Water Control Dakotah series User manual

Metered Water Softener

Installation / Operation Manual

2

For help with installation

or troubleshooting

please contact

Water Control Corporation.

Water Control Tech Services Department:

Toll Free: 1-866-405-1268

Local: 763-427-9638

Fax: 763-427-5665

3

Installation Procedure

1. Identify installation location for water softener. Piping should be such that all household water, with the

exception of outside hydrants, flows through softener. A hard water line may be run to a kitchen tap if so

desired. This system and installation must comply with state and local laws and regulations.

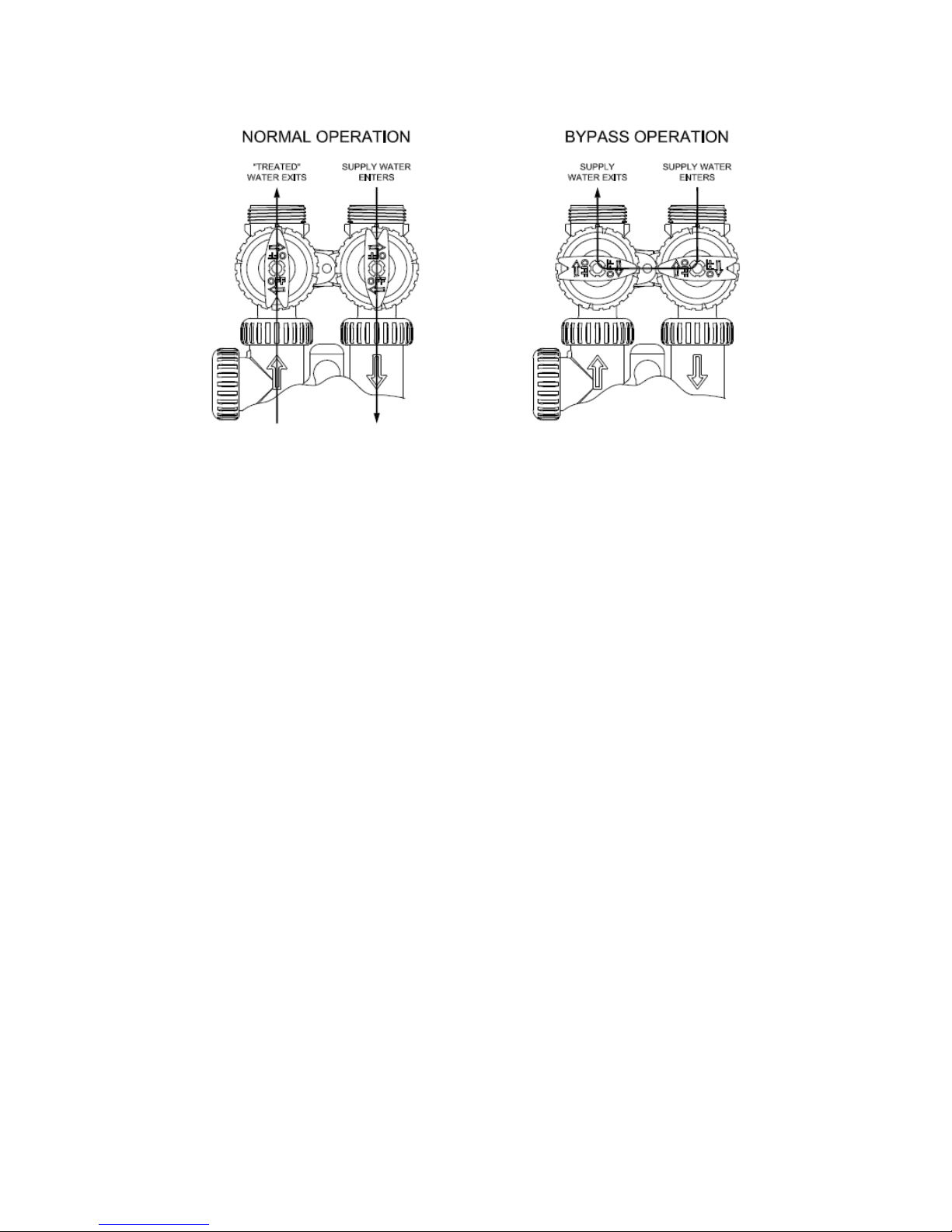

2. Connect water piping. This unit has been supplied with a manually operated bypass device which ena-

bles the softener to be isolated from the water service lines for maintenance and service, and also to main-

tain the continuity of the water supply when the softener is disconnected. Separate bypass fittings from

valve before sweating any copper. Overheating may cause damage to valve. Turn supplied bypass valve to

