WaterClinic LOTUS-72 User manual

Innovation has a name.

LOTUS-72

Cabinet Reverse Osmosis User Manual

Kabinetli Ters Osmoz Kullanma Kılavuzu

ENG 1

Dear customer,

Thank you for purchasing a "Waterclinic by A.O. Smith" branded water purier!

You are now the owner of water treatment equipment produced by the world’s leading

manufacturer of water treatment systems. This equipment produces pure water that can

be consumed directly, providing you with a cleaner and healthier source of drinking water.

Please read this user manual carefully before you install and operate your

"Waterclinic by A.O. Smith" branded water purier. To achieve maximum efciency this user

manual provides detailed instructions regarding the installation of your water purier as

well as information related to the proper operation and maintenance.

The installation should only be handled by professionals authorized by A.O. Smith

Su Teknolojileri A.Ş.

Spare parts used for maintenance and replacement lters should be approved

by A.O. Smith Su Teknolojileri A.Ş. before they are installed.

Any degradation of performance caused by the use of spare parts or lters that have not

been approved by A.O. Smith Su Teknolojileri A.Ş. will not be covered by our warranty.

If you experience any difculties during installation or operation, please contact your local

distributor to have them carry out repairs or maintenance on your equipment.

ENG 2

CONTENTS

İÇİNDEKİLER

ENG

SAFETY CONSIDERATIONS 4

PRODUCT DESCRIPTION 7

Brief Introduction 7

Description of Components 7

Electrical Diagram 8

Water Route Map 8

Technical Specications 9

Functions of Main Components 9

Functions of Accessories 10

TRANSPORTATION 10

INSTALLATION METHODS 10

Pre-Installation Preparations 10

Instructions to Quick Fitting 11

Instructions for Proper Installation 12

Installation Notes 15

ADJUSTMENT METHODS 15

OPERATION WARNINGS 16

MAINTENANCE AND REPAIR 16

Filter Replacement Intervals 16

Filter Replacement Methods 17

Warnings 17

Notes 18

PACKING LIST 18

AFTER-SALES SERVICE 19

TROUBLESHOOTING GUIDE 20

TR

24

ÜRÜN TANITIMI 27

Kısa Tanıtım 27

Su Arıtma Cihazının Ayrıntılı Proli 27

Elektrik Şeması 28

Su Akış Şeması 28

Teknik Bilgiler 29

Ana Bileşenlerin İşlevleri 29

Aksesuarların İşlevleri 30

30

30

Kurulum İçin Ön Hazırlık 30

Quick Fittings Bağlantı Elemanları 31

Doğru Kurulum için Uyulması Gereken Talimatlar 32

Kurulum Uyarıları 35

35

KULLANIM UYARILARI 36

BAKIM VE ONARIM 36

Filtre Değişim Aralıkları 36

Filtre Değişim Yöntemleri 37

Uyarılar 37

Notlar 38

38

39

40

42

BAKIM KARTI 41 - 43

MONTAJ KONTROL KARTI 44

45

ENG 4

Do not disassemble or modify this water

purier on your own!

Unauthorized disassembly or modication

of the machine could lead to machine

malfunctions or leakage accidents. Please

check with the store where you purchased

this product for product consultation in order

to arrange for repairs.

Do not put the water purier close

to a source of ame!

Do not put the water purier near a source

of ame or a place where the temperature

is too high as this may cause deformation,

causing damage or leakage, which could lead

to serious personal and property damage.

Do not put heavy objects on the water

purier!

Placing heavy objects on the water purier

may cause damage to the water purier’s

external cover or internal components, which

in turn could lead to leakage, equipment

malfunctions or even serious property

damage.

Do not place any objects on top of your

water purier!

Obstructing the heat dissipation may lead to

machine damage or res.

Warnings

Please read carefully and take into consideration the following notications. Otherwise, it may cause permanent damage to your equipment or cause

serious property damage.

Safety Considerations

(Be sure to read and remember these safety considerations)

Make note of the following safety precautions In order to avoid property damage and harm to you and others.

•Not considering the following safety precautions could result in risky situations for you, your cabinet water softener

and your environment.

ENG 5

Do not use this water purier under high

water pressure conditions!

Operating under high pressure conditions

may cause the water purier pipes to rupture,

resulting in leakage, the machine working

improperly, or even serious property damage.

Recommended inlet pressure is

0.25MPa to 0.58MPa. (2.5 - 5.8 Bar)

Do not use a power source exceeding

the equipment’s specied value. Use only

220V AC power!

The electrical current supplied to your

equipment by the outlet must not be greater

than the specied value; otherwise it may

lead to the overheating of your equipment

or re.

Do not touch the power plug with wet hands!

It may lead to electric shock.

Do not damage the power cord

or the outlet!

Doing so may lead to electric shock, short

circuiting or re.

Do not let the machine come in contact with

corrosive materials!

These materials could corrode the outer cover

and adversely affect various parts of the

equipment. Toxic and hazardous compounds

could penetrate the water purier pipes,

causing contamination of the water or

leakage, which in turn may cause personal

damage or property damage.

The equipment must be disconnected from

the power supply during installation

and repairs!

