Watts Industries Powers HydroGuard e420 Series Owner's manual

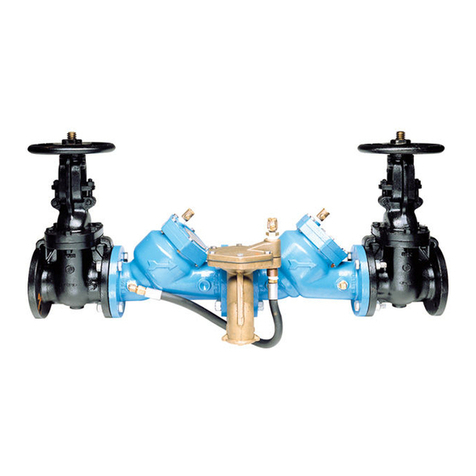

The Series e420 HydroGuard T/P automatically mixes

hot and cold water to deliver blended water within a

specified range. Using an advanced thermal actuator,

the Series e420 quickly compensates for temperature

fluctuations induced by water temperature and pressure

changes. In the event of cold water failure, the thermo-

static motor virtually shuts of the flow of hot water.

Featuring heavy, cast-brass construction, all parts of

the e420 Series valve are accessible from the front of

the valve and are corrosion resistant. The unit also fea-

tures a concealed handle rotation stop to guard against

overadjustment of the handle, and all Series e420

valves open in the cold water position to ensure maxi-

mum bather safety and comfort.

The accuracy, reliability and water economy of the

Series e420 HydroGuard make it preferable for applica-

tions that require precise, consistent water control:

showers, baths, hospital hydrotherapy and residential

areas.

