Water Process Solutions Encore 700 Manual

ENCORE® 700 DIAPHRAGM

METERING PUMP

MANUAL NO. WT.440.400.001.UA.IM.1012

V 2.0

ENCORE® 700

DIAPHRAGM

METERING PUMP

MANUALNO.WT.440.400.001.UA.IM.1012

ENCORE® 700 METERING PUMP

EQUIPMENTSERIALNO._____________________________

DATEOFSTART-UP________________________________

START-UP BY ____________________________________

Prompt service available from nationwide authorized service contractors.

ORDERINGINFORMATION

In order for us to fill your order immediately and correctly, please order material by description and part number, as shown

in this manual. Also, please specify the serial number of the equipment on which the parts will be installed.

Statements and instructions set forth herein are based upon the best information and practices known to WPS at the time

of publication, but it should not be assumed that every acceptable safety procedure is contained herein. WPS does not

guarantee that actions in accordance with such statements and instructions included in this manual will result in the

complete elimination of hazards and it assumes no liability for accidents that may occur.

WT.440.400.001.UA.IM.1012

1.010-

ENCORE® 700 METERING PUMP

INTRODUCTION

This manual provides installation, operating, and maintenance instructions

for the Encore® 700 Diaphragm Metering Pumps,

here in after referred

to as the "pump" or "metering pump". The pump

provides accurate

metering and transfer of a wide variety of chemicals.

It is available in

six head sizes, three gear ratios, direct and pulley drive configurations,

and a single or double simplex configuration. A non-loss-

of-motion

stroke adjustment is used to vary the stroke for a smoother

pumping

action. Non-loss-of-motion is achieved through the use of a

variable

eccentric mechanism. Stroke adjustment is accomplished either

manually or with an optional electric stroke length positioner.

An optional Silicon Control Rectifier (SCR) controls drive motor speed

variations through a signal received from an external source.

When an electric stroke length positioner and/or variable speed drive

is used with the pump, a separate instruction manual for each will be

furnished.

WARNING: TO AVOID POSSIBLE SEVERE PERSONAL IN-

JURY OR DAMAGE TO THE EQUIPMENT, THIS EQUIPMENT

SHOULD BE INSTALLED, OPERATED AND SERVICED ONLY

BY TRAINED, QUALIFIED PERSONNEL WHO ARE THOR-

OUGHLY FAMILIAR WITH THE ENTIRE CONTENTS OF THIS

INSTRUCTION MANUAL. WHEN DEALING WITH HAZARDOUS

MATERIAL IT IS THE RESPONSIBILITY OF THE EQUIPMENT

USER TO OBTAIN AND FOLLOW ALL SAFETY PRECAUTIONS

RECOMMENDED BY THE MATERIAL MANUFACTURER/SUP-

PLIER. AVOID CONTACTING ELECTRICALLY HOT METER

POSTS AND CIRCUIT BOARD COMPONENTS WHILE MAKING

METER ADJUSTMENTS.

NOTE: When submitting correspondence always specify model and

serial number of apparatus.

!

IWT.440.400.001.UA.IM.1012

Introd.

ENCORE® 700 METERING PUMP

Table of Contents

Very Important Safety Precautions ......................................SP-1,-2,-3

Preventive Maintenance Schedule and Record of

Performance

............................................................................

1.010-13

Notes on Protective Equipment and Clothing

..........................

1.010-6

Protect Your Equipment Investment

........................................

1.010-5

Headquarters

.............................................................................

1.010-1

Technical Data ....................................................................Section 1

Installation ......................................................................... Section 2

Operation...........................................................................Section 3

Service ...............................................................................Section 4

Illustrations ........................................................................ Section 5

Preventive Maintenance Kits and Spare Parts List.................Section 6

Capacity Test Data ..............................................................Section 7

WT.440.400.001.UA.IM.1012 lntrod. (Cont'd)

ENCORE® 700 METERING PUMP

VERY IMPORTANT SAFETY PRECAUTIONS

This page provides very important safety information related to safety in installation, operation, and

maintenance of this equipment.

WARNING

TO AVOID POSSIBLE SEVERE PERSONAL INJURY OR EQUIPMENT DAMAGE, OBSERVE THE FOLLOWING:

THIS EQUIPMENT SHOULD BE INSTALLED, OPERATED AND SERVICED ONLY BY TRAINED, QUALIFIED PER-

SONNEL WHO ARE THOROUGHLY FAMILIAR WITH THEENTIRE CONTENTS OF THIS INSTRUCTION MANUAL.

