Watts Industries FEBCO 805Y Series User manual

Other Watts Industries Control Unit manuals

Watts Industries

Watts Industries AMES Silver Bullet 4000SS Series User manual

Watts Industries

Watts Industries Powers HydroGuard e420 Series Owner's manual

Watts Industries

Watts Industries Powers HydroGuard LFLM495 User manual

Watts Industries

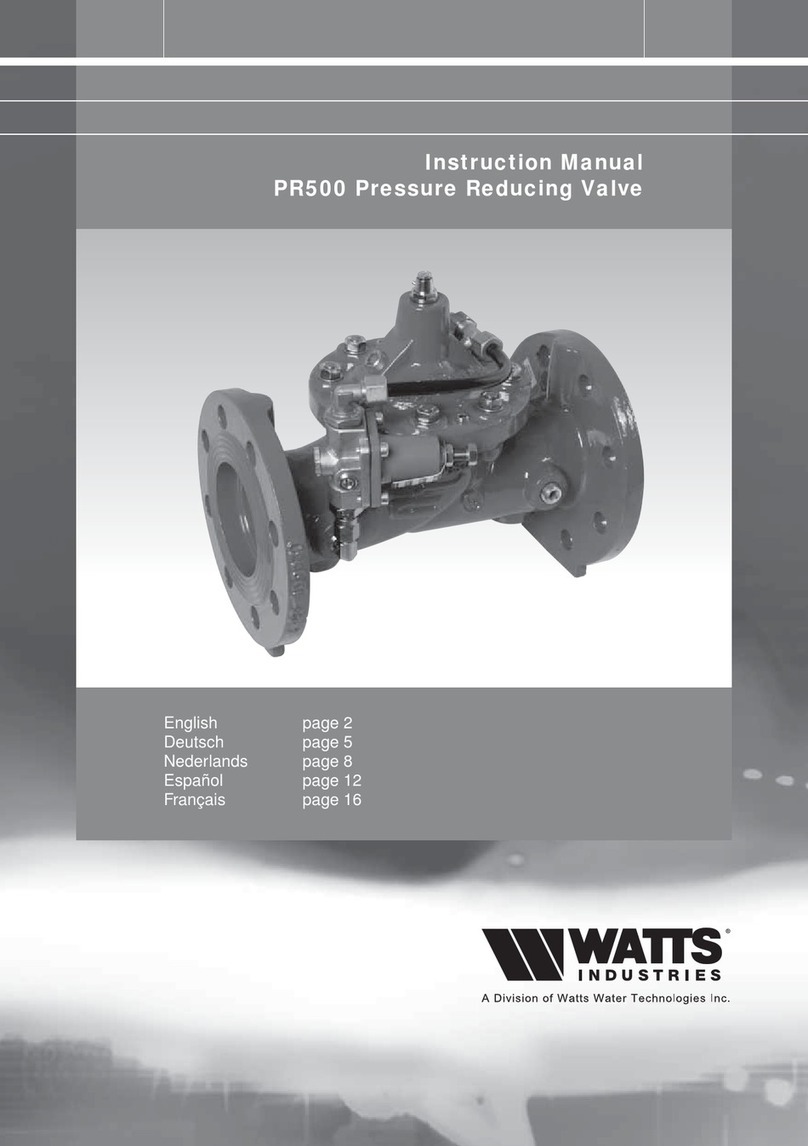

Watts Industries PR500 User manual

Watts Industries

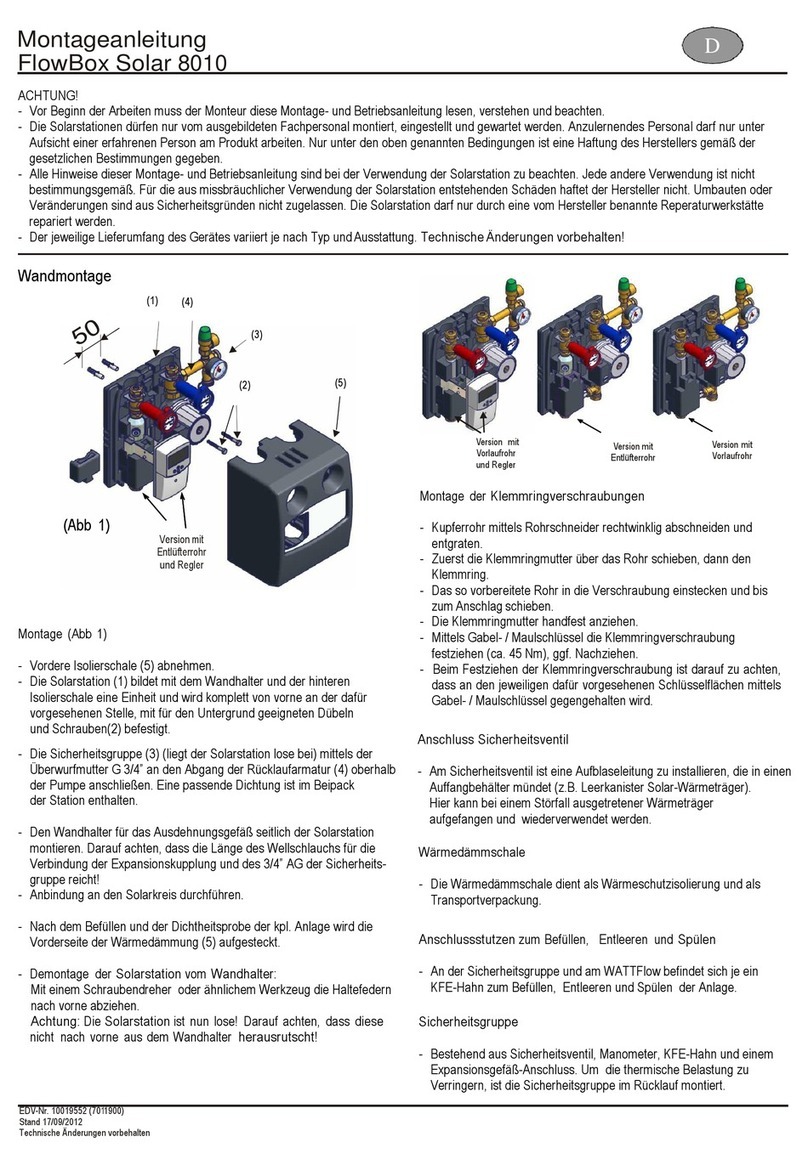

Watts Industries FlowBox Solar 8010 User manual

