Water Process Solutions CHEMTUBE 2000 Manual

Operation & Maintenance Manual

CHEMTUBE® 2000

TUBULAR DIAPHRAGM

METERING PUMP

Manual No.

WPSCH2000MAN

CHEMTUBE® 2000

TUBULAR DIAPHRAGM

METERING PUMP

MANUAL NO. WT.430.500.0AA.UA.IM.0813

EC-DECLARATION OF CONFORMITY

Directives covered by this declaration

89/336/EEC Electromagnetic Compatibility Directive, amended by 92/31/EEC & 93/68/EEC

73/23/EEC Low Voltage Equipment Directive, amended by 93/68/EEC

89/392/EEC Machinery Directive, amended by 91/368/EEC, 93/44/EEC & 93/68/EEC

Products Covered by this declaration

CHEMTUBE® 2000 Tubular Diaphragm Metering Pumps [2", 2.5" & 3"]

The products identified above comply with the requirements of the EMC Directive and

with the principle elements of the safety objectives of the Low Voltage and Machinery

Directives. The following standards have been applied

EMC Emissions: EN 50 081 Parts 1 & 2

EMC Immunity: EN 50 082 Parts 1& 2

Electrical Safety: EN 60034

Machinery Safety: BS EN 292

BS EN 294

The CE mark was first applied in 1996

Date of Declaration: 09/02/14

......................................................

C.B. Dean

Managing Director

WT.430.500.0AA.UA.IM.0813

1.010-42D

EQUIPMENTSERIALNO. .......................................

DATEOFSTART-UP................................................

START-UP BY ...........................................................

Prompt service available from nationwide authorized service contractors.

ORDERING INFORMATION

In order for us to ll your order immediately and correctly, please order material by

description and part number, as shown in this book. Also, please specify the serial

number of the equipment on which the parts will be installed.

Statements and instructions set forth herein are based upon the best information and

practices known to WPS, Inc. at the time of publication, but it should not be assumed

that every acceptable safety procedure is contained herein. WPS does not guarantee

that actions in accordance with such statements and instructions included in this

manual will result in the complete elimination of hazards and it assumes no liability

for accidents that may occur

WT.430.500.0AA.UA.IM.0813

Introd.

Introduction

DESCRIPTION

This instruction book provides information for the proper

installation, operation, and maintenance of the Chemtube® 2000

Tubular Diaphragm Metering Pump. Chemtube 2000 is a

hydraulically actuated tubular diaphragm pump.

The Chemtube 2000 provides accurate metering and transfer of a

wide variety of chemicals and is available in three piston sizes (52,

68, and 88mm), four stroking speeds (36, 72, 96, and 144 strokes per

minute), and a simplex or a double simplex arrangement.

The liquid end uses two diaphragms. A flat disc diaphragm and

tubular diaphragm form a sealed intermediate chamber between

the process fluid (inside the tubular diaphragm) and the hydraulic

fluid (inside the piston displacement cylinder). The liquid surrounding

the tubular diaphragm is a water/propylene glycol mixture (50/50) and

is compatible with most process fluids. There are no mechanical

connections between the two diaphragms and the pump drive. Both

diaphragms are hydraulically balanced during pump operation. The

disc diaphragm is driven by hydraulic fluid, which is driven by the

pump piston. The piston causes the liquid in the intermediate

chamber to displace the tubular diaphragm and create pumping

action with each stroke of the piston.

The pump features built-in, adjustable pressure relief valve and

cartridge type valves for ease of service; an automatic hydraulic

fluid make-up valve that is mechanically actuated by sensing

the position of the flat intermediate diaphragm; a stroke adjuster

(manual or optional electric) that is capable ofvarying the stroke from

zero to 100%; and the electronic leak detection system that monitors

the conductivity of the intermediate fluid and will automatically

signal a change due to leakage through the tubular diaphragm of

the process fluid. Also, when the optional Teflon-lined tubular

diaphragm is used, the Chemtube 2000 pump is capable of handling

a variety of corrosive fluids.

When an electric stroke length positioner or variable speed drive is

used with the pump, a separate instruction manual covering

the particular equipment used will be furnished.

WT.430.500.0AA.UA.IM.0813

Introd. (Cont’d)

WARNING: TO AVOID POSSIBLE SEVERE PERSONAL INJURY

OR DAMAGE TO THE EQUIPMENT, THIS EQUIPMENT SHOULD

BE INSTALLED, OPERATED AND SERVICED ONLY BYTRAINED,

QUALIFIED PERSONNEL WHO ARE THOROUGHLY FAMILIAR

WITH THE ENTIRE CONTENTS OFTHIS INSTRUCTION BOOK.

WHEN DEALING WITH HAZARDOUS MATERIAL IT IS THE

RESPONSIBILITY OFTHE EQUIPMENT USER TO OBTAIN AND

FOLLOW ALL SAFETY PRECAUTIONS RECOMMENDED BYTHE

HAZARDOUS MATERIAL MANUFACTURER/SUPPLIER. AVOID

CONTACTING ELECTRICALLY HOT METER POSTS AND CIRCUIT

BOARD COMPONENTS WHILE MAKING METER ADJUSTMENTS.

