Water Soft ISOBAR II User manual

Filter Manual

Installation / Operation Manual

2

www.watersoftinc.com

Online at

Register Your Product

General Specifications............................................................ Page 3

Filter Media................................................................................ Page 4

Installation Requirements....................................................... Page 5

Programming the Control Valve............................................... Page 9

Utilizing Bluetooth................................................................... Page 11

Master Programming............................................................... Page 14

Control Valve Powerhead Assy. ISO II & ISO III.................... Page 15

Valve Body Assembly ISO II.................................................... Page 16

Bypass Assembly ISO II.......................................................... Page 17

Valve Body Assembly ISO III................................................... Page 18

Bypass Assembly ISO III.......................................................... Page 19

Service Instructions................................................................. Page 20

Troubleshooting........................................................................ Page 21

Error Codes.............................................................................. Page 22

Warranty Information............................................................... Page 23

FCC Compliance Statement:

http://www.chandlersystemsinc.com/files/FCC_Compliance_Statement.pdf

Industry Canada Compliance Statement:

http://www.chandlersystemsinc.com/files/Industry_Canada_Compliance_Statement.pdf

3

WARNING

Lubricants

Do NOT use Vaseline, oils, hydrocarbon lubricants or spray silicone anywhere! Petroleum base lubricants will cause

swelling of o-rings and seals. The use of other lubricants may attack plastic Noryl®. It is recommended that Dow Corn-

ing® silicone grease be used as a lubricant for all control valves. Dow Corning® 7 Release Compound is used in the

manufacture of Chandler Systems control valves. (Part # LT-150)

Sealants

Pipe dope and liquid thread sealers may contain a carrier that attacks some plastic materials. It is recommended that

Teflon® tape be used to seal plastic Noryl® threaded fittings.

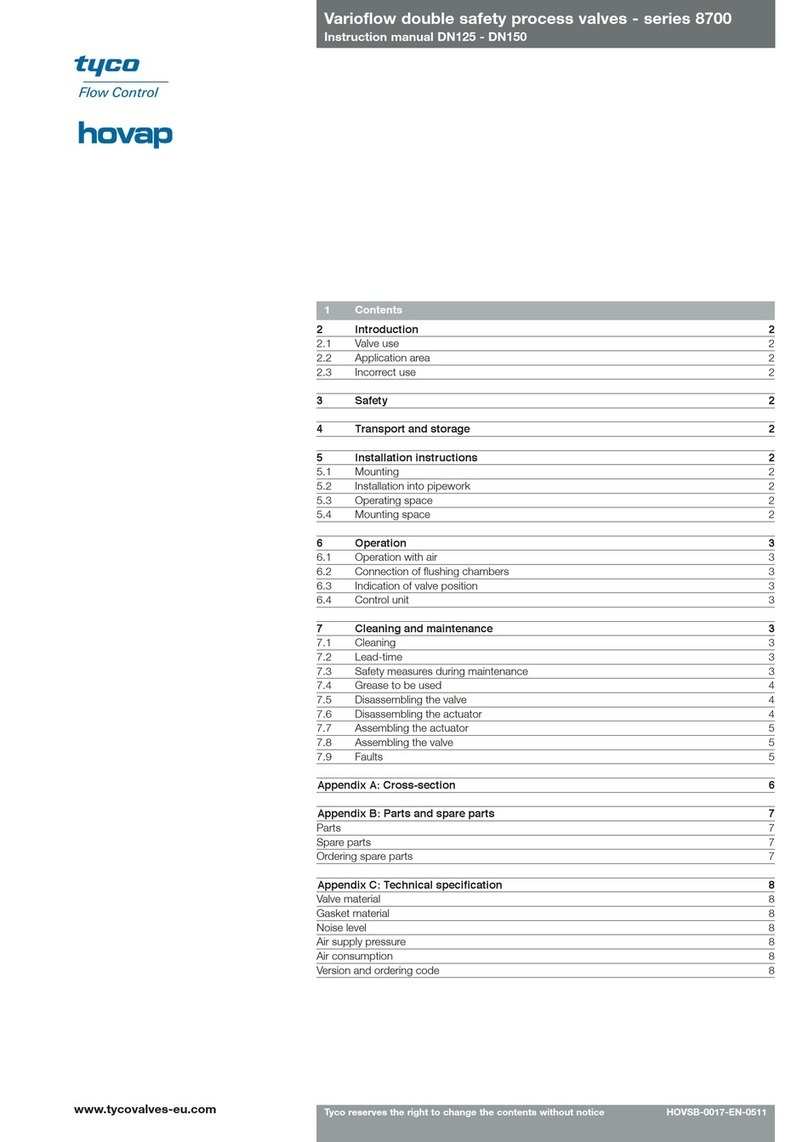

Filter Specifications

1 See “Filter Media” section for selection of proper media for your filtration application.

2 Use of a flow control in the Service line is highly recommended.

3 Caution should always be used in sizing filters! Always choose a unit by first satisfying the Backwash Flow Rate requirement above.

Consult the factory or your field sales person with questions.

