2Warner Electric • 800-825-9050 P-269

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 3

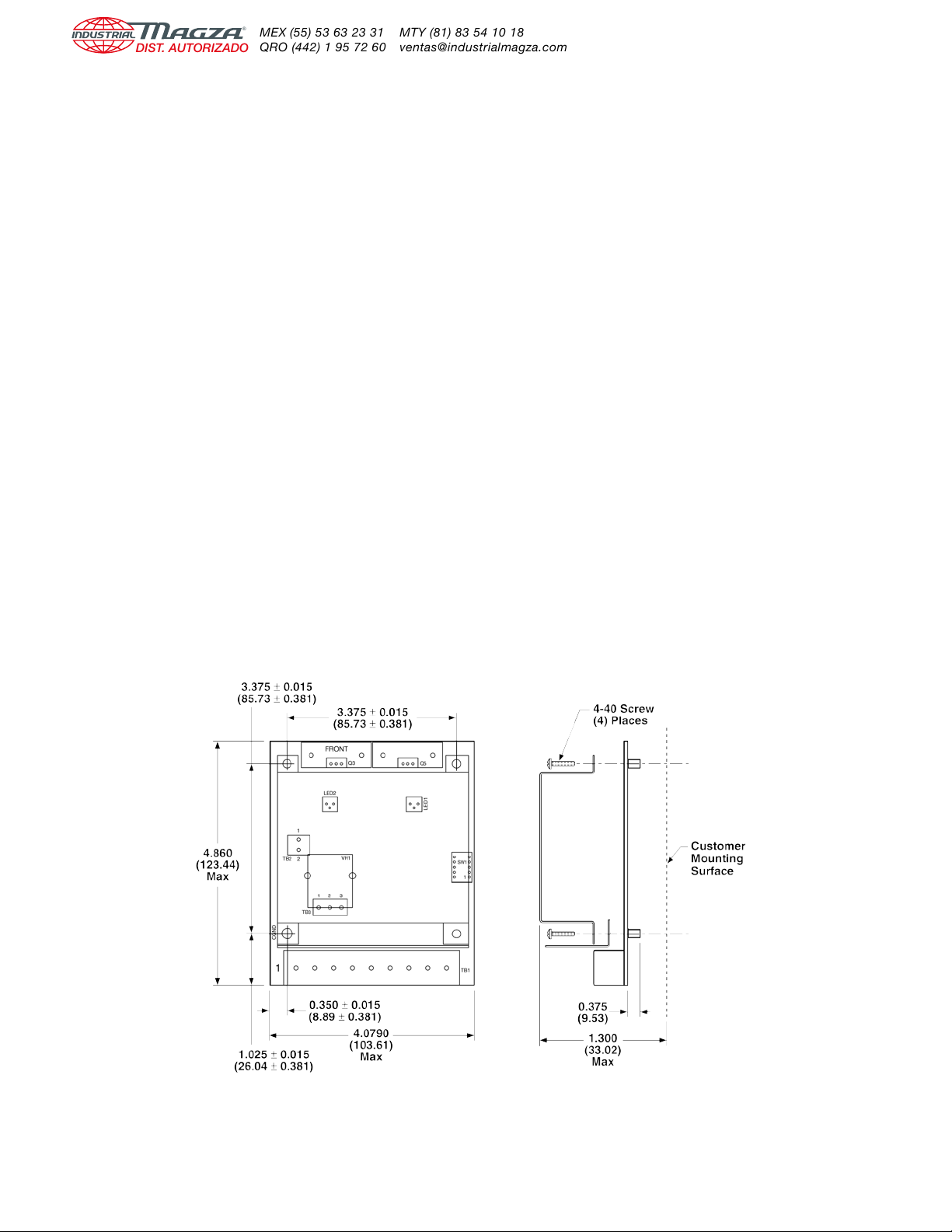

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

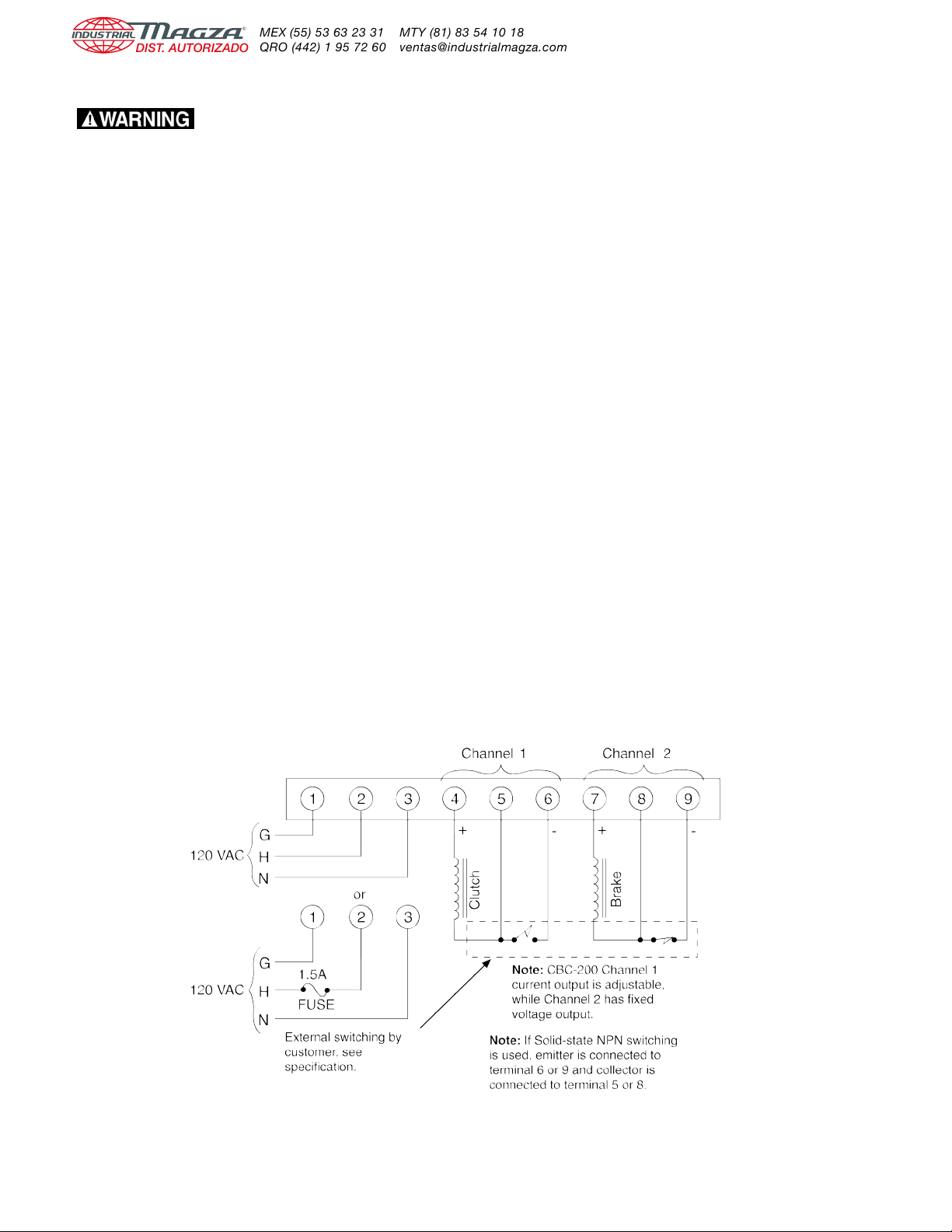

Electrical Connections. . . . . . . . . . . . . . . . . . . 6

Internal Adjustments . . . . . . . . . . . . . . . . . . . 11

Troubleshooting Checklist . . . . . . . . . . . . . . . 12

Warranty . . . . . . . . . . . . . . . . . . . . . . Back Page

or control panel. The standard version is offered

the same as before, but with the chassis version

added. The CBC-200-1 and CBC-200-C1

version is being offered where an external limit

adjustment potentiometer is required. The

CBC-200-2 and CBC-200-C2 version maintains

the limit adjust potentiometer on the PC board

but allows for an external potentiometer for level

adjustment of the output. This allows the output

to be controlled from zero to maximum level on

both the current adjust channel and steady state

output channel. The CBC-200-3 and

CBC-200-C3 allow for both the current limit and

level adjustment potentiometers to be mounted

remotely.

Operations of all units are identical except for

the method of the control potentiometer

mounting. All units that have external poten-

tiometer options have terminal blocks mounted

on the PC boards for connection of the poten-

tiometers.

The potentiometers used can be supplied either

as optional accessory items or be obtained from

a local electronic supply house.

A short circuit protection scheme is integral

which trips on occurrence of line to line shorts

on the output. No protection is provided for line

to ground shorts because the unit is not

isolated.

Two LED indicators are provided on the front

panel of the control for “POWER” and “SHORT”

indications. The green indicator marked

“POWER” is illuminated whenever the AC input

power is applied to the control. A red indicator

