Installation

WARNING Installer must be suitably qualified and ensure compliance with all

local codes and standards including AS/NZS 3500.1.

Failure to comply even partially with installation instructions may void the

warranty.

Positioning

Unpack machine, check for damage & complete delivery. Install machine on sound

waterproof self-draining floor & adjust feet to level machine. Adjacent surfaces

should be heat resistant and moisture proof, especially benchtop lower surfaces

above undercounter machines. Allow room for detergent to one side of machine

or in adjacent cupboard. 20litre container requires about 450H x 250W x 350D,

but smaller containers are available from many suppliers.

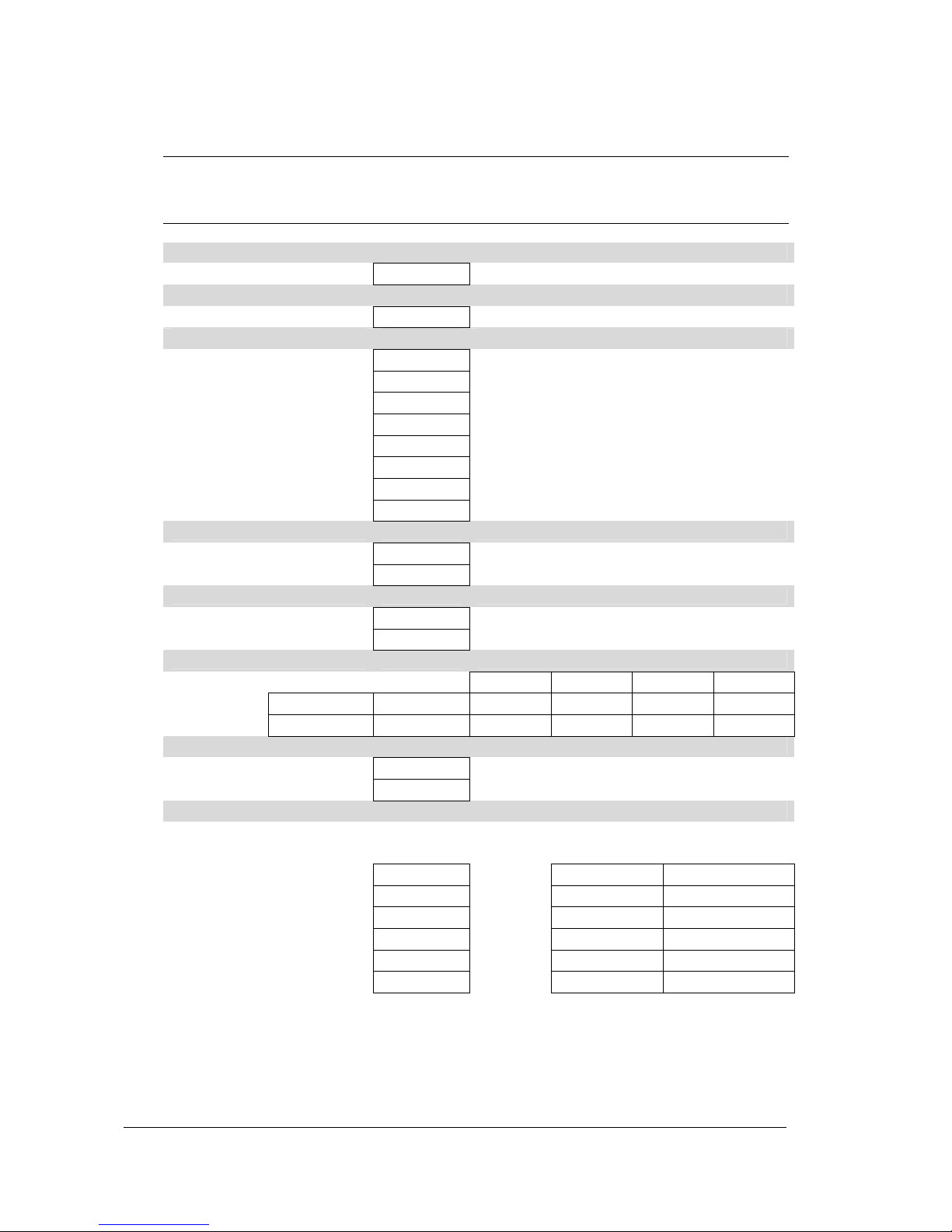

Hot Water Temperature 65°C ± 5°C

Connection 20 mm (3/4” BSP) male – flexible hose supplied

Flow rate minimum 20 litres per minute

Consumption per cycle 3 litres approximately

Backflow prevention DCV = Dual Check Valve supplied with machine

Pressure 200-350 KPa = 30 - 50 Psi

Above this range fit pressure limiter. Don’t use small diameter plastic supply lines

especially below this range when optional rinse booster pump may be required.

FLUSH supply line before connection. Connect supplied DCV to water supply.

Poor quality supply or excessive water hardness may affect performance or damage

machine – filtration and/or softening is recommended.

Waste Fit drain pump hose to sink waste trap or 750 high open waste - refer installation

diagram

Power Electrical supply required is 15A 240V 50Hz via switched outlet adjacent to

machine, which is supplied with cord set including 15A plug (located under the

rear cover)

Detergent

If detergent pump is fitted insert pump inlet hose with white ceramic collar into

container of commercial low foam detergent. Commercial detergents are usually

hazardous – read instructions and handle with care.

Rinse Aid

If rinse aid injector is fitted insert injector inlet hose with steel collar into rinse aid

container. Check fluid is steadily rising inside hose during pulse at start of rinse

cycle. Rotate adjusting screw clockwise to reduce flow, anticlockwise to increase

flow. The injector is activated by rinse pressure - to prime the system switch the

machine off and back on several times during filling to mimic multiple rinse cycles

(otherwise it will take several operating cycles to bring rinse fluid to required

concentration).

Installation Checklist

Complete attached Installation Checklist to ensure machine is installed and

running correctly, and operator is familiar with operating procedures.

Troubleshooting

If machine doesn’t fill after switching on power, check & ensure that hot water

supply tap is open, water supply pressure is not below specification & Dual Check

Valve is correctly installed (arrow on the DCV body specifies water flow direction).