NOTE: When submitting correspondence or ordering material,

always specify model and serial number of apparatus.

TABLE OF CONTENTS

Very Important Safety Precautions

Preventive Maintenance General Information

Preventive Maintenance Schedule and Record

of Performance

Protective Equipment and Clothing

Regional Offices

Technical Data

Installation

Operation

Service

Illustrations

Preventive Maintenance Kits

SP-1,-2

1.010-5

1.010-13

1.010-6

1.010-1

Section 1

Section 2

Section 3

Section 4

Section 5

Section 6

WARNING: THIS EQUIPMENT MAY HANDLE HAZARDOUS

MATERIALS SUCH AS ACID OR CAUSTIC, WHICH CAN

CAUSE SEVERE BURN-TYPE INJURIES. WHEN HANDLING

ANY HAZARDOUS MATERIAL, USE EXTREME CARE TO AVOID

CONTACT WITH THE HAZARDOUS MATERIAL AND POSSIBLE

SEVERE PERSONAL INJURY. USE APPROPRIATE PROTECTIVE

CLOTHING AND EYE PROTECTION. REFER TO THE SAFETY

PRECAUTIONS OFTHE MANUFACTURER OFTHE HAZARDOUS

MATERIAL AND THIS EQUIPMENT BOOK FOR FURTHER

IMPORTANT DETAILS AND PRECAUTIONS.

!

!

WT.430.500.0AA.UA.IM.0813

SP-1

Very Important Safety Precautions

This page titled “Very Important Safety Precautions” provides, in brief, information

of urgent importance relative to SAFETY IN THE INSTALLATION, OPERATION, AND

MAINTENANCE of this equipment.

WARNING

TO AVOID POSSIBLE SEVERE PERSONAL INJURY OR DAMAGE TO THE EQUIPMENT,

OBSERVE THE FOLLOWING:

THIS EQUIPMENT SHOULD BE INSTALLED, OPERATED, AND SERVICED ONLYBY

TRAINED,QUALIFIEDPERSONNELWHOARETHOROUGHLYFAMILIARWITHTHE

ENTIRE CONTENTS OFTHIS INSTRUCTION BOOK.

REPLACE GUARD AFTER SERVICING EQUIPMENT.

TURN OFF POWER BEFORE SERVICING.

WHEN DEALING WITH HAZARDOUS MATERIAL ITISTHE RESPONSIBILITYOFTHE

EQUIPMENT USER TO OBTAIN AND FOLLOW ALL SAFETY PRECAUTIONS

RECOMMENDED BYTHE HAZARDOUS MATERIAL MANUFACTURER/SUPPLIER.

USE APPROPRIATE PROTECTIVE CLOTHING AND EYE PROTECTION WHEN

HANDLING HAZARDOUS MATERIAL.

DO NOT DISCARD THIS INSTRUCTION BOOK UPON COMPLETION OF

INSTALLATION. INFORMATION PROVIDED IS ESSENTIALTO PROPER AND SAFE

OPERATION AND MAINTENANCE.

USE ONLYWPS LISTED PARTS, EXCEPT FORTHOSE COMMERCIALLYAVAILABLE

PARTSTHATARE IDENTIFIED BY COMPLETE DESCRIPTION ON THE PARTS LIST.

THE USE OF UNLISTED PARTS CAN RESULT IN EQUIPMENT MALFUNCTIONS

HAVING HAZARDOUS CONSEQUENCES.

ADDITIONALOR REPLACEMENT COPIES OFTHIS INSTRUCTION BOOK ARE

AVAILABLE FROM:

Water Process Solutions

Unit 10 Mill Hall Business Estate

Aylesford, Kent, ME20 7JZ

Phone: +44(0) 1622 719945

Email: enquiries@waterprocesssolutions.com

WT.430.500.0AA.UA.IM.0813

VERY IMPORTANT SAFETY PRECAUTIONS (CONT’D)

NOTE

Minor part number changes may be incorporated into WPS products from time to

time that are not immediately reflected in the instruction book. If such a change has

apparently been made in your equipment and does not appear to be reflected in your

instruction book, contact WPS for information.

Please include the equipment serial number in all correspondence. It is essential for

effective communication and proper equipment identification.

WT.430.500.0AA.UA.IM.0813

1.010-5E

PROTECTYOUR EQUIPMENT INVESTMENT

MINIMIZE DOWNTIME

ORDER A PREVENTIVE MAINTENANCE KIT NOW ... KEEP ONE ON HAND

Quality

+

Preventive

=

Dependable Operation

Equipment

Maintenance

Minimum Downtime

There’s no question about it.

Equipment that is properly maintained is dependable equipment.

It will give optimum performance with minimum unscheduled downtime

WPS manufactures quality equipment designed for performance and reliability.

Each product is carefully tested and inspected before shipment to ensure that it

meets our high standards.

Our equipment is engineered for easy maintenance.

