Watlow Controls 981 Series Use and care manual

Calibrating Watlow

Process Controls

(Applies to Series 981, 982, 983, 984, 986, 987, 988, 989)

Calibration Manual

Watlow Controls, 1241 Bundy Blvd., P.O. Box 5580, Winona, MN 55987-5580, Phone: 507/454-5300, Fax: 507/452-4507

W988-CM10-9345

November, 1993 $5.00

Made in the U.S.A.

Printed on Recycled Paper

2WATLOW Series 988 Calibration Manual

Contents

Page Description

Calibrating Your Watlow Process Control

3 The Factory (Fcty) Menus

3 Entering the Fcty Prompt

4 Diagnostics Menu

6 Calibration Menu

7 Calibration Restore Prompt

7 The dFL Prompt

7 Input Calibration

7 Output Calibration

Calibration Procedures

8 Low Gain Thermocouple Input

9 High Gain Thermocouple Input

10 RTD Input

11 mA Process Input

12 VDC Process Input

13 mVDC Process Input

14 Slidewire Feedback Input

14 Current Transformer Input

15 mA Process Output 1 and 2

16 VDC Process Output 1 and 2

17 mA Retransmit Output 3

17 VDC Retransmit Output 3

WATLOW Series 988 Calibration Manual 3

Menus/Prompts

Calibrating Your Watlow Process Control

This manual is a supplement to the Series 981/982 and 988/989 User’s Manual.

The calibration procedures within this manual pertain to the following controls:

Series 981 Series 986

Series 982 Series 987

Series 983 Series 988

Series 984 Series 989

Use in conjunction with the appropriate user’s manual. From this point on, 988 will

be used in place of the above listed models.

Before attempting to calibrate, make sure you read through the

procedures carefully and have the proper equipment called for

in each procedure.

The Factory (Fcty) Menus

The Fcty prompt consists of three menus: PLOC, diAg, and CAL. The Fcty prompt

will not appear if the hardware lockout DIP switch is ON. Refer to Chapter 1 of the

User’s Manual (white book).

• The Panel Lockout (PLOC) menu is explained in detail in the Series 988

User’s Manual.

• The Diagnostics (diAg) menu contains specific information for each control. It

is explained in detail on Page 4 of this manual.

• In the Calibration menu (CAL), various input signals must be supplied for the

control to go through its auto calibration. See Page 5 for the complete

Calibration menu and procedures.

Make sure the input type DIP switches are in the proper position before beginning.

Refer to the 988 User’s Manual.

Entering the Fcty Prompt

The Fcty prompt can only be entered from the SEt prompt.

• Press the Up/Down keys simultaneously for 3 seconds ( ±1 second). Any inad-

vertent change in the displayed data, when pressing the Up/Down keys is

ignored. The SEt prompt appears in the lower display.

• Continue pressing the Up/Down keys simultaneously for another 3 seconds and

the Fcty prompt appears in the lower display with PLOC in the upper display.

For 981 - 984 units the dIAg prompt appears in the upper display.

TL

W

W

A

PROCESS

L1 L2 L3 L4

DEV

% OUT

DISPLAY

SERIES 988

MODE

AUTO

MAN

TL

W

W

A

PROCESS

L1 L2 L3 L4

DEV

% OUT

DISPLAY

SERIES 988

MODE

AUTO

MAN

Figure 1 -

Entering the

Fcty Prompt

3 Seconds

NOTE:

The Fcty menu is

not available on a

Series 981 - 984.

NOTE:

The Series 981 - 984

units have a

Hold/Run key in

place of the

Auto/Man key.

TL

W

W

A

PROCESS

L1 L2 L3 L4

DEV

% OUT

DISPLAY

SERIES 988

MODE

AUTO

MAN

4WATLOW Series 988 Calibration Manual

Diagnostics

Diagnostics Menu

The Diagnostics menu (diAg) contains specific information for each control. This

menu is for factory use only, but can be accessed for viewing or technical assis-

tance.

• At the Fcty prompt, press the Up or Down key to advance the upper display to

the diAg prompt. See below. Use the Mode key to advance through this menu.

Do not enter any readings here; make photocopies instead.