WHEN HAZARDOUS CHEMICALS ARE BEING PUMPED, AND/OR ELEVATED PRESSURE/TEMPERATURES

ARE ENCOUNTERED, RIGID PIPE IS RECOMMENDED. WHEN WORKING WITH RIGID PIPING COMPONENTS,

LATERAL AND TORSIONAL FORCES IN THE METERING PUMP SUCTION AND DISCHARGE FITTINGS MUST

BE AVOIDED. THESE FORCES CAN LEAD TO COMPONENT FAILURE, WHICH COULD RELEASE HAZARDOUS

CHEMICALS THAT COULD PRESENT A PERSONAL HAZARD AS WELL AS AN ENVIRONMENTAL HAZARD.

IN RARE CASES, THESE FORCES CANNOT BE ELIMINATED THROUGH THE APPLICATION OF PROPER

PIPING PRACTICES AND/OR PIPING SUPPORT SYSTEMS. IN THESE CASES WPS SHOULD

BE CONSULTED

TO AID IN THE SELECTION OF AN APPROPRIATE FLEXIBLE CONNECTOR.

DUE TO THE SINUSOIDAL FLUID DELIVERY CHARACTERISTICS OF A RECIPROCATING METERING PUMP,

ADDITIONAL PRESSURE IS CREATED IN THE SUCTION AND DISCHARGE LINE TO OVERCOME THE INERTIA

OF THE FLUID AT REST IN THE LINES. INERTIAL PRESSURE ENCOUNTERED IN THE LINES IS A FUNCTION OF

SEVERAL FACTORS (LINE SIZE AND LENGTH, VISCOSITY OF THE FLUID, STROKING SPEED, FLUID DELIVERY

RATE, ETC.). THE SUCTION AND DISCHARGE LINES MUST BE SIZED TO THE PRESSURE SURGES DEVELOPED

IN THE LINES. INERTIAL PRESSURE SURGE CAN CREATE STRESSES IN THE PIPING THAT COULD LEAD TO

COMPONENT FAILURE. IF THE PULSING EFFECTS OF THIS PHENOMENON CANNOT BE CONTROLLED BY

PROPER LINE SIZING, THEN ENGINEERING CONTROLS SUCH AS VENTED RISERS, PULSATION

DAMPENERS, OR HEADBOXES CAN BE EMPLOYED TO MINIMIZE THE STRESSES PRODUCED IN THE

PIPING SYSTEM CAUSED BY THE PRESSURE SURGES. IT IS IMPORTANT TO NOTE THAT THESE ENGINEERING

CONTROLSREQUIRE PERIODIC MAINTENANCE. ADDITIONALLY, THE OPERATORS ANDSERVICE PERSONNEL

OF THIS EQUIPMENT MUST HAVE A WORKING UNDERSTANDING OF THE ENGINEERED CONTROL DEVICES

FUNCTION, AND THE CONSEQUENCES OF MISAPPLICATION AND/OR INADEQUATE MAINTENANCE.

IT IS THE RESPONSIBILITY OF THE OWNER TO ENSURE THAT THE INSTALLATION, OPERATION, AND

MAINTENANCE OF THIS EQUIPMENT AND ITS ASSOCIATED COMPONENTS ARE IN COMPLIANCE WITH

ALL FEDERAL, STATE, AND LOCAL REGULATIONS.

AVOID CONTACTING ELECTRICALLY HOT METER POSTS AND CIRCUIT BOARD COMPONENTS WHILE MAK-

ING METER ADJUSTMENTS.

WHEN DEALING WITH HAZARDOUS MATERIALS, IT IS THE RESPONSIBILITY OF THE EQUIPMENT USER

TO OBTAIN AND FOLLOW ALL SAFETY PRECAUTIONS RECOMMENDED BY THE HAZARDOUS MATERIAL

MANUFACTURER/SUPPLIER.

IWT.440.400.001.UA.IM.1012

SP-1

ENCORE® 700 METERING PUMP

VERY IMPORTANT SAFETY PRECAUTIONS (CONT'D)

CONSULT YOUR REPRESENTATIVE IF THE PUMP IS TO BE USED UNDER CONDITIONS OTHER THAN

ORIGINALLY SPECIFIED AND IF THERE IS ANY QUESTION REGARDING THE SIZE OF

THE DISCHARGE

LINE.