TECHNICAL INSTRUCTIONS

HydroGuard T/P®Series e420

Thermostatic Valve

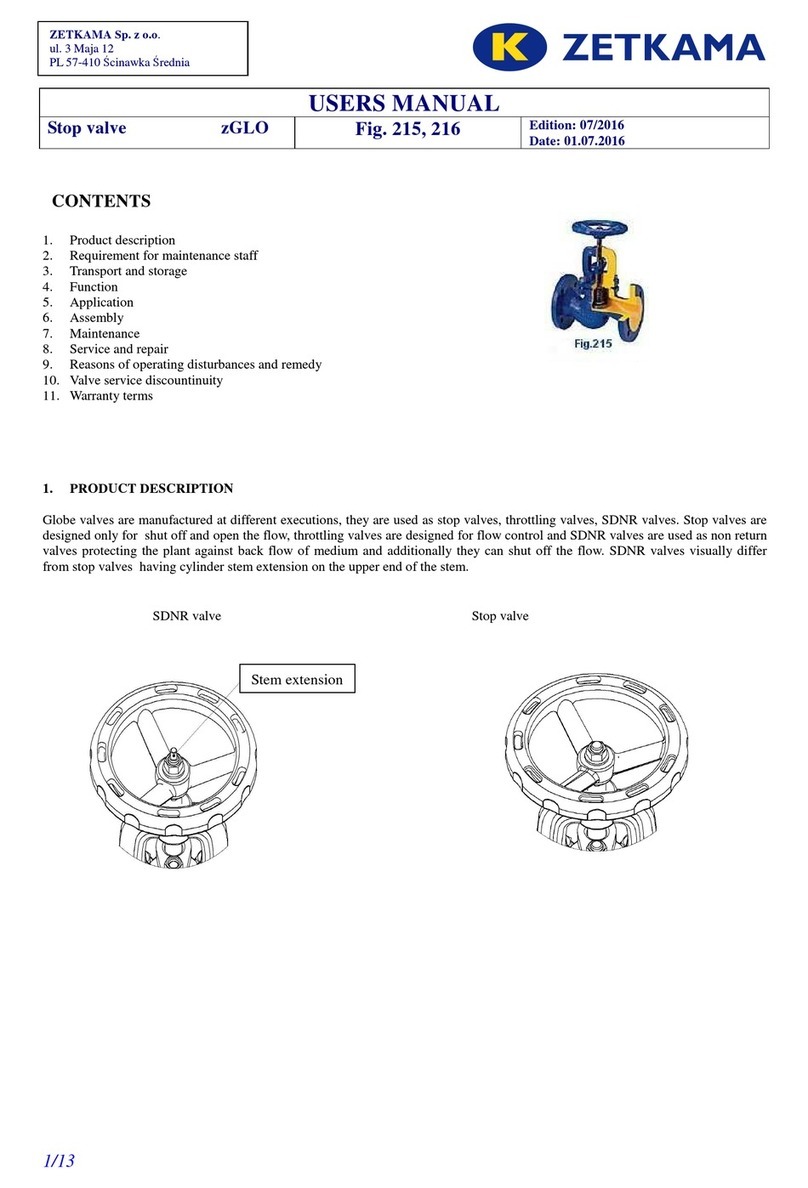

Model 1

Valve Construction: Thermostatic mixing valve, with heavy cast bronze body and brass stem. Concealed handle rotation

stop. Available with acrylic handle, chrome-plated metal tri-handle, or ADA-compliant lever handle.

Capacity............................................................................................................................ 5.0 gpm ± .25 @ 45 psi

∆P 50/50 mix

Maximum Hot Water Supply Temperature........................................................................................................ 190°F (88°C)

Minimum Hot Water Supply Temperature.................................................................................. 5°F (2.8°C) above set point

Maximum Operating Pressure....................................................................................................................... 125 psig (862 kPa)

Temperature Ranges

ASSE 1016 Type T/P.............................................................................................................................. 90 - 110°F (32 - 43°C)

ASSE 1016 Type T.................................................................................................................................. 65 - 115°F (18 - 46°C)

Temperature Limit Stop................................................................................................. Adjustable (factory set at 110°F [43°C])

Maximum Static Pressure.............................................................................................................................. 125 psig (862 kPa)

Minimum Flow and Pressure Differential: Minimum Flow

Standard Capacity................................................................................................................................... 1 gpm (3.781 L/min)

Wall Seal Gasket.............................................................................................................................................. Furnished with Dial

Dial Plate..................................................................................................................................... Color-Coded Temperature Scale

Shipping Weight....................................................................................................................................................... 5 lbs. (2.3 kg)

All HydroGuard Series e420 thermostatic mixing valves meet above performance specifications based on typical operating

conditions as stated in ASSE 1016 [45 psi pressure differential, hot water supply between 140°-180°F (60°-82°C), cold water

supply less than 70°F (21°C)].

If your operating conditions vary from those stated in the standard, performance may vary as well. Consult your local

sales representative or a Powers factory engineer to discuss your specific application. All Powers thermostatic mixing

valves perform to the requirements of standards ASSE 1016 and CSA B125.

Many HydroGuard Series e420 valves and shower sys-

tems can be selected to meet the Americans with

Disabilities Act (ADA) (see page 4 for details).

Connections: Type 421, 423, 425 (3-port): 1/2” NPT Inlets Type 422, 426 (4-port): 1/2” NPT Inlets

1/2” NPT Top Outlet 1/2” NPT Top Outlet

3/4”NPT Bottom Outlet

Form TI 420 v5

SPECIFICATIONS

DESCRIPTION

TI 420 v5 0515 Page 2

To be sure you order and install the appropriate parts into

your valve, first determine the correct model number and

temperature range of your valve.

The temperature range of the valve is stamped on a

nameplate (A). In the example, "115" is shown.

The model number is the first digit of the four-digit date

code stamped on the nameplate (B).

In the example, the date code starts with an 9, so the

model number is 9.