To ensure maximum service

life and minimize unscheduled repairs, we recommend a program of regular preventive

maintenance, as described in the Service section of this book. To support this

program, we developed. standard parts kits. These kits can also be used for minor

emergency repairs to minimize downtime.

We recommend that these kits be available in your stock at all times.

When the

complete kit orany ofits parts are used, the kit should be replaced immediately.

Preventive maintenance kits may be ordered directly from the company that

supplied yourequipment, orthey may be ordered directly from WPS:

For ordering

numbers, refer to the parts list at the rear of this book.

WT.430.500.0AA.UA.IM.0813

1.010-13B

Maintenance &Performance

PREVENTIVE MAINTENANCE SCHEDULE AND RECORD OF PERFORMANCE

This equipment should receive preventive maintenance on a one (1) year cycle.* It is

recommended that the following table be used to plan, schedule, and record this

important work.

Preventive Maintenance Log

Schedule Date

Date Performed

*NOTE: This is the recommended cycle. Your local operating conditions may call for

more frequent preventive maintenance.

WT.430.500.0AA.UA.IM.0813

1.010-6C

Notes On Protective Equipment AndClothing

The following Warning appears in several locations in this book. It is general in nature

due to the variety of hazardous liquids this equipment is capable of handling.

WARNING: WHEN DEALING WITH HAZARDOUS MATERIAL, IT ISTHE RESPONSIBILITY

OF THE EQUIPMENT USER TO OBTAIN AND FOLLOW ALL SAFETY PRECAUTIONS

RECOMMENDED BYTHE MATERIAL MANUFACTURER/SUPPLIER.

It is good general practice to make

use of protective equipment when

handling any hazardous material.

IT IS RECOMMENDED THAT SUCH

PROTECTIVE EQUIPMENT BE USED

BY ALL PERSONS SERVICING THIS

PUMP, ASSOCIATED PIPING, TUBING,

VALVES, AND ACCESSORIES, WHEN

THE EQUIPMENT IS HANDLING ANY

HAZARDOUS MATERIAL.

NOTE:

(1)

ANSI Z87.1 “practice for occupational. .....eye and face protection” recommends

goggles (#1 above) as the “preferred protection” when handling chemicals that

present a hazard from splash, acid burns or fumes; for severe exposure, a face

shield (#2 above) over the goggles is recommended.

(2)

An eye flushing fountain and a deluge-type shower may be recommended

or required by insurance carriers or governmental safety agencies, which should

be consulted for specific requirements.

1. Goggles, flexible fitting, hooded

ventilation (per ANSI Z87.1)

2. Face Shield (per ANSI Z87.1)

3. Chemical Apron

4. Chemical Gloves

WT.430.500.0AA.UA.IM.0813

1.010-1D

Wps Headquarters

INSTALLATION,OPERATION, MAINTENANCE, AND SERVICE INFORMATION

Direct any questions concerning this equipment that are not answered in this

instruction book to the reseller from whom the equipment was purchased. If the

equipment was purchased directly from WPS, contact the office indicated below.

UNITED KINGDOM

Water Process Solutions

Unit 10 Mill Hall Business Estate

Aylesford, Kent, ME20 7JZ

Phone: +44(0) 1622 719945

Email: enquiries@waterprocesssolutions.com

Viton® and Teflon® are registered trademarks of E. I. du Pont de Nemours and Company or its affiliates.

WT.430.500.0AA.UA.IM.0813

1

Section 1 - Technical Data

List Of Contents PARA./DWG. NO.

Technical Data

Capacity Specifications and Motor Selection

High Pressure Effects on Capacity

Illustrations

Performance

Compatibility

Application GuideforWPSSolution

Tanks

1.1

1.2

1.3

430.500.190.010A-F

430.500.190.010A-F

WT.430.500.0AA.UA.IM.0813

2

TechnicalData

1.1 Technical Data

PARAMETER

Type

Service

Capacities

Maximum Liquid Temperature

Control

Ambient Temperature Limits

Accuracy

Operating Range

Suction Condition

Connections

Viscosity/Stroke SpeedLimits

Standard Intermediate Fluid

SPECIFICATION

Hydraulically actuated tubular diaphragm,

simplex, or double simplex.

See Dwg. 430.300.190.010A-F

RefertoPowerRequirements(paragraph1.1.1)

180°F for 316SS valves

150°F for Kynar valves 125°F for PVC valves

Stroke length adjustable -- Manual

Optional Electric Positioner Electrical speed --

Optional

SCR variable

10° to 120°F

±1% of full scale over a 10:1 range

10 to 1

Flooded suction recommended, suction lift

maximum 5’ of water

52 mm piston suction and discharge 1” male

NPT, 1” socket, R1

68 mm piston suction and discharge 1-1/2”

male NPT, 1-1/2” socket, R1-1/2

88 mm piston suction and discharge 2” male

NPT, 2” socket, R2

10,000 centipoise (Brookfield spindle No. 3

@ 12 rpm) under any condition. Higher

viscosities (up to 20,000 centipoise) with

decreased capacity (10 - 15%)

