appliance and its individual shutoff valve must be discon-

nected from the gas supply piping system during any

pressure testing of that system at test pressure in excess

of ½ psi (3.5kPa);

The appliance must be isolated from the gas supply pip-

ing system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping sys-

tem at test pressures equal to or less than ½ psi (3.5 kPa).

12. Ignite burner. See applicable ignition instructions

within Operating Instructions, page 20.

13. Electronic ignitions can either be hard wired into main

-

let/receptacle per local codes. The electrical supply

must be connected to an ON/OFF switch that is ex-

ternal to the pit. Remote controls, emergency stops,

and dial timers are optional add-ons.

14. Once appliance is lit, perform leak test on all gas con-

nections and repair as needed.

15. Turn off appliance and allow to cool.

16. Set appliance into properly constructed, level, non-com-

bustible enclosure. The enclosure must be on a stable

surface. The weight of the appliance must be supported

by the plate or pan and not by any control box or gas

valve. Blocks, bricks, metal collars or L-brackets can be

used to build a support ledge for the system plate or

pan. Control boxes and gas valves must be above grade

with adequate drainage to prevent water damage.

Installer is responsible for making sure there is enough

space in the cavity for any electronics and piping. The

interior space of the enclosure cannot be lled with

any material (i.e. gravel, crushed rock, concrete, etc).

wind and to allow coverage of burner. See Clearances

Diagram for details.

17. To allow for regular maintenance, any capstone

materials should not overhang the interior edge of

Clearances Diagram on page 8 for

placement. Warming Trends® is not responsible for

any damages to the capstone.

18. Venting is required to avoid heat damage to inter-

pooling. Incorporate 1 vent on at least two opposing

sides (2 vents total) at a minimum size of 18 sq. inches

each for 36” total (example: 3”x 6”). Installation of

the vents in the mid to lower area of the enclosure is

recommended. Some enclosures may require more

ventilation based on material, size, and extended use.

Ready-to-Finish Kits come with Fire Pit Vent Kit (FPVK).

Vents do not come pre-installed on Ready-to-Finish.

Fire Pit Vent Kits must be installed on site.

19.

etc.) approved for use with high temperatures that

-

tures. Never use any material for media that is non-po-

rous and holds moisture such as gravel, pebbles, river

rock, etc. Such material, when heated, may cause the

trapped moisture to boil, fracture unexpectedly and/

or explode and which could cause personal injury,

damage or death.

20. To avoid dust and clogs getting into the system, do not

dump the media over the burner. Place the media onto

the plate or pan. Burner should be covered by ap-

proved media up to ½” above the jets. Media may be

positioned so that jet tips or barrels are visible. Exces-

sive media coverage may cause back pressure and

dangerous pooling of gas which can result in explo-

sion which could cause property damage, personal

injury, or death.

21. Do not cover the ignition pilot assembly or wind cage

more than half way with any form of media. Do not

place ceramic logs too close to the pilot assembly as

this may cause excessive heat and system failure that

is not covered by warranty.

22. Ceramic log sets, must be pre-treated before use to

avoid breaking or crumbling. Burn logs for 15 minutes,

then leave untouched to cool for at least one hour before

moving them again, or they could break or crumble.

23.

24. Review instruction manual with end user and instruct end

WARNING: Improper installation, adjustment

alteration, service or maintenance can cause

property damage, personal injury or loss of

life. Refer to the owner’s information manual provided

with this appliance. Installation and service must be

gas supplier.

WARNING: Do not store or use gasoline, or

of this or any other appliances.

An LP-cylinder not connected for use shall not be stored

in the vicinity of this or any other appliance.

AVERTISSEMENT: Une installation, un

cause de blessures ou de dommages. Veuillez lire

attentivement les instructions d’installation, d’utilisation

AVERTISSEMENT: Ne pas entreposer ni

utiliser de l’essence ni d’autres vapeurs ou

de tout autre appareil.

voisinage de cet appareil ou de tout autre appareil.