(diAg)

Software revision

Serial number

Ambient temperature

Ambient A/D count

(Diagnostics)

Factory ship date

Your

Readings

DAtE

SOFt

Sn _

_

AMb

Acnt

gnd

cnt2

itY1

itY2

cnt1

OtY1

OtY2

OtY4

dISP

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

Input 2 A/D count

Input 1 A/D count

Input 1 modul

e

Input 2 module

Ground A/D count

Output 1 module

Output 2 module

Output 4 module

Test displays

Your

Readings

tout ( )

Test outputs

OtY3

( )

( )

Output 3 module

OPLP ( )

Open Loop

TL

W

W

A

PROCESS

L1 L2 L3 L4

DEV

% OUT

DISPLAY

SERIES 988

MODE

AUTO

MAN

TL

W

W

A

PROCESS

L1 L2 L3 L4

DEV

% OUT

DISPLAY

SERIES 988

MODE

AUTO

MAN

Figure 2 -

Entering the

Diagnostics Menu

Figure 3 -

The Diagnostics

Menu

Press the Mode key to advance

through the Diagnostics menu.

WATLOW Series 988 Calibration Manual 5

Diagnostics

When contacting the factory for technical assistance, make sure you have the informa-

tion documented from the following prompts. All prompts in this menu are read only.

Date: This prompt represents the date the final control test was performed. The first

two numbers are the week (01 through 52), and the last two numbers are the year.

Software Revision: Signifies the control software revision.

Serial Number: Represents the control serial number. The first two LED’s in the

upper display are Sn followed by the serial number. The number is six digits in

length beginning with the last two digits in the upper display, and wrapping around

to the lower display where the remaining four digits are shown.

Ambient Temperature: The ambient temperature at the Input 1 terminals, in °F.

Acnt, gnd, cnt1 and cnt2 are for factory use only.

itY1, itY2, OtY1, OtY2, OtY3, and OtY4 are input and output module types respec-

tively. Below is a listing of the displays, and what they represent. Please docu-

ment the displays before contacting the factory for technical assistance.

Input Types

nonE

No module

Utch

Universal thermocouple high gain

tc

Thermocouple only

UtcL

Universal thermocouple low gain

Curr

Current detect

UMu

Universal millivolts

SLid

Slidewire

UPrc

Universal process

UOFF

Universal OFF

Ei2

Event input 2

Urtd

Universal RTD

Curr

Heater current

Output Types

nonE

No module

rLAB

Relay A/B

SSR1

0.5A SSR

rABS

Relay A/B with suppression

SS1S

0.5A SSR with suppression

2rLY

Two relays

SSr2

2.0A SSR

Proc

Process

SS2S

2.0A SSR with suppression

Uret

Voltage/retransmit

2SSr

Two 0.5A SSR

Iret

Current/retransmit

dc

Switched DC

SPLY

Power supply

2dc

Two switched DC

232

RS-232 communications

rLYc

Form C relay

485

EIA-485/422 communications

rLcS

Form C relay with suppression

Display: Press the Up or Down key to change the upper display from no to YES. Each

display and LED is tested. If any display or LED is absent contact the factory.

Test Output: This prompt tests each output. As the Up or Down key is pressed, it

cycles through the available outputs. Once the corresponding LED is lit the respective

output is energized. Press the Up or Down key again to advance to the next output.

If any LED’s are non-functional, or if the outputs fail to energize, contact the factory.

Open Loop: This prompt enables open heater or shorted sensor detect, and

enables the error code function. This prompt only functions in the proportional

control mode. The error message OPLP flashes in the lower display when on is

selected and heat or cool is full ON and no temperature change has occurred over

a period of time. The time period is based on the system characteristics.

Range: on or OFF

Default: OFF

This menu will continue looping through the parameters until you press the

Display key to return to the Display loop.

DAtE

SOFt

Sn

AMb

itY1

itY2

OtY1

OtY2

OtY3

OtY4

dISP

tout

OPLP

6WATLOW Series 988 Calibration Manual

CAL Menu

Calibration Menu

Enter the Factory menu again by pressing the Up and Down keys simultaneously

for three seconds to enter the Setup menu, and an additional three seconds to

enter the Factory menu.

• At the Fcty prompt, press the Up or Down key to advance to the upper display to

the CAL prompt.