Otherwise it may lead to electric shock.

220 V

ENG 6

Do not use the water purier when

the drainage is blocked up!

If the purier is used while the drainage is

blocked, it may cause waste water to back

up into the purier and pollute the water

and parts inside.

Do not place the water purier under direct

sunlight!

Placing the water purier under direct

sunlight for a certain period of time may

create a breeding ground for microorganisms;

decreasing the output water quality

and potentially causing the internal

components of the water purier

to become contaminated.

The waste water discharge pipe and

waste water rationing device cannot be

blocked!

When the waste water discharge pipes and

waste water rationing devices are obstructed

or clogged, it may lead to high levels of TDS

efuent, the RO membrane may get blocked

or the water purier may not work.

Do not use in conditions under 5°C!

If the ambient temperature falls below 5°C,

please be sure to take measures to prevent

freezing, such as turning on a heater or air

conditioner to prevent leakage or cracked

pipes caused by water freezing inside

the equipment.

Water purier inlet water temperature

should not exceed 45°C!

If the inlet water temperature is over 45°C,

it will damage the reverse osmosis membrane

leading to membrane failure.

Do not use this water purier outdoors!

If this water purier is used outdoors, it can

lead to accelerated aging of the

water purier pipes and parts, which can

cause leaking or machine failure.

ENG 7

Brief Introduction

This equipment utilizes the current, most advanced international

RO technology. RO technology relies on the articial reversing of the

naturally occurring osmosis phenomena. The RO membranes have pores

with a diameter of 0.0001 micron (0.1 nm), so they can effectively remove

bacteria, viruses, heavy metals, pesticide residue, and other harmful

substances from the water. The water produced is fresh, pure and suitable

for use directly.

Description of Components

Product Description

Connection Port

1/4" 4-6 QF Male Run Tee

1/4" Male Juncture Filter Housing

1/4" PVC Nipple

1/4" 4-6 QF Male Elbow

4-6 QF Stem Elbow

24 VDC - 0.31 GPM High Pressure Pump

220V AC - 24 VDC Transformer

1/8" 4-6 QF Male Elbow

18x12 Membrane Housing

1/8" 4-6 QF Check Valve Male Elbow

300cc Flow Restrictor

Shut Off (4-Ways) Valve

High Pressure Switch

Low Pressure Switch

4-6 QF Side Stream Tee

Inline Post Carbon Filter

Membrane Housing Clips

Inline Post Carbon Filter Clips

Cabinet Hanging Plaque

Steel Bracket

Cabinet Cover

Storage Tank Valve

3.6G Storage Tank

Filter Housing O-Ring

Memrane Housing O-Ring

Lotus-72 Diagram 1

1

8

16

2

9

17

3

10

18

4

11

19

5

12

20

6

13

21

24

7

14

22

25

15

23

26

1

2

3

3

3

4

4

55

5

15

16

17

18

18

6

6

7

8

9

910

13

14

11

12

19 19

20

21

22 23

24

25

25

26

25

ENG 8

Electrical Diagram

Diagram 2

High Pressure Switch

Low Pressure Switch

Transformer

220 V 24 V (36 V) Pump

Water Route Map

Diagram 3

Osmosis Faucet

Pure Water

3-Way

Inlet Valve

Running Water

Waste Water Discharge

Post Carbon Filter

RO Membrane

& Membrane Shell

6 mm

Ball

Valve

Check

Valve High

Pressure

Switch

High Pressure

Pump

4-Way Valve

Shut off InletsShut off Outlets

Storage Tank Ball Valve

Flow Restrictor

Device

10" 5m

Sediment

Low Pressure Switch 10" Block Carbon

Filter

10"

GAC Filter

Storage

Tank

ENG 9

Functions of the Main Components

The standard conguration of the water purier that utilizes the current,

most advanced international RO technology is as follows:

The rst stage is a 10" 5-micron PP Filter (Sediment):

The pores on the aperture within the PP lter is 5 microns wide so it

can effectively lter rust, sand, other larger particles and solid impurities

suspended in the water.

The second stage is a 10" Granular Activated Carbon Filter:

The lter effectively absorbs chlorine, mould, disinfection by-products,

odors, discolorations and other materials suspended in the water.

The third stage is a 10" Block Carbon Filter:

This lter further removes small particles within in the water, suspended

solids, colloids, etc.

The Fourth stage is the RO membrane:

The membrane has an aperture of 0.0001 micron (0.1 nm) that reduces

bacteria by 4,000 fold, reduces viruses by over 200 fold, so you can

effectively remove bacteria, viruses, heavy metals, pesticide residue,

and other harmful substances contained in your water supply.

The fth-stage is a post-activated carbon lter:

This lter regulates the taste of water and keeps the water fresh.