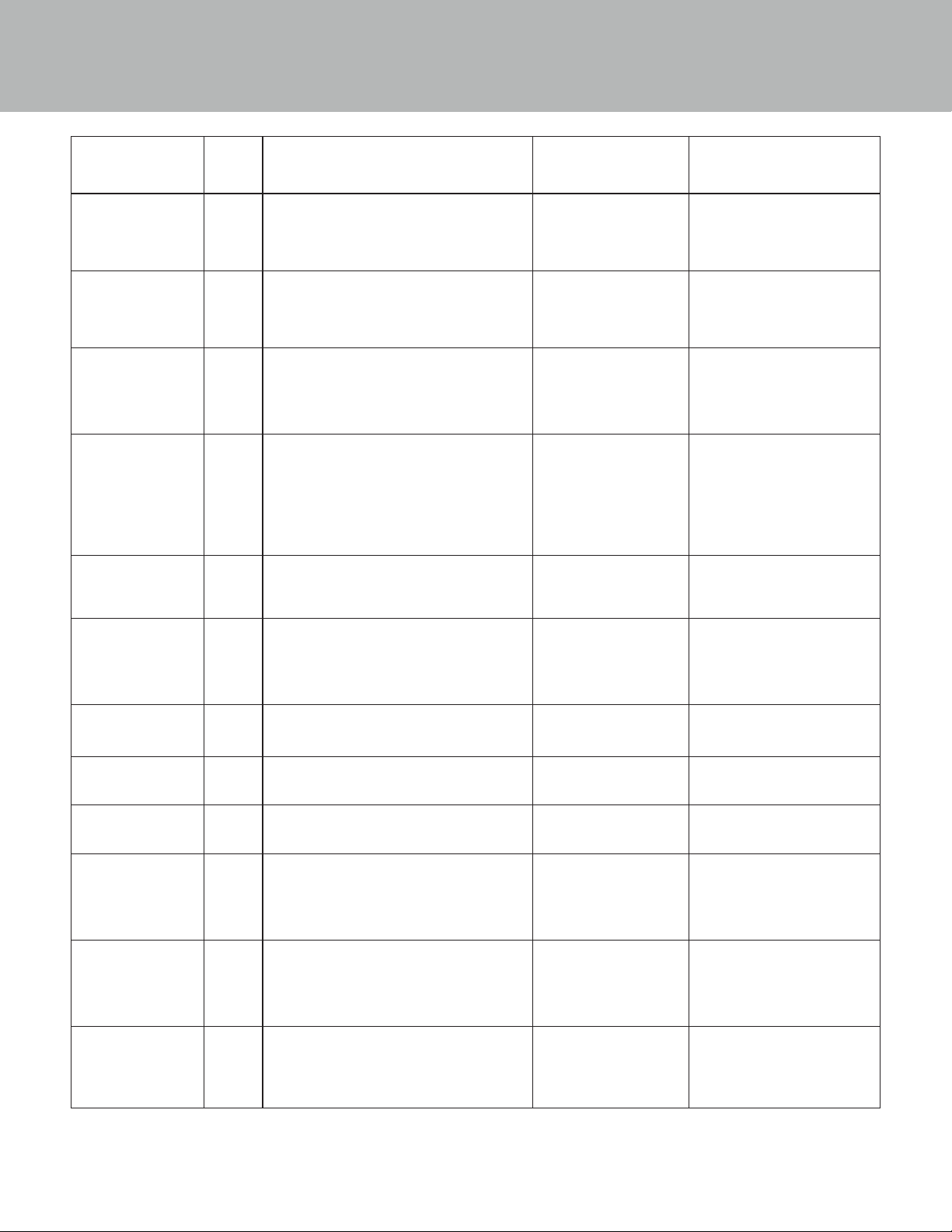

General Specifications G9

G9-3

G10

G10-3

G12

G12-3

G13

G13-3

G14

G14-3

Filtration1Less Filter Media

Filter Media Capacity (cu ft) 1.0 1.5 2.0 2.5 3.0

Mineral Tank (Vortech ™) 9 X 48 10 X 54 12 X 52 13 X 54 13 X 65

Service Flow Rate - Continuous2(gpm) 45689

Service Flow Rate - Intermittent2(gpm) 6 7 8 10 11

Backwash Flow Rate3(gpm) 5.0 5.0 6.0 7.0 7.0

Gallons Used / Backwash 100 100 120 140 140

Space Required 9 X 9 X 56 10 X 10 X 62 12 X 12 X 60 13 X 13 X 62 13 X 13 X 74

Approximate Shipping Weight (lbs) 27 32 35 40 49

4

Filter Media

Media Ship Wt.

(lbs) Description Handles... Used in...

SmartBlend

SB75

SB10

45

61

Granular / White-Black / Filter Ag Plus and Katalox Light

/ Max life expectancy about 8-10 years but is dependent

upon pH

Sediment

Iron (clear & red)

Manganese (clear & red

Sulfur Particles

PROVECTR®

Soft ‘N’ Filter w/ Mid-Vortech4

CENTURI

Neutralizer

NE50

NE75

NE10

50

64

85

Granular / White / Sacrificial to water with pH, 7.0 / Max

pH correction to 7.2 / Lowest pH application 5.8 / Must be

replenished about every 3-6 months

Sediment

pH correction

“G” Series Filters

“U” Series Filters2

Soft ‘N’ Filter w/ Mid-Vortech

Neu-Cor™

NC75

NC10

62

82

Granular / Semi-round / White & Off-white / 70%-30%

Blend of Neutralizer & Corosex®must be replenished on a

regular basis since both components are sacrificial to low

pH / Use on pH levels as low as 5.06

Sediment (downflow)

pH Correction

“G” Series Filters

“U” Series Filters

Corosex®

CX75

CX10

79

103

Semi-round / Off-White / Magnesium Oxide / Extremely

reactive to pH dissolving rapidly adding alkalinity / NEVER

use 100% Corosex®in a filter as it will “cement” / 30%

Corosex®- 70% Neutralizer is best blend for correcting

low pH / Will raise pH from lows around 5.0 to as high as

9.0+ / Must be replenished frequently / consult factory with

specific application questions

Sediment (downflow)

pH Correction

“G” Series Filters5

“U” Series Filters5

Coconut Shell Carbon

CN75

CX10

79

103

Black / High carbon-Low ash content. Practical for ordinary

taste, odor and chlorine loads. Will impart a high “polish” to

the filtered water.

Taste/Odor/Color “G” Series Filters5

“U” Series Filters5

Activated Carbon

AC75

AC10

21

28

Granular / Black / Wide application for removal of organics

and some inorganics / Must be replaced on a regular basis

/ Life expectancy varies based on use

Sediment

Taste/Odor/Color

Chlorine/Iodine

“G” Series Filters

“U” Series Filters

Soft ‘N’ Filter w/ Mid-Vortech

Drinking Water Filters

Catalytic Carbon

CC75

CC10

26

34

Granular/Black / enhanced activated carbon that has

a higher catalytic power which produces an increased

electron transfer for better absorption.

Sulfur Removal

Chloramine

PROVECTR®

“G” Series Filters

City Soft

Filter Ag®

FA75

FA10

21

28

Granular / Off-White / Wide application for removal of

sediment / Life expectancy is unlimited Sediment “G” Series Filters

Soft ‘N’ Filter w/ Mid-Vortech

Filter Ag Plus

FP75

FP10

37

50 Light tan to white, 5 micron filtration Sediment “G” Series Filters

Birm®

BM75

BM10

37

29

Granular / Gray / Must not be used on waters with a pH

< 6.8 / Must have dissolved oxygen present at a level

of at least 15% of iron & manganese ppm / Max iron &

manganese level 10 ppm / Estimated life about 8-10 years

Sediment

Iron (clear & red)

Manganese (clear & red)

“G” Series Filters

Soft ‘N’ Filter w/ Mid-Vortech3

Greensand Plus

GP75

GP10

63

85

Granular / Black / Must not be used on waters with a pH

<6.8 / Must be regenerated with potassium permanganate

on a regular basis / Max iron & manganese level 10ppm/

Max H2S level 3ppm / Estimated life about 8-10 years

Sediment

Iron (clear & red)

Manganese (clear & red)

Hydrogen Sulfide

“GIP” Series Filters

“D” Gravel

DG20

DG50

20

50

Semi-Round / Brown / #20 Flint / Used as underbed for all

media in all filters providing for excellent flow distribution

in both service and backwash modes / Permanent unless

fouled but can be cleaned and re-used.