TL

W

W

A

PROCESS

L1 L2 L3 L4

DEV

% OUT

DISPLAY

SERIES 988

MODE

AUTO

MAN

Figure 5 -

The Calibration

Menu

Figure 4 -

Entering the

Calibration Menu

TL

W

W

A

PROCESS

L1 L2 L3 L4

DEV

% OUT

DISPLAY

SERIES 988

MODE

AUTO

MAN

(CAL)

(Calibration)

A 50

tc

A 0H

A 20

A 15

A 00

A380

A 0U

A20A

b 15

b380

A10U

b10U

b 0U

b 4

A

b 0

u

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

Your Settings

b100

1 4

1 20

1 0

1 10

2 4

A 4A

b20A

Default parameters

Your Settings

2 20

2 0

2 10

3 LO

3 HI

rSt

dFL

A 0u

A100

b 00

b 0H

b 50

( )

( )

( )

( )

( )

( )b 20

Restore factory values

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

Input #1

Input #2

Input #2

(cont.)

Output #1

Output #2

Output #3

The Calibration menu begins with the Input 1 prompts and continues through to the

Output 3 prompts. Located at the end of the Calibration menu are the “restore fac-

tory values” and “default parameters” prompts. See below.

Before continuing through the calibration menu, refer to the proper calibra-

tion procedure for your control.

Press the Mode key to advance

through the Diagnostics menu.

WATLOW Series 988 Calibration Manual 7

rSt/dFL Prompts

Calibration Restore Prompt

If you make a mistake while calibrating your control, the rSt prompt near the end of

the calibration menu restores the original factory calibration settings. At the rSt

prompt, simply press the Up or Down key to change the upper display to read YES;

press the Mode key. The original factory calibration values are restored.

The dFL Prompt

To set the operating parameter defaults for either domestic or international, use

the dFL (default) prompt at the end of the Calibration menu. Once you have

entered the Calibration menu, use the Mode key to advance to the dFL prompt.

Press the Up or Down key to change the upper display to US or SI. For domestic

prompts, select US and receive:

•°F • Rate in minutes

• Proportional band in degrees or units • Reset in repeats per minute

For international prompts, select SI and receive:

•°C • Derivative in minutes

• Proportional band in % of span • Integral in minutes per repeat

Input Calibration

Once you enter the Factory menu, press the Up or Down key until the CAL prompt

appears in the upper display with Fcty in the lower display. Press the Mode key to

advance to the first calibration prompt. See Figure 2 on the previous page. The

upper display shows the prompt default no, while the lower display indicates the

input signal prompt.

Each input calibration prompt is preceded by an A or B, signifying Input 1 or 2

respectively. Refer to the Calibration menu on the previous page again. Before

advancing to the next prompt when calibrating, always apply the correct input signal

and allow to stabilize for 10 seconds before changing the upper display to YES. If

the parameter is left at no, the calibration information

will not be entered.

Once the

appropriate parameters are calibrated, press the Display key to exit the CAL menu.

Output Calibration

After calibrating the Input 1 and 2 prompts, the next prompts apply to Output 1

through 3 which are for process outputs only.

Model numbers affected are Output 1 98_ _ - _ _ F_ - _ _ _ _

Output 2 98_ _ - _ _ _ F- _ _ _ _

Output 3 98_ _ - _ _ _ _ - M_ _ _

98_ _ - _ _ _ _ - N_ _ _

The prompt in the lower display indicates the output signal while the upper display

reads a hexidecimal value which matches the output value. The upper display

value is for internal use only and should be ignored.

Each output calibration prompt is preceded by a 1, 2, or 3, signifying Output 1, 2, or 3

respectively. If your unit does not have Output 2 or 3, these prompts will not appear.

Once the appropriate parameters are calibrated, press the Display key to exit the

CAL menu.

