WaterSoft G9P User manual

Filter Manual

Installation / Operation Manual

Fully Automatic

Water Filter

with 2092 Isobar Control Valve

Filter Specifications.................................................................................................Page 3

Installation Requirements.......................................................................................Page 4

Installation Procedures...........................................................................................Page 6

WARNING

Lubricants

Do NOT use Vaseline, oils, hydrocarbon lubricants or spray silicone anywhere! Petroleum base lubricants will cause

swelling of o-rings and seals. The use of other lubricants may attack plastic Noryl®. It is recommended that Dow

Corning® silicone grease be used as a lubricant for all control valves. Dow Corning® 7 Release Compound is used in the

manufacture of Chandler Systems control valves. (Part # LT-150)

Sealants

Pipe dope and liquid thread sealers may contain a carrier that attacks some plastic materials. It is recommended that

Teflon® tape be used to seal plastic Noryl® threaded fittings.

Filter Specifications

3

General Specifications G9P G10P G12P G13P

Filtration1Less Filter Media

Filter Media Capacity (cu ft) 1.0 1.5 2.0 2.5

Mineral Tank (Vortech ™) 9 X 48 10 X 54 12 X 52 13 X 54

Service Flow Rate - Continuous2(gpm) 4568

Service Flow Rate - Intermittent2(gpm) 6 7 8 10

Backwash Flow Rate3(gpm) 5.0 5.0 7.0 7.0

Gallons Used / Backwash 130 130 156 182

Space Required 9 X 9 X 56 10 X 10 X 62 12 X 12 X 60 13 X 13 X 62

Approximate Shipping Weight (lbs) 27 32 35 40

Filter Media Selection Guide

Media Description Handles

Neutralizer Granular / White / Sacrificial to water with pH < 7.0 /

Max pH correction to 7.2 / Lowest pH application 5.8 /

Must be replenished about every 3-6 months

Sediment

pH Correction

Granular

Activated

Carbon

Granular / Black / Wide application for removal of

organic and some inorganic / Must be replenished on a

regular basis / Life expectancy varies based on use

Sediment

Taste / Odor / Color

Chlorine / Iodine

Neu-Cor™ 70% neutralizer / 30% Corosex™ mix / Sacrificial to

water with any pH / Max pH correction determined by

contact time used for correction of extremely low pH

down to 5.0 / Must be replenished every 3 - 6 months

Sediment (downflow)

pH Correction

Filter Ag™ Granular / Off-White / Wide application for removal of

sediment / Life expectancy is unlimited

Sediment

Filter Ag™ Plus Light tan to near white in color / Mesh size 14 x 40 /

55 lb/ft3 / The Filter Ag Plus filter beds operate at less

than half the hydraulic loading rate vs. 20 x 40 mesh

sand and 50% of sand / anthracite or multi-media

Enhanced Particle Removal

(down to 5 microns)

