8

Maintenance

The TPR valve should not vent under normal conditions so to ensure the valve does not become inoperable, instruct the

home owner to manually open and vent every 6 months according to the maintenance section in the owner’s manual.

Rotate the red knob approximately ¼ of a turn and hold in that position for 5 seconds while hot water is vented into the

drain. This helps clear any naturally occurring lime deposits that may cause it to malfunction. If it fails to vent any

water or continues to vent water when released, immediately switch off the power and replace it.

7. Cold Water Expansion Control

Protanks require a cold water expansion valve with a maximum set point of 600kPa which must also be fitted with a drain

pipe. For convenience sake the TPR and CWE valves are vertically aligned to allow an easy connection to a common drain.

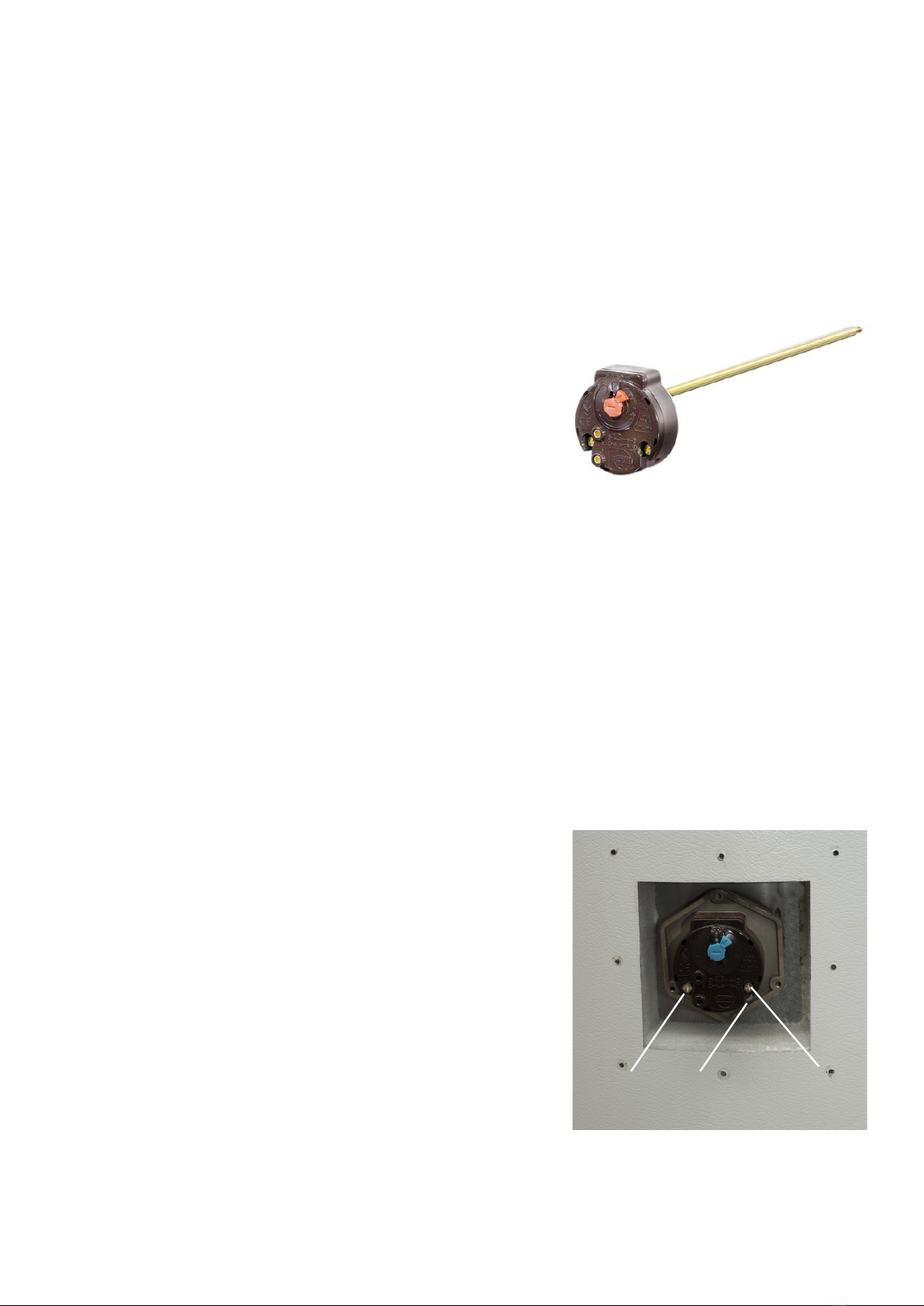

8. Thermostat Control

In accordance with G12 AS1 requirement to disinfect stored water

for legionella bacteria, the cylinder thermostat has been set to 62°C.

Thermostat settings must only be adjusted by an electrician or other

suitably qualified tradesperson. The access cover to the element and

thermostat must only be removed by an electrician or other suitably

qualified tradesperson.