Low Gain Thermocouple Input Procedure

For all thermocouple inputs excluding Type R, S and B

Equipment Required

• Type J reference compensator with reference junction at 32°F/0°C, or

Type J thermocouple calibrator set at 32°F/0°C

• Precision millivolt source, 0 - 50mV minimum range, 0.01mV resolution

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the Series

988. See Chapter 2 in the user's manual.

2. For Input #1 calibration: Connect the millivolt source to terminal #9 (+) and

terminal #10 (-) on the 988 terminal strip. Use 20 to 24 gauge copper wire. If

you have model number 98_ _ - 2_ _ _ - _ _ _ _, remove the control from the

case and set the Input 1 DIP switches to: 1 OFF 2 ON 3 ON

For Input #2 calibration: Connect the millivolt source to terminal #19 (+) and

terminal #20 (-) on the 988 terminal strip. Use 20 to 24 gauge copper wire. If

you have model number 98_ _ - _2_ _ - _ _ _ _, remove the control from the

case and set the Input 2 DIP switches to: 1 OFF 2 ON 3 ON

3. Apply power to the unit and let it warm up for 15 minutes. After warm-up, put

the unit in the CAL menu. See Page 6.

When performing calibration procedures, always do the Input 1 prompts

(beginning with an “A”) first, then continue on to the Input 2 prompts

(beginning with a “B”). See the Calibration menu on Page 6.

4. At the A 50 prompt, or the B 50 prompt, enter 50.00mV from the millivolt source

to the Series 988. Allow at least 10 seconds to stabilize. Press the Up key to

change the upper display to YES. Press the Mode key.

5. At the A 00 prompt, or the B 00 prompt, enter 0.00mV from the millivolt source

to the Series 988. Allow at least 10 seconds to stabilize. Press the Up key to

change the upper display to YES. Press the Mode key.

6. At the tc prompt, disconnect the millivolt source, and connect the reference

compensator or T/C calibrator to terminal #9 (+) and terminal #10 (-) on the 988

terminal strip. If using a compensator, turn it on and short the input wires.

When using a Type J calibrator, set it to simulate 32°F/0°C. Allow 10 seconds

for the control to stabilize. Press the Up key to change the upper display to

YES. To conclude the T/C calibration, press the Display key.

8WATLOW Series 988 Calibration Manual

Low Gain T/C

NOTE:

Any prompt begin-

ning with an “A”

applies to Input 1.

Those beginning

with a “B” apply to

Input 2.

WATLOW Series 988 Calibration Manual 9

High Gain T/C

High Gain Thermocouple Input Procedure

Type R, S and B only

Equipment Required

• Type J reference compensator with reference junction at 32°F/0°C, or

Type J thermocouple calibrator set at 32°F/0°C

• Precision millivolt source, 0 - 50mV minimum range, 0.01mV resolution

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See Chapter 2 in the user's manual.

2. For Input #1 calibration: Connect the millivolt source to terminal #9 (+) and

terminal #10 (-) on the 988 terminal strip. Use 20 to 24 gauge copper wire. If

you have model number 98_ _ - 2_ _ _ - _ _ _ _, remove the control from the

case and set the Input 1 DIP switches to: 1 OFF 2 ON 3 ON

For Input #2 calibration: Connect the millivolt source to terminal #19 (+) and

terminal #20 (-) on the 988 terminal strip. Use 20 to 24 gauge copper wire. If

you have model number 98_ _ - _2_ _ - _ _ _ _, remove the control from the

case and set the Input 2 DIP switches to: 1 OFF 2 ON 3 ON

3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

When performing calibration procedures, always do the Input 1 prompts

(beginning with an “A”) first, then continue on to the Input 2 prompts

(beginning with a “B”). See the Calibration menu on Page 6.

4. At the A 50 or B 50 prompt, enter 50.00mV from the millivolt source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press the Mode key.

5. At the A 00 or B 00 prompt, enter 0.00mV from the millivolt source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press the Mode key.

6. At the tc prompt, disconnect the millivolt source, and connect the reference

compensator or T/C calibrator to terminal #9 (+) and terminal #10 (-) on the 988

terminal strip. If using a compensator, turn on and short the input wires. If

using a J calibrator, set it to simulate 32°F/0°C. Allow 10 seconds for the con-

trol to stabilize. Press the Up key to change the upper display to YES. To con-

clude the T/C calibration, press the Display key.

7. For Input #1 calibration: Remove the control from the case and set the

Input #1 DIP switches to: 1 OFF 2 ON 3 OFF

8. For Input #2 calibration: Remove the control from the case and set the Input

#2 DIP switches to: 1 OFF 2 ON 3 OFF

9. At the A 0H or B 0H prompt, enter 0.00 mV from the millivolt source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press the Mode key.