“Bypass” position (see Bypass Valve Diagram) and make connections to household water lines. Ensure

that inlet and outlet are properly piped, per arrows on valve body. Leave unit in “Bypass” position until

startup procedure.

3. Connect drain line. Remove barbed drain line fitting from parts bag. Apply Teflon tape to threads, and turn

into the female threaded opening on the back side of the control valve. Connect 5/8” drain line (supplied in

parts bag) to barbed end of drain line fitting and run to a nearby drain. Be sure not to submerse drain line

end into drain, as a 1 1/2” minimum air gap must be maintained to prevent potential backflow hazard. Firm-

ly secure at drain, while maintaining a minimum 1 1/2” air gap.

4. Connect brine line (two-tank models only). Connect 3/8” brine line (supplied in parts bag) to fitting on

brine tank and on the control valve. Tighten both fittings with an adjustable wrench.

5. Install brine tank overflow line. Install overflow fitting (supplied in parts bag) into hole in side of brine

tank. An owner-supplied overflow line should then be attached and run to a nearby drain. Failure to run

overflow line could cause flooding and water damage should the brine tank overflow.

6. Connect to electrical power source. Connect power cord to a dedicated 120v, 15 amp, ground fault inter-

rupt (GFI) outlet.

Proceed to start-up procedure.

Note: This system is not intended to be used for treating water that is microbiologically unsafe or of unknown

quality without disinfection before or after the system.