Underbed All Non Vortech Filter Systems

5

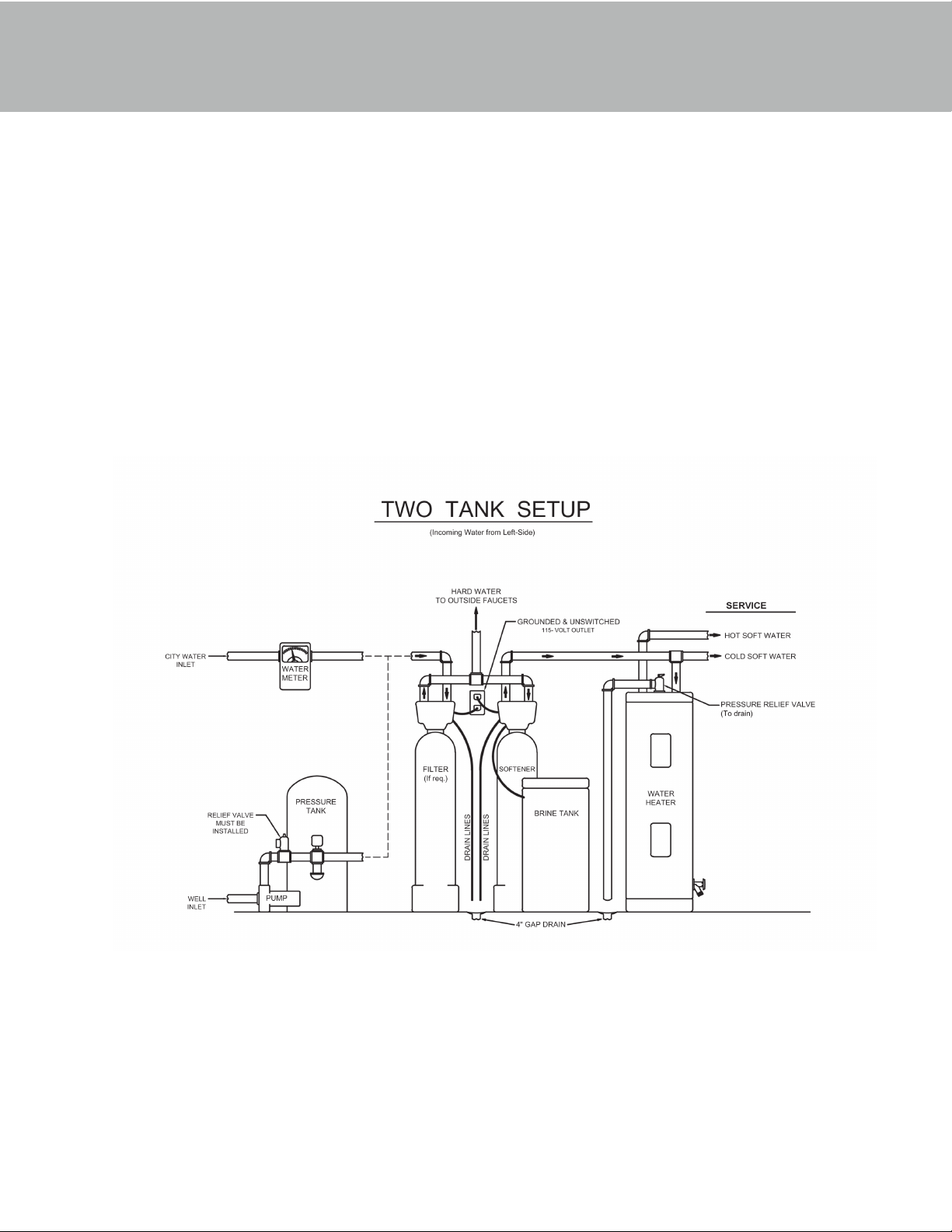

Installation Requirements

• A level floor position ahead of piping into water heater.

• Unit must be installed at least 10’ ahead of the inlet to a water heater to prevent damage due to

back-up of hot water.

• DO NOT install the unit in an area of direct sunlight or where freezing temperatures may occur!

(See Installation Diagrams for proper placement and plumbing connections.)

Filter Media Installation

6

Note:

• If household plumbing is galvanized and you intend to make the installation with copper (or vice versa), obtain

di-electric unions to prevent dissimilar metal corrosion.

• All plumbing lines not requiring “soft” water should be connected “upstream” of the softener, if installed. (See Typical

Installation Diagrams.)

Caution:

• If sweat soldering copper pipe (remember to always use lead free solder and flux), cover yoke and bypass valve with wet

rags to prevent heat damage to connections and control valve. If using PVC or plastic pipe, primers and solvent cements

specifically recommended for use with potable water are required.

Installation

7

Installation Procedure

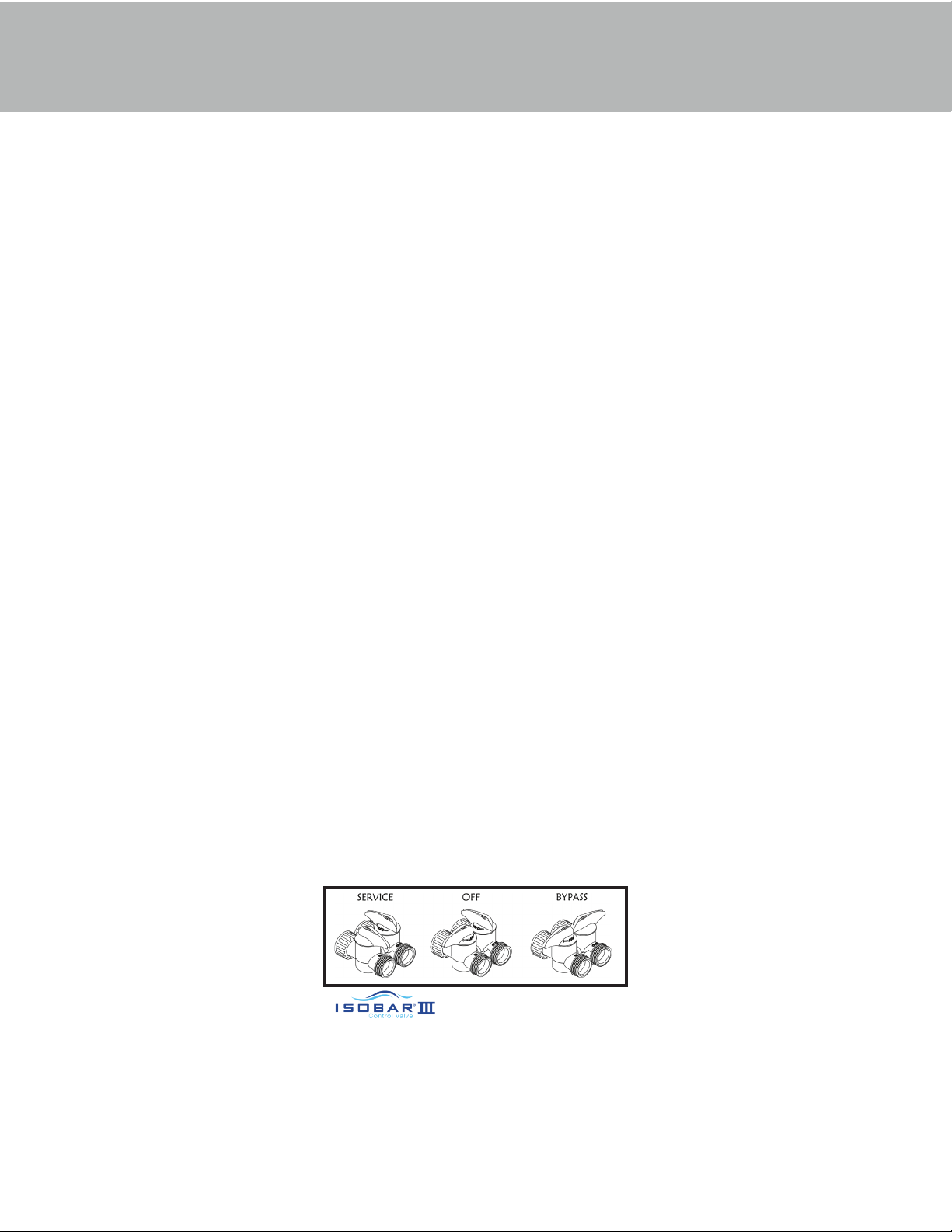

- Water Supply Connection and Bypass Valve -

To allow for filter servicing, swimming pool filling or lawn sprinkling, a manual Bypass Valve has been installed at the

factory. The Bypass allows raw water to be manually routed around the filter.