10.At the A 20 or B 20 prompt, enter 20.00 mV from the millivolt source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press and hold the Mode key, while also pressing

the Up key until the lower display reads tc.

NOTE:

Any prompt begin-

ning with an “A”

applies to Input 1.

Those beginning

with a “B” apply to

Input 2.

10 WATLOW Series 988 Calibration Manual

RTD

RTD Input Procedure

Equipment Required

•1Kprecision decade box with 0.01resolution

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See Chapter 2 in the user's manual.

2. For Input #1 calibration: Connect the decade box to terminals #8, 9

and 10 on the 988 terminal strip, see below. Use 20 to 24 gauge copper wire.

Remove the control from the case and set the Input 1 DIP switches to:

1 OFF 2 OFF 3 ON

For Input #2 calibration: Connect the decade box to terminal #18, 19 and 20

on the 988 terminal strip, see below. Use 20 to 24 gauge copper wire. If you

have model number 98_ _ - _2_ _ - _ _ _ _, remove the control from the case

and set the Input 2 DIP switches to: 1 OFF 2 OFF 3 ON

NOTE:

Any prompt begin-

ning with an “A”

applies to Input 1.

Those beginning

with a “B” apply to

Input 2. 3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

When performing calibration procedures, always do the Input 1 prompts

(beginning with an “A”) first, then continue on to the Input 2 prompts

(beginning with a “B”). See the Calibration menu on Page 6.

4. At the A 15 or B 15 prompt, enter 15.00from the decade box to the Series

988. Allow at least 10 seconds to stabilize. Press the Up key to change the

upper display to YES. Press the Mode key.

5. At the A380 or B380 prompt, enter 380.00from the decade box to the Series

988. Allow at least 10 seconds to stabilize. Press the Up key to change the

upper display to YES. Press the Mode key. To conclude the RTD calibration,

press the Display key.

H

L

G

Ω

General Radio Model #1433-T

To 8 or 18

To 9 or 19

To 10 or 20

Series 98X

Terminals

WATLOW Series 988 Calibration Manual 11

mA Process Input

mA Process Input Procedure

0 to 20mA and 4 to 20mA units

Equipment Required

• Precision current source, 0-20mA range with 0.01mA resolution

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See Chapter 2 in the user's manual.

2. For Input #1 calibration: Connect the voltage source to terminal #8 (-) and

terminal #10 (+) on the 988 terminal strip. Use 20 to 24 gauge copper wire.

Remove the control from the case and set the Input 1 DIP switches to:

1 ON 2 ON 3 ON

For Input #2 calibration: Connect the voltage source to terminal #18 (-) and

terminal #20 (+) on the 988 terminal strip. Use 20 to 24 gauge copper wire.

Remove the control from the case and set the Input 2 DIP switches to:

1 ON 2 ON 3 ON

3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

When performing calibration procedures, always do the Input 1 prompts

(beginning with an “A”) first, then continue on to the Input 2 prompts

(beginning with a “B”). See the Calibration menu on Page 6.

4. At the A20A or B20A prompt, enter 20.00mA from the current source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press the Mode key.

5. At the A4Aor B 4A prompt, enter 4.00mA from the current source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press the Mode key. To conclude the current

process calibration, press the Display key.

NOTE:

Any prompt begin-

ning with an “A”

applies to Input 1.

Those beginning

with a “B” apply to

Input 2.

12 WATLOW Series 988 Calibration Manual

VDC Process Input Procedure

0 to 5VDC and 0 to 10VDC units

Equipment Required

• Precision Voltage source 0-10 volt minimum range with .001 volt resolution.

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See chapter 2 in the user’s manual.

2. For Input #1 calibration: Connect the voltage source to terminal #9 (+)

terminal #10 (-) on the 988 terminal strip. Use 20 to 24 gauge copper wire.

Remove the control from the case and set the Input 1 DIP switches to:

1 ON 2 ON 3 ON

For Input #2 calibration: Connect the voltage source to terminal #19 (+) and

#20 (-) on the 988 terminal strip. Use 20 to 24 gauge copper wire. Remove the

control from the case and set the Input 2 DIP switches to:

1 ON 2 ON 3 ON

3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

When performing calibration procedures, always do the Input 1 prompts

(beginning with an “A”) first, then continue on to the Input 2 prompts

(beginning with a “B”). See the Calibration menu on Page 6.