USE RIGID PIPE WHEN HAZARDOUS CHEMICALS ARE PUMPED AND/OR ELEVATED PRESSURE/TEMPERA-

TURES ARE ENCOUNTERED.

USE EXTREME CARE TO AVOID CONTACT WITH THE MATERIAL AND POSSIBLE SEVERE PERSONAL INJURY.

CONSULT YOUR CHEMICAL SUPPLIER FOR INSTRUCTIONS IN THE PREPARATION OF SOLUTIONS AND THE

HANDLING OF CHEMICALS. OBSERVE ALL RECOMMENDED SAFETY PRECAUTIONS.

DO NOT SPILL SOLUTION. IF ANY SOLUTION IS SPILLED, DILUTE OR WASH AWAY WITH WATER IMMEDI-

ATELY OR FOLLOW SUPPLIER'S INSTRUCTIONS FOR HAZARDOUS MATERIALS.

AVOID BEING SPRAYED WITH LIQUID UNDER PRESSURE. PRIOR TO DISASSEMBLY OF PIPE CONNECTIONS

REFER TO SERVICE SECTION FOR DETAILED INSTRUCTIONS ON RELIEVING PRESSURE AND DRAINING.

ALLOW SYSTEM TO DRAIN FULLY BEFORE ATTEMPTING TO DISASSEMBLE PIPING AND REMOVING VALVES

AND/OR HEAD.

SINCE THE STORAGE AND HANDLING OF SODIUM CHLORITE PRESENTS VERY SPECIFIC HAZARDS, THE

USER MUST SEEK THE ADVICE OF THE SODIUM CHLORITE SUPPLIER WITH REFERENCE TO STORAGE FA-

CILITIES, HANDLING PRECAUTIONS AND HEALTH HAZARDS.

SODIUM CHLORITE, WHEN FINELY DIVIDED IN THE PRESENCE OF ORGANIC COMPOUNDS, IS A POSSIBLE

FIRE HAZARD. FOR THIS REASON, EXTREME CARE MUST BE EXERCISED TO PREVENT SOLUTIONS FROM

DRYING OUT IN THE THREADED PORTIONS OF THE PUMP BODY AND RELATED PARTS. OBSERVE CARE-

FULLY THE MANUFACTURER/SUPPLIER'S RECOMMENDED SAFETY PROCEDURES AND THE HANDLING

AND STORAGE PROCEDURES IN THIS MANUAL.

WHEN SERVICING HEADS AND/OR VALVES, FOLLOW PROCEDURES IN THE SERVICE SECTION FOR

DISASSEMBLY.

USE EXTREME CARE TO AVOID CONTACT BECAUSE LIQUID IS PRESENT BETWEEN DISCHARGE DRAIN

VALVE AND UNION ELBOW. FLUSH SPILLED LIQUID IMMEDIATELY.

USE EXTREME CARE TO AVOID CONTACT WITH THE MATERIAL AND POSSIBLE SEVERE PERSONAL INJURY.

WHEN USING HAZARDOUS MATERIAL, OBSERVE ALL SAFETY PRECAUTIONS RECOMMENDED BY THE

HAZARDOUS MATERIAL MANUFACTURER/SUPPLIER. USE APPROPRIATE PROTECTIVE CLOTHING AND EYE

PROTECTION WHEN HANDLING HAZARDOUS MATERIAL.

USE EXTREME CARE TO AVOID CONTACT WITH LIQUID PRESENT IN HEAD. ALLOW SUCTION VALVE TO

FALL INTO SUITABLE CONTAINER AND CATCH LIQUID.

TURN POWER OFF BEFORE SERVICING.

WT.440.400.001.UA.IM.1012

SP-2

ENCORE® 700 METERING PUMP

VERY IMPORTANT SAFETY PRECAUTIONS (CONT'D)

DO NOT RUN THE PUMP WITH THE BELT GUARD REMOVED.

USE ONLY WPS LISTED PARTS EXCEPT FOR COMMERCIALLY AVAILABLE PARTS WHICH

ARE IDENTIFIED

BY COMPLETE DESCRIPTION ON PARTS LIST. THE USE OF UNLISTED PARTS CAN RESULT IN EQUIPMENT

MALFUNCTIONS HAVING HAZARDOUS CONSEQUENCES.

