Watt Drive V2000 Series User manual

INVERTER

Series V2000

M A N U A L

NB588XA

Manual

Page 2 / 51

MANUAL

These two manuals provide you with a general information how to use V2000 frequency

inverter and how to apply, if needed, special applications.

V2000 Installation manual provides you with the information necessary to install, start-up

and operate the V2000 frequency converters. It is recommended that this manual is read

thoroughly before powering up the frequency converter for the first time.

If any problem occurs, please contact your local distributors. WATT DRIVE Antriebstechnik

GmbH is not responsible for the use of the frequency converters against the instructions.

Manual

Page 3 / 51

WATT DRIVE WORLDWIDE

WATT DRIVE Antriebstechnik GmbH A-2753 Markt Piesting

Tel.: +43/2633/404-0 Fax: +43/2633/404-220 Wöllersdorferstraße 68

Internet: http:\\www.wattdrive.com e-mail: watt@wattdrive.com

Power Drive Services Ltd, Unit 1, Victoria St. Ind. Est. Leigh WN7 5SE U.K.

Tel.: +44 1942260206 Fax: +44 1942260525 e-mail: www.wattdrive.co.uk/contact.htm

WATT DRIVE Süd GmbH D-72379 Hechingen

Tel.: +49/7471/9685-0 Fax: +49/7471/9865-29 e-mail: watt-sued@t-online.de

WATT DRIVE Nord GmbH D-51429 Bergisch Gladbach

Vertriebs- und Servicecenter Köln

Tel.: +49/2204/84-2800 Fax: +49/2204/84-2819 e-mail: watt-koeln@t-online.de

WATT DRIVE D-97044 Würzburg

Vertriebs- und Servicecenter Max LAMB KG

Tel.: +49/931/2794-0 Fax: +49/931/27455 e-mail: ant@lamb.de

WATT EURO DRIVE (Far East) PTE LT SGP-629082 Singapore

Tel.: +65/86 23 220 Fax: +65/86 23 33 e-mail: watteuro@pacific.net.sg

WATT EURO DRIVE (Malaysia) SDN BH 40400 Selangor, Malaysia

Tel: +603/736 89 81 Fax: +603/736 89 76 e-mail: cmfoo98@tm.net.my

Version: BA-FBE_UR.004.R001.06_00

File: H: V2000 Kurzanleitung_englisch.doc

Date: 27hof June 2000 / DE

Manual

Page 4 / 51

Please read this manual carefully before you install and operate an V2000 series inverter and

observe all of the instructions given in there. This manual may also serve as a reference guide und

therefore should always be kept at hand.

Symbols used

There are several safety instructions in this manual which are marked with a special hazard alert

symbol (flash or exclamation mark in the center of a triangle). Additionally, either the word

CAUTION or WARNING is added following the triangle with the exclamation mark.

This symbol means hazardous high voltage. It is used to call your attention to items or

operations that could be dangerous to you or other persons life. Please read the safety

message carefully and follow all the instructions given.

This symbol is used to call your attention to situations which are potentially dangerous to

persons. Please read the safety message carefully and follow all the instructions given.

The safety messages given following this symbol are further divided into two categories:

WARNING This message indicates a situation which may lead to serious injury

or even death if the instruction is not observed.

CAUTION This message indicates a situation which may lead to minor or

moderate injury, or damage of product.

HAZARDOUS HIGH VOLTAGE

Motor control equipment or electronic controllers are connected to hazardous

line voltages. When servicing drives and electronic controllers there might

exist exposed components with cases ore protrusions at or above line

potential. Extreme care should be taken to protect against shock.

For these reasons, the following safety guidelines should be observed:

Stand on an insulating pad and make it a habit to use only one hand when

checking components. Disconnect power before checking controllers or

performing maintenance. Be sure that equipment is grounded properly. Wear

safety glasses whenever working on an electronic controller or rotating

electrical equipment.

WARNING This equipment should be installed, adjusted and serviced only by qualified

electrical maintenace personell familiar with the construction and operation of

the equipment and the hazards involved. Failure to observe this precaution

could result in bodily injury.

WARNING The user is responsible that all driven machinery, drive train mechanism not

supplied by WATT DRIVE Antriebstechnik GmbH, and process line material

are capable of safe operation at an applied frequency of 150% of the

maximum selected frequency range to the AC motor. Failure to do so can

result in destruction of equipment and injury to personnell should a single point

failure occur.

WARNING HAZARD OF ELECTRICAL SHOCK. DISCONNECT INCOMING POWER

BEFORE WORKING ON THIS CONTROL.

WARNING SEPERATE MOTOR OVERLOAD AND OVERCURRENT PROTECTION

DEVICES ARE REQUIRED TO BE PROVIDED IN ACCORDANCE WITH THE

SAFETY CODES REQUIRED BY JURISDICTIONAL AUTHORITIES.

CAUTION These instructions should be read and clearly understood before working on

V2000 series equipment.

CAUTION Proper grounds, disconnecting devices (e.g. fuses) and other safety devices

and their location are the responsibility of the user and are not provided by

WATT DRIVE.

Manual

Page 5 / 51

CAUTION DANGEROUS VOLTAGE EXISTS UNTIL THE POWER LIGHT ON THE

DIGITAL OPERATOR IS OFF.

CAUTION Rotating shafts and electrical potentials above ground level can be hazardous.

Therefore it is strongly recommended that all electrical work conform to the

national electrical codes and local regulations. Installation, maintenance and

alignment should be performed by qualified personnell only.

Factory recommended test procedures included in this instruction manual

should be followed. Always disconnect electrical power before working on the

unit.

WARNING a) Any motor used must be of suitable rating.

b) Motors may have hazardous moving parts so that suitable protection must

be provided in order to avoid injury.

CAUTION Alarm connections may have hazardous live voltages even when the inverter

is disconnected. In case of removing the front cover for maintenance or

inspection, confirm that incoming power for alarm connections is surely

disconnected.

CAUTION Main terminals or other hazardous terminals for any interconnection (terminals

for connecting the motor, contact breaker, filter etc.) must be inaccessible in

end installation.

All of the above instructions, together with any other requirements, reccommendations,

and safety messages highlighted in this manual must be strictly complied with.

NOTES ON EMC (ELECTRO MAGNETICAL COMPATIBILITY)

WARNING This equipment should be installed, adjusted and serviced by qualified

personnell familiar with construction and operation of the equipment and

the hazards involved. Failure to observe this precaution could result in

bodily injury.

When using V2000 series inverters in EU countries, the EMC directive 89/336/EEC must be

observed. To satisfy the EMC directive and to comply with the standard, the following provisions

should be obeyed:

A) Environmental conditions for the inverter:

•Ambient temperature: -10°C to 40°C.

•Relative Humidity: 20% to 90% (no dew condensation)

•Vibrations: max. 5,9m/s2(0.6 g) at 10–55Hz.

•Location: 1000 meter or less altitude, indoors (no corrosive gas or dust).

B) The power supply to the V2000 inverter must conform to the conditions stated below. If one of

the conditions mentioned is not satisfied then an appropriate V2000 AC reactor will have to be

installed.

•Voltage fluctuation +/-10% or less

•Voltage unbalance +/-3% or less

•Frequency variation +/-4% or less

C) Wiring

•Shielded wiring (screened cable) is required for motor wiring, and total length has to be kept

to less than 50m. When using motor cables longer than 50m, V2000 motor filters should be

installed. Directions for installing filters can be found in the V2000 installation manual.

Manual

Page 6 / 51

•Seperate the mains circuit wiring from the wiring used for signals or process circuit. Please

refer to the V2000 installation manual.

D) Installation

•For V2000 series inverters, the filters described hereafter have to be used and the

installation notes have to be observed.

If installed according to the following directions, the frequency inverters comply with the following

standards:

Emmissions: EN 61800-3 (EN 55011 group 1, class B)

Immunity: EN 61800-3, industrial environments

For the best possible damping of interference, special line filters have been developed which

guarantee you easy assembly and installation along with the necessary electrical reliability.