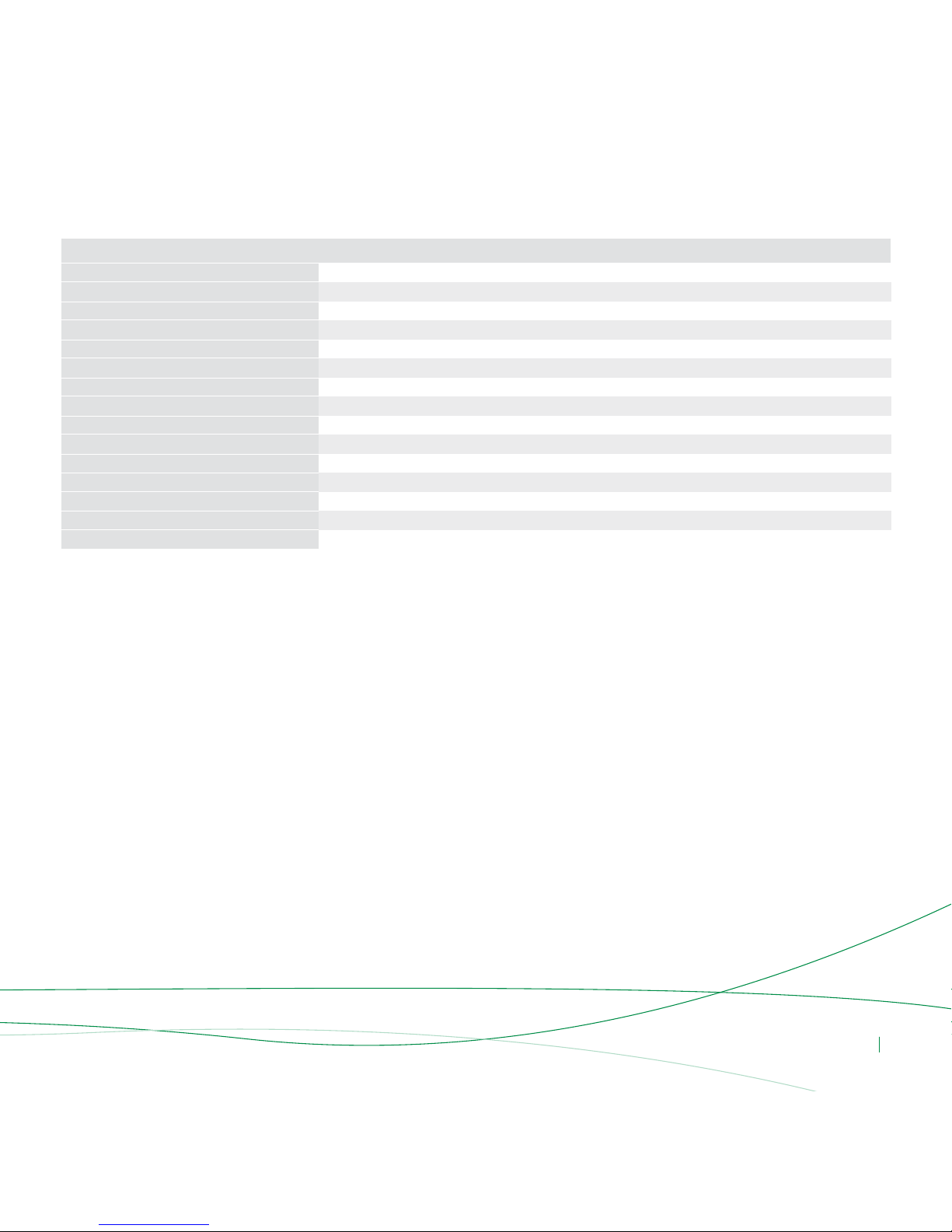

Technical Specications

dissolved solids.

Model No.

Voltage

Operating Pressure

Open Flow

Feed Water Pressure

Feed Water Tempreature

Feed Water pH

Feed Water TDS

Feed Water Hardness

Feed Water Iron

Feed Water Manganese

Power Rating

Maximum Daily Water Production Volume

AC 220V AC 50HZ

19.2 W

0.4 ~ 0.6 MPa

0.31 GPM

0.25 ~ 0.58 MPa

75 Gallons, approximately 280 Liters

5 ~ 45°C

5 - 10

Max. 2000 PPM

< 17 Fr

< 0.1 Ppm

< 0.05 Ppm

LOTUS-72

NOTE:

0.1 MPa = 1.02 Kg/cm2 = 14.5Psi = 1 Bar

1 Psi = 0.07 Kg/cm2

1 Gallon = 3.785 Liters

75 GPD = 75 Gallons/Day = 284 Liters/Day = 197 Milliliters/Minute

Dimensions

Tank Capacity

Weight

400 x 490 x 210 mm

3.6 Gallons (13.6 Liters)

14.2 kg

ENG 10

Pre-Installation Preparations

Choose the location where the water purier will be installed.

Conrm the availability of the various tools required

for installation.

Conrm that you have all the connectors required for installation.

Make sure to turn off the water supply and electricity before

starting installation.

Stock up on top of each other more than 8 pieces.

Before lifting the packages be sure that xing tapes below the package

are intact.

Lift the packages holding from bottom.

Persons, who are vulnarable to heavy lifting shoud not carry the packages

to prevent any health issues.

While lifting the RO, hold from the metal shaft.

Functions of Accessories

Storage Tank: Used to store water ltered by the water purier.

High Pressure Pump: Boosts pressure to create a stable environment

for the RO membrane.

