WaterLine Controls WLC-9000 User manual

Installation Instructions for Model WLC-9000

IMPORTANT SAFETY INSTRUCTIONS

Page 1

© SDI 2008

is the optimum choice for any situation requiring the

precise control of a water level. It is ideal for automatically maintaining the

correct level in cooling towers, storage tanks, or process water applications.

Model WLC-9000 achievescontrol by the use of a

corrosion resistant probes that sense the water level and then in conjunction with

electronics and a microprocessor, provides signals that can be used to open/close

valves and other control or recording devices thus maintaining correct levels.

Levolor is a registered trademark of Jandy Pool Products, Inc. and used under license only. SDI and Jandy Pool Products, Inc. are not affiliated companies.

Waterline Controls is a registered trademark of SDI.

1. Call the factory with any questions. 1-888-905-1892 or write to:

System Dynamics, P.O. BOX 12544, Scottsdale, AZ 85260

2. Read and follow all instructions.

3. Disconnect all power before opening the internal cover/s or making any connections to the unit.

4. Do not install in locations where sprinklers or other watering devices will allow water to impinge on the unit.

5. Sensor wires must be continuous and not spliced.

6. Make sure the unit is connected properly to earth ground.

7. Only qualified personnel should install this unit or replace the "replaceable" parts.

8. Only factory supplied parts should be used whenever a replaceable part is needed.

9. The manufacture will not be liable for any injury or damage that may arise from the misuse of this

unit or from failure to follow all of these instructions.

10. Save these instructions and provide them to the end user.

11. This unit shall not be used in any "safety critical" application or where the failure of any function or component may cause death or personal injury.

11. Ne pas utilisez cet élément quand les blessures oú la mort peuvent les présenter.

12. Use copper (CU) wire only for all connections.

TM

Page 2

© SDI 2008

T

he unit is powered by either 110 VAC or

220 VAC 60 HZ 0.5 Amp. The input voltage is determined by

the option selected. If the 110 VAC option is selected, then the

input power wires are: one black and one white. If the 220 VAC

option is selected, then the two input power wires are both black.

The unit is rated for indoor or outdoor installation.

These power relays may be used to control valves, or

solenoids; but not motors. There are also low power SPST

relays whose contacts are rated at 50 VAC/DC 0.25 Amp.

that can be used as an additional indicator or to provide an

indication to an event recorder, computer or automation system.

The normal indicator on the unit is a green LED that is

a "power ON" indicator and is on whenever power is applied to

the unit. There are also other LED's that turns ON whenever

the relay contacts are closed. These indicate a very high

level condition, or a DRAIN

I

or DRAIN

II

condition and will

remain ON until the level changes to some other level.

See Table 1 for the LED functions associated with the

various models. The contact with the water is sensed by

electronics and the microprocessor then provides the

necessary control for the various outputs.

The parts supplied are:

1 - The Waterline Control CONTROLLER.

1 - Stainless steel probe assembly with 50 feet of wire.

2 - U bolts with nuts.

1 - Mounting bracket.

* Power Relays (as required)

Figure 1.

WLC-8000

Sensor Low Voltage Raceway

POWER

ALARM DRAIN IHIGH

ALARM

TESTING

PRESS TO TEST

Green (Ground)

Black

Black

220VAC OR 110VAC

White

Black

LOW ALARM

(LA)

HIGH ALARM

(HA)

FILL

Brown

Pair

Green

Pair

Red

Pair

Quantity of relays

and lights are a

function of

the model.

"Bottom plate removed

in illustration."

DRAIN II

WLC Relay

(N.O.)

LOAD

(Solenoid, Pump,

Contactor)

* All loads combined

cannot exceed

Circuit Breaker Rating

Hot

Neutral

Single Pole Relay

LINE

(110VAC)

The "replaceable" parts are:

Waterline Control CONTROLLER part # WLC-9000 with option110 or

220 vac (specify option: 110 or 220 VAC)

Stainless steel probe assembly See Sensor assembly appendix.