Nameplate Stamp

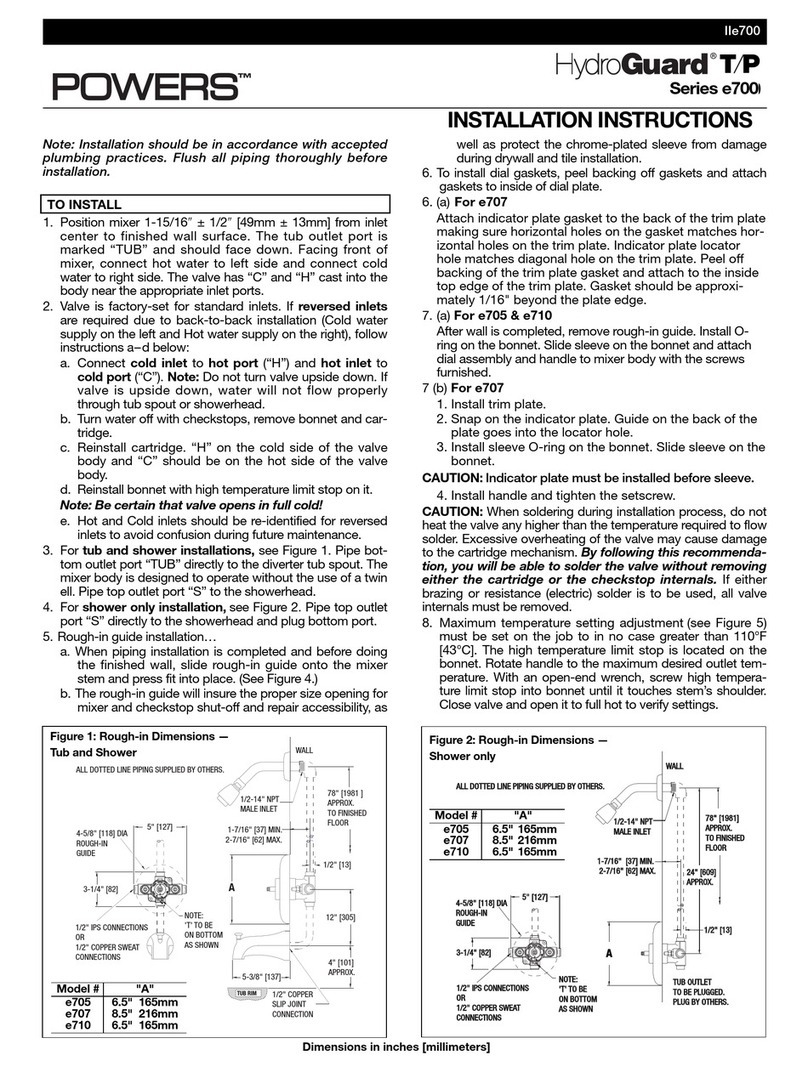

Before installation of any HydroGuard e420 valve:

●Flush all piping thoroughly.

●Rotate the stem (or handle if attached) of

the valve to its full clockwise position (OFF).

Positioning the Valve:

Note the following differences:

3-Port Valves (421, 423, 425): All ports are 1/2" NPT.

INLETS: Piped to hot and cold water supply.

OUTLET: Piped to the showerhead

(see illustration on page 4).

4-Port Valves (422 & 426):

BOTH INLETS AND TOP OUTLET: 1/2" NPT.

BOTTOM OUTLET: 3/4" NPT, and is piped directly to a

diverter-type tub spout (see illustration on page 4).

1. Mount the rough-in guide, Powers Part #420-202, to

the mixing valve.

A

B

Hot and cold water enter respective ports in the valve

and mix in a chamber containing an advanced thermal

actuator (refer to cutaway view). This actuator controls

the valve assembly.

Rotating the adjustment handle repositions the shuttle in

the cartridge assembly to produce the desired tempera-

ture. The mixed water passes over the shut-off disc to

the outlet. If the hot or cold supply water temperature or

pressure changes, the thermal actuator will contract or

expand. This movement repositions the shuttle to main-

tain the desired temperature. With the adjustment handle

in full clockwise (OFF) position, the shut-off disc closes

the mixing chamber from the outlet.

A handle rotation stop limits the movement of the control

handle. The standard HydroGuard e420 valve is factory

set to deliver tempered water up to 110°F [43°C] with

equal supply pressures, with hot water temperature

14O°F [60°C], cold water temperature 6O°F [15.6°C].