Flow Restrictor Device: Controls waste water ow.

Low Pressure Switch: Prevents pump idling. When the inlet water

pressure is less than 0.03 MPa or when the inlet water stops,

the low-pressure switch automatically shuts off the power source

so the machine comes to a halt.

High-Pressure Switch: Prevents pump from overdrive. When the storage

tank is full or has reached the set pressure level, power supply is

automatically cut off to stop the operation of the machine.

Inlet Water Valve: It is used to turn on/off incoming water.

Check Valve: Also known as a one-way valve, controls the direction

of water ow.

Transformer: Converts 220V AC to 24V DC (the machine’s safe

operating voltage).

Shut-Off (4 Way) Valve: It directs the ow of puried and drain water.

It is synchronized with the RO pump action. When the pure water

storage tank is full of water, the RO pump and shut-off valve will

automatically shut down. When shut-off valve shuts down, the puried

and drain water both will be shut down.

Installation Methods

Our company recommends that your water purier is installed by trained professionals as the installation process is somewhat complex and requires the

use of various tools. However, if you decide to install the purier yourself, please refer to the following steps and diagrams:

Transportation

Please take into consideration the following points while transporting the device.

Adjustable Spanner

Drill

6.2 mm Drilling Bit

Hole Saw φ14 mm

Phillips and Flathead Screwdrivers

Scissors

16 mm Wrench

14 mm and 12 mm Multi Wrench

Needle Nose Pliers

1

1

1 (Waste water hole)

1 (High-speed steel or marble hole saw)

1 of each

1

1

1

1

NECESSARY TABLE FOR INSTALLATION

ENG 11

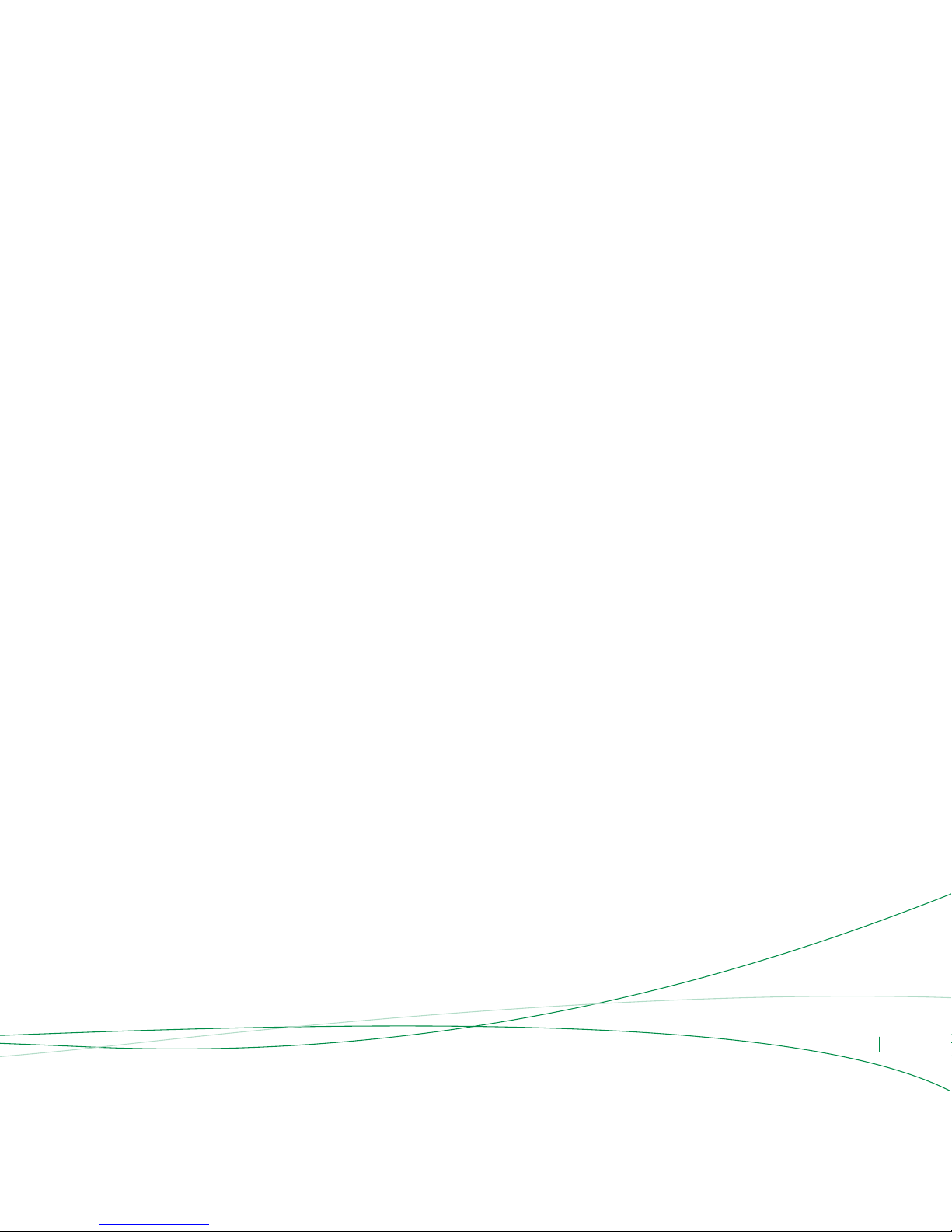

Instructions to use Quick Fittings

Your Reverse Osmosis Water Purier is outtted with the new generation

of userfriendly “quick ttings”.