However, effective EMC is only ensured if the suitable filter is selected for the particular drive and

installed in accordance with these EMC recommendations. Please choose the appropriate filter

using the table below:

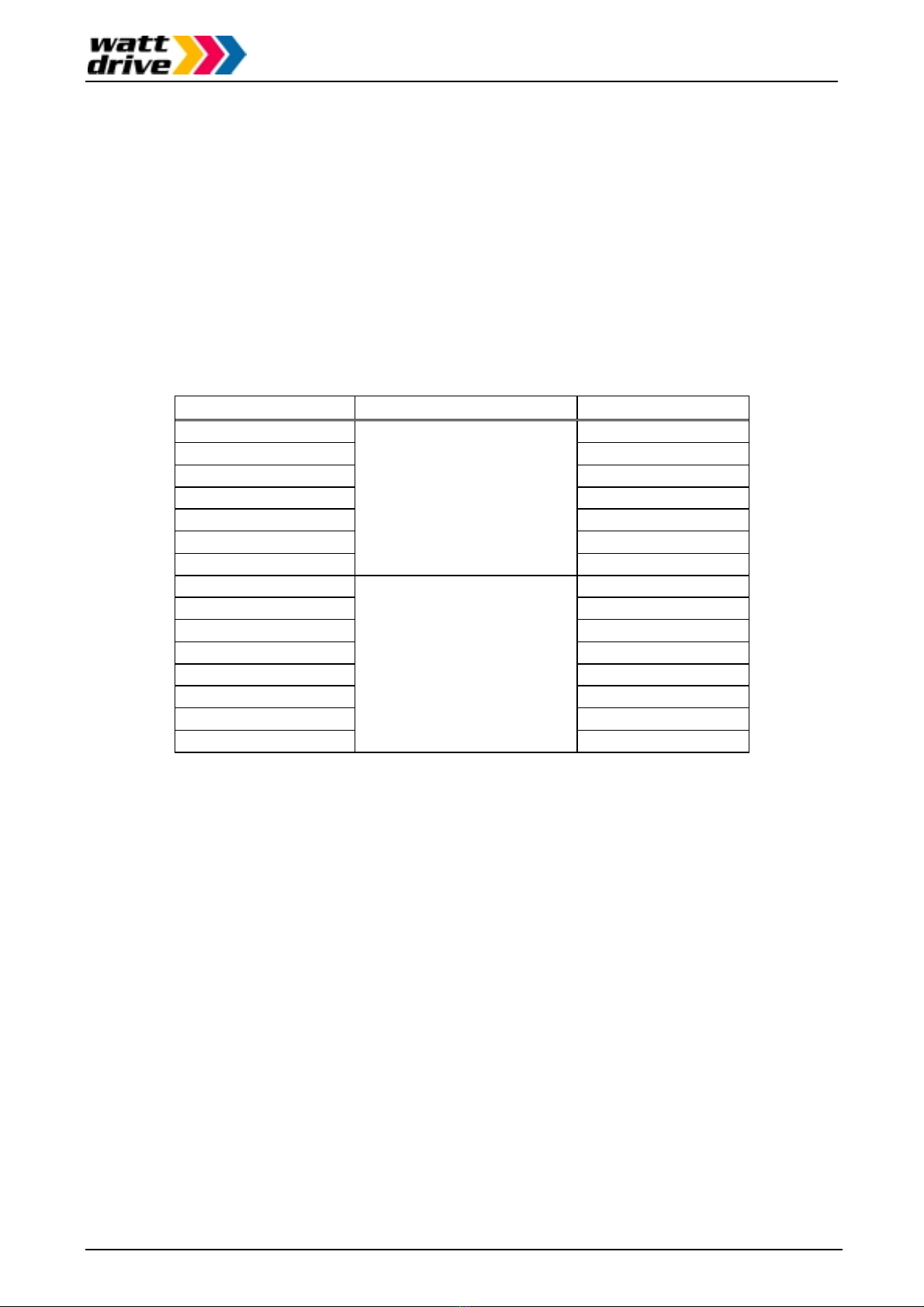

Inverter type Input voltage Filter type

V2000-002 NFE UHZNF-E-1-007

V2000-004 NFE UHZNF-E-1-007

V2000-005 NFE UHZNF-E-1-007

V2000-007 NFE UHZNF-E-1-012

V2000-011 NFE UHZNF-E-1-012

V2000-015 NFE UHZNF-E-1-024

V2000-022 NFE

1 ~ 220V -10% thru 240V

+5%

UHZNF-E-1-024

V2000-004 HFE UHZNF-F-3-007

V2000-007 HFE UHZNF-F-3-007

V2000-015 HFE UHZNF-F-3-007

V2000-022 HFE UHZNF-F-3-007

V2000-030 HFE UHZNF-F-3-011

V2000-040 HFE UHZNF-F-3-011

V2000-055 HFE UHZNF-F-3-020

V2000-075 HFE

3 ~ 380 V -10% thru 460V

+10%

UHZNF-F-3-020

Note: All filters are designed for 50Hz/60Hz +/-5%.

The amount of line-conducted interference also increases as motor cable length increases.

Adherence to the interference limits for line-conducted interference is guaranteed on following way:

•If maximum motor cable length is 10 m at maximum elementary frequency:

Class „B“.

•If maximum motor cable length is 20 m at elementary frequency 5 kHz:

Class „B“.

•If maximum motor cable length is 50 m at maximum elementary frequency:

Class „A“.

Observe the following provisions for an electromagnetically compatible setup of your drive

system:

1. As user you must ensure that the HF impedance between frequency inverter, filter and ground is

as small as possible.

•Take care that the connections are metallic and have the largest possible areas (zink-plated

mounting plates)

2. Conductor loops act like antennas, especially when they encompass large areas. Consequently:

•Avoid unnecessary conductor loops

•Avoid parallel arrangement of „clean“ and interference-prone conductors

Manual

Page 7 / 51

3. Lay the motor cable and all analog and digital control lines shielded.

•You should allow the effective shield area of these lines to remain as large as possible; i.e.,

do not move the shield further away than absolutely necessary.

•With compact systems, if for example the frequency inverter is communicating with the

steering unit, in the same control cabinet connected at the same PE-potential, the screen of

control lines should be put on, on both sides with PE. With branch systems, if for example the

communicating steering unit is not in the same control cabinet and there is a distance

between the systems, we recommend to put on the screen of control lines only on the side of

the frequency inverter. If it is possible, direct in the cable entry section of the steering unit.

The screen of Motor cabels always must be put on, on both sides with PE.

•The large area contact between shield and PE-potential you can realise with a metal PG

screw connection or a metallic mounting clip.

•Use only copper mesh cable (CY) with 85% coverage

•The shielding should not be interrupted at any point in the cable. If the use of reactors,

contactors, terminals or safety switches in the motor output is necessary, the unshielded

section should be kept as small as possible.

•Some motors have a rubber gasket between terminal box and motor housing. Very often, the

terminal boxes, and particularly the threads for the metal PG screw connections, are painted.

Make sure there is always a good metallic connection between the shielding of the motor

cable, the metal PG screw connection, the terminal box and the motor housing, and carefully

remove this paint if necessary.

4. Very frequently, interference is coupled in through installation cables. This influence you can

minimize:

•Lay interfering cables separately, a minimum of 0.25 m from cables susceptible to

interference.

•A particularly critical point is laying cables parallel over larger distances. If two cables

intersect, the interference is smallest if they intersect at an angle of 90°. Cables susceptible to

interference should therefore only intersect motor cables, intermediate circuit cables, or the

wiring of a rheostat at right angles and never be laid parallel to them over larger distances.

5. The distance between an interference source and an interference sink (interference-threatened

device) essentially determines the effects of the emitted interference on the interference sink.

•You should use only interference-free devices and maintain a minimum distance of 0.25 m

from the drive.

6. Safety measures

•Ensure that the protective conductor terminal (PE) of the filter is properly connected with the

protective conductor terminal of the frequency inverter. An HF ground connection via metal

contact between the housings of the filter and the frequency inverter, or solely via cable

shield, is not permitted as protective conductor connection. The filter must be solidly and

permanently connected with the ground potential so as to preclude the danger of electric

shock upon touching the filter if a fault occurs. You can achieve this by connecting it with a

grounding conductor of at least 10 mm² or connecting a second grounding conductor,

connected with a separate grounding terminal, parallel to the protective conductor (the cross

section of each single protective conductor terminal must be designed for the required

nominal load).