Installation

4

Installation Requirements

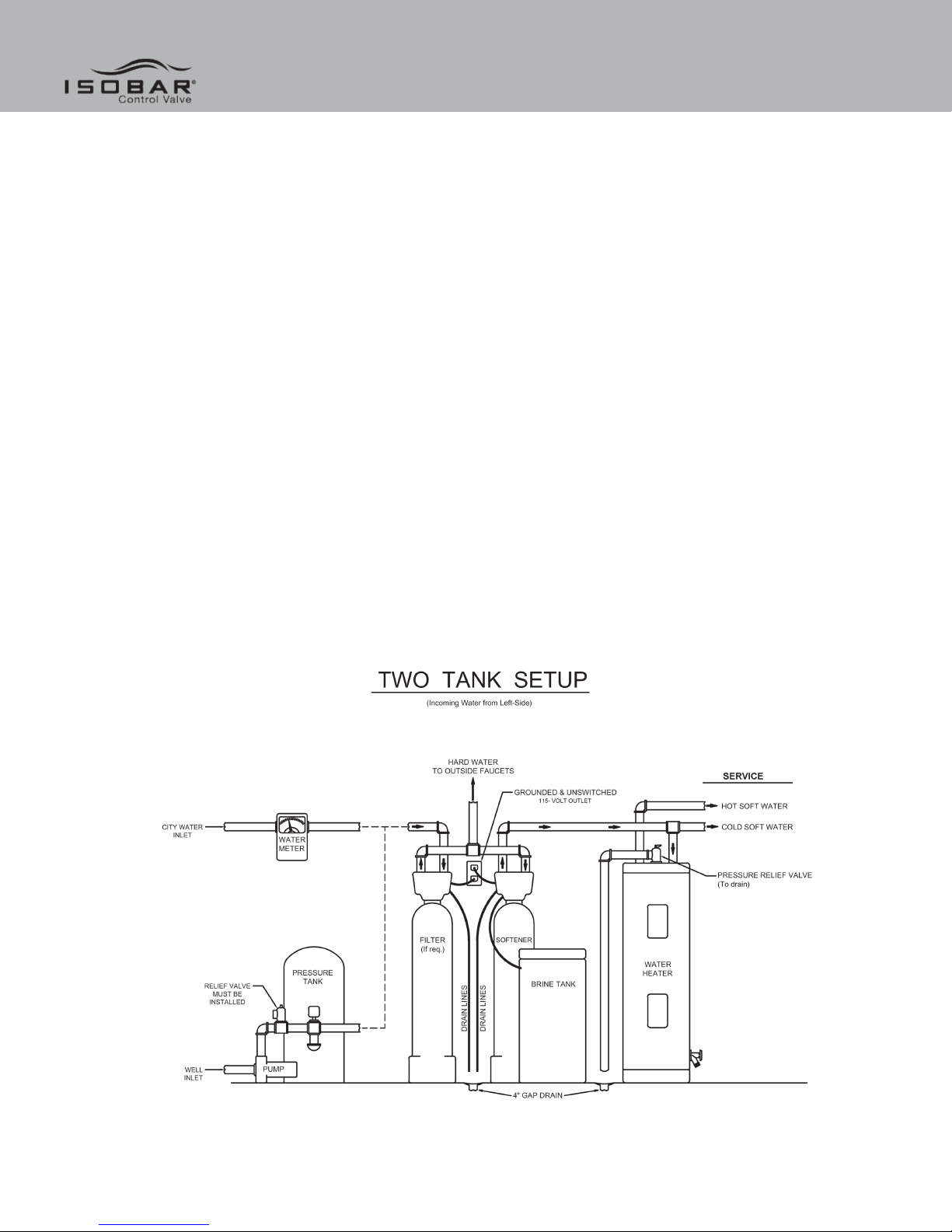

A level floor position ahead of piping into water heater.

Unit must be installed at least 10 feet ahead of the inlet to a water heater to prevent damage due to back-up hot water.

DO NOT install the unit in an area of direct sunlight or where freezing temperatures may occur!

Locate the unit near an unswitched, 120 volt / 60 Hz grounded electrical outlet.

Check for distance and proper drain installation (e.g. floor drain, washing machine standpipe).

Determine type and size of piping required for filter connection (e.g. copper, galvanized, PVC plastic).

Note: If household plumbing is galvanized and you intend to make the installation with copper (or vice versa), obtain

di-electric unions to prevent dissimilar metal corrosion.

Note: Where the drain line is elevated above the control valve or exceeds 20 feet in length to reach the drain, use 3/4"

I.D. drain line tubing instead of 1/2" I.D. Drain line tubing is not included.

Caution: If sweat soldering copper pipe (remember to always use lead free solder and flux), cover yoke and bypass valve

with wet rags to prevent heat damage to connections and control valve. If using PVC or plastic pipe, primers and

solvent cements specifically recommended for use with potable water are required.

Note: All plumbing lines not requiring “soft” water should be connected “upstream” of the softener, if installed.

(See Typical Installation Diagrams.)

Installation Installation

5

Installation Procedure

- Water Supply Connection and Bypass Valve -

To allow for filter servicing, swimming pool filling or lawn sprinkling, a manual Bypass Valve has been installed at the

factory. The Bypass allows raw water to be manually routed around the filter.

1. Position filter at desired location for installation. If a water softener is to be installed, the filter should be positioned first

and then the softener. (See Installation Diagrams.)

2. The filter material is shipped separately from the mineral tank. The tank must be loaded with material after tank has

been placed at the desired location.

