DESCRIPTION

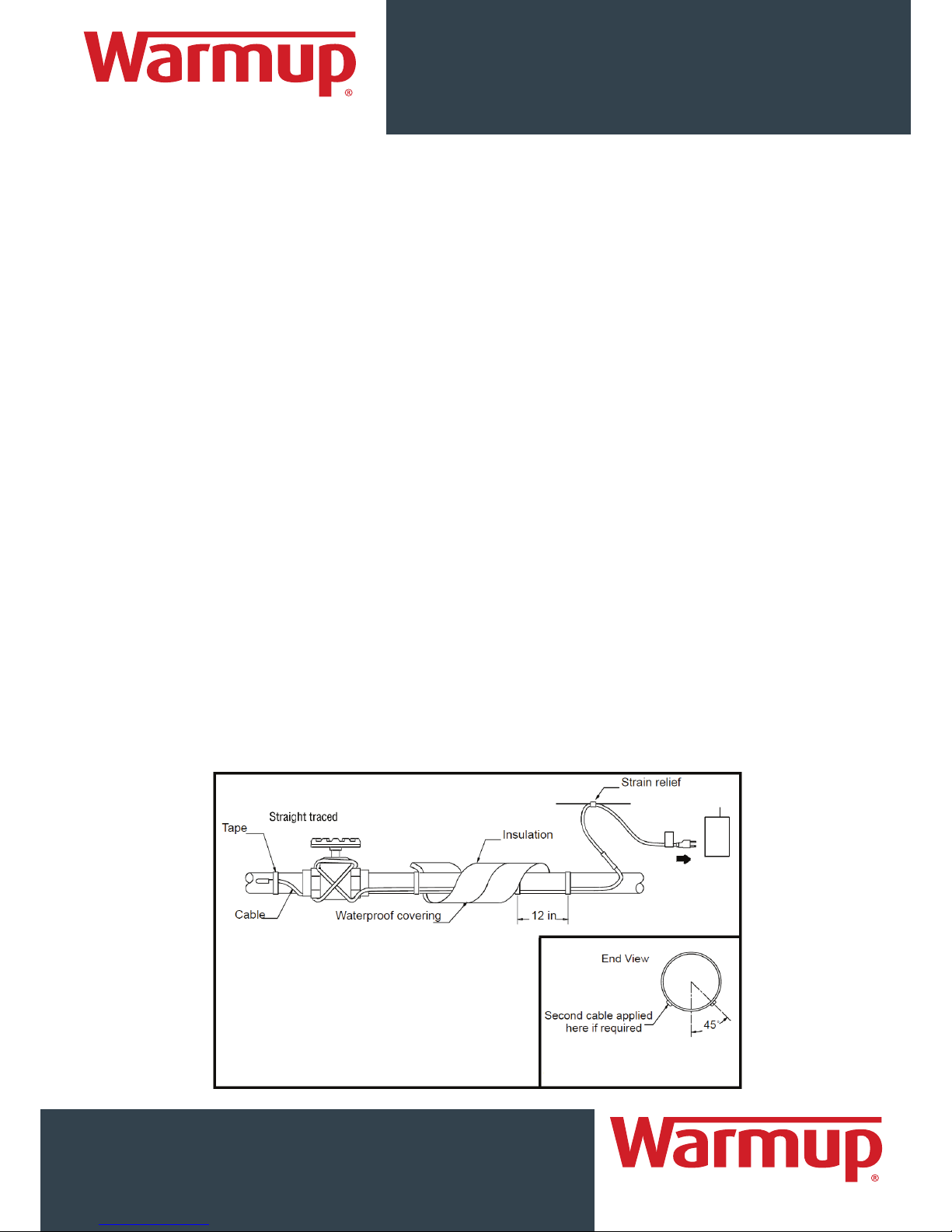

Warmup NAMSRK preassembled and pre-terminated cables

are intended for use on metal or plastic water pipes for freeze

protection of these pipes in residential, mobile home or other

ordinary area installation applications.

The cables are provided in 6, 12, 18, 24, 50, 75 and 100 foot

lengths which include a factory sealed power connection

with 30 inch power cord and plug, and a factory sealed end

termination.

PACKAGE CONTENT

1 NAMSRK preassembled electric heating cable

OTHER ITEMS REQUIRED FOR PROPER

INSTALLATION

• Thermal insulation (fiberglass or equivalent)

• GFI protected power receptacle

CONDITIONS OF USE

NAMSRK cables are designed for use in residential, mobile

home or other ordinary area installation applications on

the outside of metal or plastic piping only.

This electric heating cable is designed to be used in

conjunction with suitable thermal insulation and connected

to a an outlet with ground fault circuit interruption.

Please review the following cautions related to the use

of the NAMSRK preassembled cable.

CAUTION: ELECTRIC SHOCK AND/

OR FIRE HAZARD.

1. Do NOT use the NAMSRK cable in classified hazardous

areas. This product is approved for ordinary area use only.

2. Do NOT use the NAMSRK cable for underground or buried

pipe applications.

3. Do NOT use the NAMSRK cable for flexible hose or flexible

piping applications. This product is approved for used on

fixed metal and plastic piping only.

4. Do NOT install the NAMSRK cable without use of

proper thermal insulation and protective weather barrier.

5. Do NOT use the NAMSRK cable for piping installations

behind walls, in ceilings, through flooring or any other

inaccessible locations.

6. Do NOT use the NAMSRK cable directly INSIDE pipes.

This product is approved for use installed on the OUTSIDE

of metal and plastic pipes only.

7. Do NOT use the NAMSRK cables on piping that may

exceed 85 deg C.

8. Do NOT use the NAMSRK cables on piping that contains

fluids other than water. This product is approved for use

on pipes containing water only.

9. Do NOT use an extension cord with the NAMSRK cables.

These heating cables provide protection from damage due to

the freeze and thaw cycles on pipes, roofs and gutter systems.

For Roof & Gutter installation instructions, please refer to the

relevant document.

The cables automatically adjust heat output according to the

ambient temperature conditions. Under cooler conditions the

heat output increases, and as the temperature rises the output

decreases to save on energy. The cables are available in

various pre-assembled lengths.

GENERAL INFORMATION

TOOLS REQUIRED

• 2500 VDC megger - used to test electric heating

cable insulation resistance.

APPROVALS

NAMSRK preassembled heating cables are ETL approved

for use in residential and mobile home pipe freeze

protection applications.

VALVE

HEATING CABLE

PIPE