Manual

Page 8 / 51

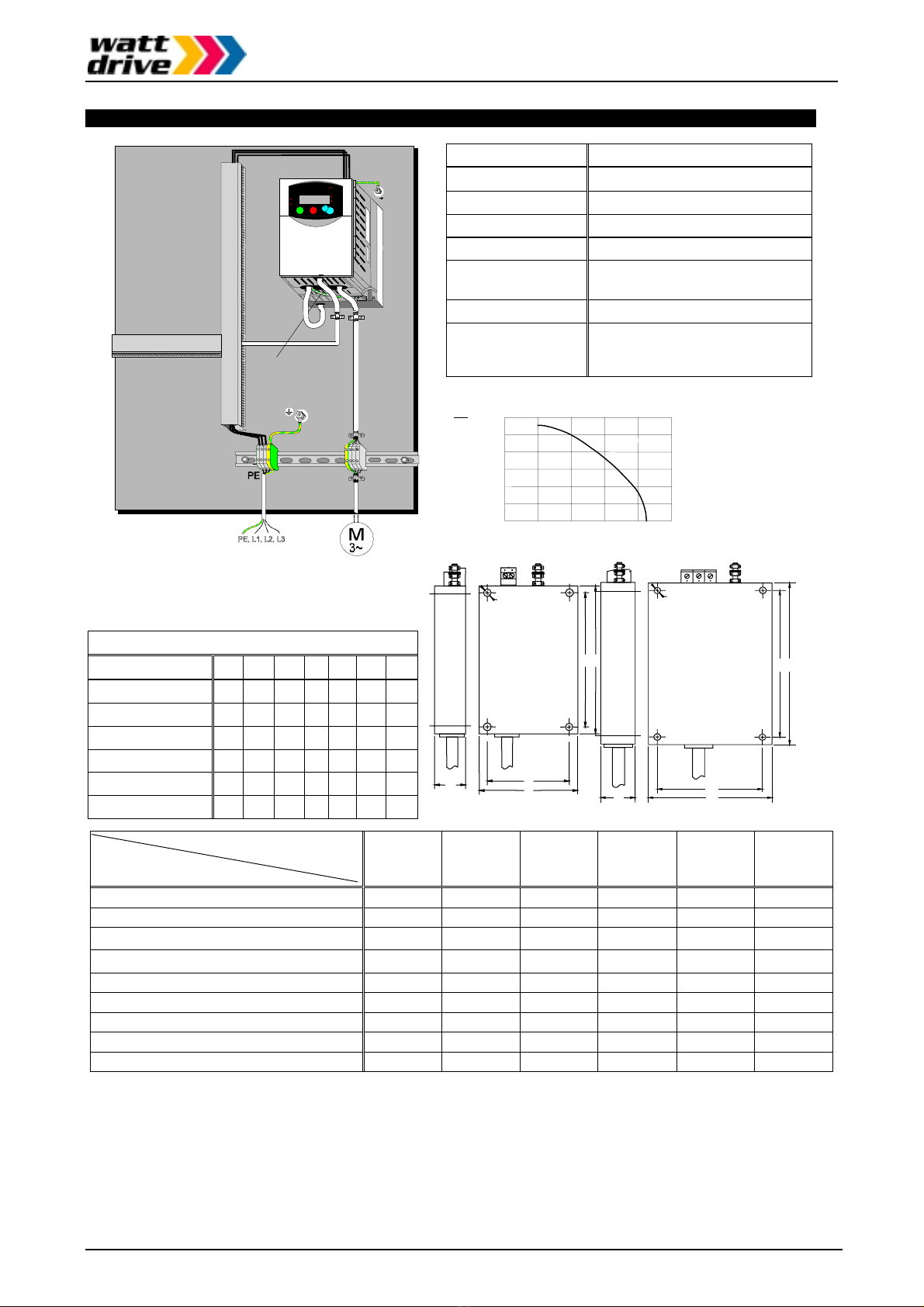

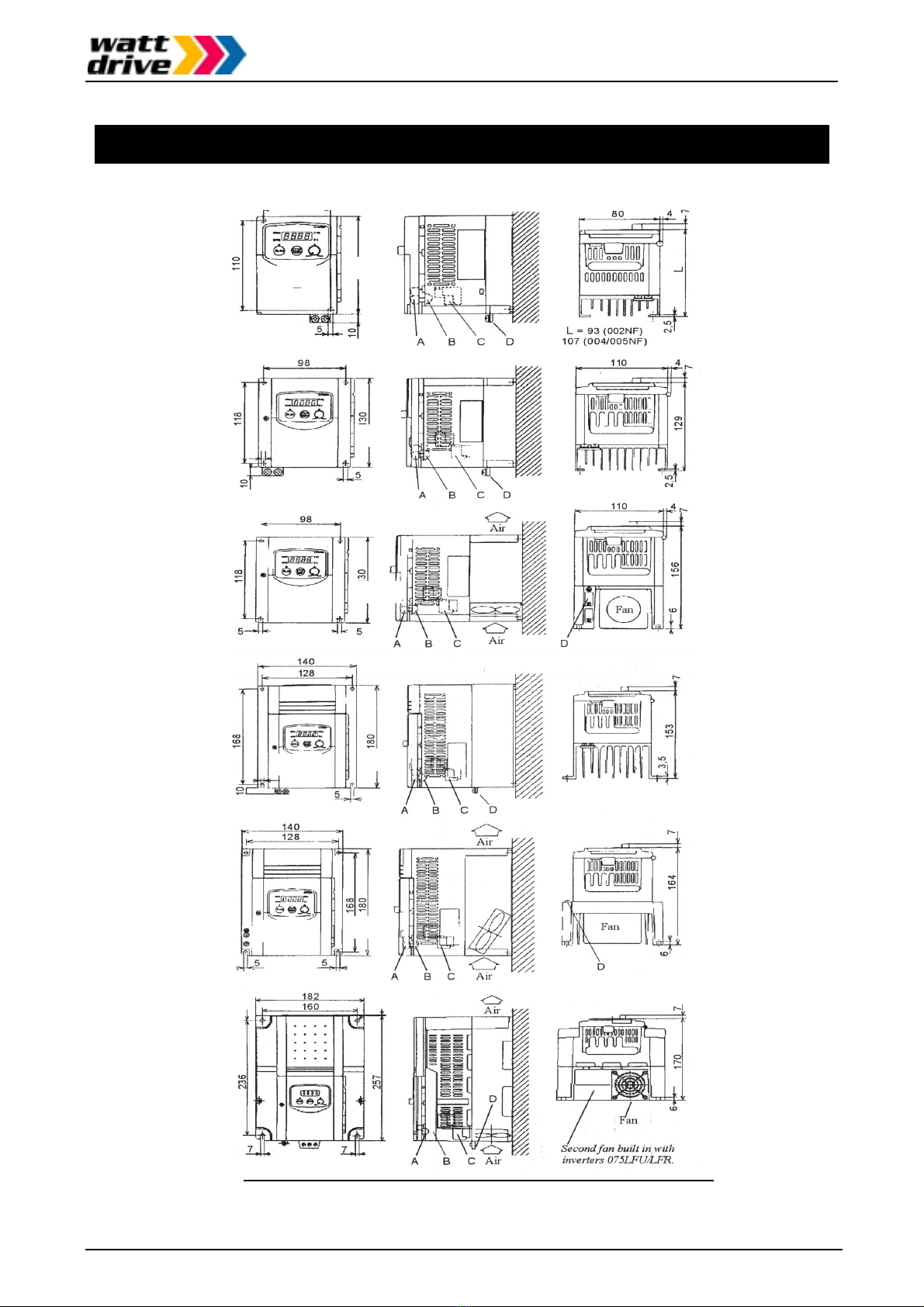

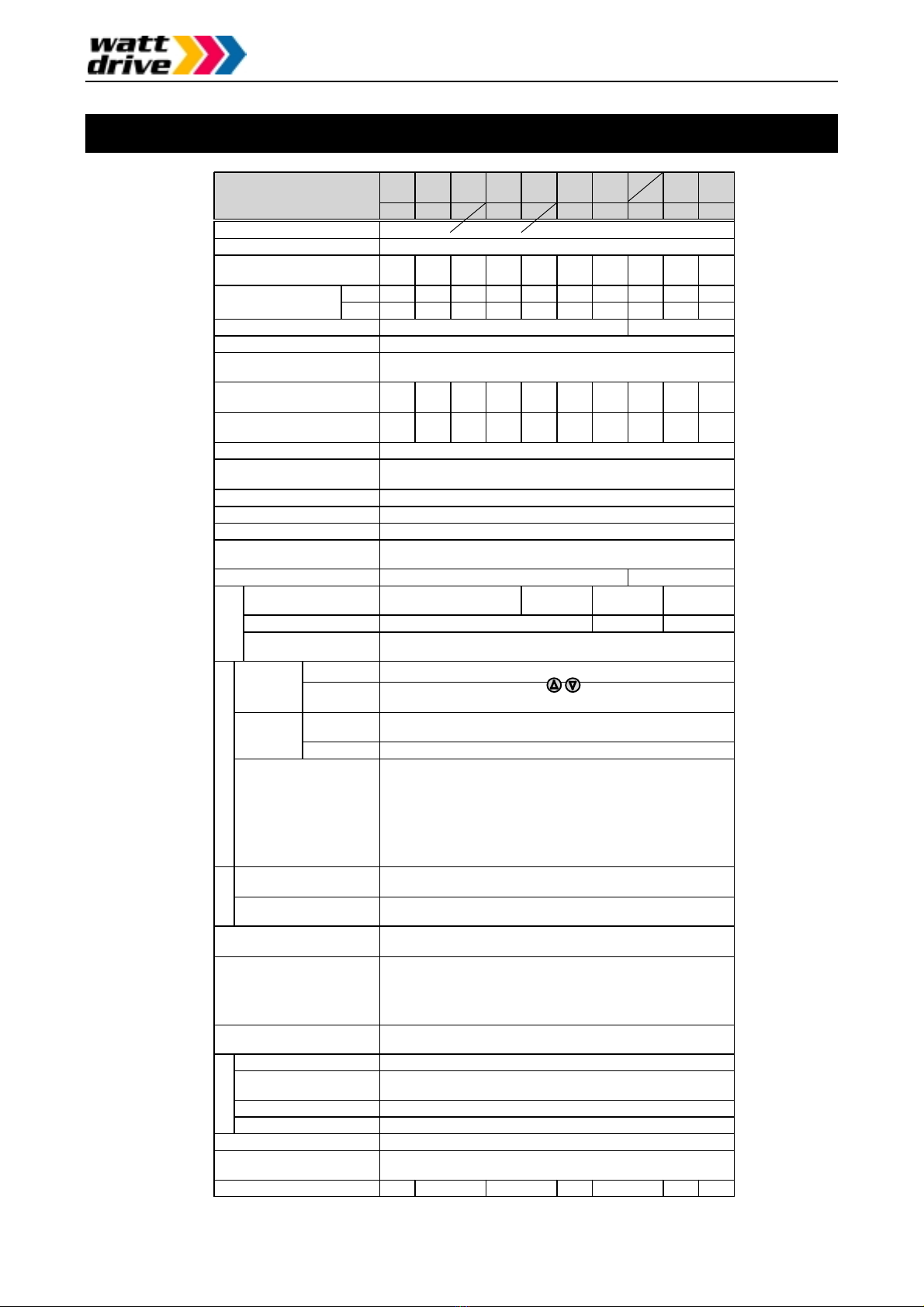

Technical specifications and dimensions of V2000 foot print filter:

WATT DRIVE

55.0

R

U

NSTOP

RESET

MI MAX

RUN

PRG

Hz

A

P

O

WER

2STR

F

U

N

C

.1

V2000

V2000V2000

V2000

WARNING

HAZARD OF PERSONAL I NJURY O

R

ELECTRIC SHOCK

Disconnect incomi n

g

p

ower and wait

5 minutes befor e o

p

enin

g

front case.