A. Remove the control valve by unscrewing from the tank.

B. Use plug provided to place over top of distributor tube to prevent material from entering tube while filling.

C. Place media funnel in hole on top of tank.

D. Pour several gallons of water in the tank. (Fill tank about 1/3 full.)

E. Pour in the required filter media. No gravel is required. The required quantity of media is listed in the filter

specifications.

Note: If rebedding an existing unit and the system utilizes a standard tube & basket style distributor, a “D” gravel under

bedding will be required.

F. After filling the tank with material, use a garden hose or several buckets to fill the tank with water.

Note: This will permit the filtering media to become soaked while preparing the installation and will prevent the control

valve from being plugged with floating material on initial backwash.

G. Remove funnel and clean filter media from tank threads.

H. Remove plug from distributor tube.

I. Replace control valve on mineral tank.

Installation

6

Caution: Be extremely careful to position distributor tube into control valve distributor tube pilot hole.

3. Turn OFF main water supply and OPEN nearest faucet to relieve pressure.

4. Cut main line and install appropriate elbows and extensions.

Caution: Raised arrows located on the sides of control valve body and bypass valve indicate proper direction of water

flow. Install inlet and outlet piping in direction of arrows.

- Drain Line Connection -

1. Remove drain line hose barb and wrap threads with Teflon tape. Reinstall drain line hose barb

Caution: Hand tighten only!

2. Install 1/2” I.D. drain line tubing (not included) from hose barb to an open drain. A 4” gap between end of the drain line

and the open drain is required to prevent waste water backflow. Keep the drain line as short as possible. An overhead

drain line can be used if necessary, but should discharge below the control valve. A syphon trap (taped loop) at the outlet

of the drain line is advisable to keep the drain line full and assure correct flow during backwash. Elbows or other fittings

must be kept at a bare minimum.

Note: Where the drain line is elevated above the control valve or exceeds 20 feet in length, 3/4” I.D. drain line tubing

should be used.

- Electrical Connection -

1. Connect the power cord and plug into a 115 volt / 60 Hz receptacle.

Note: Do not plug into an outlet controlled by a wall switch or pull chain that could inadvertently be turned off

Installation Procedures

1. Move the bypass valve slowly to the Service position or open the main valve and allow water to flow to the mineral tank.

2. When the water stops flowing into the tank, open a treated water tap and allow air to be released from the lines. Then

close the tap. Open the bypass valve or main valve completely.

3. Rotate the manual regeneration knob clockwise to the “backwash” position. On all units except a carbon filter allow to

backwash the factory preset time of 10 minutes or until water becomes clear at the drain. This will wash out the fine

material from the mineral. Check water at drain to be certain large quantities of mineral are not being lost. If mineral

is still flowing out return the controls to “Service” position and allow mineral to soak longer before being backwashed.

Anytime media - other than very fine mineral on initial startup - is apparent in the service lines, it usually indicates one of

the following problems:

A. The unit is plumbed in backward allowing the media to be carried in the service line.

B. The distributor tube inside the tank is not seated inside the valve or is damaged in some way. If the media continues

to flow to the drain during backwash after a reasonable period of soaking, check the drain line flow control to be sure

that excessive water is not going to the drain allowing mineral to siphon out of the tank.

Installation Installation

7

4. Set the days of backwash desired and the time of day as follows:

How to set the day on which the water filter is to backwash: Rotate the skipper wheel until the number “1" is at the

red pointer. Set the days that the backwash is to occur on by sliding tabs on the skipper wheel outward to expose trip

fingers. Each tab is one day. Finger at red pointer is tonight. Moving clockwise from the red pointer, extend or retract

fingers to obtain the desired backwash schedule. (See diagram.) If you want to backwash every day, you would slide all

the tabs out. Every other day would extend out tab numbers 2, 4, 6, 8, 12 (or 6 tabs). Every three days would extend tab

numbers 3, 6, 9, 12 (or 3 tabs). Every 6 days would extend tab numbers 6 & 12 (or 2 tabs). Every 12 days would extend

tab number 12 only.

How to set the time of day: Press and hold the black button on the left side of the control valve in to disengage the drive

gear. Turn the large gear (not the knob) in the center until the actual time of day appears in the “Time of Day” window at

the bottom. Release the black button to again engage the drive gear. Make sure the “AM” and “PM” is correct for your

situation. The starting time for backwash is preset to be about 1:00 a.m. the backwash and rinse cycles are also preset.