Proper use of the ttings is shown in the diagrams below.

To Attach Tubing

Push tubing straight in as far as it will go.

Tubing is secured in position.

To Insert Locking Clip

Push in collet to release tubing.

To Release Tubing

Locking clip slides between collet and tting.

It is important that the tubing selected for use with these connectors be

of high quality, exact size and roundness, and with no surface nicks or

scratches. If it is necessary to cut the tubing, use a plastic tubing cutter or

sharp razor knife, make a clean, square cut.

If there is leakage at a tting, the cause is usually a defective tubing end

cut. To x this problem, follow below steps:

Relieve pressure.

Release tubing.

Cut off at least 1/4” from end.

Reattach tubing.

Conrm connection is leak free.

Diagram 4

Diagram 6

Diagram 7

Diagram 5

Collet

Clip

(Before Installation)

Clip

(After Installation)

Tubing

Tubing

ENG 12

Instructions for Proper Installation

• Method of installing the inlet water metal hose and 3-way inlet water joint:

(If the metal hose diameter is 9 mm the 3 - way inlet water joint must be

purchased separately) First, close the inlet water valve. Screw off

the metal hose. Remove the 3-way inlet water joint from the water

purier accessories box, screw one end of the inlet water 3-way joint

onto the inlet water valve outlet. One end of the unscrewed metal hose

should be screwed into the 3-way inlet water joint using the screw nut.

(See Diagram 8)

Method of installing the 3-way inlet water joint and inlet water ball valve:

Take out the inlet water ball valve from the water purier accessories

box, wrap one end of the external threads on the ball valve with

appropriate teon tape (See Diagram 9). If you have silica gel, spread

a little over the thread and then screw the ball valve into

the corresponding hole of the 3-way inlet water joint (See Diagram 9).

Take out the Ø 9mm water pipe from the accessories box. Using a pair

of scissors, cut a suitable length of pipe and connect one end of the pipe

to the inlet water ball valve (See Diagram 10). Finally screw the nut in

place.

Diagram 8

Faucet Water Hose

Connector

Washer

Washer

Inlet Water Valve

Inlet Water Valve

Screw Nut

3-Way Inlet

Water Joint

Diagram 9

3-Way Inlet

Water Joint

Inlet Water

Ball Valve

Teon Tape

Water Pipe

Connection

Diagram 10

9mm Ball Valve

Inlet Water

3-Way

Joint

ENG 13

Installation of the osmosis faucet:

Drill a φ14mm hole in an appropriate position on the counter where

the faucet is to be installed. Then take out the faucet from the water

purier accessory box. Begin the installation of the faucet. First put

the stainless steel neck on the faucet main body (See Diagram 11), then

lower the main part of the faucet into the hole you have drilled. Put

the spacer on the lower part of the faucet and screw the xed nut on

to the bottom end of the faucet in order to x the faucet to the counter.

Finally, attach the appropriate length of 6mm pipe into the water inlet

connection. Attach the 6mm pipe stopper into one end and place it

on the 6mm nut. Screw it on the bottom of the faucet (see Diagram 12).

If you want to x the faucet on a wall, please use the faucet hanging

piece (when installing be sure to tighten the joints to prevent leakage).

Installation of the waste water pipe:

Drill a small hole into the sink drain pipe using a φ 6mm drill. Take

a suitable length of the 6mm water pipe and lay one end just inside

the drilled hole (See Diagram 12), put some silica gel where the 6mm

pipe and the drain pipe connect to prevent leakage. Use a cable tie to x

the waste water pipe to the drain pipe (for large ow water puriers;

you will need to insert a waste water clip into the drilled drain pipe hole)