Delivery Temperature

In the absence of a tempering valve the delivery temperature of water will reflect the set point of the cylinder thermostat

which could cause severe scalding. G12 AS1 prescribes the maximum permissible delivery temperature according to the

installation environment;

• 45°C for early childhood centers, schools, nursing homes or similar facilities

• 55°C for all other sanitary hot water systems

To comply with these requirements, a temperature limiting device, such as a tempering or thermostatic mixing valve is

required to ensure these limits are not exceeded.

9. Supply Pressure Control

The maximum inlet supply pressure is 500kPa and the recommended inlet supply pressure is 300kPa. 300kPa pressure

is standard practice applied in Europe to protect taps and appliances, minimise the chance of water hammer and reduce

water consumption usage. Unless certain that 500kPa cannot be exceeded (e.g. a pressure controlled pumped supply)

then a pressure limiting valve must be installed on the supply side. Failure to do so may cause damage to taps and

appliances and will unnecessarily vent and waste water which will cause

premature failure of the TPR and CWE valve.

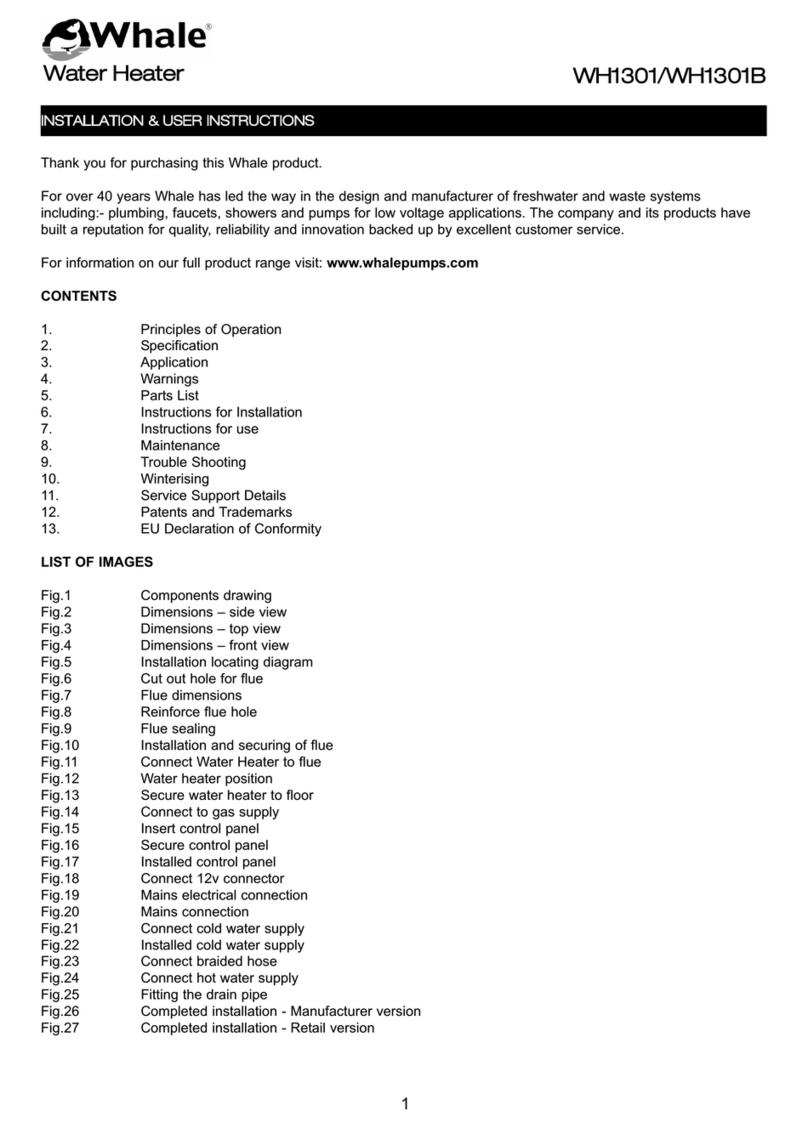

10. Electrical Supply and Connections

The electrical connection must be carried out by a qualified person in

accordance with New Zealand Electrical Regulations. The water heater

must have the heating element connected to an independent, fused, AC

230 V 50 Hz power supply capable of withstanding the appliance load

with an isolating switch installed at the switch board.

1. The water heater must be filled with water prior to connection to the

power supply.

2. Ensure the power supply is disconnected.

3. Remove the element cover fixing screws and connect all LIVE, NEUTRAL

and EARTH wires in accordance with the wiring diagram below.

4. Ensure all wiring links are secure and protected from contact with the

internal hot surface of the water heater prior to fixing the access cover

and turning the power on.

5. To ensure the over-temperature and energy cut-out is set press the

‘reset’ button on the thermostat.

NEUTRAL EARTH LIVE