Note: The handle rotation stop must be adjusted by

the installer.

Hot Water Supply

Cold Water Supply

Cartridge

Advanced

Thermal

Actuator

Handle Stop

Shutoff Disc

Shuttle

Adjustment

Stem

OPERATION

MODEL IDENTIFICATION

INSTALLATION

TI 420 v5 0515 Page 3

2. Use rough-in guide to position valve 2-3/4"± l/4"

[7.0 cm ± 0.6 cm] from center line of inlets to face of

finished wall (see Dimensional Data section).

3. Facing front of mixer, connect hot water to left side

(marked HOT) and cold water to right side (marked

COLD). Inlet and outlet connections must be piped cor-

rectly for proper operation of valve. Be certain connec-

tions are made exactly as described above. If hot and

cold inlets are reversed, valve will not function properly.

Solder Piping

Excessive heat from soldering can damage the internal

parts of the valve. If you use copper tubing, flare fittings

must be installed within 12" (30.5 cm) of the valve or

triple duty checkstops) to protect the valve. If flared fit-

tings cannot be installed, remove the internal parts of the

valve and checkstops before soldering.

Finish Rough-In

4. After finished wall is complete, remove rough-in guide

to allow installation of the dial handle.

5. Peel off backing of dial gasket and attach it to inside

top edge of dial plate. Allow approximately 1/8" [0.3

cm] of gasket to protrude past dial edge.

6. Install dial and handle and secure with screws provided.

Test the System

Before final assembly, test the system and check the

maximum temperature setting.

7. Verify that the valve is in the OFF position (fully clock-

wise position).

8. Turn on water supply, and then rotate the valve handle

counterclockwise. Water should come through the

spout/showerhead.

Maximum Temperature Setting/Handle Rotation Stop

The handle rotation setting must be adjusted to limit the

distance the user can rotate the handle towards the full

hot water position.

CAUTION: Any repair or modification of the valve may

affect the high temperature setting. The maximum

temperature setting must be checked by the installer

before use.

9. Remove the valve handle and both splined stops.

10. Adjust the valve to the desired maximum outlet temper-

ature. Install the splined limit stop with its tab against

the bottom of the bonnet stop.

11. Turn the stem clockwise until the water stops. Install

the second splined limit stop with the tab against the

top of the bonnet stop.

12. Replace handle. Repeat steps 8 through 14 until

desired maximum outlet temperature is reached.

Remove handle before final assembly.

CAUTION: Resetting of the splined stop can result in

temperatures higher than 110°F [43°C].

Bonnet Stop

Splined

Limit Stop

Stem

After Rough-In and Testing of System:

Maximum Temperature Setting (Handle Rotation Stop)

CALIFORNIA PROPOSITION 65 WARNING

WARNING: This product contains chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

(California law requires this warning to be given

to customers in the State of California.)

For more information: www.wattsind.com/prop65

INSTALLATION (continued)

Final Assembly

13. Place the graphic insert [9] into the dial plate [11], snap

the retaining ring [8] into place in the valve hole.

14. For tri-handle: slide the brass collar over the stem.

Place the tri-handle on stem [22], and secure with

retaining washer [3b] and screw [3c] using the 3/32"

wrench (included). Snap the plug button into place.

15. For lever handle: fit handle (with sleeve) [1] onto stem

and secure in place with screw [2] (provided).

16. For acrylic knob: install insert [7] into knob [6a]. Install

knob onto valve and secure with screw and washers

provided [4 & 51]. Install plug button [3].

EVERY 12 MONTHS:

●Open up the checkstops and check for free movement

of the poppet. To access the checkstops, remove the

valve handle assembly and dial plate.

●Before servicing the valve, turn off the water supply

upstream OR close the optional check-stops. To close

the checkstops, turn the adjustment screw fully clock-

wise on each checkstop.

●Remove the valve bonnet and rinse all grit and impuri-

ties from the internal components.

