INDEX 2

FIL.SILOTOP_zero.--.M.A4.0722.EN Issue: A4

07.22

III

1.0 GENERAL INFORMATION ......................................................................................................................1

1.1 Scope of the Manual .........................................................................................................................1

1.2 Symbols ............................................................................................................................................2

1.3 Glossary and terminology .................................................................................................................4

1.4 Manufacturer’s data and identication of equipment.........................................................................5

1.5 Request for assistance......................................................................................................................6

1.6 Warranty............................................................................................................................................6

1.7 Exclusion of responsibility .................................................................................................................6

2.0 INFORMATION REGARDING SAFETY...................................................................................................7

2.1 General safety prescriptions .............................................................................................................7

2.2 Safety prescriptions for transport and handling.................................................................................7

2.3 Safety prescriptions for installation ...................................................................................................8

2.4 Safety prescriptions for use and operation........................................................................................8

2.5 Safety prescriptions for maintenance and replacement of components ...........................................8

2.6 Safety recommendations on biological risks ..................................................................................... 9

3.0 TECHNICAL INFORMATION .................................................................................................................10

3.1 General description of the equipment .............................................................................................10

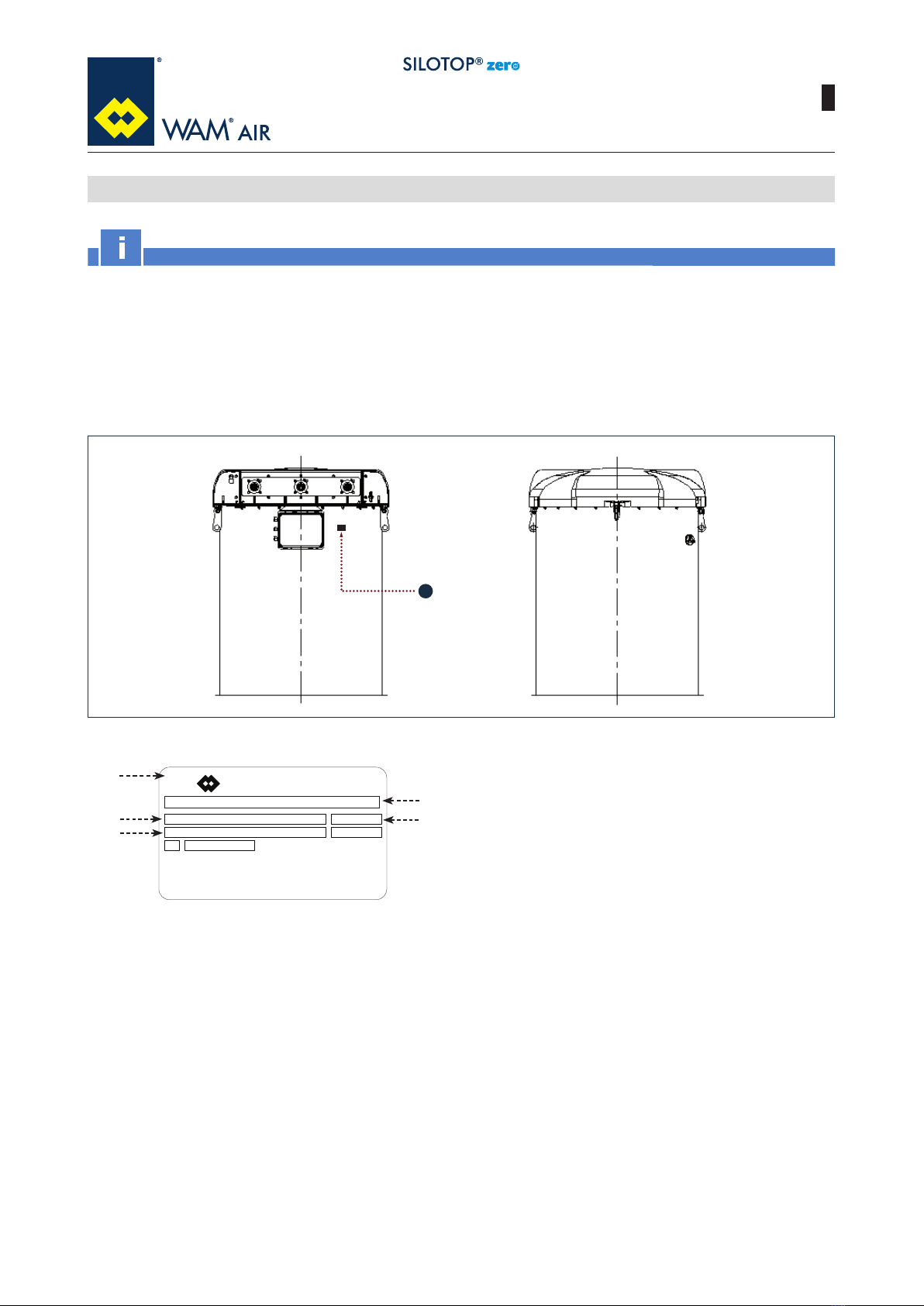

3.2 Main components............................................................................................................................ 11

3.3 Operating principle ..........................................................................................................................12

3.4 Permitted use ..................................................................................................................................12

3.5 Improper use not permitted .............................................................................................................12

3.6 Noise level.......................................................................................................................................13

3.7 Environmental operating limits ........................................................................................................13

3.8 Limits of use ....................................................................................................................................13

3.9 Safety and information signs...........................................................................................................14

4.0 INFORMATION REGARDING HANDLING AND TRANSPORT.............................................................15

4.1 Type of packaging ...........................................................................................................................15

4.2 Reception of goods .........................................................................................................................16

4.3 Lifting and unloading methods ........................................................................................................16

5.0 INSTALLATION AND FIXING.................................................................................................................18

5.1 Safety prescriptions for installation .................................................................................................18

5.2 Positioning the lter ange ..............................................................................................................20

5.3 Electronic board - connections and settings ...................................................................................21

5.4 Electrical connection .......................................................................................................................21

5.5 Pneumatic connection.....................................................................................................................22

5.6 Emissions sampling kit....................................................................................................................25

5.7 Inspection........................................................................................................................................28

5.8 Start-up ...........................................................................................................................................28

TABLE OF CONTENTS