50/50 propylene glycol and distilled water

Piston

Size

inches

(mm)

60 Hz 1725 RPM

50 Hz 1450 RPM

Pounds per Square Inch

bar

Conncection

Cartridge

Valves

Stroke

Frequency

stroke/

min

Capacity

Stroke

Frequency

stroke/min

Capacity

MotorHorespower-Induction(Variable)- 1725RPM

Motor Kilowatts - Induction (Variable) - 1450 RPM

gph

Iph

gph

Iph

Simplex

Double Simplex

Simplex

Double Simplex

1/2

(3/4)

3/4

(1)

1

(1-1/2)

1-1/2

(2)

2

(3)

1

(1-1/2)

2

(3)

3

(5)

0.37

(0.55)

0.55

(0.75)

0.75

(1.11)

1.11

(1.49)

1.49

(2.24)

0.75

(1.11)

1.49

(2.24)

2.24

(3.73)

2

(52)

36

46

175

30

38

144

200

200

13.1

13.3

1” NPT

or

1”

or

R

1

72

92

350

60

77

291

120

180

200

150

200

8

12

13.3

10

13.3

96

123

467

80

103

390

90

130

180

200

150

200

6

6.7

12

13.3

10

13.3

144

185

700

120

154

583

60

90

120

180

200

100

200

4

6

8

8.7

13.3

6.6

13.3

144

185

700

60

90

120

180

200

100

200

4

6

8

8.7

13.3

6.6

13.3

2.5

(68)

36

79

299

30

66

249

125

125

8.3

8.3

1-1/2” NPT

or

1-1/2” Soc

or

R 1-1/2

72

158

598

60

132

498

70

105

125

75

125

4.7

7

8.3

5

8.3

96

211

799

80

176

666

50

75

105

125

125

125

3.3

5

7

8.3

5

8.3

144

317

1200

120

164

1000

35

50

70

105

125

125

125

2.3

3.3

4.7

7

8.3

3.3

8.3

144

317

1200

35

50

70

105

125

125

2.3

3.3

4.7

7

8.3

3.3

8.3

3

(88)

36

132

500

30

110

416

75

75

5

5

2” NPT

or

2”

or R 2

72

264

1000

60

220

833

40

65

75

50

2.7

4.3

5

3.3

5

96

352

1333

80

293

1110

30

45

60

75

2

3

4

5

3.3

144

528

2000

120

440

1667

20

30

40

60

75

75

75

1.3

2

3.7

4

5

2

5

144

528

2000

20

30

40

60

75

75

75

1.3

2

2.7

4

5

2

5

NOTE: PVC seat with TFE ball up to 125 psi (8.3 bar). Kynar seat with glass ball or metalic valves are up to 200 psi (13.3bar)

1.2

CapacitySpecificationsandMotorSelection

WT.430.500.0AA.UA.IM.0813

3

WT.430.500.0AA.UA.IM.0813

4

1.3 High Pressure Effects on Capacity

This pump has been designed to provide a high degree of repeatability

throughout a wide range of pressures. The capacity that can be expected is

nearly that oftheoretical displacement. As discharge pressure increases, a small

decrease in capacity can be expected, approximately 1.0 to 3% per 100 psi.

WT.430.500.0AA.UA.IM.0813

5

LIQUID

REF. NO.

316 S.S

HYPALON

VITON

PVC

TFE

KYNAR 150

O

F

CERAMIC

ACETALDEHYDE

ACETATE SOLVENTS

ACETIC ACID, CRUDE

ACETIC ACID, PURE

ACETIC ACID (10%)

57

57

57

57

3

A

A

A

A

A

C

C

C

C

B

C

C

C

C

C

C

C

C

C

A

A

A

A

A

A

C

A

A

A

A

A

A

A

A

A

ACETIC ACID (80%)

ACETIC ANHYDRIDE

ACETONE

ACETYLENE

ACRYLONITRILE

57

58

B

B

A

A

A

C

A

C

B

C

C

C

C

A

C

C

C

C

A

A

A

A

A

A

N

A

C

C

A

A

A

A

A

N

N

ALUMINIUM CHLORIDE

ALUMINIUM HYDROXIDE

ALUMINIUM NITRATE

ALUMINIUM SULFATE

ALUMS

5

6

3

B

A

A

A

B

A

A

B

A

A

A

A

C

A

C

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

N

A

A

A

AMINES

AMINES (FILMINE) B

AMMONIA ANYHYDROUS (LIQ.)