●Winterize valves that are used outdoors. Remove and

store the internal components and drain all water from

the valve.

EVERY 3 MONTHS:

●Every three months, check the maximum temperature

setting (handle rotation setting). Refer to steps 8-14 of

the Installation section.

NOTE: Before servicing checkstops or piping, always turn

off the upstream water supply.

Note: When used together, Powers lever handle and handshower meet

ADA compliance standards. For complete ADA-required heights and

other information on installing an ADA-compliant bathing system, refer

to the ADAAG (Americans with Disabilities Act Accessibility

Guidelines).

TI 420 v5 0515 Page 4

INSTALLATION (continued)

PREVENTIVE MAINTENANCE

TI 420 v5 0515 Page 5

1. Thermostatic water mixing valves are control devices

which must be cleaned and maintained on a regular

basis. Powers specifies periodic maintenance at least

once a year or immediately after any changes are made

to the plumbing system. Annual cleaning is recom-

mended, however, frequency of cleaning depends on

quality of local water conditions. Refer to the Preventive

Maintenance section for recommended cleaning proce-

dure.

2. Warning: To prevent injury to the user, it is important

to periodically check the maximum temperature

adjustment on the valve for (1) any sign of motor wear

or (2) motor failure (refer to the Thermostatic Motor

Testing section). The above conditions in the thermo-

static motor can cause the valve to pass full hot water.

3. Note: The handle rotation setting must be adjusted to

limit the distance the user can rotate the handle

towards the full hot water position.

4. Quick closing valves may cause damage to the mixing

valve by creating shock waves. When the HydroGuard

supplies tempered water to self-closing and/or solenoid

valves, Powers recommends installing a shock

absorber (Powers Part #460-353) on the discharge line,

which will protect the HydroGuard thermostatic motor

from damage.

5. Position the 420 valve as close as possible to outlet fix-

ture to avoid waste of energy and water (except in

applications where the valve is used as a primary mix-

ing valve).

Adherence to these guidelines and recommenda-

tions promotes safe product use and ensures proper

valve performance.

To Disassemble:

1. Turn off hot & cold water supply-stops (required for this retrofit)

2. Remove the handle and trim plate

3. Remove 4 bonnet screws and bonnet assembly

4. Remove all internal components from valve body

5. At this point you should have an empty valve body.

IMPORTANT: After completing any maintenance/repairs,

reset the maximum discharge temperature by resetting the

handle rotation stop as necessary (refer to Maximum

Temperature Setting section).

To Reassemble:

1. Ensure the inside of the valve body is free of deposits

and debris. Clean as necessary.

2. Push the cartridge into the body without the “O”rings

installed. The cartridge should slide in easily, and

bottom out with its large fins just inside the front

surface of the casting. If the cartridge is difficult to

install, or does not go in all the way, remove the

cartridge and clean the the body or remove any

obstructions. Repeat this step until the cartridge

installs easily.

3. Remove the cartridge and install the 2 “O”rings. One is

slightly larger than the other. The larger one goes closest

to the front (fins). Lubricate the “O”rings with silicon

lubricant.

4. Install the cartridge back into the body. The cartridge

should go in until the large fins are just inside the

front surface of the casting (same position as in step 2).

If you cannot push it in all the way due to O-rings, use

bonnet and two (2) screws to force in.

5. Place the wax element into the stem assembly, stem

side first, and place this bonnet-stem-motor assembly

into/onto the valve body. Rotate the bonnet assembly to

line up the bonnet screw holes and reinstall and tighten

the four bonnet screws.

6. With handle, rotate the stem assembly clock-wise, until it

bottoms out on the cartridge. At this point your valve is

in the off position.

7. Turn the hot and cold water supplies back on and verify

there is no leakage.

8. Your valve should now be set properly. Verify proper

operation by rotating the stem from the off position,

counter-clockwise, to the high temperature position.

Verify the temperature does not exceed your desired

maximum temperature. Rotate stem back to the off

position.

9. Replace trim plate and handle.

SAFETY GUIDELINES - ALL MODELS

SERVICING

TI 420 v5 0515 Page 6

●This parts list is for the E420 Model 1 only.