4. At the A10U or B10U prompt, enter 10.000 volts from the voltage source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press the Mode key .

5. At the A 0U or B 0U prompt, enter 0.000 volts from the voltage source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press the Mode key . To conclude the voltage

process calibration press the Display key.

VDC Process Input

NOTE:

Any prompt begin-

ning with an “A”

applies to Input 1.

Those beginning

with a “B” apply to

Input 2.

WATLOW Series 988 Calibration Manual 13

mVDC Process Input

mVDC Process Input Procedure

0 to 50mVDC and 0 to 100mVDC units

Equipment Required

• Precision millivolt source, 0-100mV minimum range with 0.001mV resolution

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See Chapter 2 in the user's manual.

2. For Input #1 calibration: Connect the millivolt source to terminal #8 (-) and

terminal #10 (+) on the 988 terminal strip. Use 20 to 24 gauge copper wire.

Remove the control from the case and set the Input 1 DIP switches to:

1ON 2OFF 3ON

For Input #2 calibration: Connect the millivolt source to terminal #18 (-) and

terminal #20 (+) on the 988 terminal strip. Use 20 to 24 gauge copper wire.

Remove the control from the case and set the Input 2 DIP switches to: 1 1

ON 2 OFF 3 ON

3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

When performing calibration procedures, always do the Input 1 prompts

(beginning with an “A”) first, then continue on to the Input 2 prompts

(beginning with a “B”). See the Calibration menu on Page 6.

4. At the A 0U or B 0U prompt, enter 0.000mV from the millivolt source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press the Mode key.

5. At the A100 or B100 prompt, enter 100.00mV from the voltage source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press the Mode key. To conclude the millivolt

process calibration, press the Display key.

NOTE:

Any prompt begin-

ning with an “A”

applies to Input 1.

Those beginning

with a “B” apply to

Input 2.

14 WATLOW Series 988 Calibration Manual

Slidewire/Current

Slidewire Feedback Input Procedure

Equipment Required

•1Kprecision decade box with 0.01resolution

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See Chapter 2 in the user's manual.

2. Connect the decade box to terminal #18 and #20 on the 988 terminal strip.

Place a jumper wire between terminal #19 and #20. Use 20 to 24 gauge cop-

per wire.

3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

4. At the B 15 prompt, enter 1000.00from the decade box to the Series 988.

Allow at least 10 seconds to stabilize. Press the Up key to change the upper

display to YES. Press the Mode key.

5. At the B380 prompt, remove the jumper from terminals #19 and #20 and place

it between terminals #18 and #19. Allow at least 10 seconds to stabilize.

Press the Up key to change the upper display to YES. Press the Mode key.

To conclude the slidewire feedback calibration, press the Display key.

Current Transformer Input Procedure

Equipment Required

• DC source, 50mA minimum sourcing capacity, 0 - 5V minimum range

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See Chapter 2 in the user's manual.

2. Connect the voltage source to terminal #18 and terminal #20 on the 988 termi-

nal strip. Use 20 to 24 gauge copper wire.

3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

4. At the B 50 prompt, enter 4.72VDC from the voltage source to the Series 988.

Allow at least 10 seconds to stabilize. Press the Up key to change the upper

display to YES. Press the Mode key.

5. At the B 00 prompt, enter 0.00VDC from the voltage source to the Series 988.

Allow at least 10 seconds to stabilize. Press the Up key to change the upper

display to YES. Press the Mode key. To conclude the current transformer

input calibration, press the Display key.

WATLOW Series 988 Calibration Manual 15

mA Process Output

mA Process Output 1 & 2 Procedure

Equipment Required

• 4 1/2 digit digital multimeter

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See Chapter 2 in the user's manual.

2. For Output #1 calibration: Connect the digital multimeter to terminal

#12 (+) and terminal #14 (-). Set the DMM to read a range of 0 to 20mA.

Connect the leads of the DMM to measure current.

For Output #2 calibration: Connect the digital multimeter to terminal

#15 (+) and terminal #17 (-). Set the DMM to read a range of 0 to 20mA.

Connect the leads of the DMM to measure current.

3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

When performing calibration procedures, always do the Output 1 prompts

(beginning with a “1”) first, then continue on to the Output 2 prompts

(beginning with a “2”). See the Calibration menu on Page 6.

