WATERS CORPORATION 3465 Operating manual

Waters 3465 Electrochemical

Detector

Overview and Maintenance Guide

715007395

Version 00

Copyright © Waters Corporation 2021

All rights reserved

General information

Audience and purpose

This guide is intended for use only by professionally trained and qualified laboratory personnel

who operate and maintain Waters products.

Copyright notice

© 2021 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF AMERICA AND IN

IRELAND. ALL RIGHTS RESERVED. THIS DOCUMENT OR PARTS THEREOF MAY NOT BE

REPRODUCED IN ANY FORM WITHOUT THE WRITTEN PERMISSION OF THE PUBLISHER.

The information in this document is subject to change without notice and should not be construed

as a commitment by Waters Corporation. Waters Corporation assumes no responsibility for any

errors that may appear in this document. This document is believed to be complete and accurate

at the time of publication. In no event shall Waters Corporation be liable for incidental or

consequential damages in connection with, or arising from, its use. For the most recent revision

of this document, consult the Waters website (www.waters.com).

Trademarks list

Empower™ is a trademark of Waters Corporation.

FlexCell™ is a trademark of Antec Scientific.

HyREF™ is a trademark of Antec Scientific.

ISAAC™ is a trademark of Antec Scientific.

Microsoft® is a registered trademark of Microsoft Corporation in the US and/or other countries.

SenCell™ is a trademark of Antec Scientific.

THE SCIENCE OF WHAT'S POSSIBLE™ is a trademark of Waters Corporation.

UPLC™ is a trademark of Waters Corporation.

Waters™ is a trademark of Waters Corporation.

Waters Quality Parts™ is a trademark of Waters Corporation.

Windows® is a registered trademark of Microsoft Corporation in the US and/or other countries.

All other trademarks are property of their respective owners.

December 16, 2021, 715007395 Ver. 00

Page ii

Customer comments

Waters’ Customer Experience and Knowledge Management organization invites you to report

any errors that you encounter in this document or to suggest ideas for otherwise improving it.

Help us better understand what you expect from our documentation so that we can continuously

improve its accuracy and usability.

We seriously consider every customer comment we receive. You can reach us at

Contacting Waters

Contact Waters with enhancement requests or technical questions regarding the use,

transportation, removal, or disposal of any Waters product. You can reach us through the

Internet, telephone, fax, or conventional mail.

Contact method Information

www.waters.com The Waters website includes contact

information for Waters locations worldwide.

iRequest Request technical support for your Waters

instruments and software. iRequest is a free

and secure Web service that allows you to

request support and service for Waters

instruments and software, or schedule a

planned service activity.

Note: In areas managed by authorized

distributors, iRequest may not be available.

Contact your local distributor for more

information.

Telephone and fax From the USA or Canada, phone

800-252-4752 or fax 508-872-1990.

For other locations worldwide, phone and fax

numbers appear in the Waters Local Offices

information.

Conventional mail Waters Corporation

Global Support Services

34 Maple Street

Milford, MA 01757

USA

December 16, 2021, 715007395 Ver. 00

Page iii

Intended use

The 3465 Electrochemical Detector (ECD) is used in combination with Ultra Performance Liquid

Chromatography for the electrochemical detection and quantification of suitable analytes in liquid

samples. You can use the instrument for the chromatographic analysis of a wide range of

electroactive analytes in the following fields:

• Bioanalytical analyses

• Food analyses

• Environmental analyses

Note: For research purposes only. While clinical applications are shown, this instrument is not

tested by the manufacturer to comply with IVD regulations or standards.

Operation of an electrochemical detector can involve the use of hazardous materials, including

corrosive fluids and flammable liquids. Only users with the following expertise should operate the

instrument:

• Chemical laboratory technician degree or comparable vocational training.

• Fundamental knowledge of liquid chromatography and equipment.

• Participation in an installation of the system performed by the manufacturer or a company

authorized by the manufacturer, and suitable training on the system and chromatography

software.

• Knowledge and experience in the safe handling of toxic and corrosive chemicals and

knowledge of the application of fire prevention measures prescribed for laboratories.

Information on safety practices is provided with your instrument. Before using your instrument or

accessories, you must thoroughly read these safety practices.

EMC considerations

FCC radiation emissions notice

Changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate the equipment. This device complies with Part 15 of the FCC

Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference

that may cause undesired operation.

Canada spectrum management emissions notice

This class B digital product apparatus complies with Canadian ICES-001.

Cet appareil numérique de la classe B est conforme à la norme NMB-001.

December 16, 2021, 715007395 Ver. 00

Page iv

ISM classification: ISM group 1 class B

This classification was assigned in accordance with CISPR 11 Industrial Scientific and Medical

(ISM) instrument requirements.

Group 1 products apply to intentionally generated and/or used conductively coupled radio-

frequency energy that is necessary for the internal functioning of the equipment.

Class B products are suitable for use in both commercial and residential locations and can be

directly connected to a low-voltage, power-supply network.

This equipment complies with the emission and immunity requirements described in the relevant

parts of IEC/EN 61326: Electrical equipment for measurement, control, and laboratory use —

EMC requirements.