AMMONIA SOLUTIONS

AMMONIUM CARBONATE

A

A

A

A

A

C

C

B

B

A

C

C

C

B

A

A

A

A

A

A

A

A

A

A

A

N

N

C

A

A

N

N

A

N

A

AMMONIUM CHLORIDE

AMMONIUM DIPHOSPHATE

AMMONIUM HYDROXIDE

AMMONIUM MONOPHOSPHATE

AMMONIUM NITRATE

7

9

8

9

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

N

A

A

A

A

AMMONIUM SULFATE

AMMONIUM SULFIDE

AMMONIUM TRIPHOPH

ATEAMYL ACETATE

AMYL ALCOHOL

10

9

58

11,12

A

A

A

A

A

A

A

A

C

A

A

A

A

C

A

A

A

A

C

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

AMYL CHLOIRDE

ANILINE

ANILINE DYES

ARSENIC ACID

BARIUM CARBONATE

13

14

15

A

A

A

B

B

C

C

B

C

A

C

A

B

A

A

C

C

C

A

A

A

A

A

A

A

A

B

N

A

A

A

A

A

N

A

BARIUM CHLORIDE

BARIUM HYDROXIDE

BARIUM SULFATE

BARIUM SULFIDE

BEER

14,15

A

A

A

B

B

B

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

N

A

A

A

BEET SUGAR LIQUORS

BENZALDEHYDE

BENZENE OR BENZOL

BENZOIC ACID

BLACK SULFATE LIQUOR

13,14

57

A

A

A

A

A

C

C

C

C

B

A

C

V

A

A

A

C

C

A

A

A

A

A

A

A

A

B

B

A

A

A

A

A

A

A

BORAX(SEE SODIUM BORATE)

BORIC ACID

BUTANE

BUTADIENE

BUTYL ACETATE

16

-

A

A

A

A

-

A

A

A

A

-

A

B

B

N

-

A

A

A

B

-

A

A

A

A

-

A

A

A

C

-

A

A

A

N

WARNING:

WHEN DEALING WITH HAZARDOUS MATERIALS, IN ALL CASES THE HAZARDOUS MATERIAL SUPPLIERS

OR MANUFACTURERS’ RECOMMENDATIONS FOR SAFETY PROCEDURES MUST BE OBTAINED AND FOLLOWED.

CHEMICALCOMPATIBILITYOFMETERING PUMPS-PERFORMANCE

430.500.190.010A

ISSUE 04-98

WT.430.500.0AA.UA.IM.0813

6

LIQUID

REF. NO.

316 S.S

HYPALON

VITON

PVC

TFE

KYNAR 150

O

F

CERAMIC

BUTYL ALCOHOL

BUTYRIC ACID

CALCIUM BISULFITE

CALCIUM CARBONATE

CALCIUM CHLORATE

17

14

15

A

A

A

A

A

A

A

A

A

A

A

B

A

A

A

A

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

A

CALCIUM CHLORIDE

CALCIUM HYDROXIDE

CALCIUM HYPOCHLORITE

CALCIUM NITRATE

CALCIUM SULFATE

18

15

B

A

C

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

C

B

A

N

CANE SUGAR LIQUORS

CARBOLIC ACID (PHENOL)

CARBON BISULFIDE

CARBONIC ACID

CARBON TETRACHLORIDE

14

11,14,57

14,57

13,3

A

A

A

A

A

C

C

C

A

C

B

A

A

A

A

N

A

A

A

C

A

A

N

A

A

A

A

N

A

A

A

A

N

N

A

CHLORACETIC ACID

CHLOROBENZENE (DRY)

CHLOROFORM

CHORSULPHONIC ACID

CHROMIC ACID

19,58

C

A

A

B

A

C

C

C

C

A

C

A

A

C

A

A

C

C

A

A

C

A

A

C

A

A

A

A

A

A

A

A

A

A

A

CITRIC ACID

COPPER ACETATE

COPPER CHLORIDE

COPPER CYANIDE

COPPER NITRATE

20

5

3

3

A

A

C

A

A

A

C

B

A

A

A

C

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

N

A

N

A

COPPER CULFATE

CREOSOTE

CRESYLIC ACID (50%)

CYCLOHEXANE

DETERGENT

21

3

A

A

A

A

N

A

C

C

C

A

A

A

A

A

A

A

C

A

C

A

A

A

A

A

A

A

A

A

A

A

A

A

N

A

A

DIETHYLAMINE

DIETHYLENE GLYCOL

DOWNTHERMS

ETHERS (ETHYL)

ETHYL ACETATE

57

A

A

A

A

N

C

A

C

C

C

C

A

A

B

C

C

A

C

C

C

N

A

N

A

A

A

N

N

B

C

A

A

N

A

A

ETHYL ACLCOHOL

ETHYL CHLORIDE

ETHYLENE CHLORIDE

ETHYLENE GLYCOL

ETHYL MERCAPTAN

12

22

12

A

A

A

A

A

A

C

C

A

C

A

A

B

A

N

A

C

C

A

N

A

A

A

A

N

A

A

A

A

N

A

A

N

A

N

ETHYLENE OXIDE

FATTY ACIDS

FERRIC CHLORIDE

FERRIC NITRATE

FERRIC SULFATE

14

6

24

A

A

C

A

B

C

C

A

A

A

C

A

A

A

A

C

A

A

A

A

A

A

A

A

A

C

A

A

A

A

A

A

A

A

A

FERROUS CHLORIDE

FERROUS SULFATE

FILTER AID

FLUOSILICIC ACID

FORMALDEHYDE

14

15

6,25,26

A

A

C

A

B

C

C

A

A

A

C

A

A

A

A

C

A

A

A

A

A

A

A

A

A

C

A

A

A

A

A

A

A

A

A

FORMIC ACID

FRUIT JUICES

FURFURAL

GALLIC ACID (5%)