To be certain you are installing the correct parts, refer to Model Identification on page 2.

●Select Individual Parts from “Part#”column. Select Kits from “Kit#”column.

Item Part Description Part # Qty. Kit # Qty. Individual Parts Material

1-2 Lever Handle Assembly 420-336 1

(Models 8 &9)

1a Lever Handle -- -- 420-336 1 C.P. Zinc

1b Sleeve -- -- 420-336 1 C.P. Brass

2 Lever Handle Screw 410-365 10 1 C.P. Brass

3a-3d Tri-Handle Assembly (All Models 1-9) 410-565 1

3a Tri-Handle 410-191 1 410-565 1 C.P. Brass

3b Washer 046-008K 1 410-565 1 C.R. Steel

3c Screw 030-070 1 410-565 1 Stainless Steel

3d Plug Button (NS) 410-195 1 410-565 1

3-7 Acrylic Handle Assembly 420-337 1

3 Plug Button and Insert 420-314 1 420-337 1 C.P. Brass

4 Handle Screw 8-32 x 3/4” 034-515K 1 420-337 1 C.P. Brass

5 Washer 227-197 1 420-337 1 Neoprene

6a Acrylic Handle Knob -- -- 420-337 1 Acrylic

6b Sleeve 227-196 1 420-337 1 Brass

7 Knob Insert 420-213 2 420-337 1

8-12 Dial Assembly (Models 8 & 9) 420-335 1

8 Retaining Ring 227-166 1 420-335 1 C.P. Brass

9 Dial Graphic Insert (F°) 420-308 1 420-335 1 Aluminum

10 Dial Plate Screws:

(Concealed) 8-32 x 1-1/2” (2) 080-013 2 420-335 1 Brass

11 Dial Plate (Oval)420-166 1 420-335 1 Stainless Steel

12 Dial Gasket 410-284 1 420-335 1 Buna-N

13 Temp. Stop 420-212 2 420-451 -- Stainless Steel

14 O Ring 084-014 1 420-451 -- Buna-N

15 O Ring 047-010 1 420-451 -- Buna-N

16 Packing Gland 420-578 1 420-451 -- Brass

17 Huva Cup 225-404 1 420-451 -- Buna-N

18 Packing Stop Ring 420-508 1 420-451 -- Brass

19 Bonnet Screws 030-887 4 420-451 -- Stainless Steel

20 Bonnet 420-210 1 420-451 -- Brass

21 O-Ring 047-128 1 420-451 -- Buna-N

22 Adjustment Stem 420-139 1 420-451 -- Brass

23 Thermal Actuator -- 1 420-451/453-- Brass/Stainless Steel/EPPM

24 Cartridge Assembly -- 1 420-451/452-- Noryl/Stainless Steel

25 O Ring 047-029 1 420-451 -- Buna-N

26 O Ring 047-129 1 420-451 -- Buna-N

27 Valve Body N/A 1 N/A -- Brass

(Part of 22) Shutoff Disc 420-130 1 420-451 -- EPPM

Bonnet Stem Assembly -- -- 420-454

Soft Part Kit -- -- 420-102

-- Item not available as individual commercial part OR item not available as a commercial kit.

What to look for if:

The maximum temperature cannot be obtained...

a. Lime deposits may have accumulated in the hot water

pipes, restricting the hot water supply.

b. The hot water supply temperature may be too low.

c. The handle rotation setting may be too low. Remove valve

handle, and readjust the handle rotation stop (see Setting

the Handle Rotation Stop).

Flow of water is less than desired…

a. The upstream supply valves may not be fully open.

b. The inlet supply pressure(s) may be low.

c. Lime deposits may have accumulated in cartridge,

restricting water flow.

d. The showerhead may be clogged. Remove and clean.

e. The checkstops may be clogged. Refer to Preventive

Maintenance section and Form #129-028.

The valve opens with hot water flow rather than cold

water flow...

a. The inlet water supplies are connected to the wrong

ports. Remove the valve and reinstall.