EMC emissions

Do not use the equipment in close proximity to sources of strong electromagnetic radiation (for

example, unshielded intentional RF sources). The radiation can interfere with the equipment’s

proper operation.

Legal manufacturer

Waters Corporation

34 Maple Street

Milford, MA 01757

USA

Safety considerations

Some reagents and samples used with Waters instruments and devices can pose chemical,

biological, or radiological hazards (or any combination thereof). You must know the potentially

hazardous effects of all substances you work with. Always follow Good Laboratory Practice

(GLP), and consult your organization’s standard operating procedures as well as your local

requirements for safety.

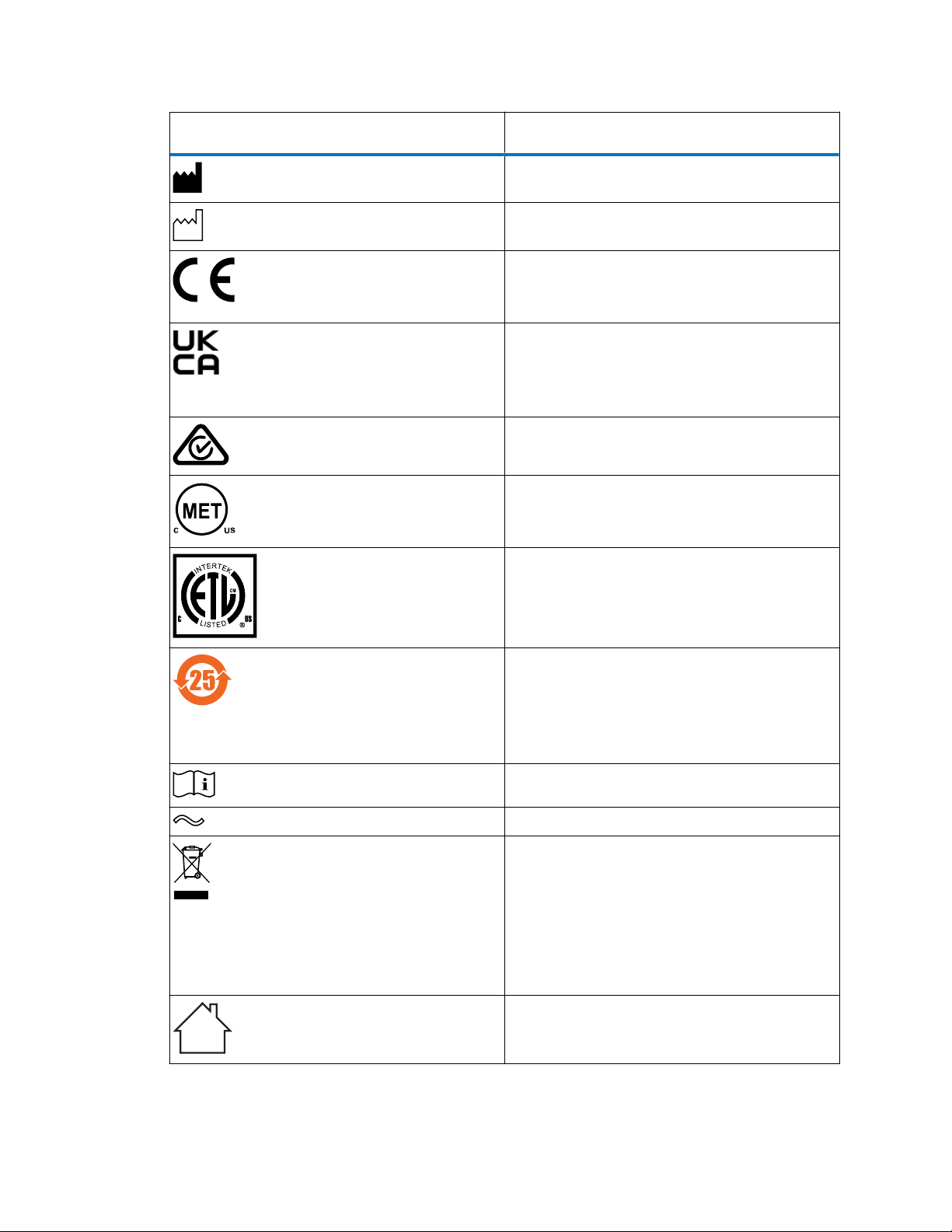

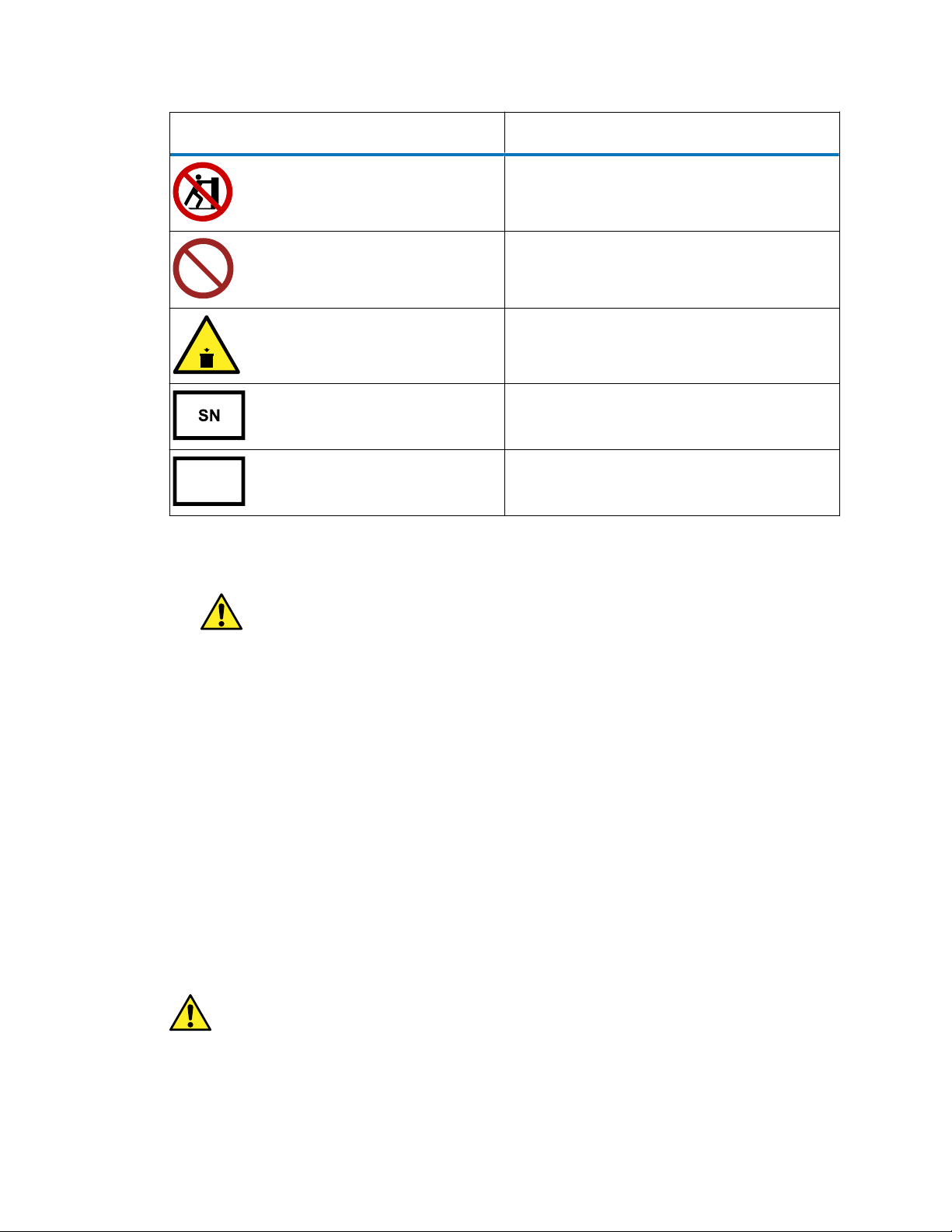

Applicable symbols

The following symbols can be present on the device, system, or packaging.

December 16, 2021, 715007395 Ver. 00

Page v

Symbol Definition

Manufacturer

Date of manufacture

Confirms that a manufactured product complies

with all applicable European Community

directives

UK Conformity Assessed marking confirms that

a manufactured product is in conformity with

the applicable requirements for products sold

within Great Britain

Australia EMC compliant

Confirms that a manufactured product complies

with all applicable United States and Canadian

safety requirements

Confirms that a manufactured product complies

with all applicable United States and Canadian

safety requirements

Environmentally friendly use period (China

RoHS): indicates the number of years from the

date of manufacture until the product, or

components within the product, are likely to be

discarded or degrade into the environment

Consult instructions for use

Alternating current