Power relay part # PG8P

Solenoid part # 8221G5 (other options for voltage &

pipe size are available; Contact the factory).

This size is 110VAC 1" pipe. (optional)

U Bolts/nuts U20P5-9

Mounting bracket MB2

© SDI 2008 Page 3

The sensor assembly (see Figure 2) must be mounted so that the end of

the PVC pipe is below the minimum water level that is to be maintained.

Secure the probe assembly to a suitable mounting surface with the correct size

"U" (U2OP5-9) bolts and the mounting bracket (M2OP5-9). Be careful to insure

that the top portion of the assembly is not in contact with the water and that the

"U" (U2OP5-9) bolts are above the high water level. Note: There are two small

1/8 inch vent holes near the top of the housing in the

PVC pipe. Make certain this vent holes are not obstructed in any way.

They must be clear in order for the sensor assembly to function properly.

The probe assembly is supplied such that it has the sensor

cable pre-installed. Route the cable along an appropriate location and

determine if the length needs to be shortened. The wire may be cut to a

shorter length if required.

NOTE: THE SENSOR WIRES MUST NOT BE SPLICED IN ORDER TO

INCREASE THE LENGTH.

Fasten the wire to a water tight PVC compression connector and then install

into the bottom of the Waterline WLC7000 housing. The output control wires

are connected to the relays output terminals

(¼ inch spade) connector supplied by the user.

NOTE: the rating on the relay should not be exceeded.

Use water tight PVC conduit for all connections and route the location

desired by the end user.

If the depth of the probes need to be seen while the sensor assembly is

installed mark the sensor probe levels on the outside of the pipe with

a "Sharpie". The center of the nominal set point is marked with

a black button in the outer pipe.

SENSOR ASSEMBLY INSTALLATION

The Waterline WLC7000 through WLC-9100 should be mounted in a covenant location where water spray will not impinge upon the

unit and at a height consistant with figure 2. The unit and the input/output cabling must be securely attached to the mounting surface.

Sensor Assembly

Structural Wall

Sensor Wire

(no splicing)

"U" Bolts

4 inches

Mounting

Bracket

Probe Illustration for WLC-9000

Figure 2.

MB2

420P5-9

Min.

© SDI 2008

Page 4

The following test procedure will test the electronics and output relay functions. The test verifies all of the electronics from the location of the

sensor wire connection to the PCB through the output relays. It verifies the functions of the Waterline WLC-9000.

THIS TEST IS VALID FOR THE WLC-9000. To initiate the test,

perform the following:

1. Press the "PRESS TO TEST" push button momentarily. The yelllow LED will light and remain on until the "test function" is completed.

2. The controller automatically sequences through the functions.

Note: once the "PRESS TO TEST" button is depressed the test sequence cannot be interrupted. This test will take approximately 2 minutes.

The functions of the LED's, the power relays and the indicator relays are shown in the following truth tables.

TEST INSTRUCTIONS

TESTING TRUTH TABLE

DEFINITIONS

DRAIN I: The water level is approaching the unsafe level.

DRAIN II: The water level is approaching the unsafe level.

HIGH ALARM: The water level is approaching the maximum allowed level.

FUNCTION TRUTH TABLE

TEST SEQUENCE DRAIN IDRAIN II HIGH ALARM

1

2

3

4

5

6

7

8

9

10

11

OFF

OFF

OFF

ACTIVATED

ACTIVATED

ACTIVATED

ACTIVATED

ACTIVATED

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ACTIVATED

ACTIVATED

ACTIVATED

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ACTIVATED

OFF

OFF

OFF

OFF

OFF

*For the WLC9100, the test sequence repeats and the DRAIN Ialternates with DRAIN II

