Watt Drive S3 Series User manual

This manual suits for next models

9

Table of contents

Other Watt Drive Inverter manuals

Popular Inverter manuals by other brands

FRONIUS

FRONIUS Personal Display DL operating instructions

Anova

Anova GC900 Instruction and user's manual

Fuji Electric

Fuji Electric FRENIC-Lift LM2 Series Starting guide

Growatt

Growatt 10000HY Installation & operation manual

Autarco

Autarco 4G-STICK instruction manual

Cobra

Cobra CPI 450 operating instructions

Olimpia splendid

Olimpia splendid DUAL INVERTER 14 Instructions for use and maintenance

Sunways

Sunways STT-80K user manual

Toshiba

Toshiba H9 quick start guide

Hitachi

Hitachi HFC-VWA2 SERIES instruction manual

Festo

Festo OVEM operating instructions

Mitsubishi Electric

Mitsubishi Electric FR-C500 instruction manual

Sima

Sima STP-1500 User instructions

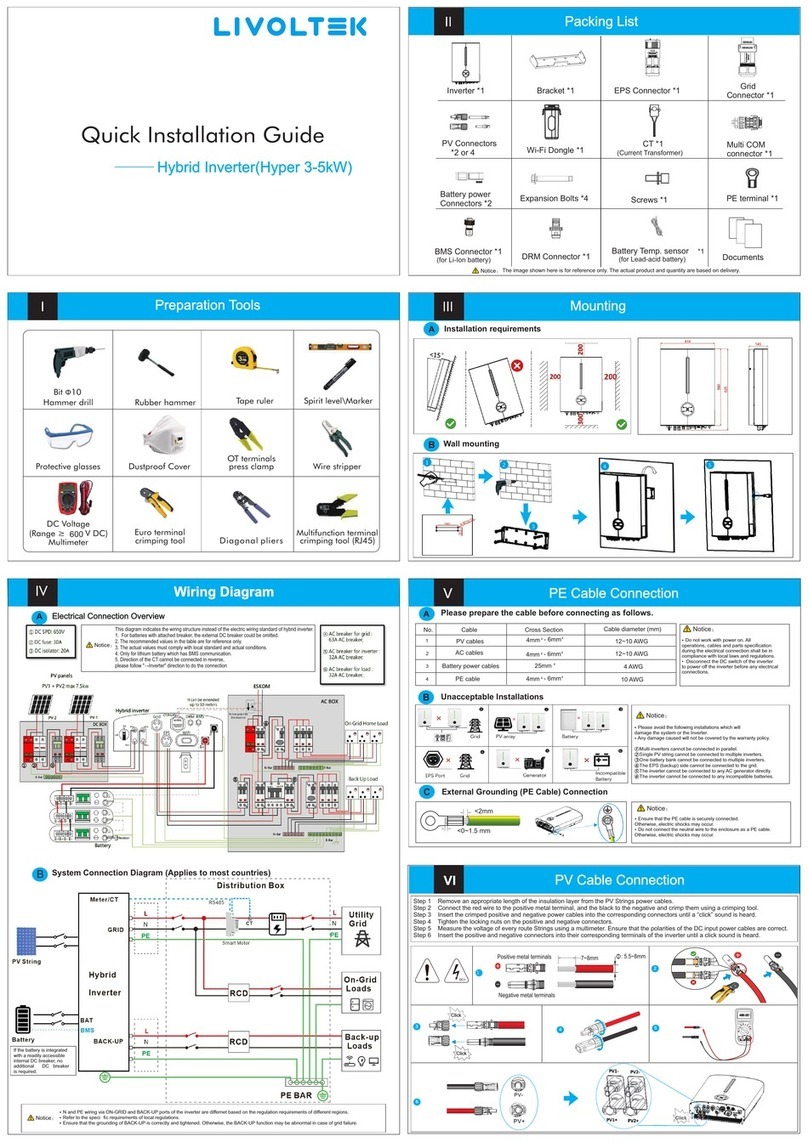

LIVOLTEK

LIVOLTEK Hyper 3-5kW Quick installation guide

CUTES

CUTES CT-2000FG Series manual

Tektronix

Tektronix Tektronix SPG8000 Technical reference

Lunt Solar Systems

Lunt Solar Systems LS80THa quick start guide

Ingeteam

Ingeteam INGECON SUN STORAGE 1Play Installation and configuration