Electrical and electronic equipment with this

symbol may contain hazardous substances and

should not be disposed of as general waste

For compliance with the Waste Electrical and

Electronic Equipment Directive (WEEE)

2012/19/EU, contact Waters Corporation for the

correct disposal and recycling instructions

For indoor use only

December 16, 2021, 715007395 Ver. 00

Page vi

Symbol Definition

No pushing

LC

Do not connect to an LC system

10kg

max

Indicates the maximum load you can place on

that item (for example, 10kg)

Serial number

REF

Part number, catalog number

Safety hazard symbol notice

The symbol indicates a potential hazard. Consult the documentation for important

information about the hazard and the appropriate measures to prevent and control the hazard.

Electrical power safety notice

Do not position the device so that it is difficult to disconnect the power cord.

Equipment misuse notice

If equipment is used in a manner not specified by its manufacturer, the protection provided by the

equipment may be impaired.

Considerations specific to the device

Working environment and safety

This instrument's intended use is to detect electroactive substances in liquid samples in

combination with a UPLC or HPLC system in a GLP-approved environment. Operators using the

December 16, 2021, 715007395 Ver. 00

Page vii

system require experience, the appropriate education, and an extensive understanding of GLP

rules. To avoid unsafe situations, use this system only for its intended use.

System operation

To ensure optimal performance, Waters recommends that you inspect the detector and carry out

maintenance procedures regularly. Preventive maintenance contracts are available for that

purpose. Contact your local dealer or the nearest sales office for more information.