THIS EQUIPMENT SHOULD BE INSTALLED, OPERATED AND SERVICED ONLY BY TRAINED, QUALIFIED PER-

SONNEL WHO ARE THOROUGHLY FAMILIAR WITH THE ENTIRE CONTENTS OF THE INSTRUCTION MANUAL.

DO NOT DISCARD THIS INSTRUCTION MANUAL UPON COMPLETION OF INSTALLATION. INFORMATION

PROVIDED IS ESSENTIAL FOR PROPER AND SAFE OPERATION AND MAINTENANCE.

ADDITIONAL OR REPLACEMENT COPIES OF THIS INSTRUCTION MANUAL ARE AVAILABLE FROM:

Water Process Solutions

Unit 10 Mill Hall Business Estate

Aylesford, Kent, ME20 7JZ

Phone: +44(0) 1622719945

Email: enquires@waterprocesssolutions.com

NOTE

Minor part number changes may be incorporated into WPS products from time to time that are not

immediately reflected in this instruction manual. If such a change apparently has been

made in your

equipment and does not appear to be reflected in your instruction manual, contact your local WPS

sales office for information.

Please include the equipment serial number in all correspondence. It is essential for effective com-

munication and proper equipment identification.

IWT.440.400.001.UA.IM.1012

SP-3

ENCORE® 700 METERING PUMP

PREVENTIVE MAINTENANCE SCHEDULE

AND RECORD OF PERFORMANCE

This equipment should receive preventive maintenance on a one (1) year cycle.* It is recommended

that the following table be used to plan, schedule, and record this important work.

Preventive Maintenance Log

Schedule Date Date Performed

*NOTE: This is the recommended cycle. Your local operating conditions may call for

more frequent preventive maintenance.

PROTECT YOUR EQUIPMENT INVESTMENT

MINIMIZE DOWNTIME

ORDER A PREVENTIVE MAINTENANCE KIT NOW ...

KEEP ONE ON HAND

Date of Installation

WT.440.400.001.UA.IM.1012

1.010-13

ENCORE® 700 METERING PUMP

NOTES ON PROTECTIVE EQUIPMENT AND CLOTHING

The following Warning appears in several locations in this manual. It is general in nature

due to the variety of hazardous liquids this equipment is capable of handling.

WARNING: WHEN DEALING WITH HAZARDOUS MATERIAL, IT IS THE RE-

SPONSIBILITY OF THE EQUIPMENT USER TO OBTAIN AND FOLLOW ALL

SAFETY PRECAUTIONS RECOMMENDED BY THE HAZARDOUS MATERIAL

MANUFACTURER/SUPPLIER.

It is good general practice to make use

of protective equipment when handling

any hazardous material.

IT IS RECOMMENDED THAT SUCH PROTEC-

TIVE EQUIPMENT BE USED BY ALL PER-

SONS SERVICING THIS PUMP, ASSOCIATED

PIPING, TUBING, VALVES, AND

ACCESSORIES, WHEN THE EQUIPMENT IS

HANDLING ANY HAZARDOUS MATERIAL.

NOTE: (1) ANSI Z87.1 “practice for occupational.......eye and face protection” recommends goggles

(#1 above) as the “preferred protection” when handling chemicals that present a hazard

from splash, acid burns or fumes; for severe exposure, a face shield (#2 above) over the

goggles is recommended.

(2) An eye flushing fountain and a deluge-type shower may be recommended or required by

insurance carriers or governmental safety agencies, which should beconsulted for specific

requirements.

1. Goggles, flexible fitting,

hooded ventilation

(per ANSI Z87.1)

2. Face Shield

(per ANSI Z87.1)

3. Chemical Apron

4. Chemical Gloves

IWT.440.400.001.UA.IM.1012

1.010-6

ENCORE® 700 METERING PUMP

Quality

+

Preventive

=

Dependable Operation

Equipment

Maintenance

Minimum Downtime

There's no question about it.

Equipment that is properly maintained is dependable equipment.

It will give optimum performance with minimum unscheduled downtime.

WPS manufactures quality equipment designed for performance and reliability.

Each

product is carefully tested and inspected before shipment to ensure that

it meets our

high standards.

Our equipment is engineered for easy maintenance.

To ensure maximum service life and

minimize unscheduled repairs, we recommend a program of regular preventive maintenance,

as described in the Service section of this manual. To support this program, we developed

standard parts kits. These kits can also be used for minor emergency repairs to minimize

downtime.