Diagram 11

Stainless Steel Faucet

Main Part of Faucet

Inlet Water

Connection

Diagram 12

Pure Water Pipe

Hot

Cold

Inlet Water Ball Valve

Waste Water Hole

Drain

Water Inlet

Osmosis Faucet

Diagram 13

ENG 14

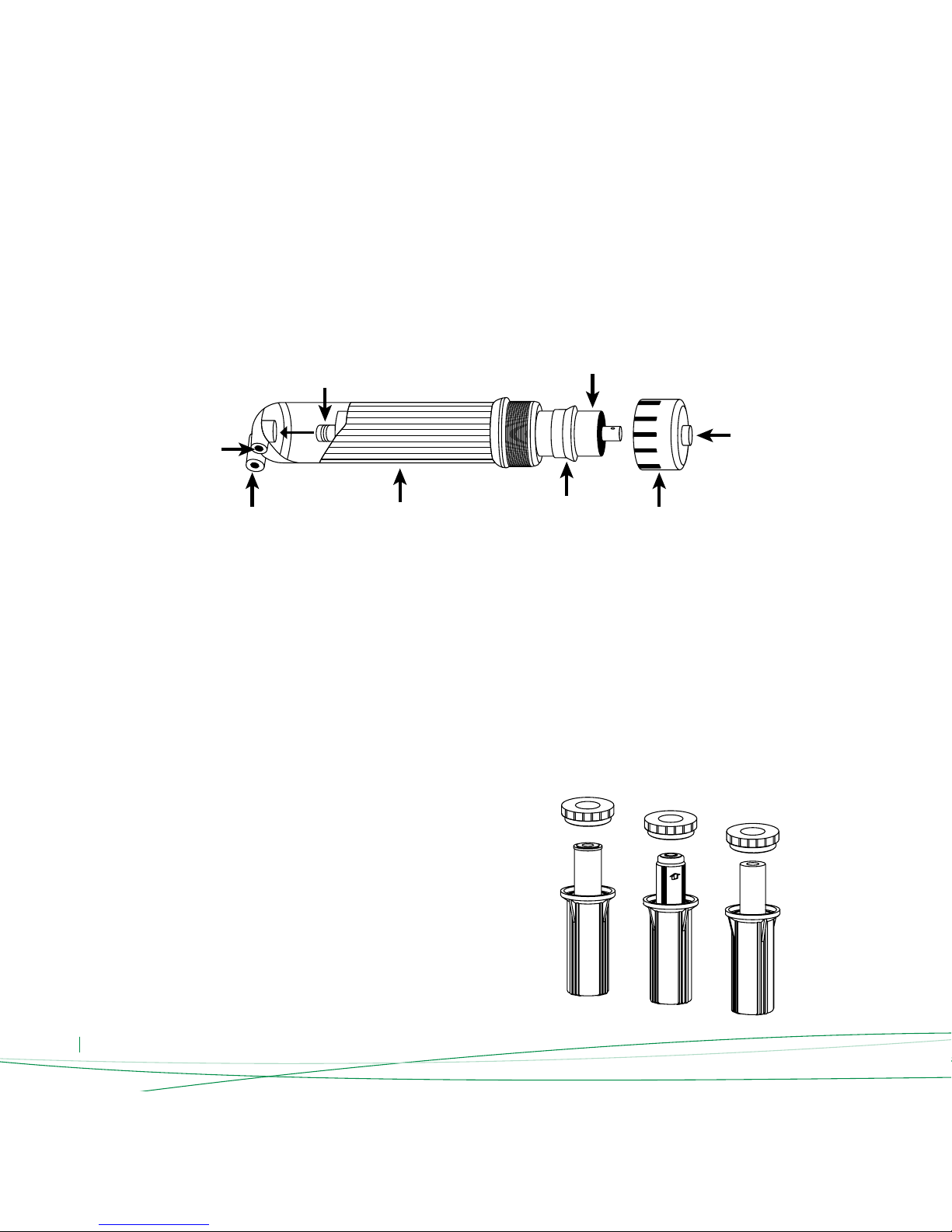

RO Membrane Installation:

First take the water purier out of its package. Open the water purier’s

outer cover. Unscrew the membrane shell cover inlet water connection

and take out the inlet water pipe. Then use the membrane shell wrench

to unscrew the membrane shell cover. Take the RO membrane out from

its package. Place the end of the membrane with the O-ring into

the reverse osmosis membrane shell (See Diagram 11) and push it in.

Finally, screw the membrane shell cover back on and use the membrane

shell wrench to tighten the membrane shell cover. Connect the inlet water

pipe into the inlet water connector on the membrane shell and screw in

the nut. Place the membrane shell card into the large single clip available

and attach the water purier cover back on.

Diagram 14

Diagram 15

Pure Water

O-ring

Membrane Shell

RO Membrane

Waste Water

Sealing Ring

Inlet Water

Membrane

Shell Cover

Membrane Installation Warnings:

The package of the reverse osmosis membrane contains a small amount

of protective solution in order to prevent microbiological contamination

of membrane components during storage and transportation.

• You should pay attention to the direction of the RO membrane during

installation.

• When installing the RO membrane; you should rst make sure that one

end of the membrane has an O-ring;

• During installation, be sure to put the end with the O-ring into the end

of the membrane shell with the pure water connection. If you install

the reverse osmosis membrane correctly, you will only need a little force

to mount it into the membrane shell. If you encounter too much

resistance, please do not force the reverse osmosis membrane into

the membrane shell. Doing so may cause permanent damage to the

membrane shell or membrane components (the membrane

manufacturer does not assume responsibility for returned components

due to damages incurred during installation).

• Damage to the membrane shell and reverse osmosis membrane

components inicted as a result of the abovementioned reasons is not

covered under the water purier’s warranty.

• Do not cut or try to disassemble the replaced membrane. RO membrane

can lter microorganisms and cutting or harming RO membrane may risk

on you and your environments health.

Installation of the Pre-Filters:

First take the pre-lters out of their packages. Tear off the packaging

of the lters in the order they should be installed: rst is the 5 micron PP

lter; second is the granular activated carbon lter, note that the rubber

pad must be installed on the top of the activated carbon lter; third is

the 10" block carbon (See Diagram 15).