The tempered water is too cold, although motor has

been replaced, 0R the hot water temperature is below

115°F...

a. Raise the temperature of the hot water supply.

Flow of water is completely shut off...

a. The upstream supply valves may be completely closed.

b. The hot or cold water supply pressure may have failed.

The HydroGuard 420 valve is designed to close down

upon cold water failure.

c. The checkstops may be closed. Access the checkstops

and open by turning the adjustment screw fully counter-

clockwise.

TROUBLESHOOTING

PARTS LIST - E420 Model 1

TI 420 v5 0515 Page 7

15

13

16

14

17

18 19

20

21

22

23 25

26

24

27

This illustration is for e420 Model 1.

To be certain you install the correct parts, refer to the Model Identification section on page 2.

INCLUDED IN BONNET ASSEMBLY

EXPLODED VIEW - e420 Model 1

TI 420 v5 0515 Page 8

© 2005 Powers, a division of Watts Water Technologies, Inc.

USA Phone: 1.800.669.5430 • Fax 1.847.824.0627

Canada Phone: 1.888.208.8927 • Fax 1.888.882.1979

www.powerscontrols.com

Form TI 420 v5 0515 EDP# 6512225 Printed in U.S. .

CHECKSTOPS

DIMENSIONAL DATA

This manual suits for next models

5

Table of contents

Other Watts Industries Control Unit manuals

Watts Industries

Watts Industries AMES Silver Bullet 4000SS Series User manual

Watts Industries

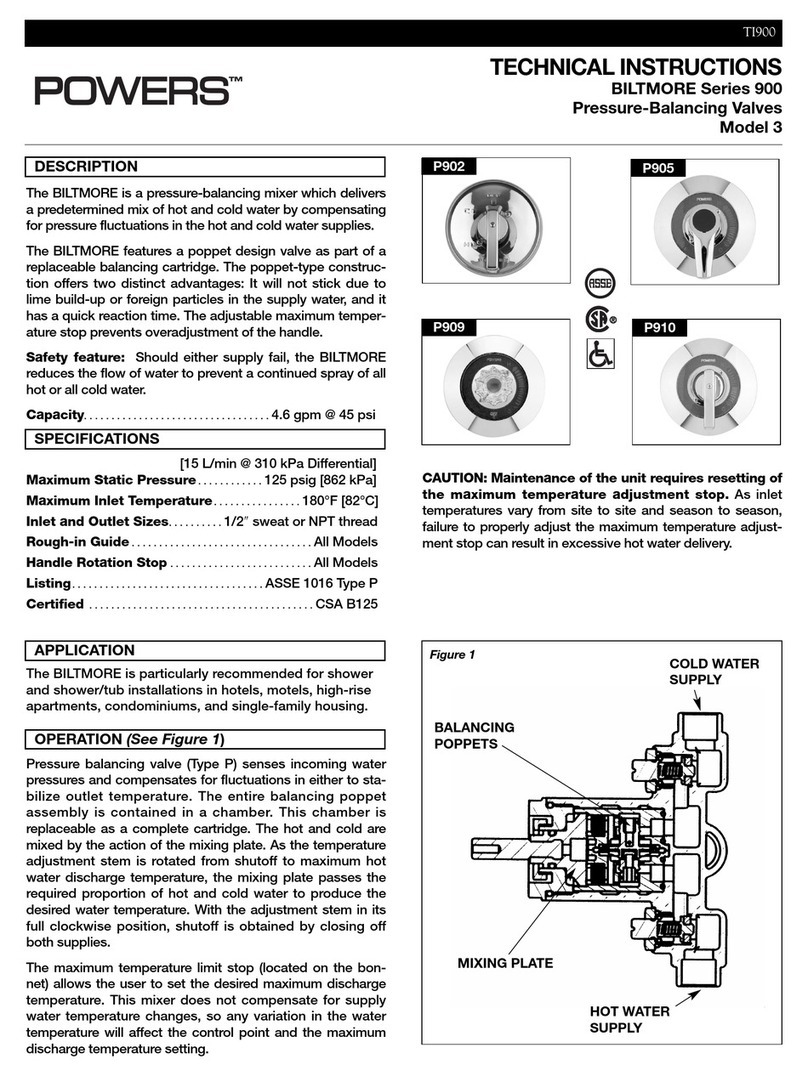

Watts Industries POWERS BILTMORE 900 Series Owner's manual

Watts Industries

Watts Industries Powers HydroGuard LFLM495 User manual

Watts Industries

Watts Industries PR500 User manual

Watts Industries

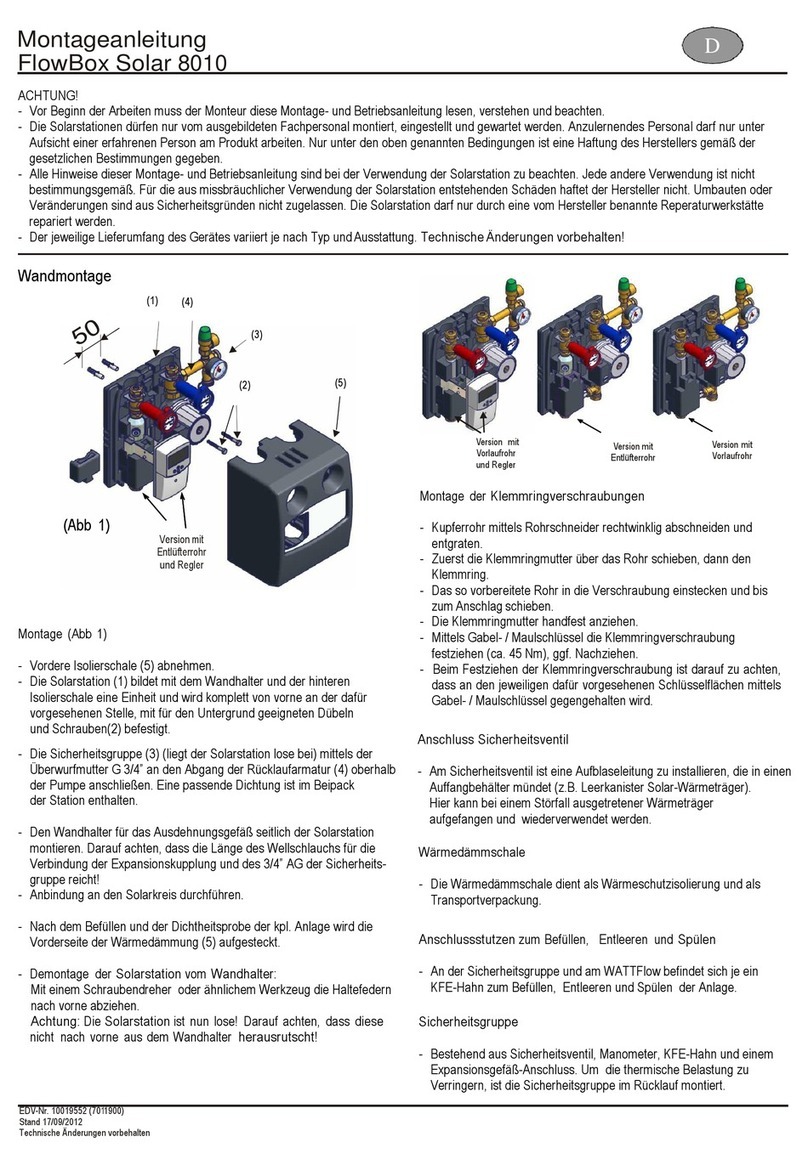

Watts Industries FlowBox Solar 8010 User manual

Watts Industries

Watts Industries AMES 4000CIV Series User manual

Watts Industries

Watts Industries Ultramis TX91 User manual

Watts Industries

Watts Industries POWERS HydroGuard T/P e700 Series User manual

Watts Industries

Watts Industries FEBCO 805Y Series User manual