PE-connection

Dimensions (in mm)

Model:UHZNF-

Type

ABCDEF

E-1-007 1 120 80 25 110 67 2x6

E-1-012 1 130 110 27 118 98 4x6

E-1-024 1 180 140 29 168 128 4x6

F-3-007 2 130 110 27 118 98 4x6

F-3-011 2 180 140 29 168 128 4x6

F-3-020 2 257 182 35 236 160 4x7

Type: UHZNF-

Specification:

E-1-007 E-1-012 E-1-024 F-3-007 F-3-011 F-3-020

Voltage in V 240 +5% 240 +5% 240 +5% 460 +10% 460 +10% 460 + 10%

Current in A at 40°C 2 x 7A 2 x 12A 2 x 24A 3 x 7A 3 x 11A 3 x 20A

Leak. current in mA/Phase, 50Hz, worst case 1)- - - 32 62 120

Leakage current in mA/ Phase, 50Hz, Un 2)< 3.5 < 3.5 < 15 < 3.5 < 3.5 <10

Test voltage in V DC, 2s ph./ph., ph./ground 1400 / 2800 1400 / 2800 1400 / 1400 1978 / 2800 1978 / 2800 1978 / 1978

Dimensions single wire / litze 4 / 4 mm² 4 / 4 mm² 4 / 4 mm² 4 / 4 mm² 4 / 4 mm² 4 / 4 mm²

Output cable 3x1.5mm² 3x1.5mm² 3x2.5mm² 4x1.5mm² 4x2.5mm² 4x2.5mm²

Weight in kg (approx.) 0.5 0.7 1.0 0.8 1.1 2.4

Heat dissip. in W (approx.) 6 7 9 7 10 14

1 )“Worst case” states the leakage current for three-phase filters in the worst of cases. That means one phase is live

and two phases of the feed-line lead-in are interrupted. These maximum values are based on an operating voltage of

460 V (ph./ph.).

2 )The normal leakage current for three-phase filters is stated. This means the filter is operating on 460 V (ph./.ph.). The

stated values are adhered to up to a neutral voltage of 5V to ground caused by line unbalance.

Current at 40°C ambient temperature

Overload 1.5 x INfor 10min

Frequency 50 / 60 Hz

Material Steel, surface refined

Humidity class C

Operation height < 1000 m without derating;

> 1000 m, IN-2%, for each 1000m

Temperature range -25°C through +85°C

Enclosure

Input terminals IP 20

and PE-holder M5.

Load side: cable, unshielded.

0

0,

2

0

,

4

0

,

6

0

,

8

1

,

0

2

0

4

0

60

80

1

00

Temperature in °C

0

1,2

IB

I

N

=

Dependency of current on ambient temperature:

F

DA

E

B

C

Type 1

F

D

A

E

B

C

Type 2

Manual

Page 9 / 51

Contents

1. Safety precautions ...................................................................................................10

Installation...................................................................................................................10

Wiring .........................................................................................................................10

Control and operation .................................................................................................11

Maintenance and inspection .......................................................................................12

Others.........................................................................................................................12

2. Inspection upon unpacking.....................................................................................14

3. External dimensions and terminal positions..........................................................15

4. Technical specifications..........................................................................................16

5. Appearance and names of parts .............................................................................18

6. Installation ................................................................................................................20

7. Wiring........................................................................................................................21

Wiring the power supply and motor.............................................................................21

Wiring the control terminals.........................................................................................22

General remarks .........................................................................................................23

Wiring equipment and options.....................................................................................24

Terminals....................................................................................................................26

8. General operation notes ..........................................................................................29

Before starting operation.............................................................................................29

Test run ......................................................................................................................29

9. Control circuit terminal functions ...........................................................................32

Overview.....................................................................................................................32

10. Using the digital operator ......................................................................................34

The digital operator control panel................................................................................34

Operating procedure example.....................................................................................34

Digital operator keys ...................................................................................................35

11. Messages................................................................................................................36

Trip messages ............................................................................................................47

Other messages .........................................................................................................48

12. Trouble shooting....................................................................................................49

Protective functions.....................................................................................................51

Safety precautions

Page 10 / 51

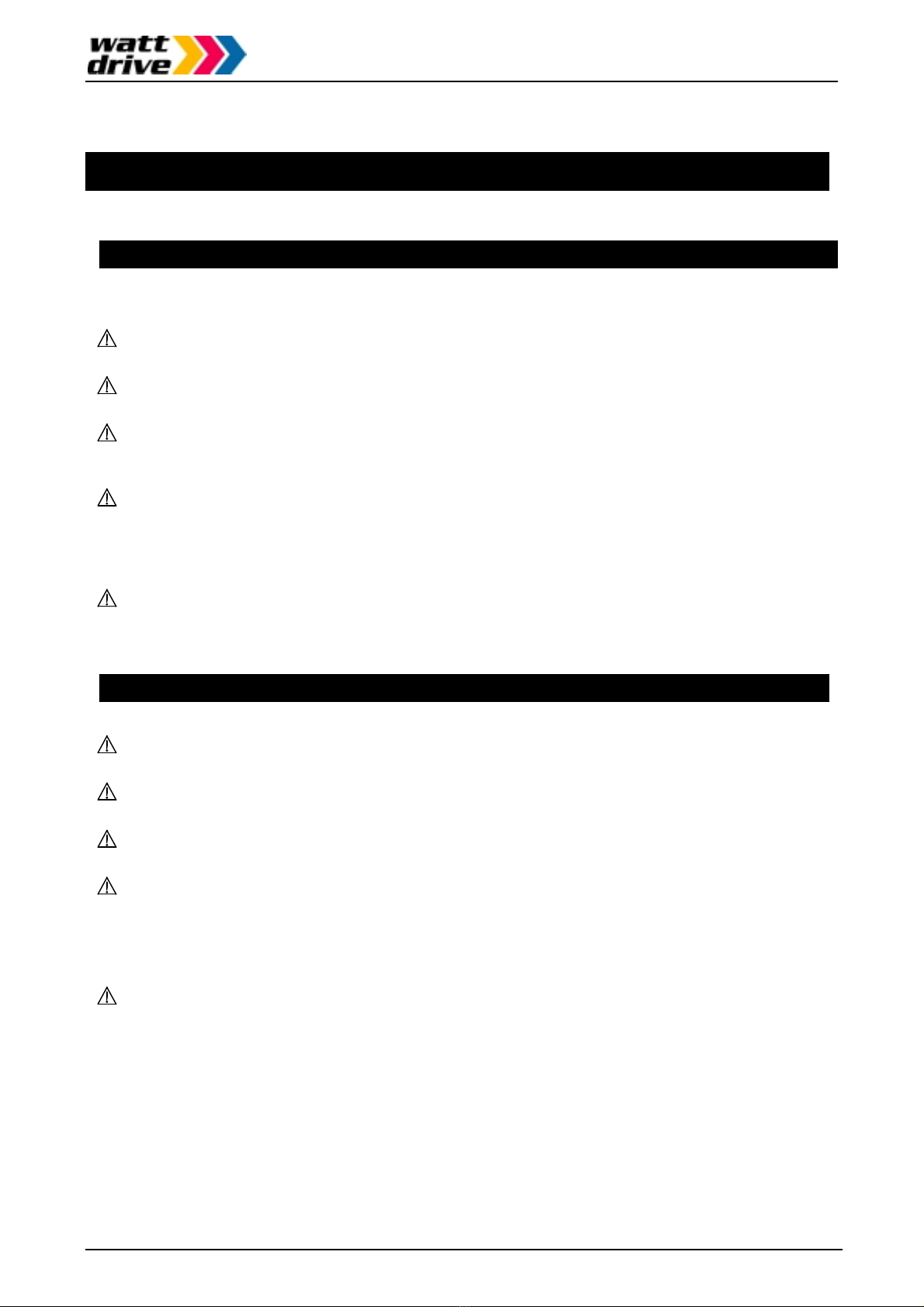

1. Safety precautions

Installation

The following safety precautions are to be observed when installing the frequency inverter:

CAUTION Be sure to install the inverter on flame resistant material such as metal.