1. Position filter at desired location for installation. If a water softener is to be installed, the filter should be positioned first

and then the softener. (See Installation Diagrams.)

2. The filter material is shipped separately from the mineral tank. The tank must be loaded with material after tank has

been placed at the desired location.

A. Remove the control valve by unscrewing from the tank. (Do not fill through dome hole, if installed.)

B. Use cap provided to place over top of distributor tube to prevent material from entering tube while filling.

C. Place media funnel (part # U-1006) in hole on top of tank.

D. Pour several gallons of water in the tank. (Fill tank about 1/3 full.)

E. Pour in the required filter media. No gravel is required. The required quantity of media is listed in the filter

specifications.

Note: If rebedding an existing unit and the system utilizes a standard tube & basket style distributor, a

“D” gravel underbedding will be required.

F. After filling the tank with material, use a garden hose or several buckets to fill the tank with water.

This will permit the filtering media to become soaked while preparing the installation and will prevent the control

valve from being plugged with floating material on initial backwash.

G. Remove funnel and clean filter media from tank threads.

H. Remove cap from distributor tube.

I. Replace control valve on mineral tank. Do not use Teflon tape or paste on valve threads, as the valve to

tank o-ring seals this joint.

Caution: Be extremely careful to position distributor tube into control valve distributor tube pilot hole.

3. Turn OFF main water supply and OPEN nearest faucet to relieve pressure.

4. Cut main line and install appropriate elbows and extensions.

Caution: Raised arrows located on the sides of control valve body and bypass valve indicate proper direction of water

flow. Install inlet and outlet piping in direction of arrows. It is recommended that a vacuum breaker be

installed on the inlet plumbing.

Installation Installation

Bypass - Shown

8

Electrical Connection -

1. Connect the power supply to the control valve and plug into a 115 volt / 60 Hz receptacle.

Note: Do not plug into an outlet controlled by a wall switch or pull chain that could inadvertently be turned off.

- Pressurizing The System -

2. Slowly rotate handle of the bypass valve to the SERVICE position.

3. Open the nearest faucet to evacuate air from plumbing lines.

4. Check for leaks! If water is observed leaking from bypass, o-rings on valve body may not be seated properly. Exercise

bypass valve.

5. After air is evacuated from plumbing lines, turn off faucet.

- Initial Control Valve Operation -

1. Advance control valve to BACKWASH (cycle 1) position and allow water to run to drain for 3 to 4 minutes.

Warning: Close handle on bypass prior to selecting the backwash position. After backwash position has been

established, slightly open valve on bypass to evacuate air from the media tank. Fully open bypass valve

when all air is depleted. This procedure will prevent media form being uplifted into control valve.

2. Advance control valve to RAPID RINSE (cycle 3) position and allow water to run to drain for 3 to 4 minutes.

3. Advance control valve to SERVICE (cycle 0) position.

Electronic Connections

P - Power Supply

B - Powered in Backwash Step Only (Cycle #1)

S - Powered in Entire Regeneration Cycle

Installation

P B S

- Drain Line Connection -

1. The drain line flow control assembly is pre-assembled for your convenience. Should you choose to hard plumb the

drain line, please remove the barb fitting. The flow control housing can be removed by removing the clip and pulling

straight out on housing.

Note: When re-installing the drain line flow control housing, be sure you hear and feel the O-Ring pop into place before

inserting the clip.

2. Install 1/2” I.D. drain line tubing (not included) from hose barb to an open drain. A 4” gap between end of the drain line

and the open drain is required to prevent waste water backflow. Keep the drain line as short as possible. An overhead

drain line can be used if necessary, but should discharge below the control valve. A syphon trap (taped loop) at the

outlet of the drain line is advisable to keep the drain line full and assure correct flow during backwash. Elbows or other

fittings must be kept at a bare minimum.

Note: Where the drain line is elevated above the control valve or exceeds 20 feet in length, 3/4” I.D. drain line tubing

should be used.

