Contents

Safety Instructions ...........................................................................................................................................................................4

Installation ...........................................................................................................................................................................................5

Installation Diagram ............................................................................................................6

Bench Work Details ............................................................................................................7

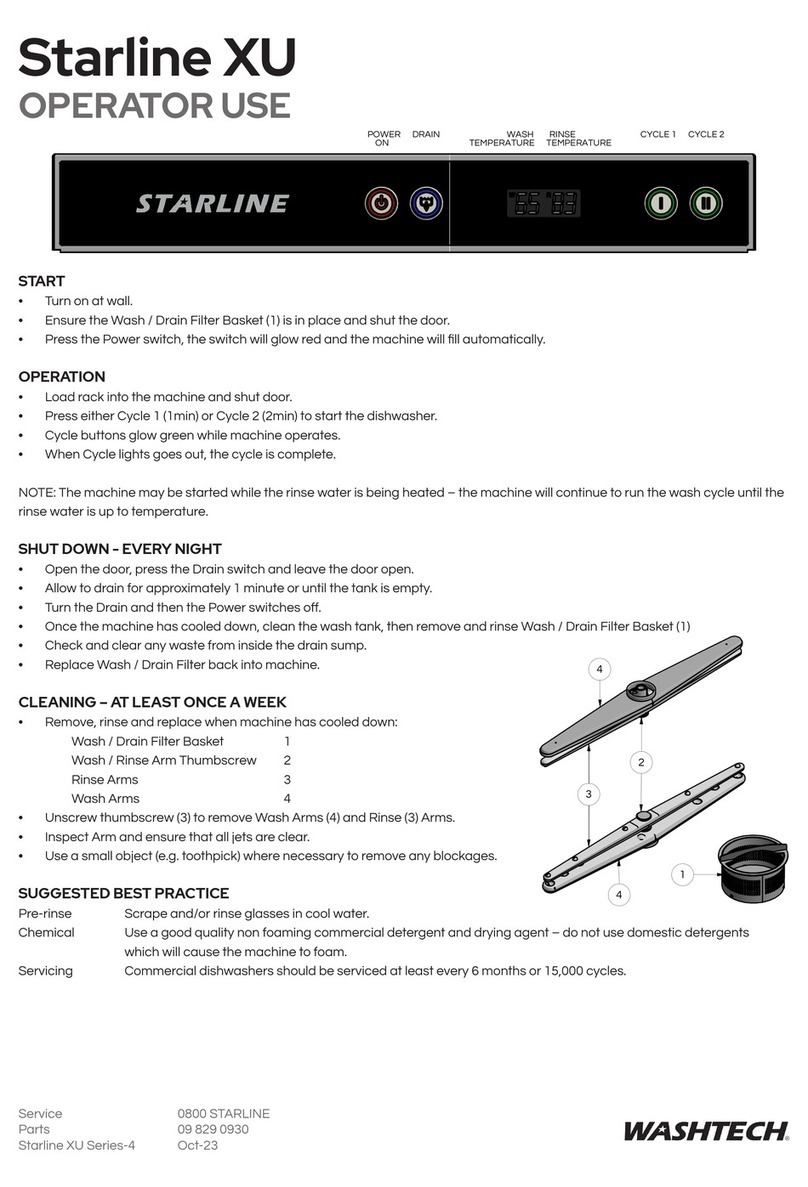

Operating Instructions..................................................................................................................................................................8

Dishwashing Procedures .............................................................................................................................................................9

Troubleshooting Chart............................................................................................................................................................... 11

Components .................................................................................................................................................................................... 13

Location and Access..........................................................................................................13

Timer....................................................................................................................................14

Rinse Thermostat...............................................................................................................15

Wash Thermostat...............................................................................................................16

Solenoid Valve....................................................................................................................17

Pressure Switch ..................................................................................................................18

Wash Pump.........................................................................................................................19

Rinse Aid Injector (Optional) ..........................................................................................20

Electrical Diagrams ..................................................................................................................................................................... 21

Schematic Diagram............................................................................................................21

Wiring Diagram..................................................................................................................22

Assembly Diagrams..................................................................................................................................................................... 23

Wiring Tray Assembly.......................................................................................................23

Control Panel Assembly ...................................................................................................24

Wash Assembly ..................................................................................................................25

Rinse Assembly ..................................................................................................................26

Rinse Tank Assembly ........................................................................................................27

Door Link Assembly .........................................................................................................28

Spare Parts ........................................................................................................................................................................................ 29

Accessories ....................................................................................................................................................................................... 31

Appendices....................................................................................................................................................................................... 32

Rinse Aid Injector Retrofit......................................................................................................................... 32

Rinse Pump Retrofit ................................................................................................................................ 33

Detergent Pump Retrofit ........................................................................................................................... 34

Revisions............................................................................................................................................................................................ 35

Service Manual M1-3 (W) 3 Revision 1B