GASOLINE

3,58

57

A

A

A

A

A

A

C

C

C

C

B

A

C

A

A

B

A

C

A

A

A

A

A

A

A

A

A

A

B

A

A

A

A

A

A

CHEMICALCOMPATIBILITYOFMETERING PUMPS-PERFORMANCE

430.500.190.010B

ISSUE 0 4-98

WT.430.500.0AA.UA.IM.0813

7

LIQUID

REF. NO.

316 S.S

HYPALON

VITON

PVC

TFE

KYNAR 150

O

F

CERAMIC

GLUCOSE

GLYCEROL (GLYCERIN)

HEPTANE, HEXANE

HYDRAZINE (35%)

HYDROBROMIC ACID

6,11,27

28

29

A

A

A

A

C

A

A

A

B

A

A

A

A

C

A

A

A

C

N

A

A

A

A

N

A

A

A

A

A

A

A

A

A

B

A

HYDROCHLORIC ACID (37%)

HYDROCYANIC ACID

HYDROFLUORIC ACID

HYDROFLUOSILICIC ACID

HYDROGEN PEROXIDE

5,30

6,26,25

6,25,26,57

31,59

C

A

C

B

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

C

C

A

HYDROGEN SULFIDE

INKS

IODINE SOLUTION

KEROSENE

LACTIC ACID

11,3

19

32,57

A

A

C

A

A

A

A

B

C

A

A

A

A

A

A

A

A

C

A

A

A

A

A

A

A

A

N

A

A

A

A

N

A

A

A

LEAD ACETATE

LIME SLURRIES

LINSEED OIL

MAGNESIUM CARBONATE

MAGNESIUM CHLORIDE

15

6,34

A

A

A

A

C

C

A

A

A

A

C

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

N

A

A

A

A

N

A

A

A

MAGNESIUM HYDROXIDE

MAGNESIUM NITRATE

MAGNESIUM SULFATE

MALEIC ACID (DILUTE)

MALIC ACID

6,15

14,5

5,14

14

A

A

A

A

A

A

A

A

C

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

N

A

A

A

A

MELAMINE RESINS

MERCURIC CHLORIDE

MERCURIC CYANIDE

MERCURY

METHYL ACETATE

5

57

A

C

A

A

A

C

A

A

A

C

N

A

A

A

C

A

A

A

A

N

A

A

A

A

A

N

A

A

A

A

A

A

N

A

N

METHYL ACETONE

METHYL ALCOHOL

METHYLAMINE

METHYL BROMIDE

METHYL CELLOSOLVE

35

A

A

A

A

A

C

A

C

C

C

C

B

C

A

C

C

A

N

C

N

N

A

N

N

A

N

A

C

A

A

N

A

N

N

A

METHYL CHLORIDE (LIQ.)

METHYLETHYL KETONE

METHYLENE CHLORIDE

MOLASSES

MONOCHLORACETIC ACID

36,14

A

A

A

A

C

C

C

C

A

N

C

C

B

A

N

C

C

C

A

A

A

A

A

A

A

A

C

C

A

A

A

A

A

N

A

MORPHOLINE

NAPHTHA

NAPHTHALENE

NICKEL CHLORIDE

NICKEL NITRATE

57

13

11

14

A

A

A

A

A

C

C

C

A

A

C

A

A

A

A

A

A

C

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

NICKEL SULFATE

NICOTINIC ACID

NITRIC ACID (10%)

NITRIC ACID (70%) TO 100

O

F

NITROBENZENE

14

60

60

A

A

A

B

A

A

C

A

C

C

A

A

A

B

C

A

A

A

A

C

A

N

A

A

A

A

A

A

A

B

A

A

A

A

A

OILS, ANIMAL

OIL, COTTONSEED

SOILS, FUEL

OLEIC ACID

OLEUM (20-25%)

11,58

37,14

3

A

A

A

A

A

C

A

A

C

C

A

A

A

C

B

A

A

A

A

C

A

A

A

A

A

A

A

A

A

C

A

A

A

A

A

CHEMICALCOMPATIBILITYOFMETERING PUMPS-PERFORMANCE

430.500.190.010C

ISSUE 0 4-98

WT.430.500.0AA.UA.IM.0813

8

LIQUID

REF. NO.