(See diagram.)

How to manually backwash your water filter at any time: Turn the manual backwash knob clockwise until you can

read “Start Cycle”. The unit will automatically continue through the backwash cycle and then return to the “In Serv”

position when complete.

- Final Checkout -

1. Be certain that the bypass valve is in Service position or main valve is completely on.

2. Check electrical supply to be certain the cord is connected to an uninterrupted 115 volt outlet.

3. Be certain the warranty card is filled out and mailed in.

4. Leave this manual with the homeowner.

Important Notice - The plumbing system, piping, pressure tank, hot water tanks, softeners, etc. that have been exposed

to iron bearing water may need to be cleaned of the precipitated iron that has been collected in them or iron bleed thru

may be a problem. We suggest all tanks be drained and flushed thoroughly.

This manual suits for next models

3

Table of contents

Other WaterSoft Water Dispenser manuals

Popular Water Dispenser manuals by other brands

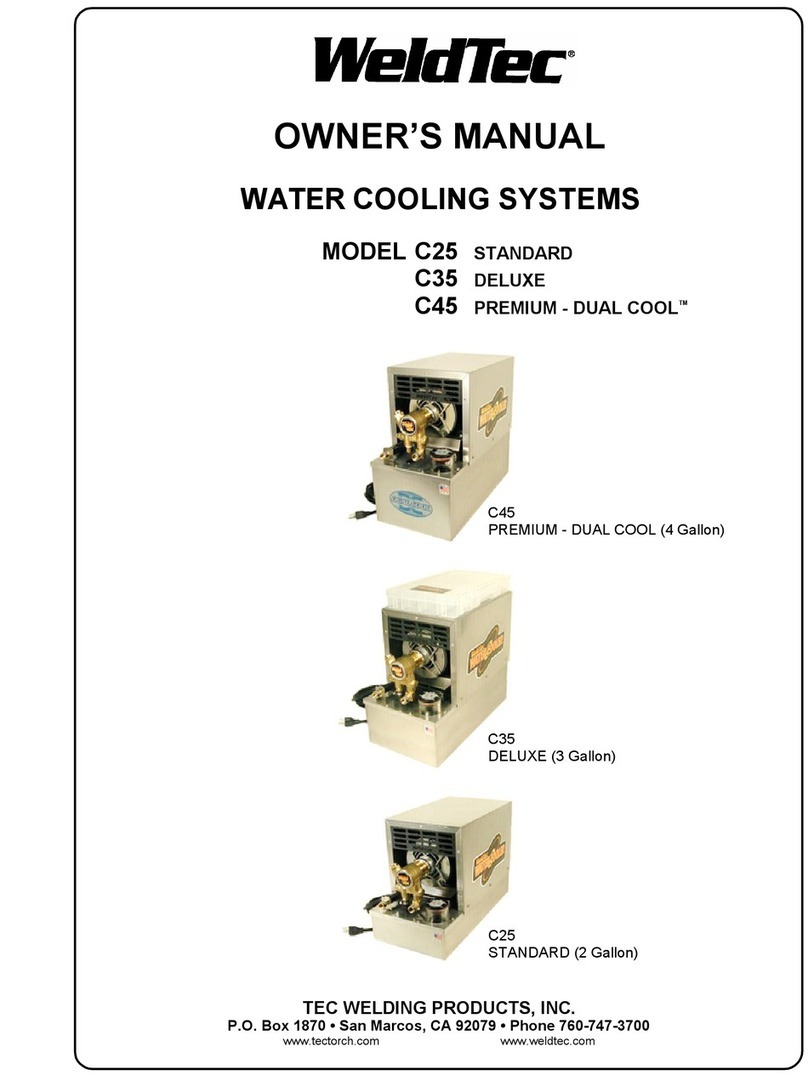

WeldTec

WeldTec C25 STANDARD owner's manual

Elkay

Elkay FLEXI-GUARD EFW Deluxe Installation, care & use manual

Puretec

Puretec SOL-E1 Series user guide

Lotus

Lotus Water Treatment System Use & care guide

Canature WaterGroup

Canature WaterGroup 85HE owner's manual

Crystal Mountain

Crystal Mountain Blizzard quick start guide