Otherwise, there is a danger of fire.

CAUTION Be shure not to place anything inflammable in the vicinity. Otherwise, there is

a danger of fire.

CAUTION Be sure not to let foreign matter (such as cut wire refuse, spatter from

welding, iron refuse, wires, dust etc.) enter the inverter. Otherwise, there is a

danger of fire.

CAUTION Install the inverter in a room which is not exposed to direct sunlight and is

well ventilated. Avoid environments which tend to be high in temperature,

high in humidity or which have dew condensation, as well as places with

dust, corrosive gas, explosive or inflammable gas, grinding-fluid mist, salt

damage etc. Otherwise, there is a danger of fire.

CAUTION The wall surface on which the inverter is mounted must be of a nonflammable

material, such as a steel plate.

Wiring

WARNING The inverter has to be grounded properly. Otherwise, there is a danger of

fire.

WARNING Wiring work must only be carried out when the power supply is off.

Otherwise, there is a danger of electric shock and/or fire.

WARNING Before carrying out the wiring work, the inverter has to be mounted properly.

Otherwise, there is a danger of electric shock or injury.

CAUTION Make shure that the input voltage is as follows (please also refer to chapter

11):

Single/three phase: 200~240V, 50/60Hz (models up to 2,2kW)

Three phase: 200~240V, 50/60Hz

Three phase: 380~460V, 50/60Hz

CAUTION Don´t connect AC power supply to the inverter output terminals U, V, and W.

Otherwise, there is a danger of injury and/or fire.

Safety precautions

Page 11 / 51

INPUTS

(L1) (N)

L1 L2 L3

OUTPUTS

(T1) (T2) (T3)

U V W

Note

)

Power

su

pp

l

y

Note) Terminals L1, N: single phase power supply

Terminals L1, L2, L3: three phase power supply

Not allowed

CAUTION Remarks for using earth leakage circuit breakers in the mains supply:

Frequency inverters with CE-filters (RFI-filter) and screened motor cables have

a higher leakage current against earth. Especially in the moment of switching

this can cause unintentional triggering of earth leakage circuit breakers.

Because of the rectifier on the input side of the inverter there is the possibility

to stall the switch-off function through amounts of DC current. For these

reasons, the following items should be observed:

Only pulse current sensitive earth leakage circuit breakers which have a short

term delay and a higher trigger current (500mA) should be used. Other

components should be secured with separate earth leakage circuit breakers.

Earth leakage circuit breakers in front of an inverter´s rectifier are not an

absolute protection against direct touching.

CAUTION Each phase of the power supply has to be provided with a fuse. Otherwise,

there is a danger of fire.

Control and operation

WARNING Be sure to turn on the input power supply only after closing the front case.

While being energized, don´t open the front case. Otherwise, there is a

danger of electric shock.

WARNING Never operate the switches with wet hands. Otherwise, there is a danger of

electric shock.

WARNING If the retry mode is selected, the inverter may suddenly restart during a stop

which was caused by a trip. In such a case, be sure not to approach the

machine. Provisions have to be taken that the driven motor or machine does

not endanger personnell even in the case of a sudden restart. Otherwise,

there is a danger of injury.

WARNING Even if the power supply is cut off for a short period of time, the inverter may

restart operation after the power supply has recovered if the operation

command is given. If this may incur danger to personnell, provisions have to

be made in order to prevent a restart after power recovery. Otherwise, there

is a danger of injury.

WARNING The STOP key is effective only if the corresponding parameters have been

set. Otherwise, there is a danger of injury.

WARNING If a reset is carried out following a trip condition the motor will restart if the

operation command has been given. Be sure to acknowledge this trip

condition with a reset only after confirming that no operation command is

active. Otherwise, there is a danger of injury.

WARNING When the power to the inverter is turned on while the operation command

is active the motor starts immediately. So before turning power supply on be

sure to confirm that no operation command is active.

Safety precautions

Page 12 / 51

WARNING If the inverter has been configured for the stop command not to be given

using the STOP key, pressing the STOP key does not stop the motor. In

this case a separate emergency stop switch is necessary.

CAUTION Operate the motor and machine connected to the inverter only within the

manufacturer´s speed specifications. Otherwise, there is a danger of injury.

CAUTION If a motor is to be operated at a frequency higher than the standard setting

value of 50 or 60Hz, be sure to check the allowable speed of the motor and

the machine with each manufacturer, and operate them only after getting

their consent.

CAUTION Check the following during and after the test run. Otherwise, there is a

danger of machine breakage:

Was the short cut bar between terminals +1 and + removed by mistake?

Was the running direction of the motor correct?

Was the inverter tripped during acceleration or deceleration?

Were the indications of the rpm and the frequency meter correct?

Were there any abnormal motor vibrations or noise?

Maintenance and inspection

WARNING Before carrying out maintenance and inspection wait for at least five minutes

after having turned off the input power supply. Otherwise, there is a danger of

electric shock.

WARNING When removing connectors (e.g. from fans and printed circuit boards) never

pull the attached wires. Otherwise, there is a danger of fire due to wire

breakage and/or injury.

Others

CAUTION Withstand voltage tests and insulation resistance tests (megger tests) are

executed before the units are shipped, so that there is no need to conduct

these tests before operation.

CAUTION Do not attach or remove wiring or connectors when power is applied. Also, do

not check signals (e.g. using a multimeter) during operation.

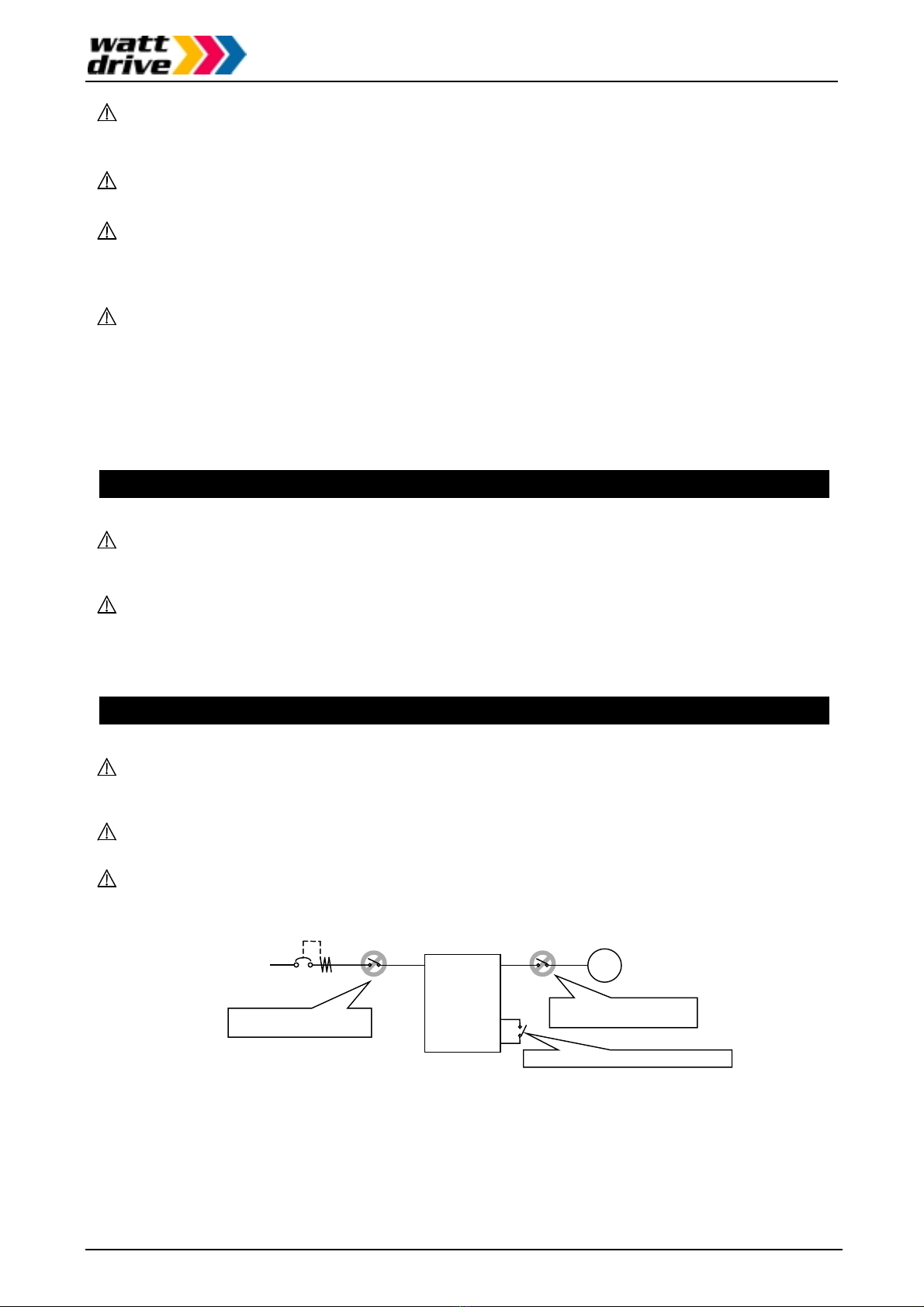

CAUTION Never stop motor operation by switching off the electromagnetic contactors on

the primary or secondary side of the inverter.