Bypass Valve Diagram

4

Start-Up Procedure

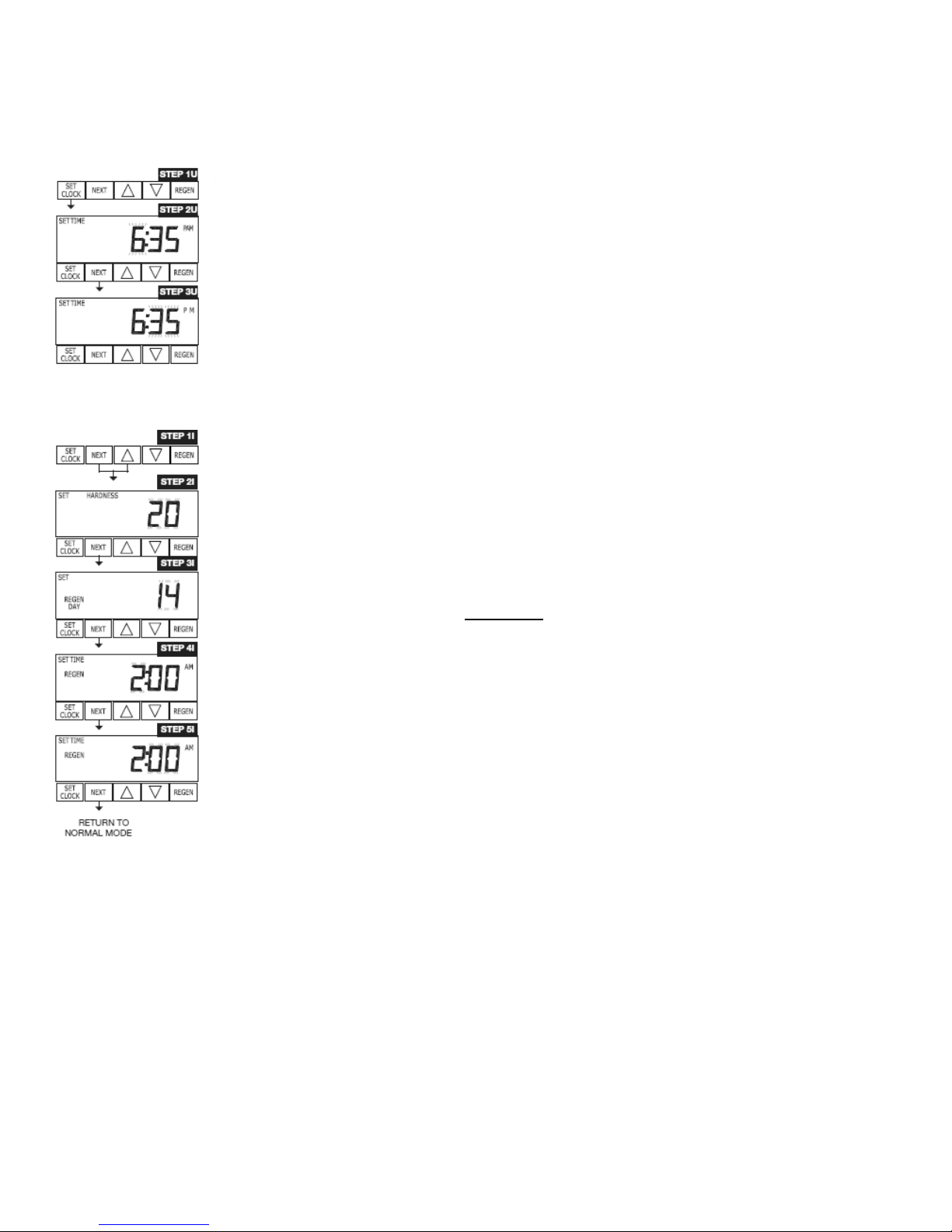

1. Set Time of Day

The user can also set the time of day. Time of day should only need to be set after

power outages lasting more than 8 hours, if the battery has been depleted and a pow-

er outage occurs, or when daylight saving time begins or ends. If a power outage last-

ing more than 8 hours occurs, the time of day will flash on and off which indicates the

time of day should be reset. If a power outage lasts less than 8 hours and the time of

day flashes on and off, the time of day should be reset and the battery replaced.

STEP 1U – Press SET CLOCK.

STEP 2U - Current Time (hour): Set the hour of the day using ▼or ▲buttons. AM/PM

toggles after 12. Press NEXT to go to step 3U.

STEP 3U - Current Time (minutes): Set the minutes of the day using ▼or ▲buttons.

Press NEXT to exit Set Clock. Press REGEN to return to previous step 2.

2. Program the System

STEP 1I - Press NEXT and ▲simultaneously for 3 seconds.

STEP 2I – Hardness: Set the amount of hardness in grains of hardness as calcium

carbonate per gallon using the ▼or ▲buttons. The default is 20 with value ranges

from 1 to 150 in 1 grain increments. Note: The grains per gallon can be in creased if

soluble iron needs to be reduced. Press NEXT to go to step 3I. Press REGEN to exit

Installer Display Settings.

STEP 3I – Day Override: When gallon capacity is set to off, Day Override sets the

number of days between regenerations. When gallon capacity is set to AUTO or to a

number, Day Override sets the maximum number of days between regenerations. If

value set to “oFF” regeneration initiation is based solely on gallons used. If value is set

as a number (allowable range from 1 to 28) a regeneration initiation will be called for

on that day even if sufficient number of gallons were not used to call for a regenera-

tion. Set Day Override using ▼or ▲buttons:

• number of days between regeneration (1 to 28); or

• “oFF”.

Press NEXT to go to step 4I. Press REGEN to return to previous step.

STEP 4I – Next Regeneration Time (hour): Set the hour of day for regeneration using

▼or ▲buttons. AM/PM toggles after 12. The default time is 2:00 a.m. Press NEXT to

go to step 5I. Press REGEN to return to previous step.

STEP 5I – Next Regeneration Time (minutes): Set the minutes of day for regeneration

using ▼or ▲buttons. Press NEXT to exit Installer Display Settings. Press REGEN to

return to previous step.