ENG 15

Installation of the Storage Tank:

First wrap teon tape around the water nozzle (4-5 turns). Use a little bit

of silica gel to prevent water leakage and loose connections. Then,

screw in the water tank ball valve into the water nozzle and nally

connect the water pipe to the storage tank: rst cut a suitable length of

the 6mm tubing, then put a screw nut on each end of the tubing. One

end of the piping should connect to the water purier labeled storage

tank connector, the other end should go in the storage tank ball valve

(See Diagram 16). Finally place the storage tank on the oor.

Installation Notes

When installing the water pipes, you should not install a drain stopper.

Furthermore, the screw nut on the water pipe bottom connector should

have no wire teeth exposed.

If the inlet water pipe is 9mm, you should ensure that the inlet water

pipe and connector have 30-40cm of straight piping to avoid pipe

bursting accidents caused by bending of the pipe.

If the power cord wiring needs to be longer, extend the cord according

to the wiring requirements and use an 8mm pinched tube to wrap

around the connection. Later, wrap insulating electrical tape

on the outside surface. Do not place the cord on the oor. The cord

should be suspended in the air or should follow a path above ground.

During installation, make sure that there is no electrical wiring or water

pipes embedded inside the walls where you will do the drilling.

Storage Tank

Diagram 16

6mm

Screw Nut

Storage Tank Ball Valve

Water Nozzle

Base

6mm

Pipe Stopper

Adjustment Methods

Make sure that the water route connections are correct, proper power supply is used and water supply is suitable.

Then, follow these steps to adjust the purier:

Open the tap water inlet valve and the water purier inlet water ball

valve and plug the purier in the power outlet (See Diagram 17).

Wait for the water purier to operate stably (for about 5-10 minutes).

Check each connection to make sure they are secure. Check to see if

there is any leakage from the membrane shell, lters, etc.

Close the pure water osmosis faucet and storage tank ball valve. Wait

approximately 30 seconds. Check to see whether or not the water

purier waste water and high pressure pump have stopped working.

Open the osmosis faucet. Check to see if the water is owing through

the faucet. If not, check to see whether the tap water pressure is too low,

whether or not the high pressure switch can be reset automatically.

Wait until the machine is operating properly, then close the inlet water

ball valve. After a short period of time, check to see if the machine stops

working, if it does not stop working, check to see whether

or not the low-pressure switch can be reset.

Perform a second check to make sure everything is ok. Now your water

purier is ready for use.

Diagram 17

Close

Inlet Water Valve

Open

ENG 16

Maintenance and Repair

The major components of this product are manufactured using plastic.

When using the water purier, always observe the integrity

of the equipment in order to ensure safe operation.

The post activated carbon lter may emit activated carbon powder

the rst time it is used. So do not open the water storage tank during

the rst hour when the water purier is put into operation. It is

recommended that the water produced during this period is disposed of.

Otherwise, the taste of the pure water may be unusual.

When you rst operate the water purier, the pure water TDS value may

be a little high. After operating for some time, the TDS value of the pure

water produced will gradually decrease until it is stable.

When you are using the water purier, the inlet water ball valve should

be opened and the pure water faucet needs to be turned on. When

you are not using water turn off the water faucet, the high pressure

switch will automatically cut off the water supply.

When you rst use the storage tank it is recommended that you discard

the rst tank of water; otherwise it may result in abnormal tasting pure

water.

It is recommended that you use the machine at least twice a week

to prevent microbiological contamination caused by the equipment lying

idle for an extended period of time, which in turn might cause odors

in the water.

If you did not use the machine for a longer period (more than one week),

before using puried water, follow the below steps:

- Turn off water inlet

- Cut off electricity

- Empty the water storage tank. Turn on the inlet water and electricity.

The machine will begin reverse osmosis.

If you did not use the machine for long periods (i.e 1-2 months), replace

the lters before using the machine.

In these “operation warnings”, “operation” refers to the power supply

being connected and/or the inlet water ball valve being open

so the water purier is in an operational state.

Operation Warnings

Filter Replacement Intervals

The lter replacement cycles for the various lters used in this purier is

derived from statistical indicators on the estimates of average tap water

usage. If there are considerable discrepancies between the supply

water quality, utilization rates and average indicators, there will be more

obvious differences between the lters actual replacement intervals

and estimated life-cycles and users may experience premature lter

clogging, premature failure, etc. If this occurs, lter replacement

intervals should be based on actual usage conditions. You should also

contact your local after-sales service department immediately to inform

the situation.

This machine’s estimated lter replacement cycle is based on average

household water consumption and is suitable only for residential use,

do not install this machine in places that require large volumes of water.

If the water volume requirements are large, our company offers

appropriate equipment tailored for commercial applications.

According to economic statistics on municipal tap water, a three person

family on average uses 10L of water a day. According to the water

volume and inlet water quality conditions, approximate ltering

volumes are as follows (the following data is for reference only):

WATER VOLUME (TONS)

7.5

7.5

10

50 - 75 - 80

6

USAGE PERIOD

3 Months

6 Months

6 Months

1-2 Years

1 Year

PROGRESSION

First: 10" 5m PP Filter

Second: 10" GAC Filter

Third: 10" Block Carbon Cartridge

Forth: Reverse Osmosis Membrane

Fifth: Post-Activated Carbon Filter

ENG 17

standard conditions. In actual usage, due to the fact that water quality

than the abovementioned estimates. This data is provided for reference

only. Under normal circumstances, if you witness the following indications,

membrane is blocked (determine that it was not caused

by a temperature drop);

Filter Replacement Method

should be disposed in a tightly closed garbage bag.