Moto

r

Inverte

r

Earth leakage

circuit breake

r

L1

(

L1

)

L2

L3

(

N

)

T1

(

U

)

T2

(

V

)

T3

(

W

)

Power

su

pp

l

y

S2

F

W

P2

4

CORRECT: Start and sto

p

usin

g

FW

S1

WRONG: Start and stop

usin

g

secondar

y

side

WRONG: Start and stop

usin

g

p

rimar

y

side contacto

r

When there has been an instantaneous power failure, and if an operation

instruction has been given, then the inverter may restart operation after the

power failure has ended. If there is a possibibility that such an occurrence may

harm humans, then install an electromagnetic contactor on the primary (power

supply) side of the inverter, so that the circuit does not allow automatic

restarting after the power supply has recoverd. If the optional remote operator

is used and the retry function has been selected, this will also cause automatic

restarting when an operation instruction has been input, so please be careful.

Safety precautions

Page 13 / 51

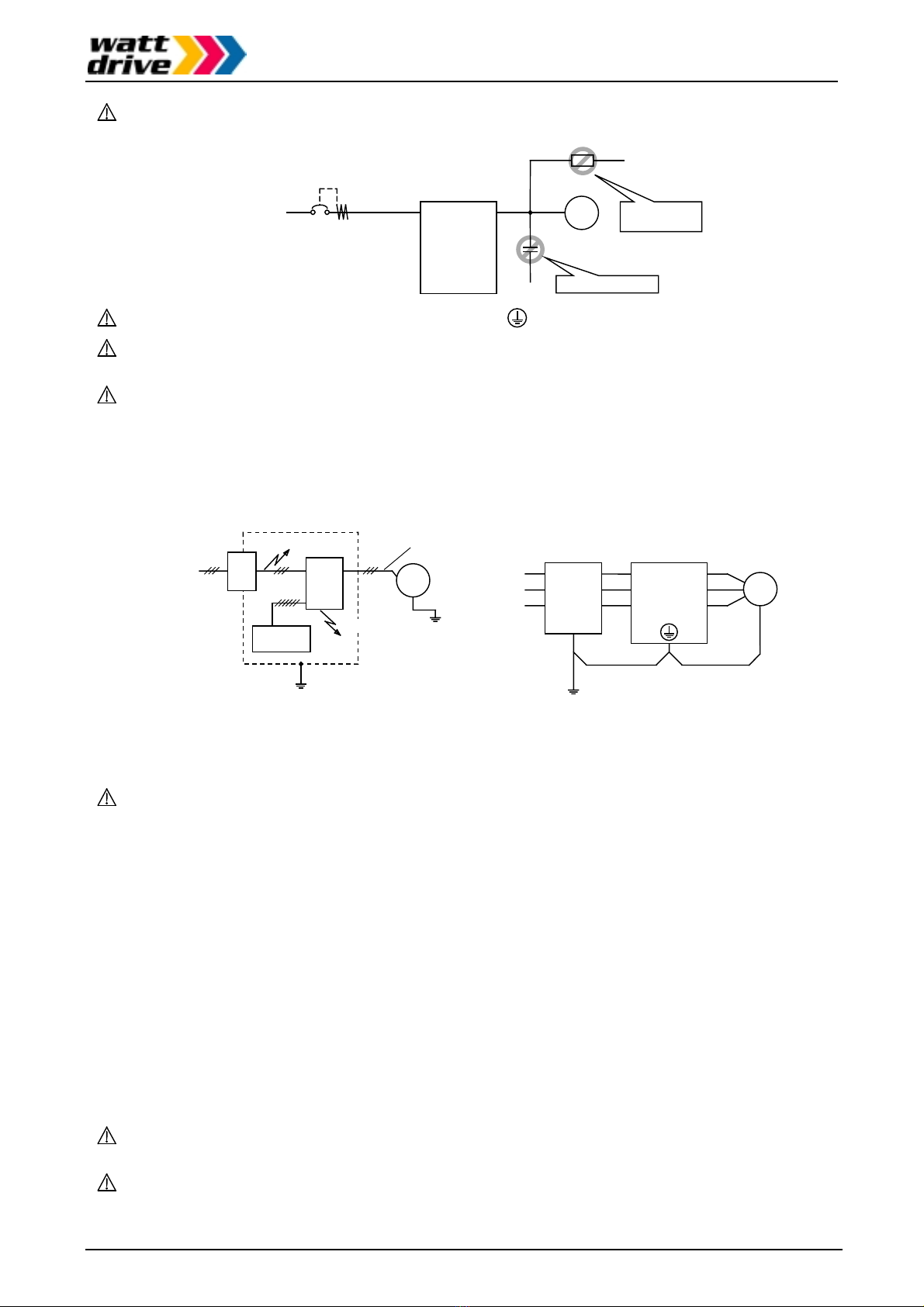

CAUTION Do not insert leading power factor capacitors or surge absorbers between the

output terminals of the inverter and the motor.

Moto

r

Inverte

r

Earth leakage

circuit breake

r

L1

(

L1

)

L2

L3

(

N

)

T1

(

U

)

T2

(

V

)

T3

(

W

)

Power

su

pp

l

y

WRONG: Ca

p

acito

r

WRONG:

Sur

g

e absorbe

r

CAUTION Be sure to ground the grounding terminal properly.

CAUTION Before inspecting the unit wait at least five minutes before opening the inverter

.

CAUTION PROTECTION AGAINST NOISE INTERFERENCE FROM THE INVERTER

V2000 series inverters use many semiconductor switching elements such as

transistors and IGBTs. For this reason, a radio set or measuring instrument

located near the inverter is susceptible to noise interference. To protect the

instruments from erreneous operation due to noise interference produced by

the inverter, they should be installed well apart from the inverter. It is also

effective to shield the whole inverter structure (refer to figure below, left part).

Motor

Inverte

r

L1(L1)

L2

L3(N)

T1(U)

T2(V)

T3(W)

R2

S2

T2

Powe

r

supply

R1

S1

T1

EMI filte

r

Grounding

Inverte

r

EMI

filter

Remote

operator

Motor

Powe

r

supply

Noise

Noise

Grounde

d

frame

Completely ground the frame

with as short a wire as possible.

Grounded piping

or shielded wire

Addition of an EMI filter on the input side of the inverter also reduces the effect

of noise from commercial power lines on external devices (refer to figure

above).

CAUTION EFFECTS OF DISTRIBUTER LINES ON INVERTERS

In the cases mentioned below involving a general purpose inverter, a large

peak current flows on the power supply side, sometimes destroying the

converter module:

A) The unbalance factor of the power supply is 3% or higher.

B) The power supply capacity is set at least ten times greater than the

inverter capacity (i.e. 500kVA or more)

C) When abrupt power supply changes are to be expected. Some examples:

1) Several inverters are interconnected using a short bus to the same

power supply.

2) A thyristor converter and an inverter are interconnected using a short

bus.

3) An installed power factor compensating device is connected or

disconnected.

In the cases mentioned above we recommend installing an AC reactor of 3%

voltage drop at rated current with respect to the supply voltage on the power

supply side.

CAUTION When an EEPROM error occurs (trip E 08) all parameter values have to be

checked for correctness (especially the RS input).

CAUTION When the intelligent digital inputs FW or RV are configured as normally closed

contact (standard setting is normally open), then the inverter starts

Safety precautions

Page 14 / 51

automatically. Do not configure these inputs as normally closed inputs unless

absolutely necessary.

GENERAL NOTICE

In all the illustrations and figures in this manual, covers and safety devices are

occasionally omitted in order to better describe the details. When the inverter

is operated make shure that all the covers and safety devices are placed in

their correct positions.

2. Inspection upon unpacking

Please check the shipment by the time of delivery for damages and completeness. Check that the

inverter and the accompanying instruction manual has been provided. Using the specification label

attached to the side of inverter make sure that the inverter model delivered is the one you ordered.

The specifications included on the specification label are described below:

In the illustration below, the contents of the model designation used for V2000 series inverters is

explained:

UHGV2000 -004 H F E 5

Inverter series

Version number ( _, 1, 2 ...)

