

2. The single phase models are supplied with

plug and lead and can be connected directly

to the mains supply. The 3 phase models

should hook up with a circuit breaker.

VI. Wiring diagram

WARNING:

Risk of Electric Shock - This pump is

supplied with a grounding conductor and

grounding-type attachment plug. To reduce

the risk of electric shock, be certain that it

is connected only to a properly grounded,

grounding-type receptacle".

Before operation, please ensure the voltage is

correct and the circuit breaker and grounding

connectors are all connected in accordance

with local regulations.

IX. Operation and maintenance

Under normal operating conditions, the pump

does not require any maintenance as long as

the following points are observed:

1. Periodically check the condition of the check

value and strainer (if used).

2. If the pump is to be inactive for long periods,

it should be rinsed thoroughly with clean

water, then, drained and stored in a dry

place.

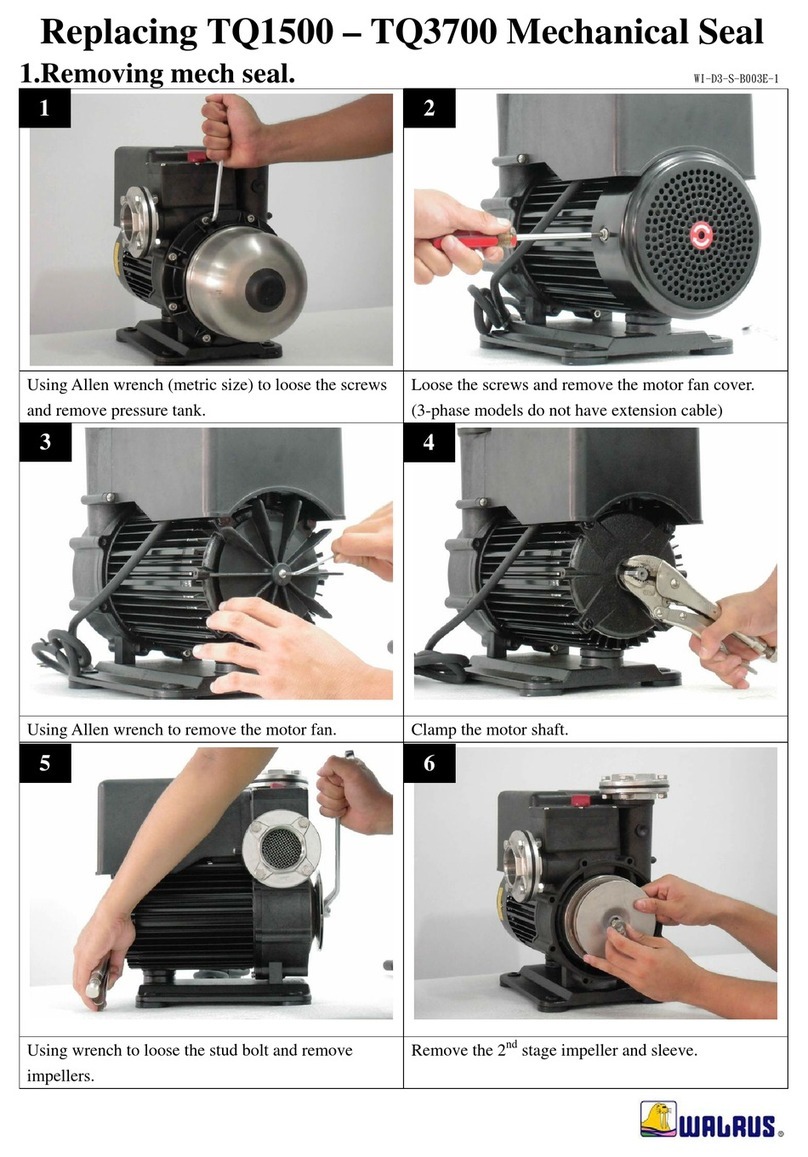

3. If the pump sticks after periods of inactivity,

a screw driver slot is provided on the motor

shaft end to free up the pump/motor. To do

so, insert a screw driver in the slot in the

motor shaft as shown in Fig 3 and turn to

free the rotor. If this does not remedy the

problem, the unit will need dismantling.

Fig. 3

4. Pressure tank air charge should be checked

at regular intervals of every 3 months and

after the pump has not been used for a

prolonged period.To check the Pressure

Tank air pressure, turn off power, open a tap

on the discharge line to release pressure

from the pump, unscrew the black plastic

cover and apply an accurate pressure gauge

to the valve as shown in Fig 4.

Pressure should be adjusted to the original

pre-charge as follows:

TQ200: 17 psi (1.2 Kg/cm²)

TQ400: 26 psi (1.8 Kg/cm²)

TQ800: 36 psi (2.5 Kg/cm²)

TQ1500 up to TQ3700: 36 psi (2.5 Kg/cm²)

Fig. 4

X. Adjustments and Reset procedures

The TQ has a preset activation pressure as per

the table below. For most applications this will

be satisfactory.

1. When the inlet pressure is below the preset

pressure range, please DO NOT adjust the

original setting.

2. The activation pressure can be adjusted

higher when the inlet pressure exceeds the

preset pressure range. Remember that inlet

pressure adds to the TQ pressure, so take

the 40 psi inlet pressure supplied to the

TQ800 for example, internal pressure can

reach approximately 107 psi (67 + 40 psi). If

too high internal pressure is the concern, it

is recommended to install a regulator to

reduce the inlet pressure. The TQ

maximum pressure as per the table below.

The factory preset activation point is as follows:

Model

TQ200

TQ400

TQ800

TQ1500

TQ2200

TQ3700

Power

( HP )

¼

½

1

2

3

5

Preset activation

point ( psi )

20

28

36

43

43

43

Model

TQ200

TQ400

TQ800

TQ1500

TQ2200

TQ3700

Maximum Pressure point ( psi )

31

40

67

58

60

72

~ 4 ~

3. Cycling can occur on pressure units when

the pressure tank pre-charge drops, or

where there is a leak in the discharge

plumbing.