104-001-A.7 Released 06/14/2019

WALTRON CUSTOMER COMMITMENT

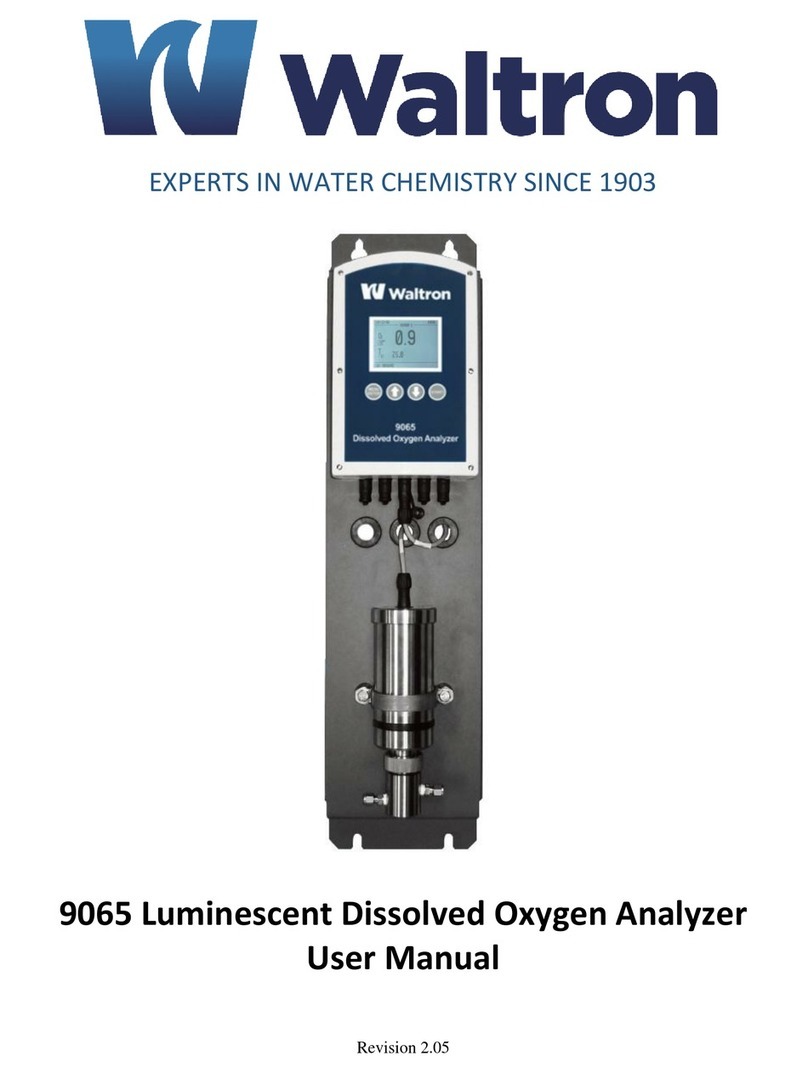

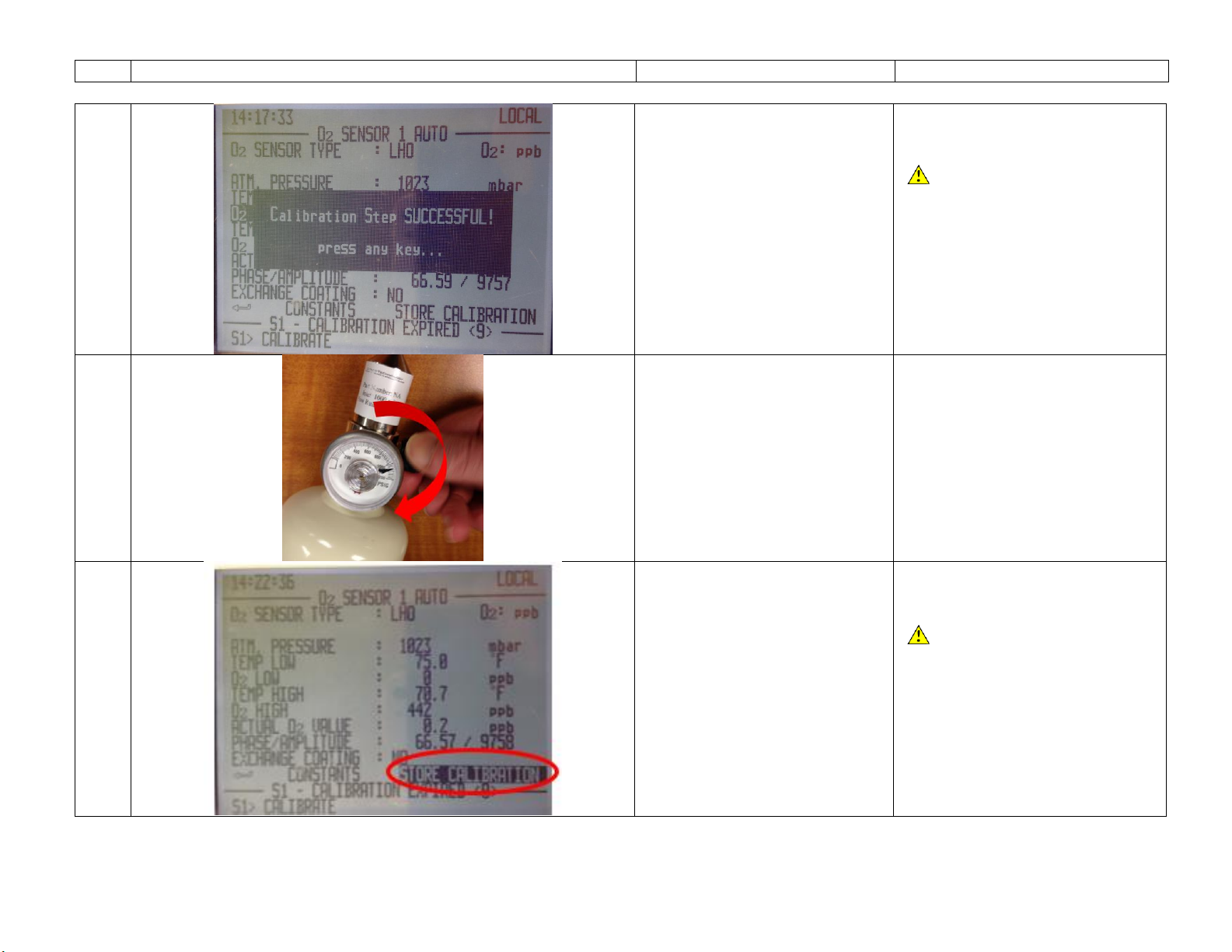

This quick reference manual is a technical guide to aid the customer in the calibration of the Waltron 9065 Dissolved Oxygen Analyzer using the

9065 calibration kit. Waltron provides continuous product improvement and reserves the right to make any modifications to the information

contained herein without notice.

To request sales information:

Inside Sales Coordinator

office: (908)534-5100 x115

For technical service:

Mike Welenteychik

Technical Service & Support

mwelenteychik@waltron.net

office: (908)534-5100 x106

For engineering and program support:

Kenneth Then

Director of Documentation/Service

office: (908)534-5100 x120

Waltron’s technical expertise and extensive experience provides personalized solutions to the water quality industry. It is Waltron’s commitment

to provide the customer with timely and accurate technical service and support.

Waltron fully expects the customer to be satisfied with the quality, performance, and cost of this product.

SAFETY

Please observe proper safety and handling precautions when operating this product. The following should be noted and adhered to:

Read and understand manual before working with the analyzer and calibration kit.

Safety precautions are highlighted throughout this manual within the Key Points column.

WARRANTY AGREEMENT

Waltron guarantees the equipment to be free of defects. If you believe you have received faulty equipment or an incomplete kit please contact

Waltron at the above contact list. Please follow carefully all instructions on the operation the equipment.