We recommend that these kits be available in your stock at all times.

When the complete

kit or any of its parts are used, the kit should be replaced immediately.

Preventive maintenance kits may be ordered directly from the company that supplied

your equipment, or they may be ordered directly from WPS

for ordering

numbers, refer

to the parts list at the rear of this manual.

WT.440.400.001.UA.IM.1012

1.010-5

ENCORE® 700 METERING PUMP

WPS HEADQUARTERS

INSTALLATION, OPERATION, MAINTENANCE, AND SERVICE INFORMATION

Direct any questions concerning this equipment that are not answered in this instruction manual to

the reseller from whom the equipment was purchased. If the equipment was purchased directly from

WPS, contact the office indicated below.

UNITED Kingdom

Water Process Solutions

Unit 10 Mill Hall Business Estate

Aylesford, Kent, ME20 7JZ

Phone: +44(0) 1622719945

Email: enquires@waterprocesssolutions.com

Teflon® is a registered trademarks of E. I. du pont de Nemours and Company or its affiliates.

IWT.440.400.001.UA.IM.1012

1.010-1

ENCORE® 700 METERING PUMP

WT.440.400.001.UA.IM.1012

ENCORE® 700 METERING PUMP

SECTION 1 - TECHNICAL DATA

List of Contents

PARA./DWG. NO.

Technical Data

........................................................

1.1

Material Identification/Composition

.........................

