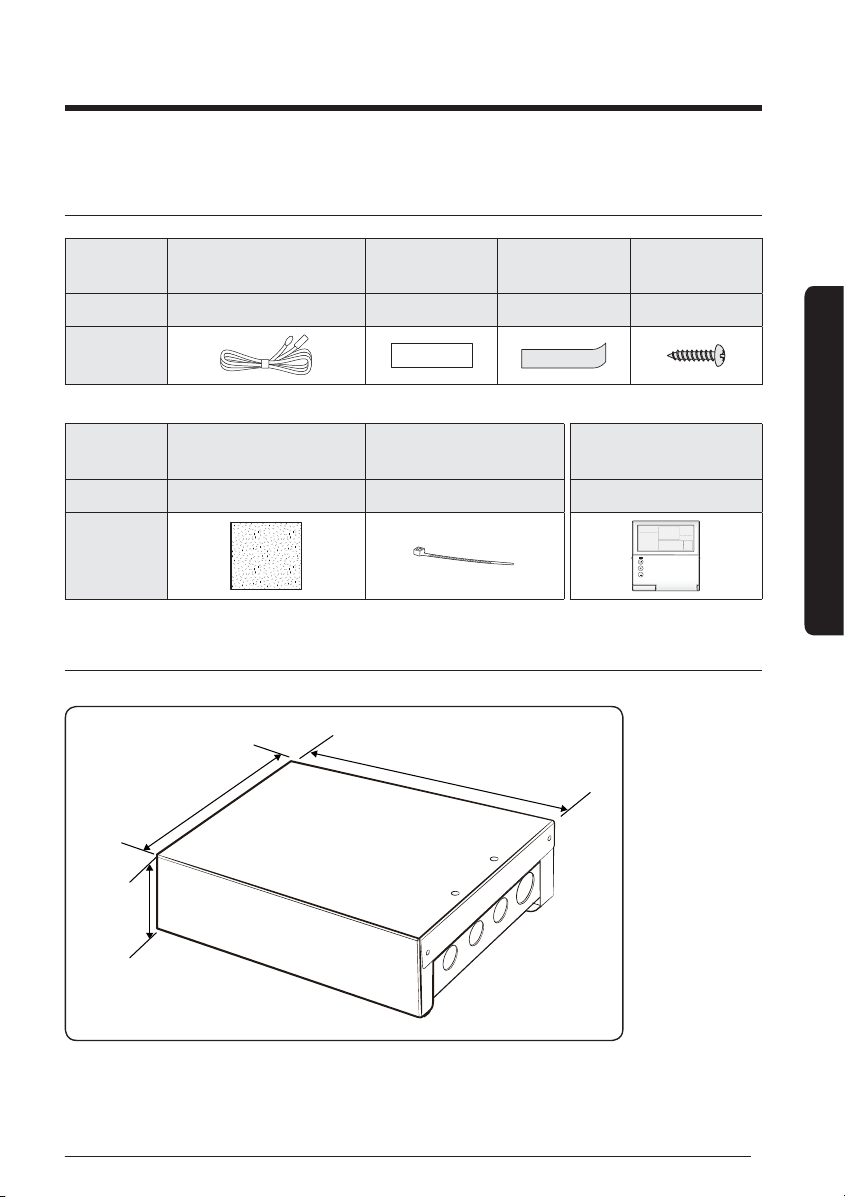

4

PREPARATION

Do not install this product near a heater, inammable material. Do not install this

product in a humid, oily or dusty location, in a location exposed to direct sunlight and

water (rain drops). Do not install this product in a location where gas may leak.

yPotential risk of electric shock or re.

Do not attempt to move or re-install the product that is already installed.

yThere is risk of electric shock or re.

Do not attempt to repair, disassemble, or modify the product yourself.

yThere is risk of product damage, electric shock or re. When repair is needed,

consult service center.

For installation

CAUTION

Install the product on a hard and even place that can support its weight.

yIf the place cannot support its weight, the product may fall down and it may cause

product damage.

Make sure there is no tension to the cable during installation.

yCable may get cut and cause re.

Install the product in a place with temperature between 0~39°C (32~102°F) with

no direct sunlight.

yIf not, there is risk of re or product malfunction.

Do not install the product in a place where special spray or acid/alkali solution is used.

yIf not, there is risk of re or product malfunction.

Do not connect the power cable to the communication cable terminal.

yThere is risk of re.

When installing the product in hospitals or other places, make sure that the product

does not interrupt with other products.

yIf not, there is risk of product malfunction.

Do not allow water to enter the product.

yIf not, there is risk of electric shock or re.

Do not press the buttons with any sharp objects.

yThere is risk of electric shock or damage to the parts.

Safety precautions