• Replacement of the 1st and 3rd stage lters:

First of all close the inlet water ball valve. Using the lter cartridge

wrench, unscrew the 1st and 3rd stage lter cartridges. Remove the old

lters and take the new lters out of their packaging. Finally place

the lters in the lter cartridges (Note: place the 5 micron PP lter

in the 1st stage lter cartridge, the block carbon in the 3rd stage

lter cartridge), using the lter wrench, tighten the lter cover.

• Replacing the 2nd stage lter:

First of all, close the inlet water ball valve. Using the lter cartridge

wrench, unscrew the 2nd stage lter. Remove the old lter and take

the new lter out of its packaging (note: the rubber pad on the lter

does not need to be taken off). Place the lter inside the lter cartridge

(note: the granular activated carbon lter should be placed with the

rubber pad end directed up towards the lter covers). Finally, use

the wrench to tighten the lter cover.

• For replacement of membrane elements please see

“RO Membrane Installation”

Warnings

• Notes before using replaced lters: After replacing the granular activated

carbon lter (2nd stage), you must rst ush out the machine in order

to avoid the activated carbon powder from the granular activated

carbon lter from owing into the 3rd stage lter or even

the RO membrane, which may result in damage to lter and membrane

components.

If there is dark colored water near the third stage lter, perform the

following steps:

- Turn off the water purier inlet water valve;

- Using the lter cartridge wrench, remove the water purier’s 3rd

stage lter;

- Place a large container near the 3rd lter cartridge cover to collect

the dark colored water;

- Open the inlet water valve, wait until the water is no longer dark;

- Close the inlet water valve, reinsert the 3rd stage lter into the lter

cartridge, and screw it in tight.

Please ush the post-activated carbon lter for 1-2 minutes before using.

• RO membrane water production volume:

The water output volume of the RO membrane component is

inuenced by inlet water pressure and water temperature.

Your equipment’s declared volume of 75GPD is tested under a net

pressure of 0.5MPa and inlet water temperature of 25°C .

If net pressure is less than 0.5MPa or if the inlet water temperature is

less than 25°C, water output volume of the RO membrane component

will be less than 75GPD.

• Storage tank capacity:

The storage tank on your equipment has a stated capacity of 3.6G.

However this gure is its theoretical capacity and its actual storage

capacity is about 70%-80% of the stated value, which is app. 2.5-2.8G.

• Disposal of old lters:

After replacing old lters, they cannot be cleaned and reused; it is

recommended that you dispose of them with solid waste garbage.

ENG 18

Notes

When any of the following situations occur, immediately disconnect

the water purier water source (close the inlet water ball valve) and/or

the power source and carry out repairs.

- If the water purier pipes or related components are leaking.

- If the water purier and/or components stop working.

- If any components leak electricity.

- If there are any other anomalies or failures.

When you go out or do not use the machine, disconnect the water

purier's water source (close the inlet water ball valve) and/or power

source.

If the water purier parts are damaged, it is recommended that the water

purier be entrusted to the manufacturer or distributor, service center,

or specialized technical personnel for replacement to prevent loss caused

by improperly performed maintenance, the manufacturer assumes

no liability for losses incurred as a result of operation or use that does

not conform with the instructions and reminders specied herein.

Packing List

LOTUS-72

1 Unit

1

1

1

1

1

1

1

1

1

1

1 Package

1

1

1

1 Roll

1

1

1

1

1

PARTS

Main Machine with Cabinet (Including Filters)

R.O. Membrane

Steel White Coating Bracket To Fit 3-Canister RO unit

Storage Tank

Filter Wrench

RO Booster Pump and Transformer 220V/50Hz with 2 Round Pin Plugs

High Pressure Switch

Low Pressure Switch

Check Valve and Male Elbow

Flow restrictor 300 ml 1/4”

Automatic shut off valve 1/4” (4 ways valve)

Standard Installation Kit consisting of

Water Inlet Valve ½”½” ¼” (3-way)

Chromed Ball Valve

Tank Shut Off Ball Valve 1/4”

Water Pipe

Drain Saddle Kit with 1/4" Screw

Chromed Osmosis Faucet

Faucet connector 1/4" x 7/16" FPT

Plastic Hanging Bracket to Fit Long Reach Faucet

User Guide (Including Warranty Card)

Table of contents

Languages:

Other WaterClinic Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Atlantic Ultraviolet

Atlantic Ultraviolet Mighty Pure MP16A owner's manual

SunSun

SunSun CBG-500 Operation manual

Hayward

Hayward XStream Filtration Series owner's manual

Contech

Contech DownSpout StormFilter Operation and maintenance

Teka

Teka Airfilter MINI operating instructions

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual

STA-RITE

STA-RITE VERTICAL GRID DE FILTERS S7D75 owner's manual