9

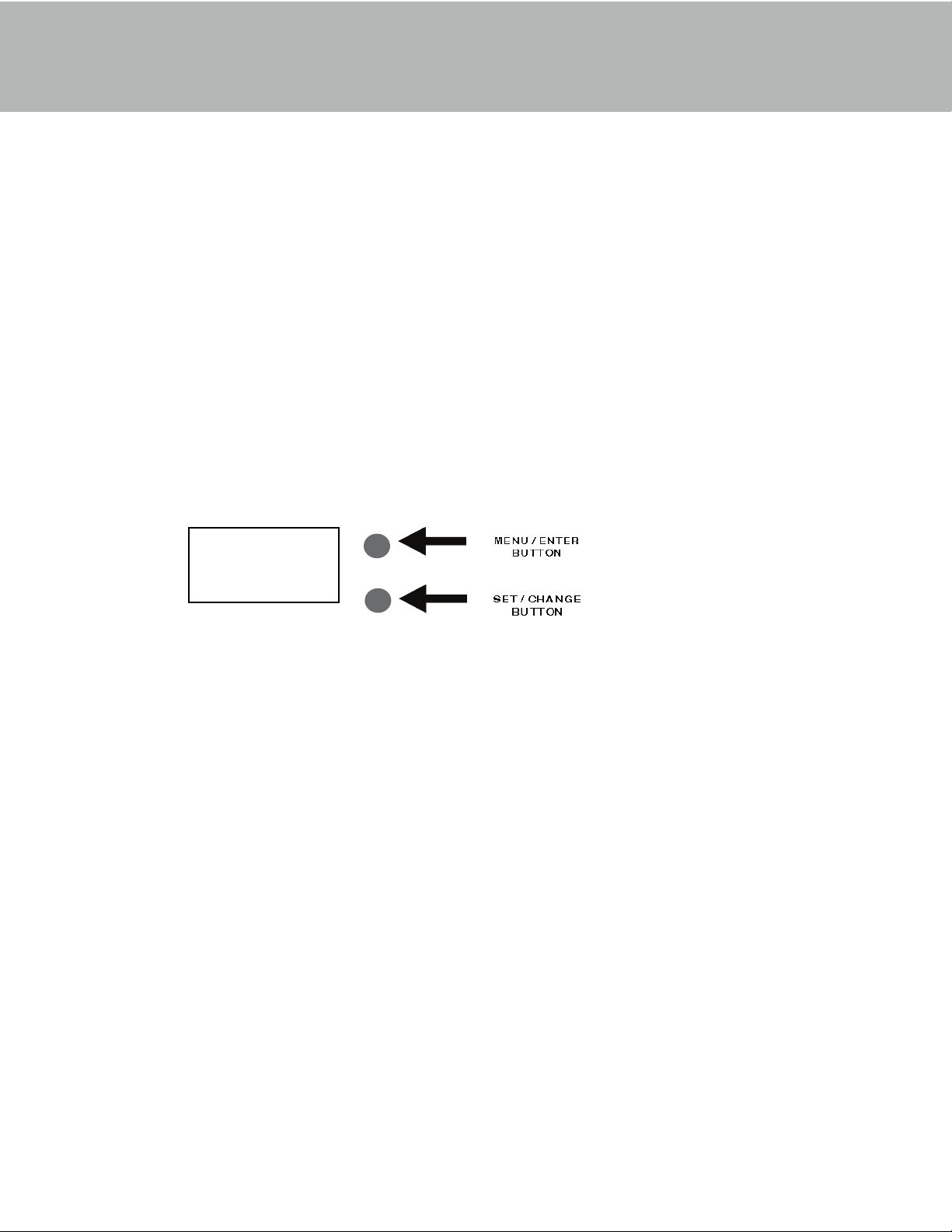

Main Menu

12:00

1. To enter Main Menu, press the Menu/Enter button.

(Time of Day will flash)

2. To set the Time of Day, press the Set/Change button.

(First digit will flash) Example (12:00) -

To change digit value, press the Set/Change button.

- To accept the digit value, press the Menu/Enter button.

- Next digit will flash to begin setting.

- Once the last digit display is accepted, all digits will flash.

3. To set A.M. or P.M., press the Menu/Enter button.

- To change digit value, press the Set/Change button. Example ( A )

- To accept the digit value, press the Menu/Enter button.

- Once A.M. or P.M. is accepted, the next menu item will flash.

4. a. To set the Number of Days between Backwash Cycles (A), press the Set/Change button. -

Repeat instructions from step (2). Example ( A - 06 )

Notes: 1) Maximum value is 29.

2) If value set to 0, Automatic Backwash will never occur.

3) Default setting is 6 days for filters.

5. To Exit Main Menu, press the Menu/Enter button.

Note: If no buttons are pressed for 60 seconds, the Main Menu will be exited automatically.

Programming the Control Valve

Installation

- Final Checkout -

1. Be certain that the bypass valve is in Service position and main valve is completely on.

2. Check electrical supply to be certain the cord is connected to an uninterrupted 115 volt outlet.

3. REGISTER YOUR PRODUCT at www.watersoftinc.com

4. Leave this manual with the homeowner.

Important Notice - The plumbing system, piping, pressure tank, hot water tanks, softeners, etc. that have been exposed

to iron bearing water may need to be cleaned of the precipitated iron that has been collected in them or iron bleed thru

may be a problem. We suggest all tanks be drained and flushed thoroughly.

- Programming The Control Valve -

1. Set time of day.

2. Set a.m. or p.m.

3. Set number of days between backwash. (This generally will be every 4 to 6 days.)

1. Set regeneration time if other than 12:00 a.m. is desired.

10

Normal Operation

1. Home Display

a. Alternates between the display of Time of Day and Number of Days until the Next Backwash.

(Metered Softeners will alternate between time of days and gallons remaining until next regeneration)

- Days Remaining until the Next Backwash will count down from the entered value until it reaches

1 day remaining.

- A Backwash Cycle will then be initiated at the next designated regeneration time.

2. Battery Back-Up (Uses a standard 9-volt alkaline battery.)

Features of Battery Back-Up:

• During power failures, the battery will maintain the time of day as long as the battery has power.

The display is turned off to conserve battery power during this time. To confirm that the battery

is working, press either button and the display will turn on for five (5) seconds.

• If power failure occurs while system is regenerating, the Isobar 2 will motor to a shut off position

to prevent constant flow to drain. Depending upon system pressure and other factors, it is

possible to observe a reduced flow to drain during this step. After power is restored, the Isobar

2 will return and finish the cycle where it left off prior to the power interruption.

• When used without battery back-up, during a power failure, the unit stops at its current point in

the regeneration position and then restarts at that point when the power is restored. The time

will be offset by the increment of time the unit was without power, so it is necessary to reset the

time of day on the unit. No other system will be affected.

Programming the Control Valve

Filters Default (Min)

Step 1 Backwash 10

Step 2 Rest 5

Step 3 Rapid Rinse 10

Step 4 Not Used 0

Starting Extra Regeneration Cycle

1. To Start Delayed Extra Cycle Example ( 1) - If Days

Remaining Until Next Backwash does not read ‘1’, press and hold the Set/Change button for 3 seconds

until the display reads ‘1’.

- Backwash cycle will initiate at the next designated backwash time.

2. To start Immediate Extra Cycle First complete above step.

- With Days Remaining Until Next Regeneration at ‘1’.

- Press and hold the Set/Change button.

- After 3 seconds, the backwash cycle will begin.

3. To Fast Cycle thru regeneration First complete above 2 steps.

Note:Press and hold the Set/Change button for 3 seconds to advance to the next cycle step.

Fast Cycle is not necessary unless desired to manually step through each cycle step.

(Repeat until valve returns to the home display)

11

For simplified set up and control, please install the Legacy View on a compatible Bluetooth 4.0+ enabled smart phone or

tablet.

1. Download and install the Legacy View app from the Google Play Store, Apple App Store

2. Open the Legacy View app

• Choose a valve device at any time from the list of available devices to connect to by clicking on it.

• If the valve you want to connect to doesn’t show up, or there is a problem connecting to a device you can

press the “Scan for Devices” button or the Legacy View logo at any time to refresh the list and start the

process over.

• If the valve device is a BTLE valve and it has a password other than the default password, the first time you

connect to it the app will ask you to enter the password. After entering it the first time you should not need to

enter it again unless it changes.

3. BTLE Valve devices can be updated by the App. When the app is updated from the Google Play Store or the Apple

App Store, it may contain an updated firmware program for the valve devices. These updates could contain new

features or operational improvements. It is up to the user to allow these updates to be sent to the valve device.

Uploading a new program takes approximately 1 minute.

Dashboard

NOTE: Consult your dealer before making any changes

From the Dashboard, all items in ORANGE can be changed, while blue fields are informational only.

If you are unsure about the function of the field click the for more information.

Utilizing Bluetooth Control

12

Set Up Utilizing Bluetooth App

Advanced Settings

NOTE: Consult your dealer before making any changes. We do not recommend changing Advanced Settings unless you

have a good understanding of the system operation.

From the Advanced Settings, all items in ORANGE with a “set” button can be changed.

For Filters:

Set Backwash Frequency

This sets the amount of day between backwash cycles

Change Time of Day (Press “SET” to set time automatically based on device).

Set Regeneration Time

Example: For 2a.m., just type 2, choose a.m., and press ‘OK’

Note: If you have a filter and a softener the valves should be set to regenerate

at different times. Factory default times are 12a.m. for filters, and 2 a.m. for

softeners.

13

Status and History

From the Status and History, all items in ORANGE can be reset.