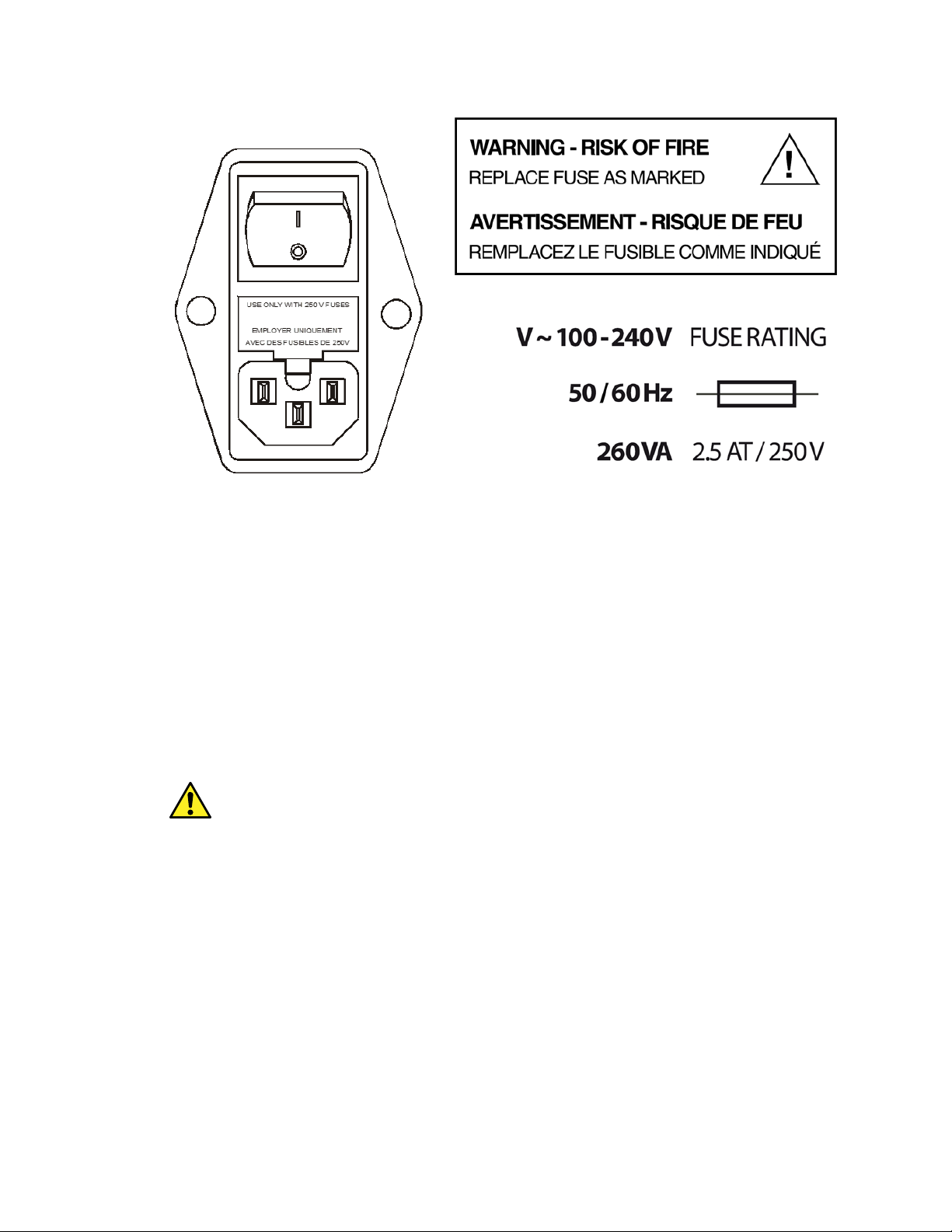

Electrical safety

Warning: To avoid electric shock, do not remove protective panels from the device.

The components within are not user-serviceable.

The removal of protective panels on the instrument can result in exposure to potentially

dangerous voltages. Disconnect the device from all power sources before disassembly.

Untrained personnel should not open the instrument. This may only be done by authorized

service engineers. Replace or repair faulty insulation on power cords immediately after discovery

of the fault. Confirm that the actual power voltage is the same as the voltage for which the

instruments are wired. Ensure that power cords are connected to correct voltage sources:

grounded AC power source, line voltage 100 – 240 VAC. Connect the instrument to a protective

earth via a ground socket. Only use the 3465 ECD with appliances and power sources with

proper protective grounding to prevent damage through build-up of static electricity. The power

source should exhibit minimal power transients and fluctuations. If necessary, connect to a

filtered mains socket.

December 16, 2021, 715007395 Ver. 00

Page viii

Replace blown fuses with fuses of the proper type and rating as indicated on the rear panel and

as noted in the list of accessories and spares. The fuse holder is integrated in the mains

connector. Ensure that the instrument is never put in operation with fuses of a different type. This

could cause fire.

Note: Only use manufacturer-supplied I/O cables to connect with other devices.

Thoroughly connect shielding to common. Manufacturer will not accept any liability for damage,

direct or indirect, caused by connecting this instrument to devices and with cables that do not

meet relevant safety standards. Place the detector on a flat, smooth surface. Do not block the

ventilation holes located at the bottom and lower rear panel of the detector. Blocking these holes

may impair the cooling capability of the power supply.