1.2

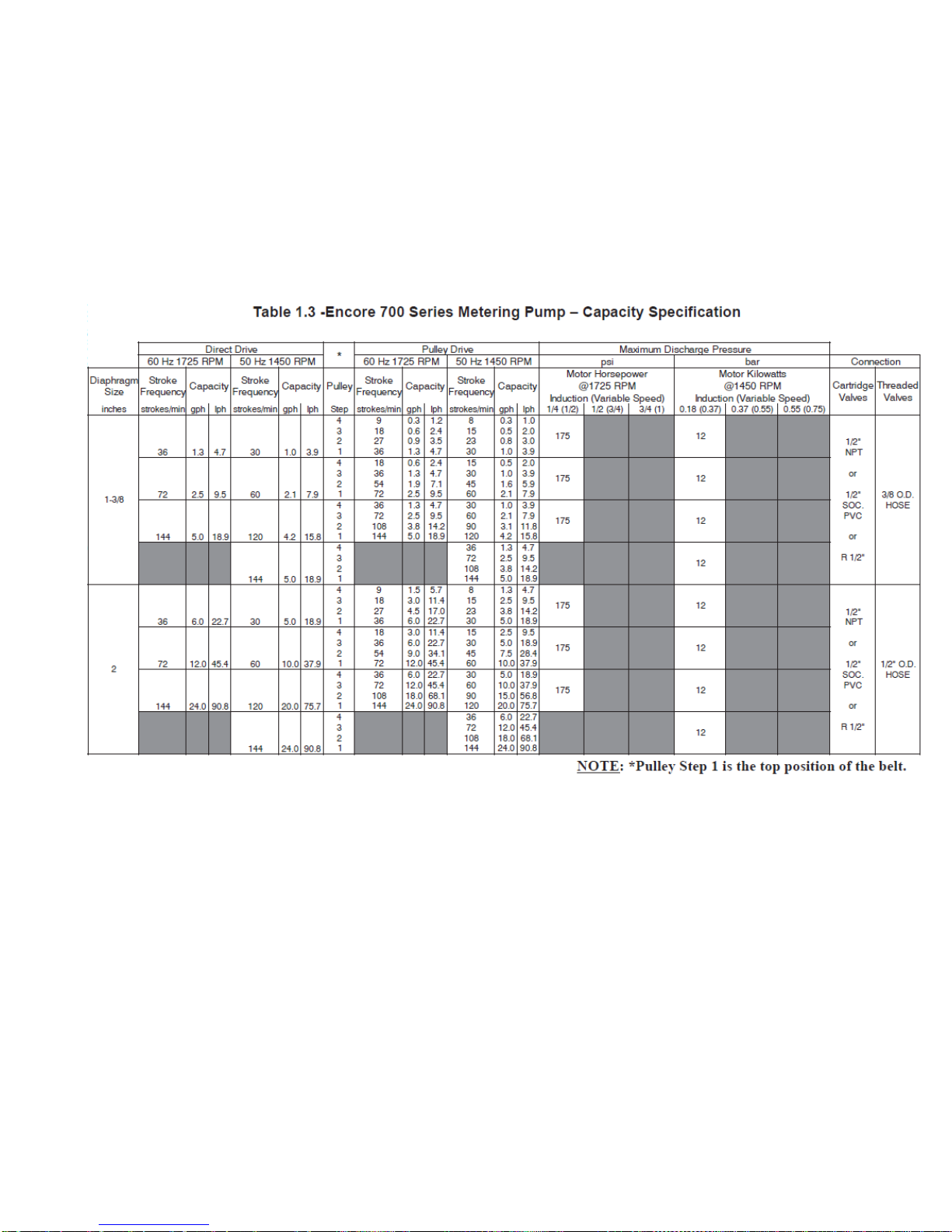

Pump Capacity

.......................................................

1.3

Pump Compatibility

................................................

1.4

Illustrations

Chemical Compatibility of Metering Pumps -

Performance .................................................. 440.050.190.010A-F

WT.440.400.001.UA.IM.1012

1

ENCORE® 700 METERING PUMP

Technical Data

The overall technical characteristics of the Encore® 700 Series Metering

Pumps are listed in Table 1.1.

Material Identification/Composition

The chemical composition of materials used in the manufacture of the

metering pump is listed in Table 1.2.

Pump Capacity

The pump capacity for the direct and pulley drive configurations are

listed in Table 1.3.

Pump Compatibility

The compatibility of the metering pump with various liquid materials are

listed on Dwg. 440.050.190.010A-F, located at the end of this section.

The table identifies the various materials that can enter and come into

contact with component materials in the wetted end of the pump and

their effects on pump performance.

WT.440.400.001.UA.IM.1012

2

ENCORE® 700 METERING PUMP

Table 1.1 - Encore® 700 Series Metering Pump - Technical Data

Pump Type

Non-Loss Motion, Mechanical Diaphragm Metering pump.

Simplex and double simplex capabilities.

Diaphragm Type

Teflon®-faced single piece mechanical diaphragm,

Six sizes: 1-3/8", 2", 3", 4", 5" and 6-1/2".

Service

Metering of mild to very corrosive chemicals;

polyelectrolytes and slurries.

Drive Unit

Directly coupled or pulley coupled motor.

Three stroking speeds 36, 72, 144 spm.

Four step pulley coupled motor provides 4:1 turn down for

each speed - 36, 72, 144 spm.

Refer to Table 1.3 for additional information.

Variable Speed

AC and DC speed control available.

Capacity Range

Up to 317 gph with single head. Up to 634 gph with

double simplex or Duplex*. Refer to Table 1.3 for additional

information.

Pressure Range

Up to 175 psi. Refer to Table 1.3 for additional information.

Stroke Length

10 turn stroke control. Adjustable over 10:1 range.

Accuracy

± 2% full scale over 10:1 range under constant suction and

discharge conditions.

Suction Lift

Up to 10 feet water lift.

Motor Voltage

115/230 VAC, 50/60 Hz

Ambient Temperature Limits

35 to 125°F ( 2 to 52°C)

Process Fluid Temperature Limits

125°F (52°C) max; 180°F (83°C) for Kynar® liquid ends.

Viscosity Limits for Polyelectrolytes

5000 centipoise @ 144 strokes per minute (SPM)

Viscosity Limits for Slurries

Hydrated Lime: Up to 3.8 lbs/gallon of water.

Activated Carbon: Up to 1.1 lbs/gallon of water

Diatomaceous Earth: Up to 1.7 lbs/gallon of water

(36 SPM minimum)

Lubrication

Food-grade synthetic oil, SAE90.

AAA5499(W2T10431) (Optional), SAE85W90 Mineral gear oil.

Weight

110 lbs (average)

* For Duplex information- Refer to Instruction Manual number WT.440.400.002.UA.IM.

WT.440.400.001.UA.IM.1012

3

ENCORE® 700 METERING PUMP

Table 1.2 - Encore 700 Series Metering Pump - Material Identification/Composition

COMMON TERM

COMPOSITION

Ceramic

99% aluminum oxide.

Hypalon®*

A chlorosulphonated polyethylene.

Kynar®** (PVDF)

Polyvinylidene fluoride.

PVC

Polyvinyl chloride.