1. Start a regeneration or backwash cycle

Option 1: Click the “Regenerate Unit Now.”

Once a regeneration has been started, if you would like to force the unit into the

next cycle step click “Go to Next Regeneration Step”.

Option 2:

Touch any graph to enlarge and see

details. Enlarged graphs are able to

be zoomed in by pinching with two

fingers.

(Enlarged graph shown below)

“Regenerate Unit at Next Regen Time” button

This will take the system into a backwash cycle at the next regeneration time.

Set Up Utilizing Bluetooth App

Pressing the .csv logo in the corner

will allow the graph data to be

exported and shared.

Enlarged graph showing water usage

Pressing this icon will show a list of

the data that is in the graph.

14

Master Programming Mode

Master Programming Mode

To enter Master Programming Mode, press and hold both buttons for 5 seconds.

Note: All Master Programming functions have been preset at the factory. Unless a change is desired, it is NOT

necessary to enter Master Programming Mode.

1. Regeneration Time ( r ) Example ( r 12A )

- The time of day at which backwash may take place is designated by the letter “r”.

- Default regeneration time settings is 12a

- The first display digit indicates A.M. or P.M. To change the value, press the Set/Change button.

- Press Menu/Enter button to accept the value and move to the next digit.

- The second and third display digits indicate the hour at which the backwash will occur.

- Change the digits with the Set/Change button and accept with the Menu/Enter button.

- After the entire display flashes, press the Menu/Enter button to move to the next menu item.

2. Regeneration Cycle Step Times (Steps 1, 2, 3, 4)

Example ( 3 - 10)

- The next 4 displays set the duration of time in minutes for each backwash cycle step.

- The step number which is currently modifiable is indicated on the far left of the display screen.

- The number of minutes allotted for the selected backwash step is displayed on the far right.

- Change the digit values using the Set/Change and Menu/Enter buttons as described above.

3. Bluetooth Enabled BE - 1 (ON)

BE - 0 (OFF)

4. Bluetooth Password BBPP is displayed for one second, then password is displayed.

5. To Exit the Master Programming Mode, press the Menu/Enter button until time of day returns.

Note: If no buttons are pressed for 60 seconds, the Master Programming Mode will be exited automatically.

15

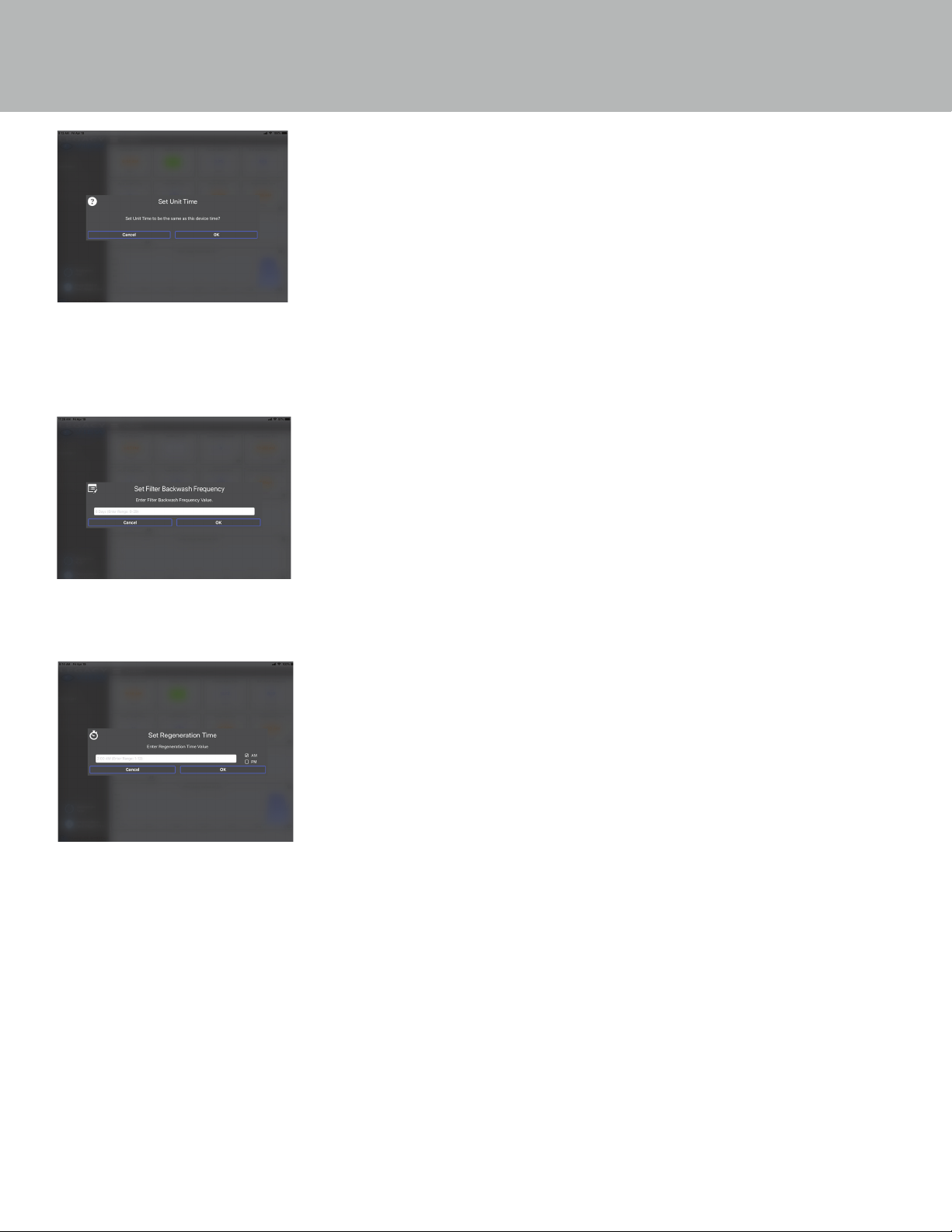

Control Valve Powerhead Assembly

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

E

M

*"F" Port is for softener flow meter connection (flow meter not shown)

LETTERS IN DIAGRAM REPRESENT WIRING CONNECTIONS

19

1

E

P

P

M

F

Ref Description Part Number Qty

0 Power Head Assy. 20942C100 1

1 Filter Circuit Boad Assy. 20942C102 1

2 Encoder 20001X124 1

3 Front Plate 20001X004 1

4 Encoder Wheel 20001X007 1

5 Main Gear 21001X120 1

6 Power Supply 20001X125 1

7 Back Plate 20001X005 1

8 Lower Front Base For Cover 20111X002 1

9 Motor 20016X006 1

10 Lower Back Base for Cover 20111X003 1

11 Valve Cover 20111X001 1

12 Piston Screw 20001X003 1

13 Screw SC10 3

14 Screw SC9 2

15 Piston Washer 20001X002 1

16 Washer Circuit Board 20111X014 1

17 Screw Motor SC2 1

16

Valve Body Drive Assy. (Filter Version)

Ref

#Description Part # Qty.