3. Fill the mineral tank with water: Slowly open bypass valve (see Bypass Valve Diagram, page 3).

Press and hold “REGEN” button until “RINSE” appears on the LCD screen. Allow water to flow until tank

is full and all air has been bled from the system, water will flow to the drain line. Allow water to flow for 3-

4 minutes.

4. Filling the brine tank with water: Slowly press “REGEN” 4 more times, waiting for the valve motor to

cycle on and off each time you press. “FILL” will appear on LCD screen. Water will begin to flow to the

brine tank. Allow control to fully complete this cycle. Once complete, the unit will go into regular service

and the time of day or gallons remaining will appear on LCD screen. This procedure will place the appro-

priate initial water fill in the brine tank.

System setup is now complete. Add salt to brine tank (Water Control recommends Morton System

Saver® pellets). Enjoy your soft water!

5

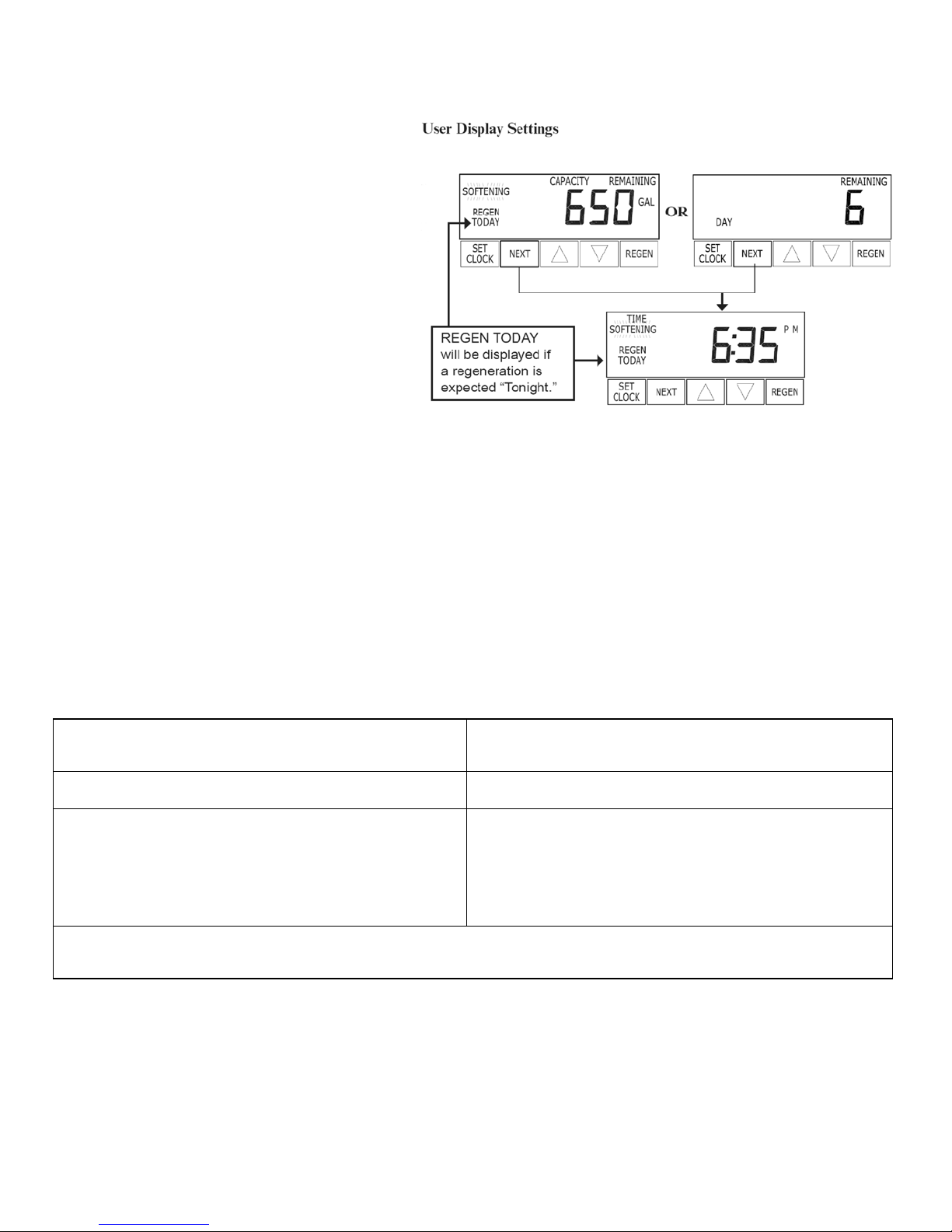

General Operation

When the system is operating one of two

displays will be shown. Pressing NEXT will

alternate between the displays. One of the

displays is always the current time of day.