MODEL HIGH ALARM DRAIN IDRAIN II TEST FUNCTION

WLC-9000 YES YES

YES YES

Popular Controllers manuals by other brands

Adaptec

Adaptec 29160LP - SCSI Card Storage Controller U160 160... installation guide

esera

esera ECO 208 PRO 48V quick guide

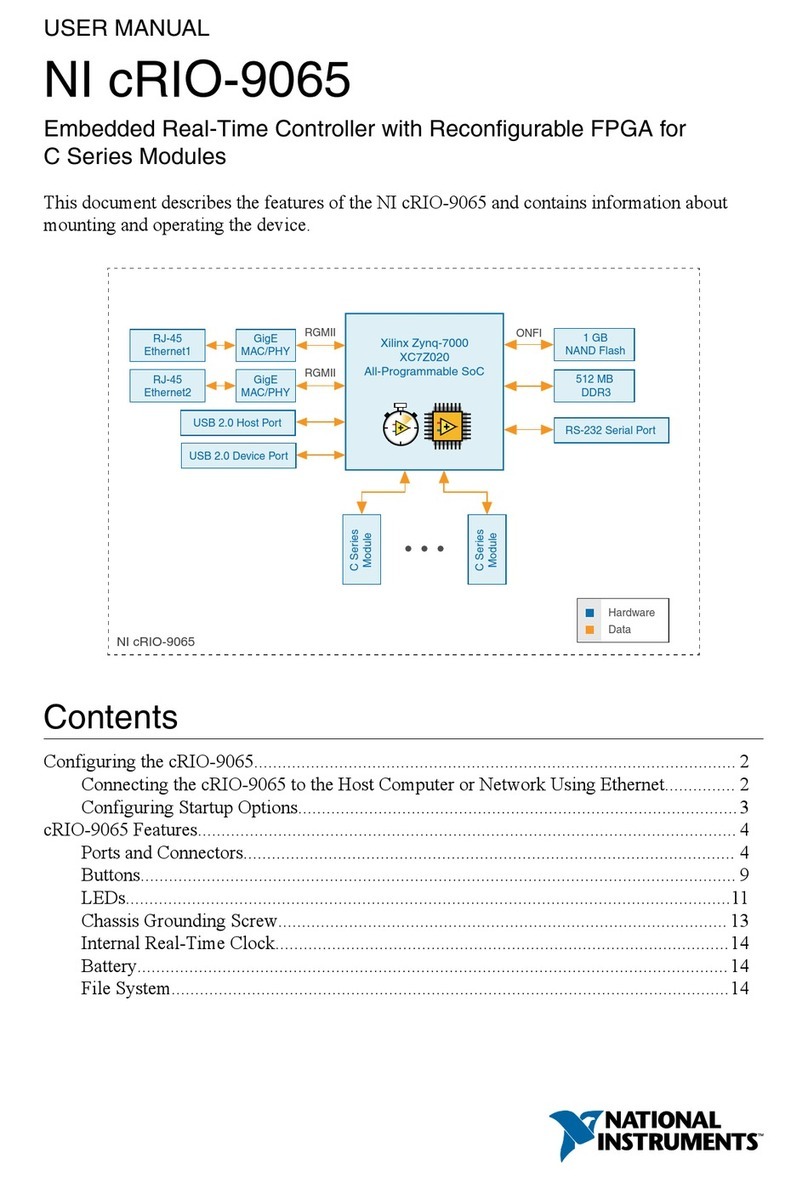

National Instruments

National Instruments NI cRIO-9065 user manual

ADJ

ADJ STAGE SETTER-8 User instructions

Contest

Contest PILOT-192PRO user guide

Linear Technology

Linear Technology DC1723A Demo Manual

SIIG

SIIG Smart Controller for HDMI over IP Series user manual

lrritrol

lrritrol Rain Dial RD-600 user guide

YASKAWA

YASKAWA PROFINET V1000 installation manual

Vaportek

Vaportek RESTORATOR Use and Operating Instructions

Hubbell

Hubbell Electric Fire Pump Controllers LXi-1200 Specifications

ABB

ABB Galaxy Millennium J2011002 product manual