1 Piston Assembly 20001X231 1

2 10-24 X 13/16” Screw 20001X226 3

3 Seal and Spacer Kit Incl (5) #3

& (4) #4

20561X253 1

4 End Spacer N/S 1

5 Flow Control Button 5.0 GPM 20251X272 1

Flow Control Button 6.0 GPM 20251X274 1

Flow Control Button 7.0 GPM 20251X274 1

6Plastic Flow Control Housing- Blk 20017X100 1

6A Flow Control Assembly-Specify GPM

Incl. (1) each #5, #6, #7

Flow Control Assy. 5.0 GPM-

PVC

20017X262 1

Flow Control Assy. 6.0 GPM-

PVC

20017X263 1

Flow Control Assy. 7.0 GPM-

PVC

20017X264 1

7 Drain Line Hose Barb 20017X235 1

8 Drain Retainer 20017X214 1

9 O Ring & Brine Valve Cap

Assembly

20001X230 1

10 O Ring & Filter Plug Assembly 20001X229 1

11 10-24 X 1 Screw 20001X226 1

12 Injector Cap 20001X223 1

13 Injector Seal 20001X224 1

14 Injector Plug & O Ring Assembly 20001X217 1

15 Valve O Ring 20561X205 1

16 Dist. O Ring 20561X204 1

17 Mounting Clip 20561X201 2

18 8-18 X 5/8” Screw 20561X217 2

19 Adapter Coupling N/S 2

19A Adapter Coupling & O Ring

Assembly Incl. (1) # 17, #18, #19

& (2) #20

20561X215 1

20 O Ring 20561X216 4

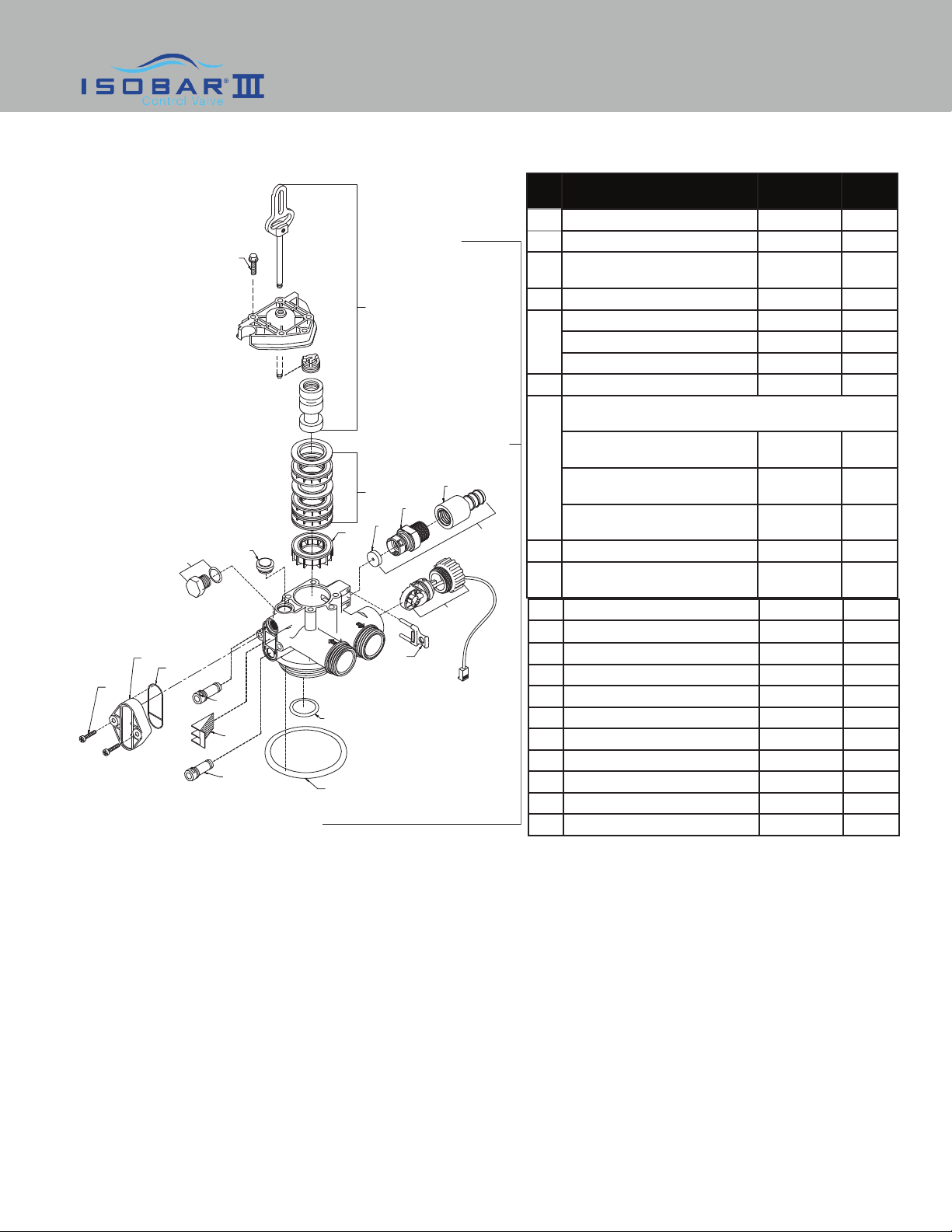

17

Valve Body Drive Assy. (Filter Version) Bypass Assembly

Ref # Description Part # Qty

1Plastic Bypass Valve Assembly 20561X292 1

2

Bypass Valve 3/4” Stainless Steel 20561X270 1

Bypass Valve 1” Stainless Steel 20561X283 1

(1)

(2)

18

2

9

1

3

12 13

11

17

18

20/21

15

16

45

6

7

6A

8

14

19

10

Ref

#Description Part # Qty.