marked “SHORT” is illuminated whenever a

short circuit condition occurs in either of the

outputs. To reset, power must be removed, the

shorted condition cleared, and the AC input

power reapplied to the control.

The enclosed version may be used with or

without the cover. Removal of the plastic cover

when the control is used in an enclosure will

increase the operating temperature range of the

control.

The chassis mount version does not have a

cover and must be mounted in an enclosure or

control panel.

Failure to follow these

instructions may result in product dam-

age, equipment damage, and serious or

fatal injury to personnel.

Introduction

Warner Electric’s CBC-200 series Constant

Current Clutch Brake Controls are solid-state

electronic power supplies designed to operate

any of the Warner Electric 90 Volt clutches and

brakes, including fail safe designs. They can

operate a single clutch or brake, two clutches,

two brakes, a combination clutch and brake, or

a combination clutch and fail safe brake,

depending on the switching arrangement used

and the application requirements.

The CBC-200 series controls operate from 120

VAC single-phase input power. They provide

constant current output as set by the torque

adjustment potentiometers on the front panel or

remote potentiometer. Additionally, on some

versions a level adjust can be used to set the

operating level with the torque adjustment

setting the maximum current level. On the

CBC-200 series Channel 2 is a fixed output level

and an adjustable output on Channel 1. Output

current ranges are selectable for the adjustable

output channels in one of five ranges by the DIP

switches located on the control’s printed circuit

board.

Several versions of the CBC-200 are provided to

handle a wide range of applications. These

include both enclosed and chassis mount

versions for mounting in an external enclosure