Solvents

The solvents used may be flammable, toxic, or corrosive. To prevent injury:

• Do not use an open flame near the device.

• Do not install the system in the same room with other equipment that emits or could

potentially emit sparks.

• Provide protective equipment near the instrument.

• When solvent gets into the eyes or on the skin, flush it away immediately.

• Provide equipment, such eye wash stations and safety showers, as close to the system as

possible.

• Use proper eye and skin protection when working with solvents.

• Seal sample containers (vials) to minimize any risks related to solvent vapor.

December 16, 2021, 715007395 Ver. 00

Page ix

Additional safety requirements or protection may be necessary depending on the chemicals used

in combination with this equipment. Ensure that you understand the hazards associated with the

chemicals and take appropriate measures with regards to safety and protection.

Biological hazard

When you analyze biological fluids, you must take all possible precautions and treat all

specimens as potentially infectious. To avoid personal contamination with biologically hazardous,

toxic, or corrosive materials, and to avoid spreading contamination to uncontaminated surfaces,

wear clean, chemical-resistant, powder-free gloves when performing procedures with the 3465

ECD.

Ventilation hazard

Warning: To avoid personal contamination with toxins and biologically hazardous materials

when using the system, follow appropriate safety precautions, and ensure adequate ventilation

and air exchange in the laboratory.

Waste disposal

Perform periodic leak checks on LC tubing and connections. Do not close or block the drain in

the oven compartment. Do not allow flammable or toxic solvents to accumulate. Follow a

regulated, approved waste disposal program. Never dispose of flammable or toxic solvents

through the municipal sewage system.

Safe disposal

Contact [email protected] with any questions or concerns regarding the proper handling or

disposal.

Dispose of Waters instrumentation products in accordance with applicable requirements and best

practices as described below.

• Follow appropriate procedures for flushing the instrument’s fluid paths of any hazardous

samples or solvents.

• Waters instruments are subject to European Union’s Waste Electrical and Electronic

Equipment (WEEE) and Restriction of Hazardous Substances (RoHS) Directives. According

to these directives, do not dispose of instruments in the general waste stream. Similar “e-

December 16, 2021, 715007395 Ver. 00

Page x

waste” laws also apply in other jurisdictions. In all cases, ensure that a certified electronics

recycler processes end-of-life instruments.

• Some Waters instruments use batteries, mercury-containing lamps, or other replaceable

components during the life span of the instrument. Handle such materials in accordance with

local laws governing their processing and safe disposal.

Applications: quality control

Routinely run three QC samples that represent subnormal, normal, and above-normal levels of a

compound. If sample trays are the same or very similar, vary the location of the QC samples in

the trays. Ensure that QC sample results fall within an acceptable range and evaluate precision

from day to day and run to run. Data collected when QC samples are out of range might not be

valid. Do not report this data until you are certain that the instrument performs satisfactorily.

Equipment misuse notice

If equipment is used in a manner not specified by its manufacturer, the protection provided by the

equipment may be impaired.

Safety advisories

Consult the "Safety advisories" appendix in this publication for a comprehensive list of warning

advisories and notices.

December 16, 2021, 715007395 Ver. 00

Page xi

Table of contents

General information........................................................................................................ii

Audience and purpose............................................................................................................................ii

Copyright notice......................................................................................................................................ii

Trademarks list....................................................................................................................................... ii

Customer comments..............................................................................................................................iii

Contacting Waters..................................................................................................................................iii

Intended use..........................................................................................................................................iv

EMC considerations...............................................................................................................................iv

FCC radiation emissions notice.......................................................................................................iv

Canada spectrum management emissions notice.......................................................................... iv

ISM classification: ISM group 1 class B........................................................................................... v

EMC emissions................................................................................................................................ v

Legal manufacturer.................................................................................................................................v

Safety considerations............................................................................................................................. v

Applicable symbols.......................................................................................................................... v

Safety hazard symbol notice.......................................................................................................... vii

Electrical power safety notice.........................................................................................................vii

Equipment misuse notice............................................................................................................... vii

Considerations specific to the device............................................................................................. vii

Safety advisories.............................................................................................................................xi

1 Introduction................................................................................................................19

1.1 Instrument description.................................................................................................................... 20

2 Installation..................................................................................................................24

2.1 Storage requirements ....................................................................................................................24

2.2 Site preparation requirements........................................................................................................ 24

2.2.1 Acquisition computer.............................................................................................................24

2.2.2 Laboratory requirements.......................................................................................................25

2.2.3 Electrical and power requirements........................................................................................26

2.2.4 Chemicals............................................................................................................................. 27

December 16, 2021, 715007395 Ver. 00

Page xii

2.3 Unpacking...................................................................................................................................... 27

2.4 Main power connection.................................................................................................................. 29

2.5 Connecting the Ethernet cable....................................................................................................... 29

2.6 Software......................................................................................................................................... 30

2.6.1 Dialogue Elite........................................................................................................................31

2.7 Fluidics connections....................................................................................................................... 32

2.7.1 Tubing connectors.................................................................................................................32

2.7.2 Mobile phase.........................................................................................................................34

2.7.3 Installation and startup..........................................................................................................35