Watts Industries

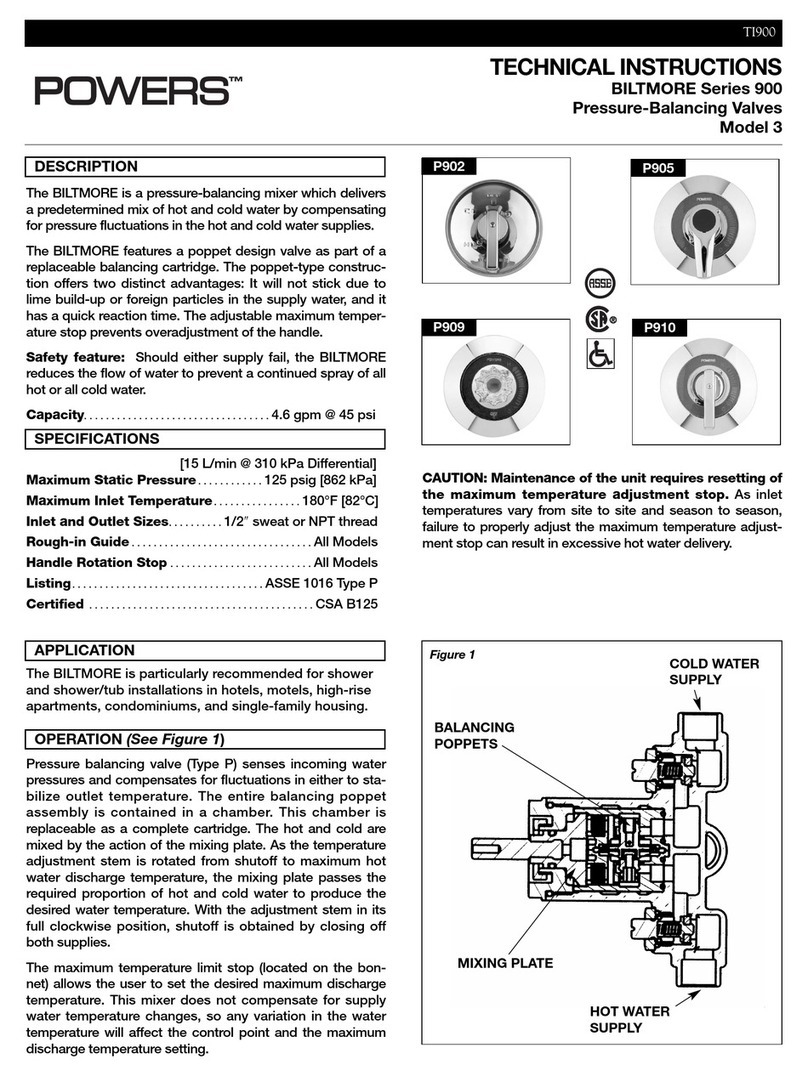

Watts Industries POWERS BILTMORE 900 Series Owner's manual

Watts Industries

Watts Industries AMES 4000CIV Series User manual

Watts Industries

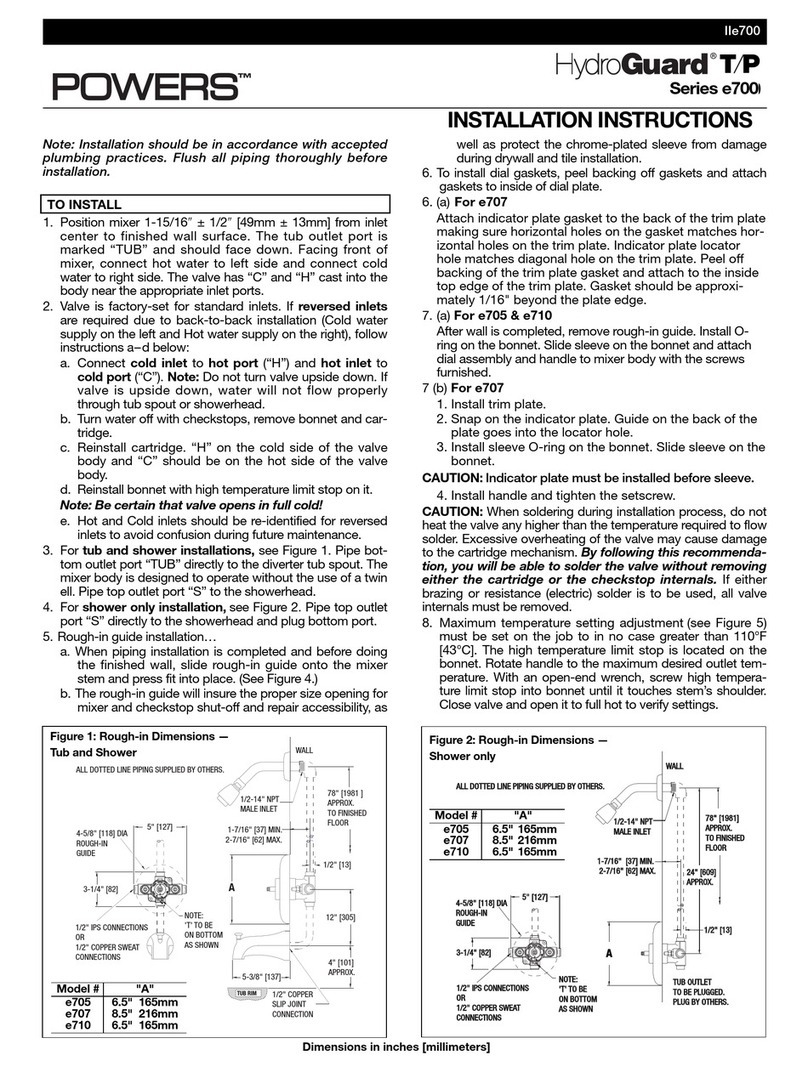

Watts Industries POWERS HydroGuard T/P e700 Series User manual

Watts Industries

Watts Industries Ultramis TX91 User manual

Popular Control Unit manuals by other brands

WAGO

WAGO 750-1415/040-000 manual

Endress

Endress E-RMA LAN Translation of the original operating manual

Pickering

Pickering 40-519A user manual

Spectrum Digital

Spectrum Digital Davinci-DM6446 Technical reference

Ricoh

Ricoh Aficio 700 operating instructions

THOMSON

THOMSON Grass Valley KAM-XM Series instruction manual

LOVATO ELECTRIC

LOVATO ELECTRIC EXP10 02 instruction manual

Emerson

Emerson Bettis 2000 Series user manual

Lenze

Lenze EPM-H505 operating instructions

Pickering

Pickering PXI 40-787 user manual

BIRD

BIRD Termaline 8890SC Series Operation manual

Flow Safe

Flow Safe F88 Series Installation, operation & maintenance manual