Distribution fo

r

(E: Europa U: USA)

Type of inverte

r

(F: with digital operator)

Input voltage

(N: 200V single / three phase)

(H: 400V three phase)

(L: three phase 200V only)

Motor capacit

y

002: 0.20kW 022: 2.20kW

004: 0.40kW 030: 3.00kW

005: 0.55kW 037: 3.70kW

007: 0.75kW 040: 4.00kW

011: 1.10kW 055: 5.50kW

015: 1.50kW 075: 7.50kW

Applicable motor capacity

Model designation

Inverter input specifications

Inverter output specifications

Manufacturin

g

numbe

r

Input current single phase

Input current three phase

Rated current

Manufacturing date

WATT Drive Antriebstechnik GmbH

Model : V2000-004NFE

In

p

ut/Ein

g

an

g

: 50

,

60Hz 200-240 V 1Ph 5

,

8 A

50

,

60Hz 200-240 V 3Ph

Output/Ausgang: 1-360Hz 200-240 V 3Ph 2,6 A

MFG No. 78B T1128270005 Date:

Tel.: +43/2633/404-0; e-mail: watt@wattdrive.com NE16452-2

HP/kW : ½ / 0.4

External dimensions and terminal positions

Page 15 / 51

3. External dimensions and terminal positions

98 110 4

118

130

10

5

129

7

2,5

DCB

A

98

110 4

118

130

5

156 7

6

D

CB

A

5

Air

Air

Fan

140

180

153 7

3,5

D

CB

A

128

168

10

5

140

CB

A

5

Air

Air

128

5

168

180

164 7

D

6

Fa

n

Legend:

AControl terminals BAlarm terminals

CMain terminals DGroundin

g

terminals

(

All dimensions are in millimeters

)

V2000

V2000

V2000

V2000

V2000

Technical specifications

4. Technical specifications

002

NFE

004

NFE

005

NFE

007

NFE

011

NFE

015

NFE

022

NFE

Inverter V2000-

(200V series)

Protective structure (Note 1)IP20

Overvoltage category III

Maximum motor size (4P)

in kW (Note 2)0.2 0.4 0.55 0.75 1.1 1.5 2.2

230V 0.6 1.0 1.1 1.5 1.9 3.1 4.3

Maximum capacity

in kVA 240V 0.6 1.0 1.2 1.6 2.0 3.3 4.5

Input supply phase Single phase / Three phase Three phase

Rated input voltage 200VAC -10% ~ 240VAC +5% 50/60Hz +/-5%

Rated output voltage

(Note 3)

Three phase 200 ~ 240VAC

(Corresponds to input voltage)

Rated input current in A

Single phase (Three phase)

3.5

(2.0)

5.8

(3.4)

6.7

(3.9)

9.0

(5.2)

11.2

(6.5)

17.5

(10.0)

24.0

(14.0)

Rated output current in A

(Note 4a)1.4 2.6 3.0 4.0 5.0 8.0 11.0

Output frequency range 0,5 ~ 360 Hz (Note 5)

Frequency accuracy

(at 25°C +/-10°C)

Digital command: +/-0.01% of maximum frequency

Analog command: +/-0.1% of maximum frequency

Frequency setting resolution Digital setting: 0.1Hz Analog setting: maximum frequency /1000

Voltage/frequency characterist. Constant, reduced or high starting (SLV) torque

Overload current capacity 150% during 60 seconds (once per 10 minutes)

Acceleration/deceleration time 0.1 ~ 3000 s in selectable linear and non-linear mode

(second acceleration/deceleration usable)

Starting torque (using SLV) >200% >180%

Dynam. braking, feedback

to capacitor (Note 6)approx. 100% approx. 70% approx. 20% approx. 30%

using ext. braking resistor approx. 150% approx. 100% approx. 80%

DC injection braking Brakin

g

is on at the minimum fre

q

uenc

y

or less

(

minimum fre

q

uenc

y

,

braking time and braking force can be set)

Dig. operator Settings using keys or potentiometer

Frequenc

y

setting External

signals

0-10VDC (input impedance 10k Ohm), 4-20mA (input impedance

250 Ohm), Pot 1k-2k Ohm, 1W (055 ~ 075LFU/LFR: 2W)

Dig. operator Via keys RUN (for start) and STOP/RESET (for stop)

(Default setting: forward run)

Forward /

Reverse run

(Start/Stop) Ext. signals Intelligent input terminals configurable as FW and RV

Intelligent input terminals

programmable as

FW: Forward run start/stop RV: Reverse run start/stop

CF1–CF4: Multistage speed JG: Jogging command

AT: Analog current input selection 2CH: 2.Accel./decel. time

FRS: Free run stop EXT: External trip

USP: USP function RS: Reset

SFT: Software lock PTC: Thermal protection

DB: Ext. DB input SET: 2. setting active

UP: Acceleration (Remote) DWN: Decelerat. (Remote)

Intelligent output terminals

programmable as

FA1/FA2: Frequ. arrival signal RUN: Motor running signal

OL: Overload signal OD: PID deviation signal AL: Alarm signal

Frequency and current

monitoring

Connection of external analog meter (0-10VDC, max. 1mA) for

frequency or current; connection of external digital frequency meter

Fault alarm contact On when inverter trips (1c contact).

Alternatively usable as intelligent output terminal

Other functions

Autotuning, Automatic voltage regulation, retry; analog gain/vias

ad

j

ustment, fre

q

uenc

y

j

um

p

, u

pp

er/lower limiter, out

p

ut fre

q

ue

n

c

y

display, trip history monitoring, carrier frequency setting, PID

control, automatic torque boost, USP function, 2. Setting function,

ON/OFF control of cooling fan, and many more

Protection functions Overcurrent, overvoltage, undervoltage, electronic thermal, temp-

erature abnormality, ground fault, overload, CT error, BRD error

Ambient temp. (Note 7)-10 ~ 50°C

Storage temperature and

humidity

-25 ~ 70°C (during short term transportation period only)

20 ~ 90% RH (no dew condensation)

Vibration Max. 5,9m/s2(=0,6g) at 10-55Hz

Installation location 1000m or less altitude indoors (IP54 or equivalent)

External color Grey

Options Remote operator, copy unit, cable for digital operator,

reactor for improving power factor, noise filter,

Overall weight (approx.) 0.7 0.8 1.3 2.3 2.8 5.5 5.7

Braking

torque

Inputs

OutputsEnvironmental

Technical specifications

Page 17 / 51

Inverter V2000-

(400V series)

004

HFE

007

HFE

015

HFE

022

HFE

030

HFE

040

HFE

055

HFE

075

HFE

Protective structure (Note 1)IP20

Overvoltage category III

Maximum motor size (4P)

in kW (Note 2)0.4 0.75 1.5 2.2 3.0 4.0 5.5 7.5

Maximum capacity

in kVA 460V 1.1 1.9 2.9 4.2 6.2 6.6 9.9 12.2

Input supply phase Three Phase

Rated input voltage 380VAC -10% ~ 460VAC +10% 50/60Hz +/-5%

Rated output voltage

(Note 3)

Three Phase 360 ~ 460VAC

(Corresponds to input voltage)

Rated input current in A 2.0 3.3 5.0 7.0 10.0 11.0 16.5 20.0

Rated output current in A

(Note 4b)1.5 2.5 3.8 5.5 7.8 8.6 13.0 16.0

Output frequency range 0.5 ~ 360 Hz (Note 5)

Frequency accuracy

(at 25°C +/-10°C)

Digital command: +/-0.01% of maximum frequency

Analog command: +/-0.1% of maximum frequency

Frequency setting resolution Digital setting: 0.1 Hz

Analog setting: max. frequency / 1000

Voltage/frequency characterist. Constant, reduced or high starting (SLV) torque

Overload current capacity 150% during 60 seconds (once per 10 minutes)

Acceleration/deceleration time 0.1 ~ 3000 s in selectable linear and non-linear mode

(second acceleration/deceleration usable)

Starting torque (using SLV) > 200% > 180%

Dynam. braking, feedback

to capacitor (Note 6)approx. 100% approx.

70% approx. 20% approx. 30%

External braking resistor approx. 150% approx. 100% approx. 80%

DC injection braking Braking is on at the minimum frequency or less (minimum frequency,

braking time and braking force can be set)

Dig. operator Settings using keys or potentiometer

Frequenc

y

setting External

signals

0-10VDC (input impedance 10k Ohm)

4-20mA (input impedance 250 Ohm)

Potentiometer 1k-2k Ohm, 1W (055 ~ 075LFU/LFR: 2W)

Dig. operator Via keys RUN (for start) and STOP/RESET (for stop)

(Default setting: forward run)

Forward /

Reverse run

(Start/Stop) Ext. signals Intelligent input terminals configurable as FW and RV

Intelligent input terminals

programmable as

FW: Forward run start/stop RV: Reverse run start/stop

CF1–CF4: Multistage speed JG: Jogging command

AT: Analog current input selection 2CH: 2.Accel./decel. time

FRS: Free run stop EXT: External trip

USP: USP function RS: Reset

SFT: Software lock PTC: Thermal protection

DB: Ext. DB input SET: 2. setting active

UP: Acceleration (Remote) DWN: Decelerat. (Remote)

Intelligent output terminals

programmable as

FA1/FA2: Frequency arrival signal

RUN: Motor running signal OL: Overload signa

l

OD: Deviation signal at PID control AL: Alarm signal

Frequency and current

monitoring

Connection of external analog meter (0-10VDC, max. 1mA) for

frequency or current; connection of external digital frequency meter

Fault alarm contact On when the inverter trips (1c contact).