Stainless 316

AISI 316 - Cr 16-18%

Ni 10-14%, C 0.08%, Mn 2%

Si 1%, P 0.045%, S 0.03%

Mo 2-3%

TFE

Fluorocarbon resin of tetrafluoroethylene polymer.

Viton®*

Copolymer of vinylidene fluoride and perfluoropro-

pylene or hexafluoropropylene.

* Trade names of E.I. DuPont de Nemours & Co., Inc.

** Trade name of Atochem North America, Inc.

WT.440.400.001.UA.IM.1012

4

Other manuals for Encore 700

1

Table of contents

Other Water Process Solutions Water Pump manuals

Popular Water Pump manuals by other brands

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS ULTRA V V3B60-B Installation, operation, and maintenance manual with parts list

Renkforce

Renkforce 1217916 operating instructions

Pentair

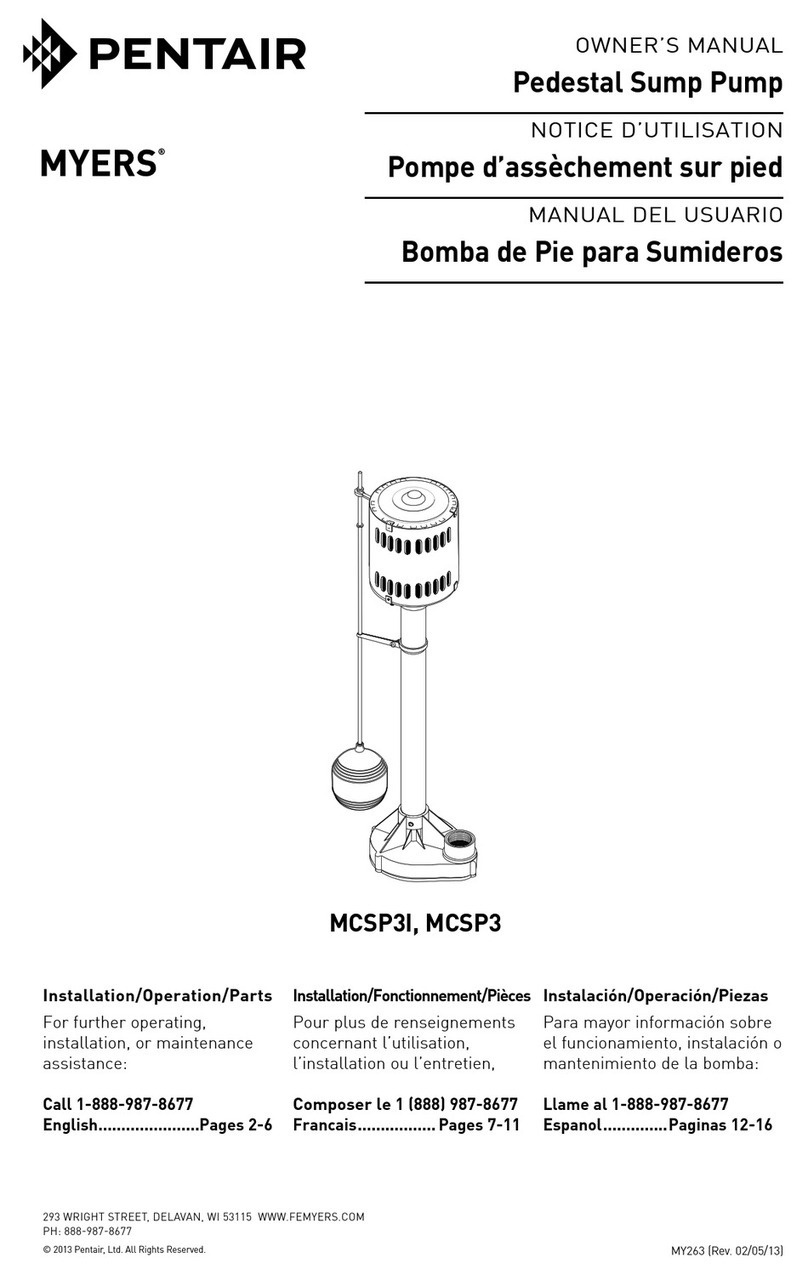

Pentair MYERS MCSP3I owner's manual

KSB

KSB Etaseco RVP Installation & operating manual

DAISHIN

DAISHIN CORAL SCR252M2 Instructions for use

Alemite

Alemite 9961 series Service guide