1 Piston Assembly 20001X231 1

2 10-24 X 13/16” Screw 20001X226 3

3 Seal and Spacer Kit Incl (5) #3

& (4) #4

20561X253 1

4 End Spacer N/S 1

5 Flow Control Button 5.0 GPM 20251X272 1

Flow Control Button 6.0 GPM 20251X274 1

Flow Control Button 7.0 GPM 20251X273 1

6 Plastic Flow Control Housing 20017X100 1

6A Flow Control Assembly-Specify GPM

Incl. (1) each #5, #6, #7

Flow Control Assy. 5.0 GPM-

PVC

20017X262 1

Flow Control Assy. 6.0 GPM-

PVC

20017X263 1

Flow Control Assy. 7.0 GPM-

PVC

20017X264 1

8 Drain Retainer 20017X254 1

9 O Ring & Brine Valve Cap

Assembly

20001X230 1

10 O Ring & Filter Plug Assembly 20001X229 1

11 10-24 X 1 Screw 20001X226 1

12 Injector Cap 20001X223 1

13 Injector Seal 20001X224 1

14 Injector Plug & O Ring Assembly 20001X217 1

15 Screen 20001x222 1

16 Injector Plug & O Ring Assembly 20001X217 1

17 Valve O-Ring 20551X205 1

18 Dist. O-Ring 20561X204 1

19 Meter Assembly 20017X203 1

20 Valve Body Assembly VH2-B-D15 1

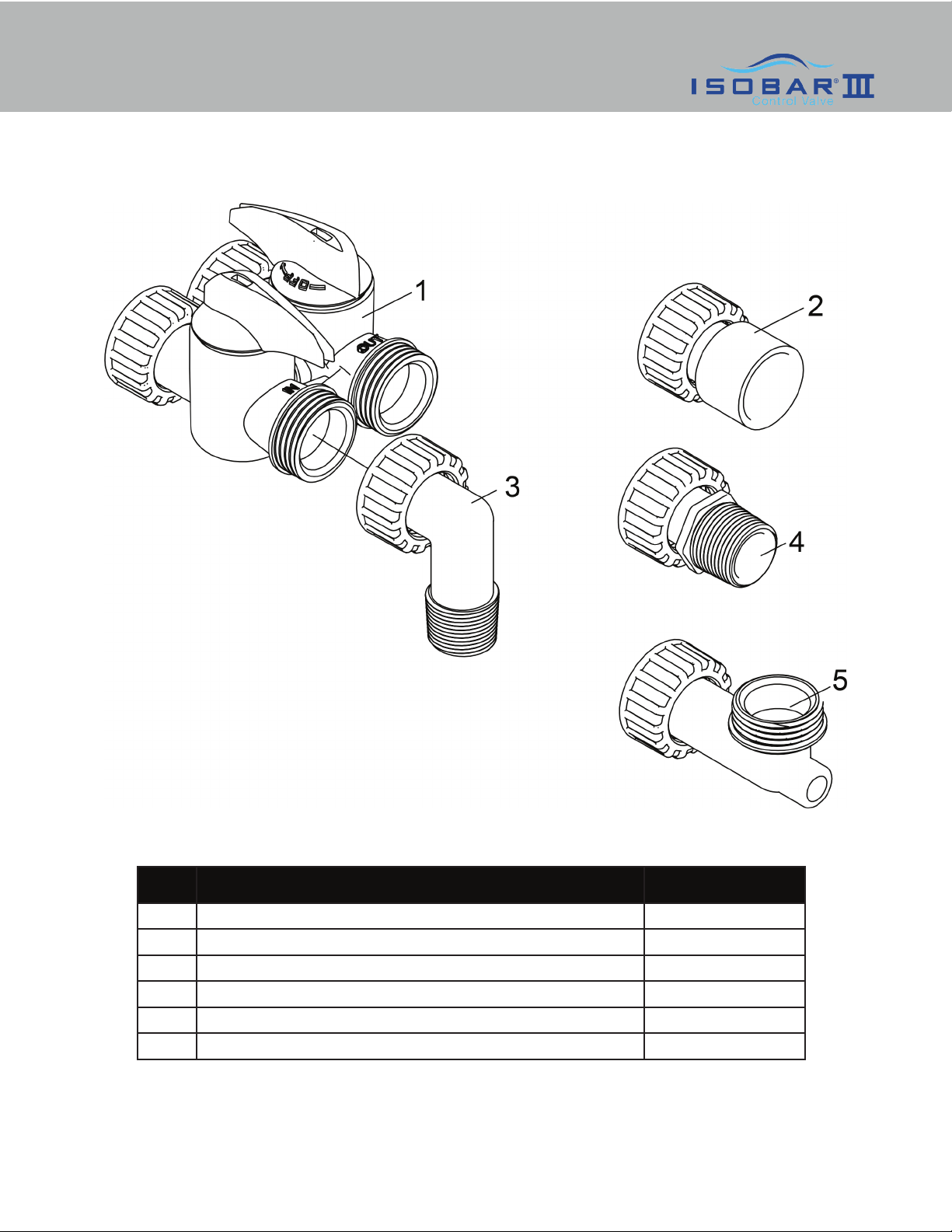

Valve Body Drive Assy. (Filter Version)

19

Ref Description Part No.

1 D15 Bypass 20017X283

2 1” Female Straight Slip Set (optional) 20017X288

3 1” NPT Elbow Set 20017X284

4 1” NPT Straight Set (optional) 20017X289

5a Elbow, Vertical Adapter Blank (optional) 20017X295

5b Elbow, Vertical Adapter 1/4” NPT Tapped (optional) 20017X294

Bypass Assembly

20

Service Instructions / Instructional Videos

Available at www.watersoftinc.com

A. General Preliminary Instructions

PERFORM BEFORE ALL SERVICING OPERATIONS

1. Turn off water supply to conditioner.

-If the conditioner installation has a “three valve” bypass system, first open the valve in the bypass line, then

close the valves at the conditioner inlet and outlet.

-If the conditioner has an integral bypass valve, put it in the bypass position.

-If there is only a shut off valve near the conditioner inlet, close it.

2. Remove cover and relieve water pressure in the conditioner by stepping the control into the backwash

position momentarily. Return the control to the service position.

3. Unplug electrical cord from outlet.

B. To Replace Powerhead

1. Remove the control valve cover and disconnect the power supply.

2. Disconnect the meter cable from circuit board and feed back through control (if existing meter is being re-used)

3. Remove lower back base screws and detach lower back base.

4. Remove screw and washer at drive yoke. Remove powerhead mounting screws. The entire powerhead

assembly will now lift off easily.

5. Put new powerhead on top of the valve. Be sure the drive pin on main gear engages slot in drive yoke (wide

side of drive yoke upright must face to the left away form the motor).

6. Replace powerhead mounting screws. Replace screw and washer at drive yoke.

7. Reattach lower back base.

7. Reconnect meter signal, wire and power supply.

8. Reinstall cover.

C. To Replace Piston Assembly

1. Follow steps A1 - A3

2. Disconnect the meter signal wire from the circuit board.

3. Remove lower back base screws and detach lower back base.

4. Remove screw and washer at piston drive yoke. Remove powerhead mounting screws. The entire powerhead

assembly will now lift off easily.

5. Remove piston retaining plate screws.

6. Pull upward on end of piston yoke until assembly is out of valve.

7. Inspect the inside of the valve to make sure that there is no foreign matter that would interfere with the valve

operation.

8. Install new seals and spacers.

9. Take new piston assembly and push piston into valve by means of the end plug. Twist drive yoke carefully in a

clockwise direction to properly align it with drive gear. Reinstall piston retaining plate screws.

10. Follow steps B5 - B9

D. To Replace Seals and Spacers

1. Follow steps A1 - A3.

2. Disconnect the meter signal wire from the circuit board.

3. Remove screw and washer at piston drive yoke. Remove powerhead mounting screws. The entire powerhead

assembly will now lift off easily. Remove piston retaining plate screws.

4. Pull upward on end of piston rod yoke until assembly is out of valve. Remove seals and spacers. (Note: Special

end spacer must be reused)

5. Lubricate new seals with silicone lubricant included in the seal and spacer kit. Make sure the special end

spacer is properly seated in the valve body. Install new seals and spacers individually, pressing around the

outer edge of each seal to make sure it is seated. (When all seals and spacers are seated properly, you will

have a 1/4” of space between the top seal the the top of the valve body)

6. Follow Steps C9 - C10.

Other manuals for ISOBAR II

1

This manual suits for next models

1

Table of contents

Other Water Soft Control Unit manuals