The second display is one of the following:

days remaining or gallons remaining. Days

remaining is the number of days left before

the system goes through a regeneration cy-

cle. Capacity remaining is the number of gal-

lons that will be treated before the system

goes through a regeneration cycle. The user

can scroll between the displays as desired.

If the system has called for a regeneration

that will occur at the preset time of regenera-

tion, the words “REGEN TODAY” will appear

on the display.

When water is being treated (i.e. water is flowing through the system) the word “Softening” or “Filtering”

flashes on the display if a water meter is installed.

Manual RegeneraƟon

To initiate a manual regeneration at the preset delayed regeneration time, press and release “REGEN”. The

words “REGEN TODAY” will flash on the display to indicate that the system will regenerate at the preset

delayed regeneration time. If you pressed the “REGEN” button in error, pressing the button again will cancel

the request.

To initiate a manual regeneration immediately, press and hold the “REGEN” button for three seconds. The

system will begin to regenerate immediately. The request cannot be cancelled.

SpecificaƟons

Minimum/Maximum Operating Pressures 20 psi (138 kPa or 1.4 bar) -

125 psi (862 kPa or 8.6 bar)

Minimum/Maximum Operating Temperatures 40°F (4°C) - 110°F (43°C)

Power Adapter:

Supply Voltage

Supply Frequency

Output Voltage

Output Current

120 V AC

60 Hz

12 V AC

500 mA

No user serviceable parts are on the PC board, the motor, or the power adapter. The means of

disconnection from the main power supply is by unplugging the power adapter from the wall.

6

General Warnings

The control valve, fittings and/or bypass are designed to accommodate minor plumbing misalignments but are not designed to sup-

port the weight of a system or the plumbing.

Do not use Vaseline, oils, other hydrocarbon lubricants or spray silicone anywhere. A silicone lubricant may be used on black o-

rings but is not necessary. Avoid any type of lubricants, including silicone, on the clear lip seals.

The nuts and caps are designed to be unscrewed or tightened by hand or with the special plastic wrench. If necessary a pliers can

be used to unscrew the nut or cap. Do not use a pipe wrench to tighten or loosen nuts or caps. Do not place a screwdriver in the

slots on caps and/or tap with a hammer.

Do not use pipe dope or other sealants on threads. Use Teflon tape on the threaded inlet, outlet and drain fittings. Teflon tape is not

necessary on the nut connection or caps because of o-ring seals.

After completing any valve maintenance involving the drive assembly or the drive cap assembly and pistons, unplug power source

jack from the printed circuit board (black wire) and plug back in or:

For valves that use a TC circuit board (three buttons) press and hold SET and DOWN buttons for 3 seconds. The cover button

may have other names like “SET HOUR”, “CLOCK” or “SET CLOCK” but the circuit board is labeled with SET.

For all other valves press and hold NEXT and REGEN buttons for 3 seconds.

This resets the electronics and establishes the service piston position. The display should flash all wording, then flash the software

version, and then reset the valve to the service position.

All plumbing should be done in accordance with local plumbing codes. The pipe size for the drain line should be a minimum of ½”.

Backwash flow rates in excess of 7 gpm (26.5 lpm) or length in excess of 20’ (6.1m) require ¾” drain line.

Solder joints near the drain must be done prior to connecting the drain line flow control fitting. Leave at least 6” between the drain

line control fitting and solder joints when soldering pipes that are connected on the drain line control fitting. Failure to do this could

cause interior damage to the drain line flow control fitting.