3 Maintenance and shutdown......................................................................................39

3.1 Maintenance...................................................................................................................................39

3.1.1 Periodic check for leakage....................................................................................................39

3.1.2 Periodic check of the oven temperature............................................................................... 39

3.1.3 Flow cell................................................................................................................................39

3.1.4 Cleaning................................................................................................................................40

3.1.5 Replacement of fuses........................................................................................................... 40

3.2 Shutting down the system ............................................................................................................. 40

4 Detector controller.....................................................................................................42

4.1 Introduction.....................................................................................................................................42

4.2 Overview of 3465 Detector screens............................................................................................... 44

4.3 Parameters.....................................................................................................................................46

5 Detection and parameters.........................................................................................51

5.1 Introduction.....................................................................................................................................51

5.2 Three-electrode configuration........................................................................................................ 51

5.3 Internal organization.......................................................................................................................52

5.4 Dual flow cell control (optional)...................................................................................................... 52

5.4.1 Serial mode detection........................................................................................................... 53

5.4.2 Navigation in dual cell menu.................................................................................................53

5.5 Parameters.....................................................................................................................................54

December 16, 2021, 715007395 Ver. 00

Page xiii

5.5.1 Range................................................................................................................................... 54

5.5.2 Offset.................................................................................................................................... 55

5.5.3 Polarity..................................................................................................................................56

5.6 Filter............................................................................................................................................... 56

5.6.1 DC mode...............................................................................................................................56

5.6.2 Pulse mode...........................................................................................................................57

5.6.3 Pulse 2 mode (available in remote control only) ..................................................................57

5.7 Autozero.........................................................................................................................................57

6 Measurement modes................................................................................................. 59

6.1 DC mode........................................................................................................................................ 59

6.2 Pulse mode.................................................................................................................................... 60

6.3 Pulse mode 2................................................................................................................................. 61

6.4 Scan mode..................................................................................................................................... 62

7 Noise suppression - ADF.......................................................................................... 64

7.1 Introduction.....................................................................................................................................64

7.2 Frequency...................................................................................................................................... 64

7.2.1 Frequency of signal and noise..............................................................................................65

7.2.2 Low pass noise filters............................................................................................................67

7.2.3 Amplitude response plot....................................................................................................... 68

7.3 Applying ADF in chromatography...................................................................................................69

8 Pulsed amperometric detection (PAD).....................................................................72

8.1 Introduction.....................................................................................................................................72

8.1.1 Pulse mode versus DC mode............................................................................................... 72

8.1.2 High pH of mobile phase.......................................................................................................73

8.1.3 Pulse settings........................................................................................................................73

8.1.4 Optimization of wave forms...................................................................................................74

8.1.5 Output frequency.................................................................................................................. 74

8.1.6 Working electrode material................................................................................................... 75

8.1.7 References............................................................................................................................75

9 Optimization of the working potential..................................................................... 76

December 16, 2021, 715007395 Ver. 00

Page xiv

9.1 Introduction.....................................................................................................................................76

9.2 Electrochemical reactions.............................................................................................................. 76

9.3 Hydrodynamic and scanning voltammograms............................................................................... 77

9.3.1 Hydrodynamic voltammogram.............................................................................................. 77

9.3.2 Scanning voltammogram...................................................................................................... 77

9.4 Optimization using a voltammogram.............................................................................................. 78

9.5 Construction of a hydrodynamic voltammogram............................................................................ 79

10 3465 Detector specifications.................................................................................. 81

10.1 Environmental, dimensional, weight, and power requirements.................................................... 81

10.2 3465 General................................................................................................................................82

10.3 3465 DC Mode............................................................................................................................. 82

10.4 3465 PULSE mode.......................................................................................................................83

10.5 3465 PULSE mode 2....................................................................................................................83

10.6 3465 SCAN mode........................................................................................................................ 83

11 Rear panel I/O...........................................................................................................85

11.1 USB B connector..........................................................................................................................85

11.2 LAN connector..............................................................................................................................86

11.3 Digital I/O connector..................................................................................................................... 86

11.3.1 TTL inputs and outputs....................................................................................................... 86

11.3.2 Relays................................................................................................................................. 86

11.3.3 Aux......................................................................................................................................87

11.3.4 Overload..............................................................................................................................87

11.3.5 Cell on Cell off.....................................................................................................................88

11.3.6 Autozero..............................................................................................................................88

11.3.7 3465 Start............................................................................................................................88

11.4 Chassis grounding stud................................................................................................................ 89

12 Troubleshooting.......................................................................................................91

12.1 Instrument errors.......................................................................................................................... 91

December 16, 2021, 715007395 Ver. 00

Page xv

12.1.1 Erratic cell current value or offset after current compensation............................................93

12.2 Analytical troubleshooting............................................................................................................ 93

12.3 Dummy cell test............................................................................................................................93

12.3.1 External dummy cell............................................................................................................93

12.3.2 Internal dummy cell.............................................................................................................95

12.4 Stop flow test................................................................................................................................95

12.4.1 Possible solutions for analytical problems ......................................................................... 97

13 Detector accessories.............................................................................................100

13.1 Detector accessory kit................................................................................................................ 100

13.2 Optional AD converter cables.....................................................................................................100