4. At the 1 4 or 2 4 prompt, the multimeter should read approximately 4 mA. Use

the Up or Down keys to adjust the reading on the multimeter for 3.85mA

±.05mA. Allow the control to stabilize for 10 seconds. Press the Mode key to

enter and advance to the next prompt.

5. At the 1 20 or 2 20 prompt, use the Up or Down keys to adjust the reading on

the multimeter for 20.15mA ±.05mA. Allow the control to stabilize for 10 sec-

onds. Press the Mode key to enter and advance to the next prompt. To con-

clude the process output calibration, press the Display key.

NOTE:

Any prompt begin-

ning with a “1”

applies to Output 1.

Those beginning

with a “2” apply to

Output 2.

16 WATLOW Series 988 Calibration Manual

VDC Process Output

VDC Process Output 1 & 2 Calibration

Equipment Required

• 4 1/2 digit Digital Multimeter

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See Chapter 2 in the user's manual.

2. For Output #1 calibration: Connect the digital voltmeter to terminal #13 (+)

and terminal #14 (-). Set the DVM to read a range of 0 to 10VDC. Connect the

leads of the DVM to measure volts DC.

For Output #2 calibration: Connect the digital multimeter to terminal

#16 (+) and terminal #17 (-). Set the DVM to read a range of 0 to 10VDC.

Connect the leads of the DVM to measure volts DC.

3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

When performing calibration procedures, always do the Output 1 prompts

(beginning with a “1”) first, then continue on to the Output 2 prompts

(beginning with a “2”). See the Calibration menu on Page 6.

4. At the 1 0 or 2 0 prompt, the multimeter should read approximately 0 Volts.

Use the Up or Down keys to adjust the reading on the multimeter for 0.0VDC ±

0.1VDC. Allow the control to stabilize for 10 seconds. Press the Mode key to

enter, and advance to the next prompt.

5. At the 1 10 or 2 10 prompt, use the Up or Down keys to adjust the reading on

the multimeter for 10.0VDC ±0.1VDC. Allow the control to stabilize for 10 sec-

onds. Press the Mode key to enter, and advance to the next prompt. To con-

clude the process output calibration, press the Display key.

NOTE:

Any prompt begin-

ning with a “1”

applies to Output 1.

Those beginning

with a “2” apply to

Output 2.

WATLOW Series 988 Calibration Manual 17

Retransmit

mA Retransmit Output 3 Procedure

Equipment Required

• 4 1/2 digit Digital Multimeter

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See Chapter 2 in the user’s manual.

2. Connect the digital multimeter to terminal #1 (+) and terminal #2 (-). Set the

DVM to read a range of 0 to 20mA. Connect the leads of the DVM to measure

current.

3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

4. At the 3 LO prompt, the multimeter should read approximately 0.1mA. Use the

Up or Down keys to adjust the reading on the multimeter for 0.00mA ±0.05mA.

Allow the control to stabilize for 10 seconds. Press the Mode key to enter and

advance to the next prompt.

5. At the 3 HI prompt, use the Up or Down keys to adjust the reading on the multi-

meter for 20mA ±.05mA. Allow the control to stabilize for 10 seconds. Press

the Mode key to enter and advance to the next prompt. To conclude the

process retransmit output calibration, press the Display key.

VDC Retransmit Output 3 Calibration

Equipment Required

• 4 1/2 digit Digital Multimeter

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See Chapter 2 in the 988 User’s Manual.

2. For Output #1 calibration: Connect the digital multimeter to terminal

#1 (+) and terminal #2 (-). Set the DVM to read a range of 0 to 10VDC.

Connect the leads of the DVM to measure volts DC.

3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

4. At the 3 LO prompt, the multimeter should read approximately 0 volts. Use the

Up or Down keys to adjust the reading on the multimeter for 0.0VDC ±0.1 volt.

Allow the control to stabilize for 10 seconds. Press the Mode key to enter, and

advance to the next prompt.

5. At the 3 HI prompt, use the Up or Down keys to adjust the reading on the multi-

meter for 10.0VDC ±0.1VDC. Allow the control to stabilize for 10 seconds.