Alternatively usable as intelligent output terminal

Other functions

Autotuning, Automatic voltage regulation, retry; analog gain/vias

adjustment, frequency jump, upper/lower limiter, output freque

n

c

y

display, trip history monitoring, carrier frequency setting, PID

control, automatic torque boost, USP function, 2. Setting function,

ON/OFF control of cooling fan, and many more

Protection functions Overcurrent, overvoltage, undervoltage, electronic thermal, temp-

erature abnormality, ground fault, overload, CT error, BRD error

Ambient temperature -10 ~ 50°C (Note 7)

Storage temperature and

humidity

-25 ~ 70°C (during short term transportation period only)

20 ~ 90% RH (no dew condensation)

Vibration Max. 5.9m/s2(=0.6g) at 10-55Hz

Installation location 1000m or less altitude indoors (IP54 or equivalent)

External color Grey

Options Remote operator, copy unit, cable for digital operator,

reactor for improving power factor, noise filter

Overall weight (approx.) 1.3 1.7 2.8 5.5 5.7

Braking

torque

InputsOutputsEnvironmental

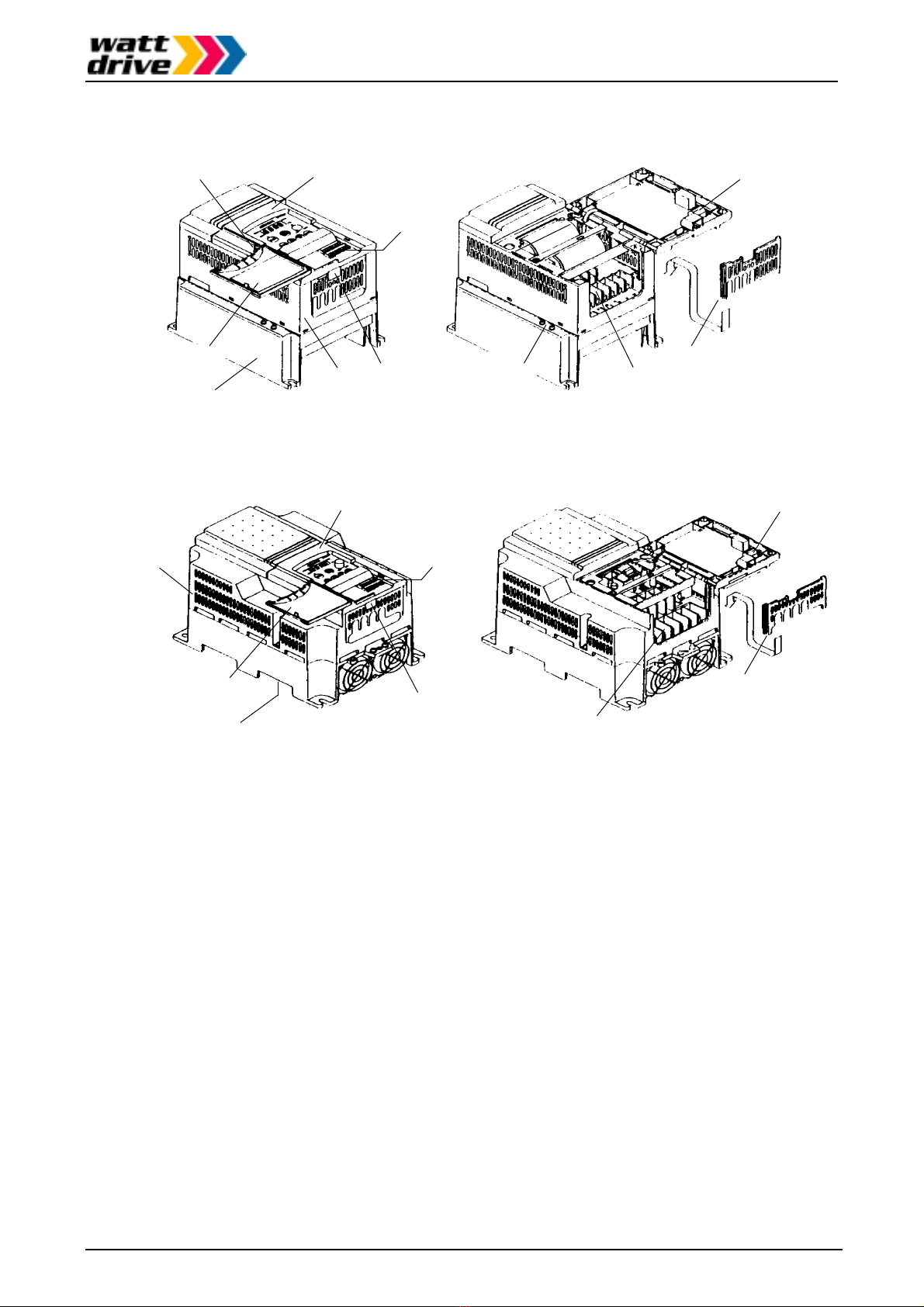

Appearance and name of parts

5. Appearance and names of parts

Key cove

r

(Note 1)

Casin

g

Coolin

g

fi

n

Digital operator

(can be opened)

(Note 2)

Coolin

g

fi

n

Serial

interface

Casin

g

Screw

(Note 2)

Key cover

(Note 1)

Digital operator

(can be opened)

(Note 2)

Serial

interface

Screw (Note 2)

Control terminals

Grounding

terminal (PE)

Grounding

terminal (PE)

Control terminals

Alarm terminals

Rear cove

r

Mains circuit

terminals Rear cover

Mains circui

t

terminals

Alarm terminals

Note 1: The key cover can be opened by hand without any additional tool.

Note 2: The screw must be loosened before the digital operator can be opened.

Appearance and name of parts

Page 19 / 51

KEY COVER

(

OPENED

)

CASING

COOLING FIN

SERIAL

INTERFACE

DIGITAL OPERATOR

(CAN BE OPENED)

(Note 2)

SCREW

(

Note 2

)

GROUNDING

TERMINAL

(

PE

)

REAR COVER

CONTROL

TERMINALS

MAINS CIRCUIT

TERMINALS

ALARM

TERMINAL

KEY COVER

(OPENED)

CASING

COOLING FIN

SERIAL

INTERFACE

DIGITAL OPERATOR

(CAN BE OPENED)

(Anm.2)

KEY COVER

CONTROL

TERMINAL

MAINS CIRCUIT

TERMINALS

ALARM

TERMINALS

Note 1: The key cover can be opened by hand without any additional tool.

Note 2: The screw must be loosened before the digital operator can be opened.

Installation

Page 20 / 51

6. Installation

The inverter must be mounted vertically on a non-flammable wall in order to prevent from

overheating and fire. The minimum clearances to the surrounding walls shown in the figure below

must be complied with to ensure a good ventilation. Foreign matter (especially conductive objects)

must nut be dropped into the inverter since they not only cause malfunction and damage but may

also lead to electrical and fire hazards.

Cover all ventilation holes on the inverter during installation so that no foreign objects can enter the

inverter. Be sure to remove those covers from the inverter before you put the inverter to work.

a

pp

rox. 10c

m

approx. 8cm

approx.

12cm

Inverter

Air flo

w

The inverter must be installed vertically

(do not install it on the floor or horizontally)

Wall or mounting surface

The mounting base must be a non-

flammable material (e.g. metal)

a

pp

rox. 10c

m

The minimum clearances to the surrounding walls shown in the figure are only meant for reference.

A more compact installation (back to back) may well be possible and should be discussed with

WATT DRIVE. Please always leave enough room for the key cover to be opened without problems

in order to connect wires to the control terminals.

The ambient temperature should be in the range of -10°C to 50°C. At a temperature of 40~50°C

the carrier frequency has to be reduced to 2kHz, the output current must be kept below 80% of the

rated current, and the top cover (see figure below) has to be removed. Higher ambient temperature

causes shorter inverter life. So if there is hot equipment in the vicinity of the inverter, keep it away

from the inverter as far as possible.

If the inverter is to be installed in a cabinet, ambient temperature is considered to be the

temperature prevailing withing this cabinet. Fans have to be provided if necessary so that ambient

temperature remains within the limits specified above.

For safety reasons the digital operator must be closed and not be opened during inverter operation.

The end application must be in accordance with the BS EN 60204-1 standard.

To

p

cove

r

Ventilation holes

(

on either side

)

Table of contents

Other Watt Drive Inverter manuals

Popular Inverter manuals by other brands

Siemens

Siemens SINAMICS G120P Technical manual

Hoymiles

Hoymiles MI-300T user manual

Trannergy

Trannergy TRM025KTL user manual

Yingli Solar

Yingli Solar PANDA 108CELL 182TOPCon Installation and user manual

Santerno

Santerno SUNWAY TG610 1000V TE OD installation guide

Mitsubishi Electric

Mitsubishi Electric FR-F700 Series Instruction manual supplement