14 FlexCell................................................................................................................... 102

14.1 The FlexCell............................................................................................................................... 102

14.1.1 Introduction....................................................................................................................... 102

14.1.2 The three-electrode configuration.....................................................................................103

14.1.3 Requirements and limitations ...........................................................................................104

14.1.4 Working electrodes........................................................................................................... 104

14.1.5 Reference electrode..........................................................................................................105

14.2 General precautions................................................................................................................... 109

14.3 Installation...................................................................................................................................110

14.3.1 Connecting a FlexCell to an LC system............................................................................ 111

14.4 Maintenance............................................................................................................................... 112

14.4.1 Disassembly of the flow cell.............................................................................................. 112

14.4.2 Working electrode cleaning ..............................................................................................114

14.4.3 Polishing a working electrode........................................................................................... 114

14.4.4 Flattening a metal working electrode................................................................................ 114

14.4.5 HyREF and ISAAC reference electrodes.......................................................................... 115

14.4.6 Salt bridge Ag/AgCl reference electrode...........................................................................115

14.4.7 Salt bridge Ag/AgCl reference electrode check................................................................ 116

14.4.8 Refilling a salt bridge Ag/AgCl reference electrode...........................................................117

14.4.9 Refritting a salt bridge Ag/AgCl reference electrode......................................................... 118

14.4.10 Assembly of the flow cell.................................................................................................119

14.5 Specifications............................................................................................................................. 120

14.6 Parts list......................................................................................................................................121

December 16, 2021, 715007395 Ver. 00

Page xvi

15 SenCell....................................................................................................................123

15.1 The electrochemical flow cell..................................................................................................... 123

15.1.1 Introduction....................................................................................................................... 123

15.1.2 Three-electrode configuration...........................................................................................123

15.1.3 Working electrode.............................................................................................................124

15.1.4 Detection limit................................................................................................................... 125

15.1.5 Cell working volume adjustment....................................................................................... 127

15.2 Reference electrodes................................................................................................................. 131

15.2.1 ISAAC reference electrode............................................................................................... 131

15.2.2 Salt bridge Ag/AgCl reference electrode...........................................................................133

15.2.3 HyREF reference electrode.............................................................................................. 134

15.3 Installation.................................................................................................................................. 134

15.3.1 Introduction ...................................................................................................................... 134

15.3.2 Adjusting the SenCell working volume..............................................................................135

15.3.3 Installation in LC system...................................................................................................136

15.3.4 Installing the SenCell........................................................................................................ 136

15.4 Maintenance ..............................................................................................................................140

15.4.1 Assembling/disassembling the cell .................................................................................. 140

15.4.2 HyREF ............................................................................................................................. 142

15.4.3 ISAAC............................................................................................................................... 142

15.4.4 Ag/AgCl salt bridge........................................................................................................... 144

15.4.5 Working electrode.............................................................................................................146

15.5 Specifications............................................................................................................................. 148

15.6 Parts list......................................................................................................................................149

16 VT-03 flow cell........................................................................................................ 150

16.1 The FlexCell............................................................................................................................... 150

16.1.1 Introduction....................................................................................................................... 150

16.1.2 Three-electrode configuration...........................................................................................152

16.1.3 Working electrode.............................................................................................................154

16.1.4 Detection limit .................................................................................................................. 154

16.1.5 Working electrode diameter..............................................................................................156

16.1.6 Spacer thickness ..............................................................................................................157

16.2 Reference electrodes................................................................................................................. 159

16.2.1 ISAAC reference electrode............................................................................................... 159

16.2.2 Salt bridge Ag/AgCl reference electrode...........................................................................163

December 16, 2021, 715007395 Ver. 00

Page xvii

16.2.3 HyREF reference electrode.............................................................................................. 163

16.3 Installation.................................................................................................................................. 164

16.3.1 VT-03 flow cell with HyREF or ISAAC...............................................................................164

16.3.2 VT-03 flow cell with salt bridge REF................................................................................. 165

16.3.3 VT-03 micro flow cell.........................................................................................................168

16.4 Maintenance ..............................................................................................................................175

16.4.1 HyREF.............................................................................................................................. 175

16.4.2 ISAAC............................................................................................................................... 175

16.4.3 Ag/AgCl salt bridge........................................................................................................... 176

16.4.4 Working electrode.............................................................................................................179

A Safety advisories.....................................................................................................181

A.1 Warning symbols..........................................................................................................................181

A.1.1 Specific warnings................................................................................................................182

A.2 Notices.........................................................................................................................................183

A.3 Bottles Prohibited symbol............................................................................................................ 184

A.4 Required protection......................................................................................................................184

A.5 Warnings that apply to all Waters instruments and devices.........................................................184

A.6 Warnings that address the replacement of fuses.........................................................................188

A.7 Electrical symbols........................................................................................................................ 190

A.8 Handling symbols.........................................................................................................................191

December 16, 2021, 715007395 Ver. 00

Page xviii

1 Introduction

Congratulations on your purchase of the 3465 Detector. This detector enables you to perform all

LC/UPLC applications using electrochemical detection. The 3465 Detector includes a highly

stable Faraday-shielded oven compartment accommodating column and flow cell. The flow cell

provides an unsurpassed S/N ratio for extremely sensitive electrochemical analyses. The 3465

Detector has three operational measurement modes: DC, SCAN, and PULSE. For a few specific

applications, the 3465 Detector can support up to two flow cells (optional).