Press the Mode key to enter, and advance to the next prompt. To conclude the

voltage process retransmit output calibration, press the Display key.

18 WATLOW Series 988 Calibration Manual

Watlow Process Controls Calibration Manual

Watlow Controls, 1241 Bundy Blvd., P.O. Box 5580, Winona, MN 55987-5580, Phone: 507/454-5300, Fax: 507/452-4507

This manual suits for next models

7

Table of contents

Popular Control Unit manuals by other brands

Task Force Tips

Task Force Tips Ball Intake Valve INSTRUCTIONS FOR SAFE OPERATION AND MAINTENANCE

Powrmatic

Powrmatic HEM-SL Series User, installation and service manual

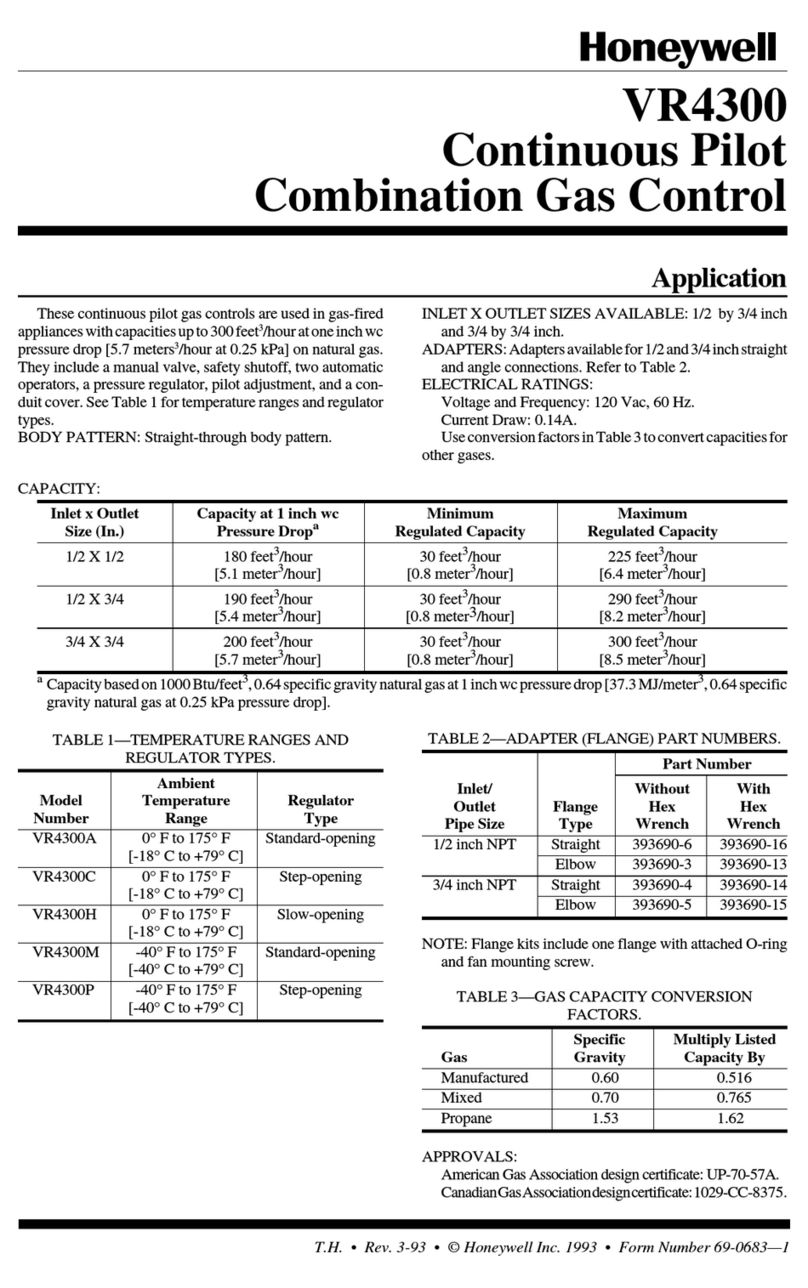

Honeywell

Honeywell VR4300 manual

iWave

iWave iW-RainboW-G54M STM32MP13 Series Hardware user's guide

Tews Technologies

Tews Technologies TPMC917-10 user manual

Bray

Bray S30/S70 Calibration & Testing