When assembling the installation fitting package (inlet and outlet), connect the fitting to the plumbing system first and then attach

the nut, split ring and o-ring. Heat from soldering or solvent cements may damage the nut, split ring, or o-ring. Solder joints should

be cool and solvent cements should be set before installing the nut, split ring, and o-ring. Avoid getting primer and solvent cement

on any part of the o-rings, split rings, bypass valve, or control valve.

Plug into an electrical outlet. Note: All electrical connections must be connected according to local codes. (Be certain the outlet is

uninterrupted.)

Install grounding strap on metal pipes.

Control Valve Function and Cycles of Operation

This glass filled Noryl (or equivalent) fully automatic control valve is designed as the primary control center to direct and regulate all

cycles of a water softener or filter. When the WS1 control valve is manufactured as a softener, the control valve can be ordered to

perform downflow or upflow regeneration. The WS1.25 control valve is only available in downflow regeneration. When the WS1 or

WS1.25 control valve is set up as a filter, the control valve can be set to perform downflow regeneration or simply backwash. The

control valve can be set to regenerate on demand (consumption of a predetermined amount of water) and/or as a time clock

(passage of a particular number of days). The control valve can be set so that a softener can meet the Water Quality Association

(WQA) Standard S100 or NSF/ANSI Standard 44 efficiency rating.

It is not recommended to change control valves from downflow to upflow brining or vice versa in the field. The valve bod-

ies for downflow and upflow are unique to the regeneration type and should not be interchanged. A mismatch of valve

body and regeneration piston will result in hard water bypass during service.

The control valve is compatible with a variety of regenerants and resin cleaners. The control valve is capable of routing the flow of

water in the necessary paths to regenerate or backwash water treatment systems. The injector regulates the flow of brine or other

regenerants. The control valve regulates the flow rates for backwashing, rinsing, and the replenishing of treated water into a regen-

erant tank, when applicable.

The control valve uses no traditional fasteners (e.g. screws); instead clips, threaded caps and nuts and snap type latches are used.

Caps and nuts only need to be firmly hand tightened because radial seals are used. Tools required to service the valve include one

small blade screw driver, one large blade screw driver, pliers, and a pair of hands. A plastic wrench is available which eliminates the

need for screwdrivers and pliers. Disassembly for servicing takes much less time than comparable products currently on the market.

Control valve installation is made easy because the distributor tube can be cut ½” above to ½” below the top of tank thread. The

distributor tube is held in place by an o-ring seal and the control valve also has a bayonet lock feature for upper distributor baskets.

The AC adapter power pack comes with a 15 foot power cord and is designed for use with the control valve. The AC adapter power

pack is for dry location use only. The control valve remembers all settings until the battery power is depleted if the power goes out.

After the battery power is depleted, the only item that needs to be reset is the time of day; other values are permanently stored in

the nonvolatile memory. The control valve battery is not rechargeable but is replaceable.

7

Official Warranty

Water Control Corporation

Dakotah Series Water Softeners

Limited Warranty

Water Control Corporation warrants the control valve to be free of manufacturers defects for a period of 3 (three)

years from the date of installation, and the fiberglass reinforced mineral tank, and plastic brine tank, to be free from

leaking due to manufacturer’s defects for a period of 5 (five) years. We will, at our discretion, repair or replace defec-

tive products. This warranty does not include any costs associated with removal of defective products, or installation

of replacement products. All replacement parts will be provided FOB Ramsey, MN. This warranty is transferable.

DISCLAIMER OF IMPLIED WARRANTIES

Water Control Corporation makes no warranties except those expressly stated in this document. To the extent permit-

ted by the laws of the applicable state, ALL WARRANTIES CONTAINED IN THIS DOCUMENT ARE EX-