316 S.S

HYPALON

VITON

PVC

TFE

KYNAR 150

O

F

CERAMIC

OXALIC ACID

PALMITIC ACID

PERCHLORIC ACID (10%)

PERCHLOROETHYLENE (DRY)

PHENOL (CARBOLIC ACID)

3

11

11

B

A

C

A

A

A

C

B

C

C

A

A

N

A

A

A

A

B

C

A

A

A

N

N

A

A

A

A

A

A

A

N

N

N

A

PHOSPHORIC ACID

PHOSPHORUS TRICHLORIDE

PICRIC ACID

POTASSIUM BICARBONATE

POTASSIUM BROMATE

6,11,39

57

A

N

A

A

N

A

C

A

A

N

A

A

A

A

N

A

C

C

A

A

A

A

A

A

A

A

A

A

A

A

A

A

N

A

N

POTASSIUM BROMIDE

POTASSIUM CARBONATE

POTASSIUM CHLORATE

POTASSIUM CHLORIDE

POTASSIUM CHROMATE

40

3

5,41

A

A

A

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

N

POTASSIUM CYANIDE

POTASSIUM DIPHOSPHATE

POTASSIUM HYDROXIDE

POTASSIUM MONOPHOSPHATE

POTASSIUM NITRATE

42

A

A

A

A

A

A

N

A

A

A

A

A

C

A

A

A

A

A

A

A

A

N

A

N

A

A

N

A

N

A

N

N

C

N

A

POTASSIUM PERMANGANATE

POTASSIUM SULFATE

POTASSIUM SULFIDE

POTASSIUM SULFITE

POTASSIUM TETRABORATE

5,43

41,5

A

A

A

A

N

A

A

N

B

N

A

A

A

A

N

A

A

A

A

A

A

A

A

N

N

A

A

A

N

N

A

N

A

N

N

PROPANE (LIQ.)

PROPYL ALCOHOL

PROPYLENE GLYCOL

RESINS & ROSINS

SEA WATER

12,58

A

A

A

A

B

A

A

A

N

A

B

A

A

A

A

A

B

C

N

A

A

A

A

A

A

A

A

A

N

A

A

N

A

N

A

SILVER NITRATE

SOAP SOLUTIONS (STEARATES)

SODIUM ACETATE

SODIUM ALUMINATE 27Be

SODIUM BICARBOATE

6,57

A

A

A

A

A

A

A

C

A

A

A

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

SODIUM BISULFATE (TO 100

O

F)

SODIUM BISULFITE (TO 100

O

F)

SODIUM BORATE

SODIUM CARBONATE

SODIUM CHLORATE

14

44

14

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

N

A

A

SODIUM CHLORIDE

SODIUM CHLORITE (TO 20%)

SODIUM CHROMATE

SODIUM CYANIDE

SODIUM DI- OR TRIPHOSPHATE

3

45

B

C

A

A

A

A

N

N

A

A

A

N

A

A

A

A

C

A

A

A

A

N

A

A

A

A

A

A

A

A

A

A

N

A

A

SODIUM FLUORIDE

SODIUM HYDROXIDE 20%

SODIUM HYDROXIDE 50%

SODIUM HYPOCHLORITE

SODIUM MONOPHOSPHATE

25,46

5,3,6

5,3,6

30,13,47

B

A

A

C

A

A

A

A

A

A

A

C

C

B

A

A

C

C

B

A

A

A

A

A

A

A

A

A

A

A

C

C

C

N

A

SODIUM NITRATE

SODIUM PERBORATE

SODIUM PEROXIDE

SODIUM POLYPHOSPHATE

SODIUM SILICATE

48

6

49

A

A

A

A

A

A

B

A

B

A

A

A

A

A

A

A

B

B

A

B

A

A

A

A

A

A

N

A

A

A

A

N

A

A

A

CHEMICALCOMPATIBILITYOFMETERING PUMPS-PERFORMANCE

430.500.190.010D

ISSUE 0 4-98

Table of contents

Other Water Process Solutions Water Pump manuals

Popular Water Pump manuals by other brands

ProMinent

ProMinent DULCOflex DFDa operating instructions

Kamoer

Kamoer X1 quick start guide

APS

APS 55K DIESEL HUSKY Operation and maintenance manual

Homa

Homa TP 53 Original instruction manual

AMT

AMT Submersible Pump 12VDC Series Specifications information and repair parts manual