December 16, 2021, 715007395 Ver. 00

Page 19

1.1 Instrument description

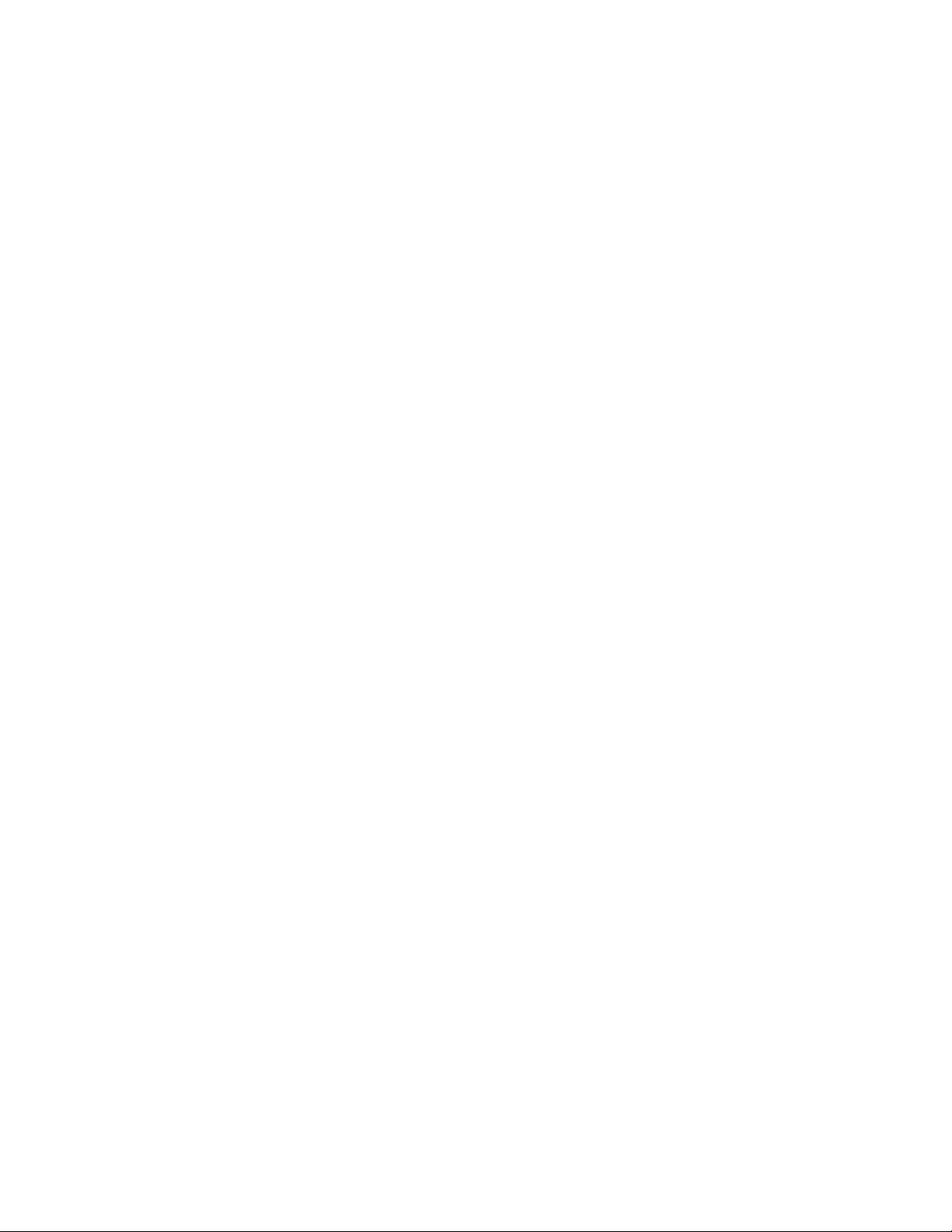

Figure 1–1: 3465 Detector - Front side

Instrument housing

LC tubing inlet/outlet

Instrument door panel

4 x 40 Ch LCD display

Function keys

<Enter> key

December 16, 2021, 715007395 Ver. 00

Page 20

Table of contents

Popular Laboratory Equipment manuals by other brands

Hamilton Beach

Hamilton Beach 74251 Read before use

Accuris

Accuris SmartDoc 2.0 instruction manual

Konica Minolta

Konica Minolta DRYPRO 793 brochure

Ocean Optics

Ocean Optics USB2000 Plus Installation and operation manual

Thermo Scientific

Thermo Scientific iCAP Q operating manual

THORLABS

THORLABS Redstone OSA305 quick start guide

cavitation

cavitation RF SUPER user manual

MELAG

MELAG Vacuklav 31 B+ user manual

Koehler

Koehler K70 Series Operation and instruction manual

Agilent Technologies

Agilent Technologies 75000 Series C User's guide and service manual

R-Biopharm

R-Biopharm RIDA qLine autoBlot user manual

Memmert

Memmert ICOmed 50 operating manual