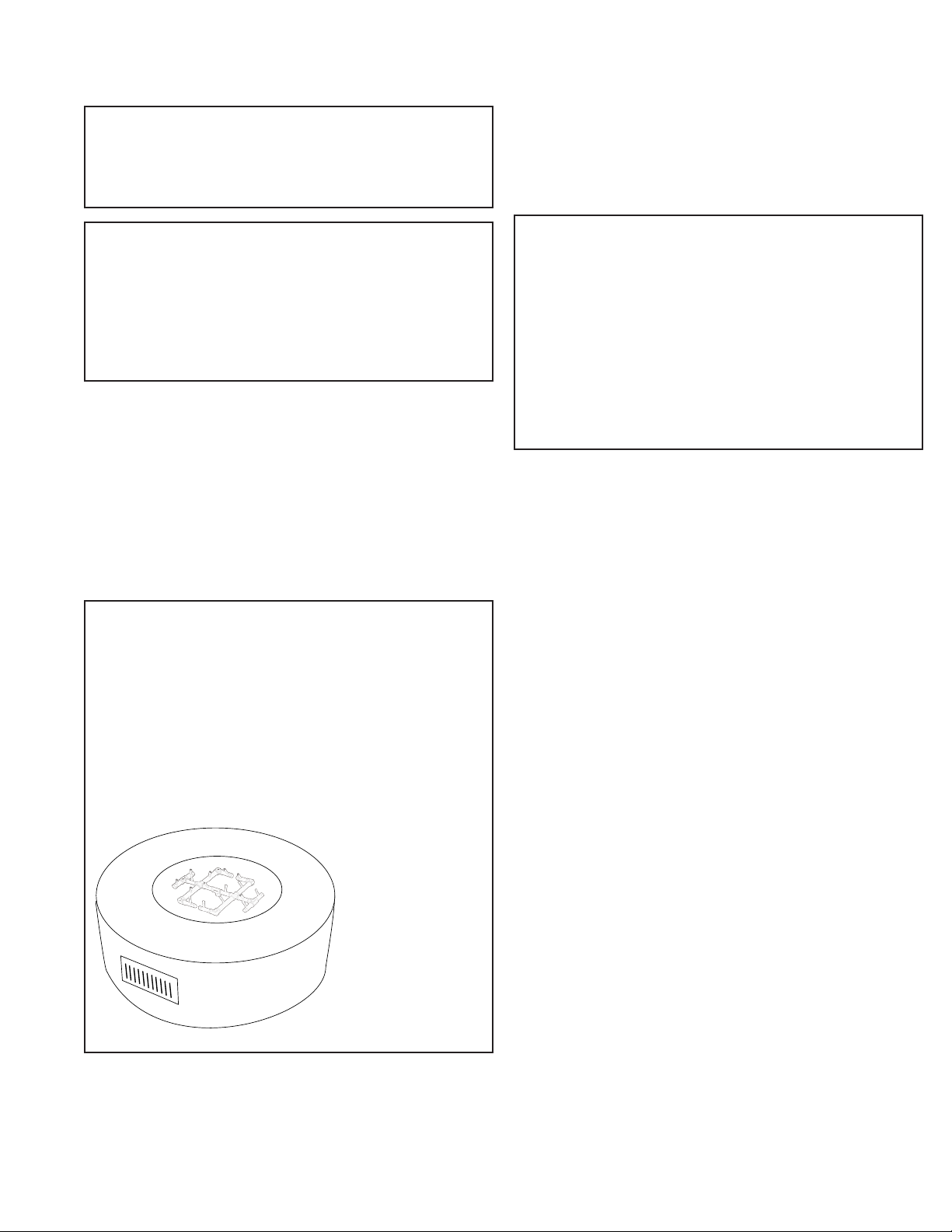

The following label has been provided with the appliance.

appliance.