Grundfos

Grundfos Unilift AP12 Installation and operating instructions

Ballons CHAIZE

Ballons CHAIZE JZX 18F12 Flight manual

GIANT PUMPS

GIANT PUMPS P55W Repair instructions

Pentair

Pentair HYPRO 9305C Series Installation and operation manual

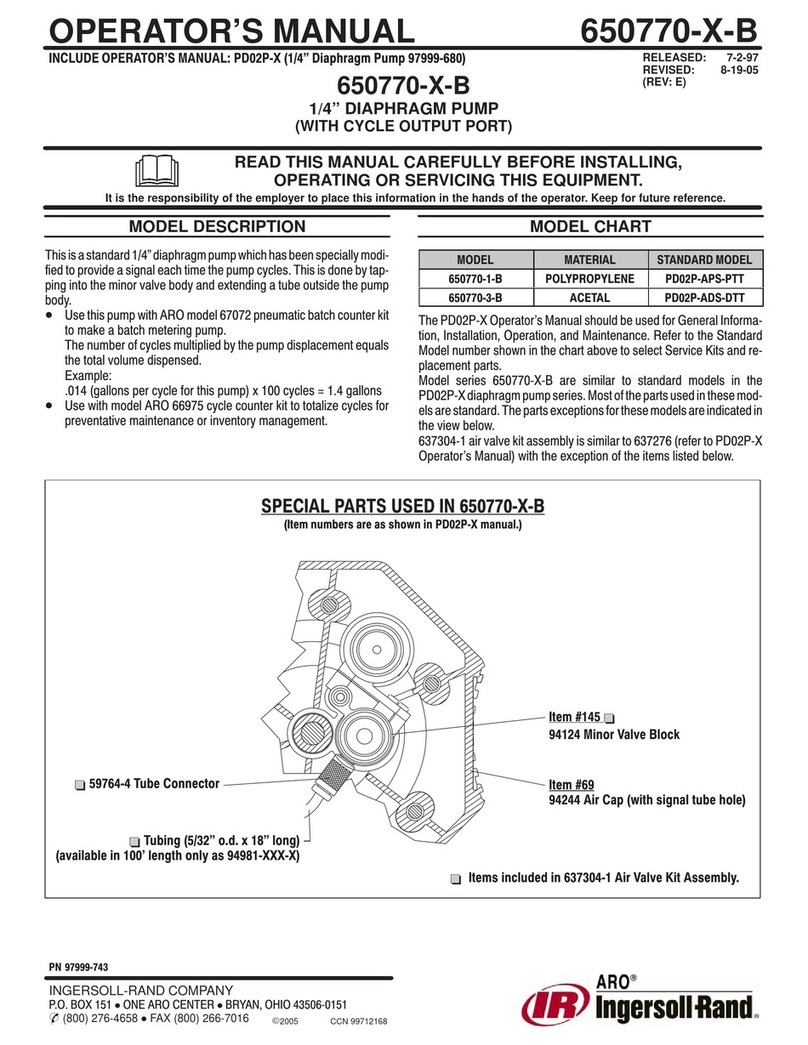

Ingersoll-Rand

Ingersoll-Rand 650770-X-B Operator's manual

BVA Hydraulics

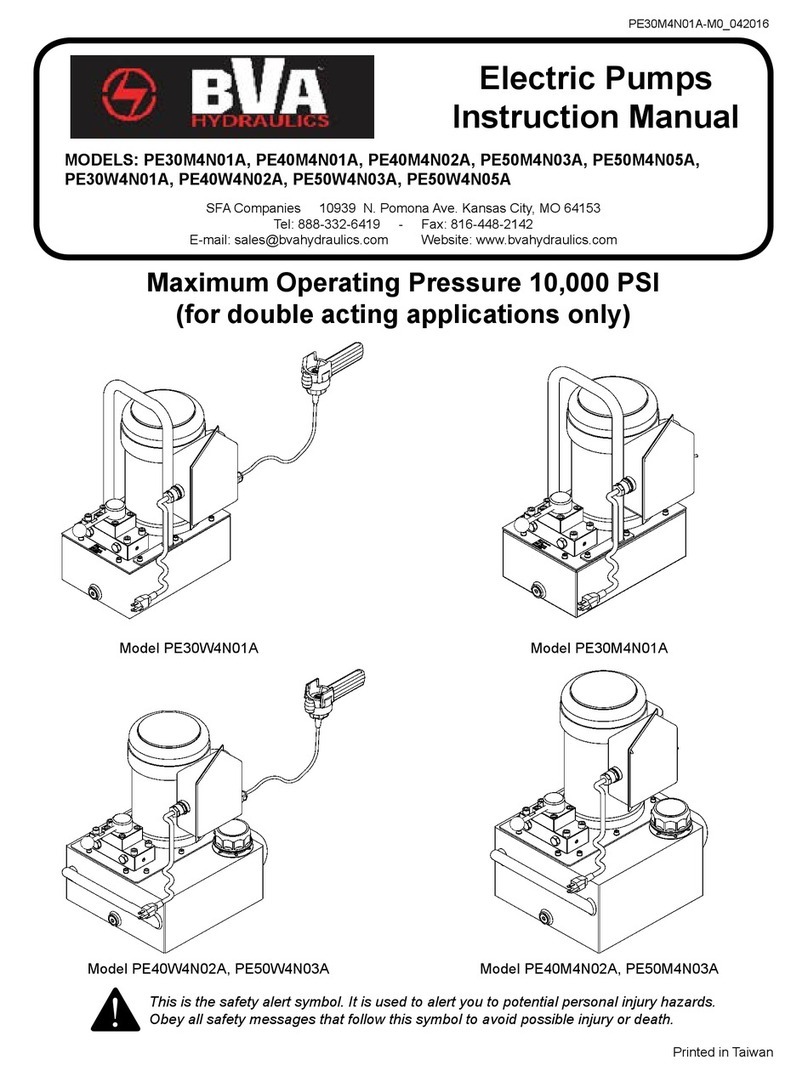

BVA Hydraulics PE30M4N01A instruction manual

SPX

SPX L450 instruction manual