PRESSLY IN LIEU OF, AND WATER CONTROL CORPORATION EXPRESSLY DISCLAIMS, ANY AND

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MER-

CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

WHAT IS NOT COVERED BY THESE WARRANTIES

1. Conditions and damages resulting from any of the following:

- Wear caused by unfavorable water conditions

- Improper installation, delivery, or maintenance

- Any repair, modification, alteration, or adjustment not authorized

by the manufacturer or an authorized servicer

- Misuse, abuse, accidents, or unreasonable use

- Improper setting of any control

- Incorrect electric current, voltage, or supply

2. Warranties are void if the original serial numbers have been removed, altered, or cannot be readily determined.

3. The cost of service or service call to:

- Correct installation errors

- Instruct the user on proper use of the product

- Transport the product to the servicer

4. Any costs associated with removal of defective products, or installation of replacement products.

5. Consequential, special, or incidental damages sustained by any person as a result of the breach of these

warranties. Some states do not allow the exclusion or limitation of consequential or incidental damages,

so the above exclusion may not apply to you.

8

WaterControlCorporation

7150143rdAveNW●Ramsey,MN55303

Phone:1‐866‐405‐1268●Fax:763‐427‐5665

www.watercontrolinc.com

Table of contents

Other Water Control Water Dispenser manuals

Popular Water Dispenser manuals by other brands

Aqua To Go

Aqua To Go Argento Cleaning instructions

Primo Water

Primo Water 900172 user manual

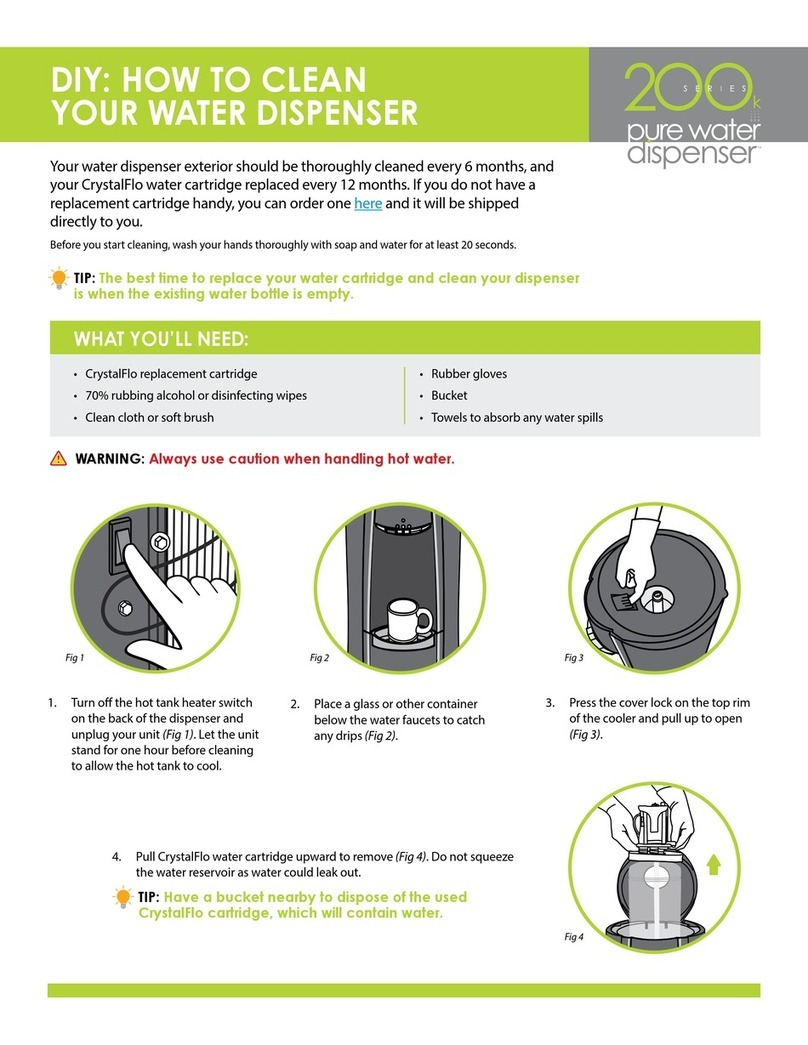

DS Services of America

DS Services of America 200K Series How to Clean

H2O International

H2O International H2O 1000 Operation manual

North Star

North Star NST30ED Installation and operation manual

Spectra Watermakers

Spectra Watermakers Z-Ion Catalina 300 Mk II installation instructions